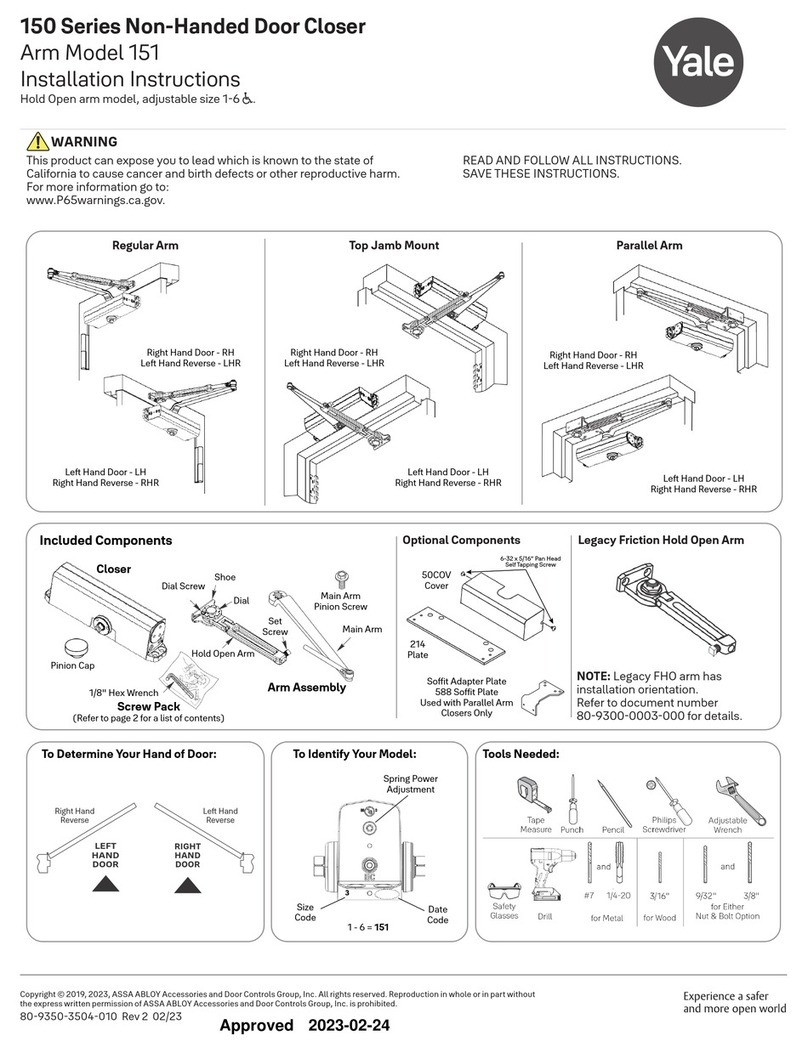

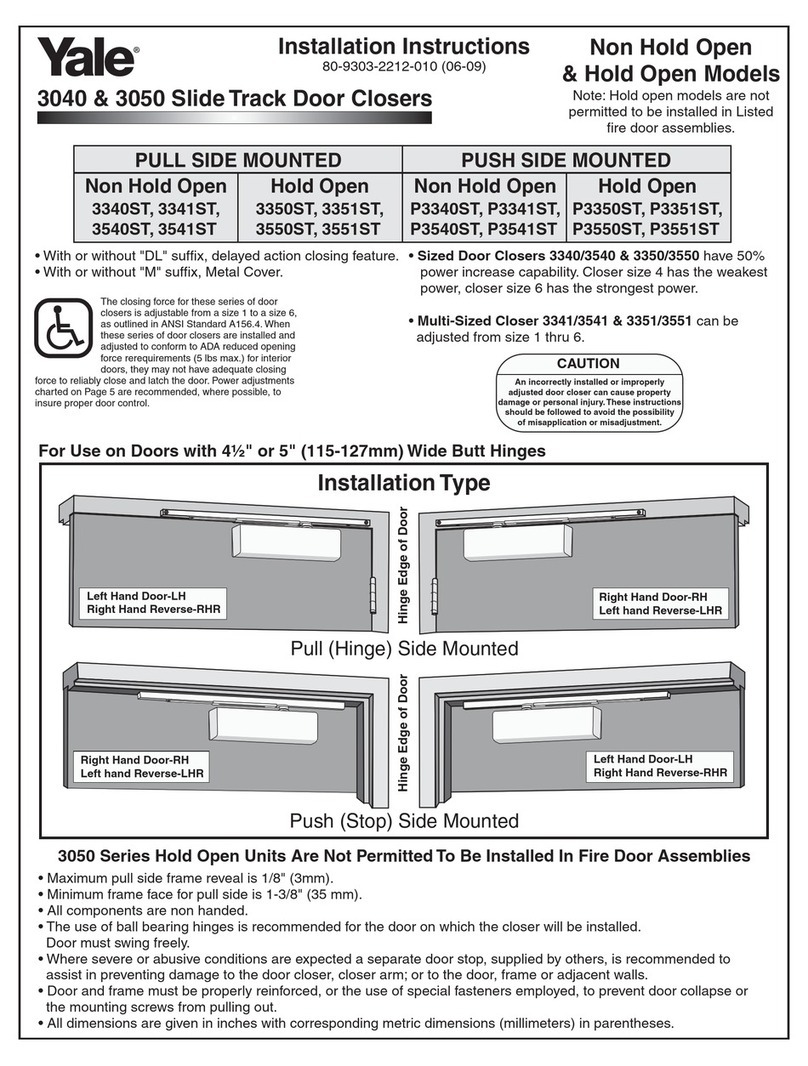

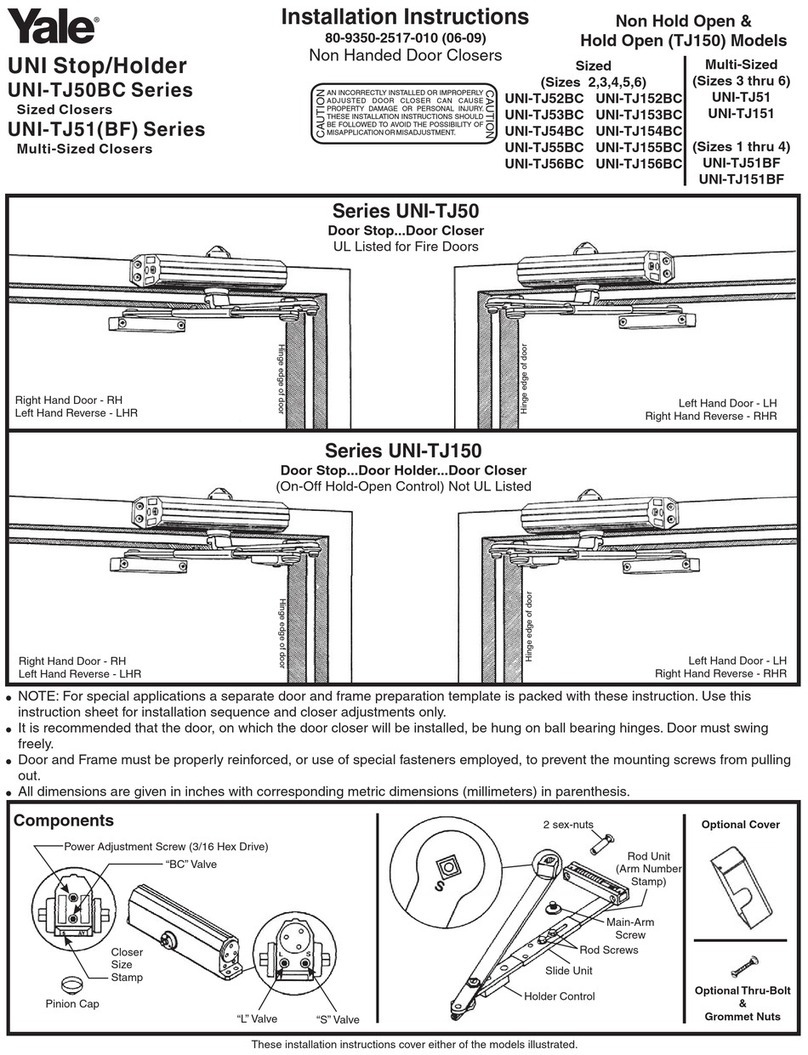

