Yale ® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company.

Copyright © 1999, 2009, Yale Security Inc., an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.

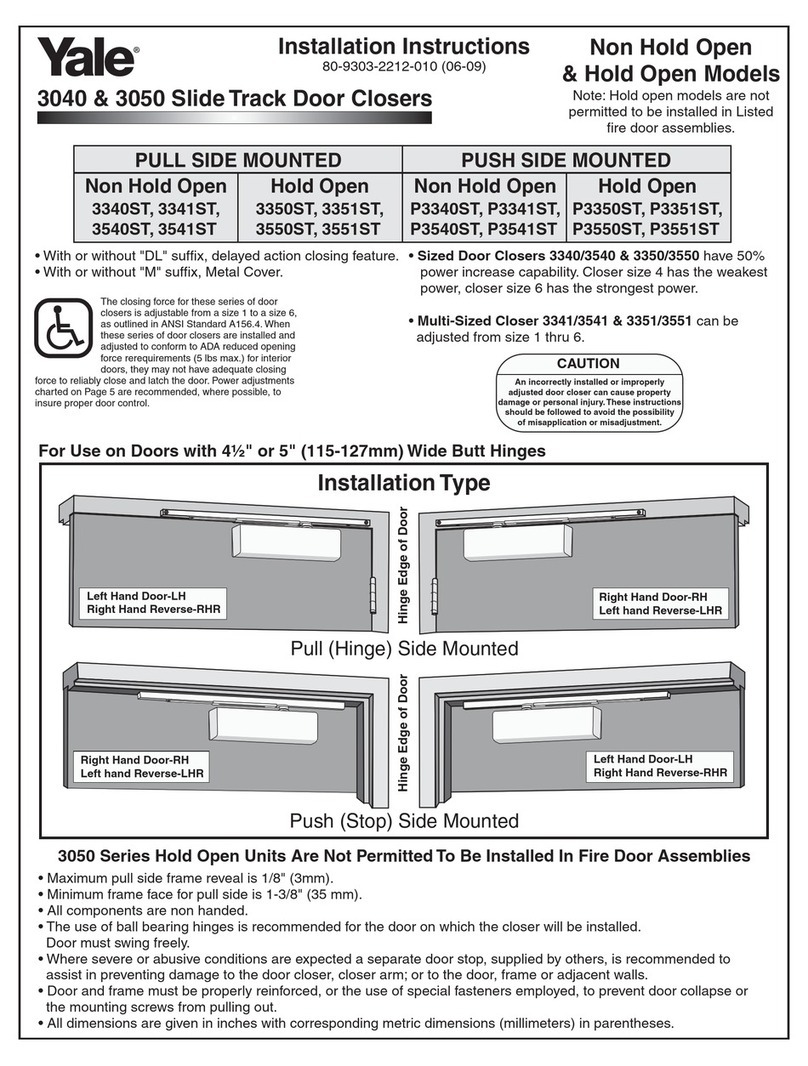

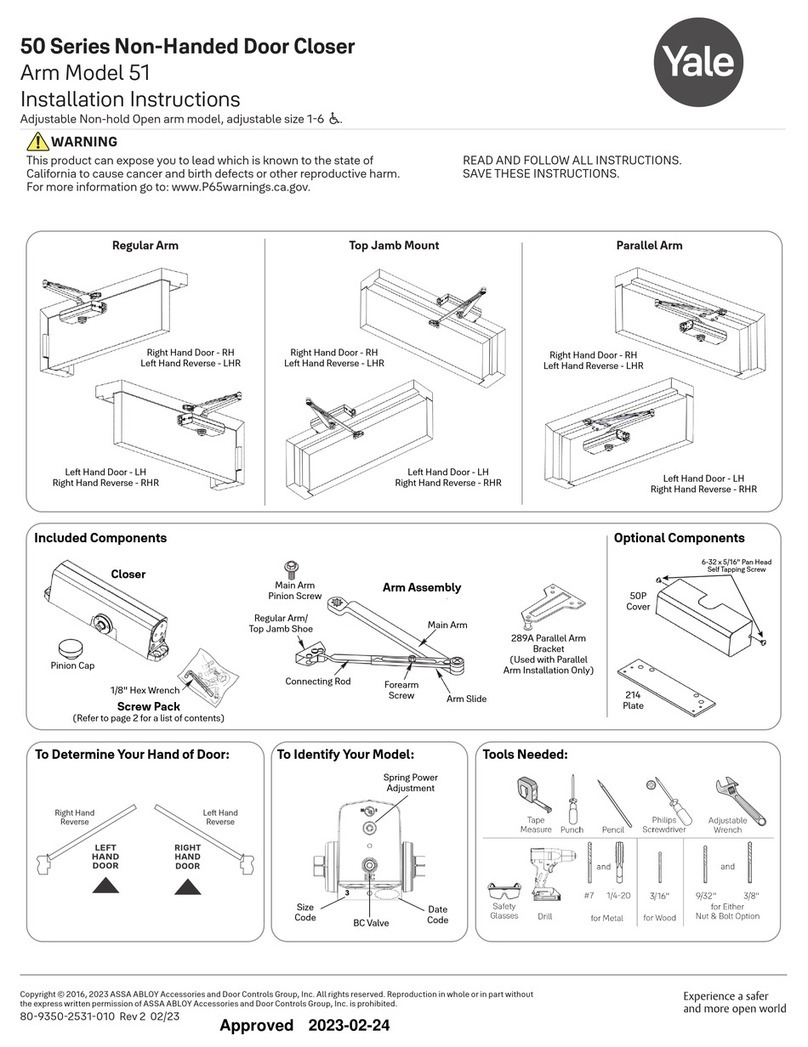

Page 4

Increase

Decrease

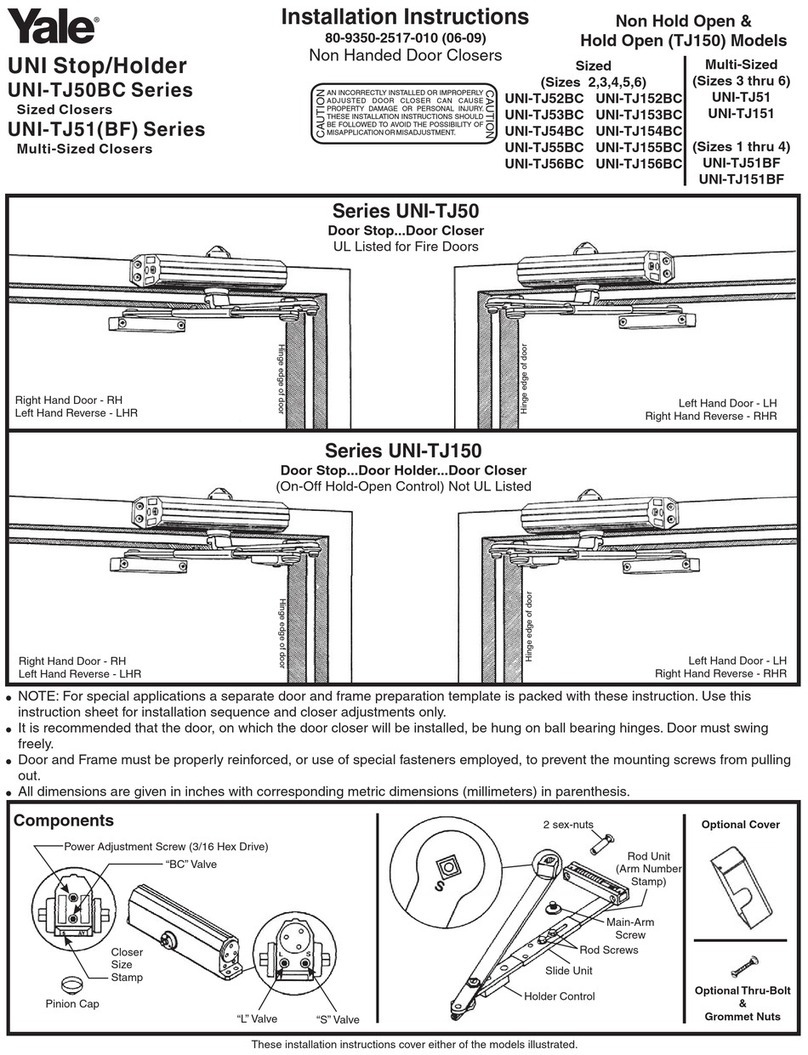

Closing Speed Control

Attention: Adjust Closing Speed

Time to between 4 to 7 seconds

from 90°. Use of the door by

handicapped, elderly or small

children may require greater

closing time. ADA code requires

that door take at least 3

seconds to close from 70° of

door opening to within 3”

(75mm) of the closed position. Closing Cycle

CLOSED

S

W

E

E

P

L

A

TC

H

10°

Figure 1

CAUTION:

DO NOT BACK VALVES OUT OF

CLOSER OR A LEAK WILL

RESULT

CAUTION:

DO NOT BACK VALVES OUT OF

CLOSER OR A LEAK WILL

RESULT

Opening Door Control

Opening Cycle

O

P

E

N

I

N

G

• Backcheck (”BC”) valve controls the hydraulic resistance to door opening in backcheck range.

NEVER close this valve completely – it is not to provide a positive stop.

B

A

C

K

C

H

E

C

K

Figure 2

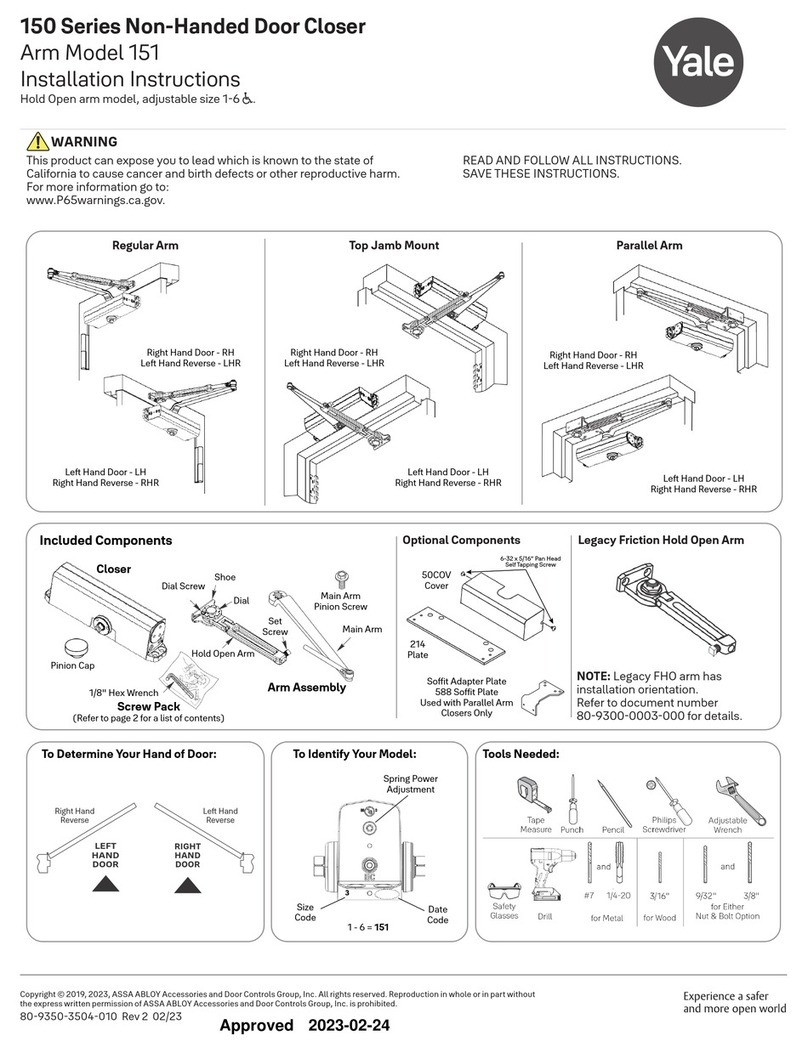

Unit Adjustment

• Valve “S” controls Sweep Range.

• Valve “L” controls Latch Range.

NOTE: By law the Americans with Disabilities Act (ADA) may

require that door closer installation comply with accessability

guidelines.

"L"Valve "S"Valve

1/8”

Hex

Key

Slow

Fast

1/8”

Hex

Key

Increase

Decrease

"BC" Valve

4

Closing Power Control Figure 3

1/8”

Hex

Key

Increase

Decrease

Adjust as required. Product is shipped

at mid range power setting.