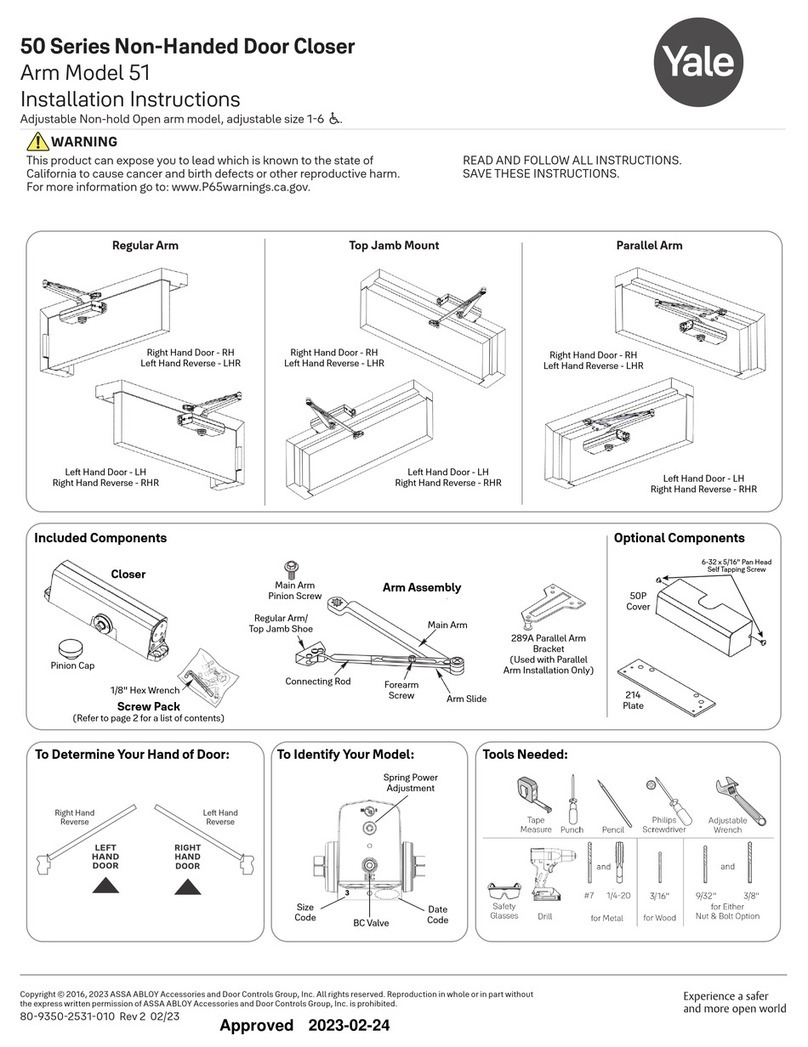

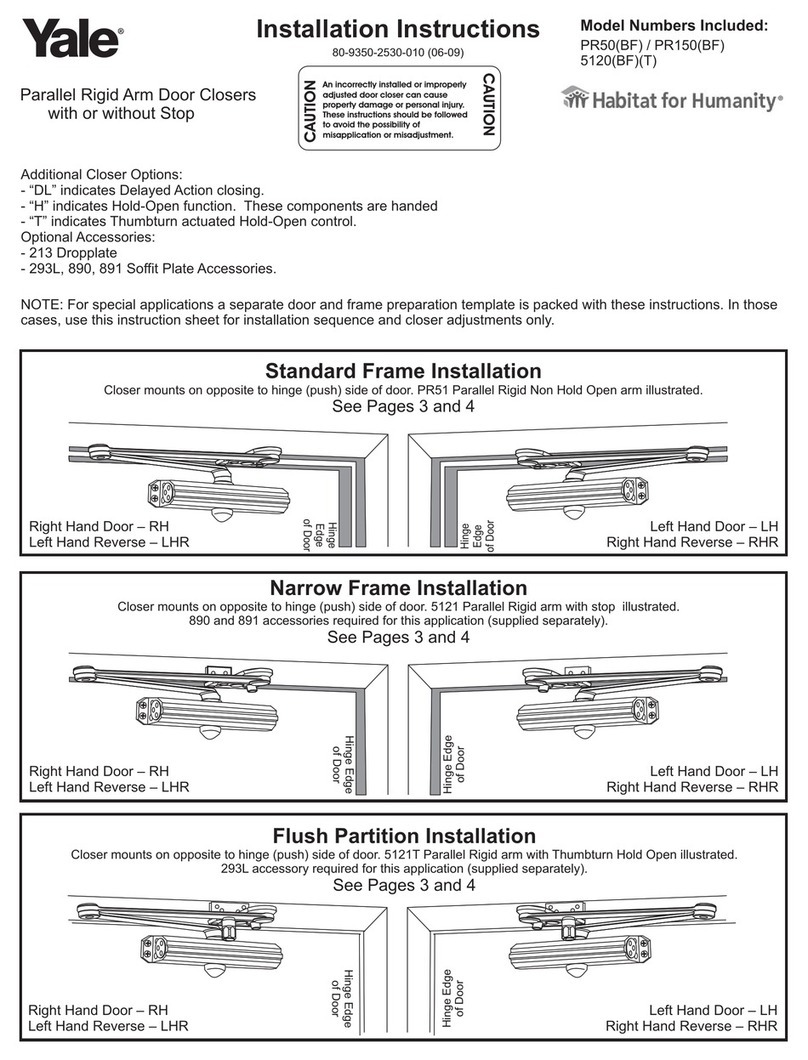

Adjustment Instructions

Closing Power See Figure 6

Closing Cycle See Figure 7A.

Latch range

Sweep range

Delay range

Opening Cycle See Figure 7B.

backcheck

range

Installation of Cover:

• Full cover:

• Narrow cover:

• Full metal cover:

Architectural plastic cover:

Architectural metal cover:

• Adjust as required.