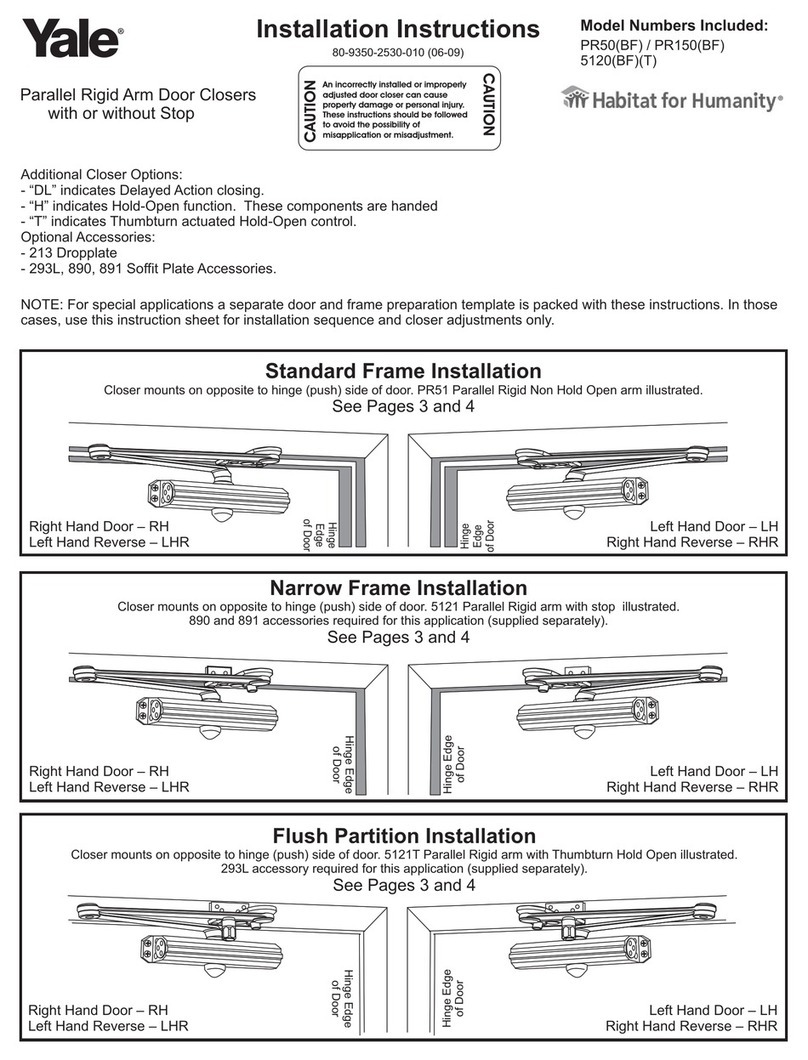

Bracket Illustrations Door Holder Option Figure 4

Power Adjustment Chart

DOOR

INT

EXT

PARALLEL ARM

INSTALLATION

MAXIMUM DOOR SIZE

34”

(0.85 m)

36”

(0.9 m)

40”

(1 m)

44”

(1.1 m)

48”

(1.2 m)

*18 -360° TURNS MAXIMUM AVAILABLE

*

FULL 360 TURNS

OF POWER ADJUSTMENT

SHAFT

o

NOT

RECOMMENDED

USE 51

51BF

51

2

8

3

5

2

9

5

7

3

7

10

45

10

14

13

16

INT

EXT

Standard 6190 Bracket

Deep Reveal Option

Spacer Block

Clamps

2 Clamp Screws

No. 6191 Reinforcing Kit No. 589L Bracket

Flush Partition Option

4 Bracket

Screws

Hold-Open option is found at the arm elbow. To select

hold-open “on” or hold-open “off” and to adjust the hold-

open force ... use screwdriver as illustrated.

Turn 90°

To “Off”

Press & Turn

To Decrease

Force

To Increase

Force

Hold-Open

“On”

Hold-Open Force

Cover (Optional Cover 50P)

Thread in screws before mounting closer. Leave enough gap

between the head of the screw and the closer to slide the

cover on. Slide the cover over the closer and secure the

mounting screws after installation is complete.

5=55BC

4=54BC

3=53BC

2=52BC

6=56BC

To identify your model:

3 - 6=51

1- 4=51BF

Date

Code

3-6

BE

Size

Code

An ASSA ABLOY Group brand

3000 Highway 74 East • Monroe, NC 28112

Tel: (800)-438-1951 • Fax: (800)-338-0965

www.yalecommercial.com