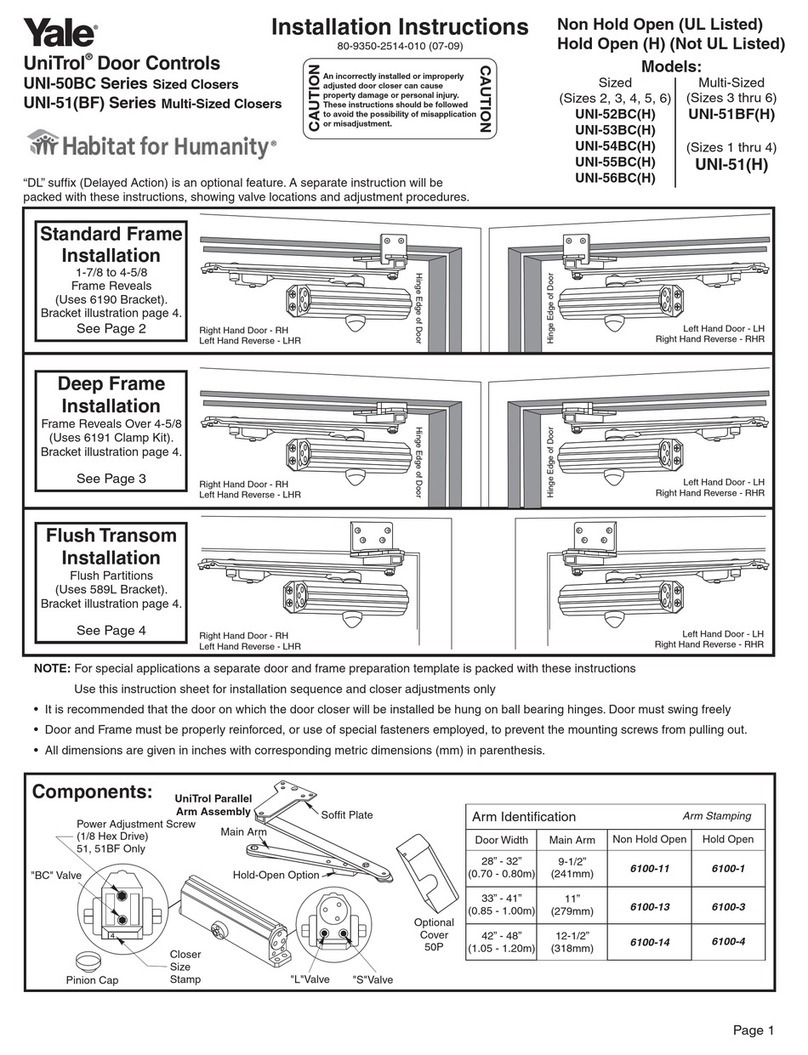

(hydraulic control)

Valve "L" controls door speed in .

Valve "S" controls door speed in .

Valve “D”–Optional–controls door speed in the .

Use 1/8” hex-key furnished and adjust as shown in Figure 8.

Door closing time should be between 3 and 7 seconds from

90º. Longer closing time may be required for the elderly or

handicapped.

(hydraulic control)

Valve "B" cushions (slows) door opening in the

.

Note: Never close this valve completely or damage to closer

may occur.

Use 1/8" hex-key furnished and adjust as shown in Figure 9.

Slide cover insert into the un-used cutout in

cover. Install cover using screws provided.

Install cover using screws provided. Screw

pinion cap onto shaft by hand or with a phillips screwdriver

- DO NOT OVERTIGHTEN.

Fasten cover to mounting clips with

screws provided.

Slide cover insert into the un-

used cutout in cover. Install standoffs in ends of closer.

Snap cover onto standoffs.

Remove cover insert where

pinion is located. Install standoffs in ends of closer. Install

cover using screws provided.

• controls are at arm elbow (models suffixed

“H”). To select hold-open on or hold-open off and to adjust

the hold open force … Use screwdriver as illustrated (

).

Hold-Open

See

Figure 10

!

!

80-9303-2214-010 (07-08)

Closing Speed

Hydraulic Control

Figure 8

Fig. 7BFig. 7A

1/8"

Hex

Key

1/8"

Hex

Key

Backcheck Figure 9

1/8"

Hex

Key

Increase

Decrease

Backcheck Valve*

*NEVER close this valve

completely.

Slow Slow

Fast Fast

Latch

Valve

Sweep

Valve

LS

Opening CycleClosing Cycle

Backcheck

Range

Closed

5°

Latch

Range

S

w

e

e

p

R

a

n

g

e

D

e

l

a

y

R

a

n

g

e

O

p

e

n

in

g

1/8"

Hex

Key

Optional Delay Valve

Slow

Fast

Door Holder Option

Hold-Open option is found at the arm elbow. To select

hold-open “on” or hold-open “off” and to adjust the hold-

open force ... use screwdriver as illustrated.

Turn 90°

To “Off”

Press & Turn

To Decrease

Force

To Increase

Force

Hold-Open

“On”

Hold-Open Force

Door Holder Option Figure 10

Closing Power Control Figure 6

Power

Adjustment Shaft

Use 5/16" Socket

or Adjustable Wrench

Increase

Decrease

For UNI TJ3301 and UNI TJ3501 series

only, see Power Adjust chart on Page 1.

An ASSA ABLOY Group brand

3000 Highway 74 East • Monroe, NC 28112

Tel: (800)-438-1951 • Fax: (800)-338-0965

www.yalecommercial.com

Yale ® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company.

Copyright © 2005, 2008, Yale Security Inc., an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.