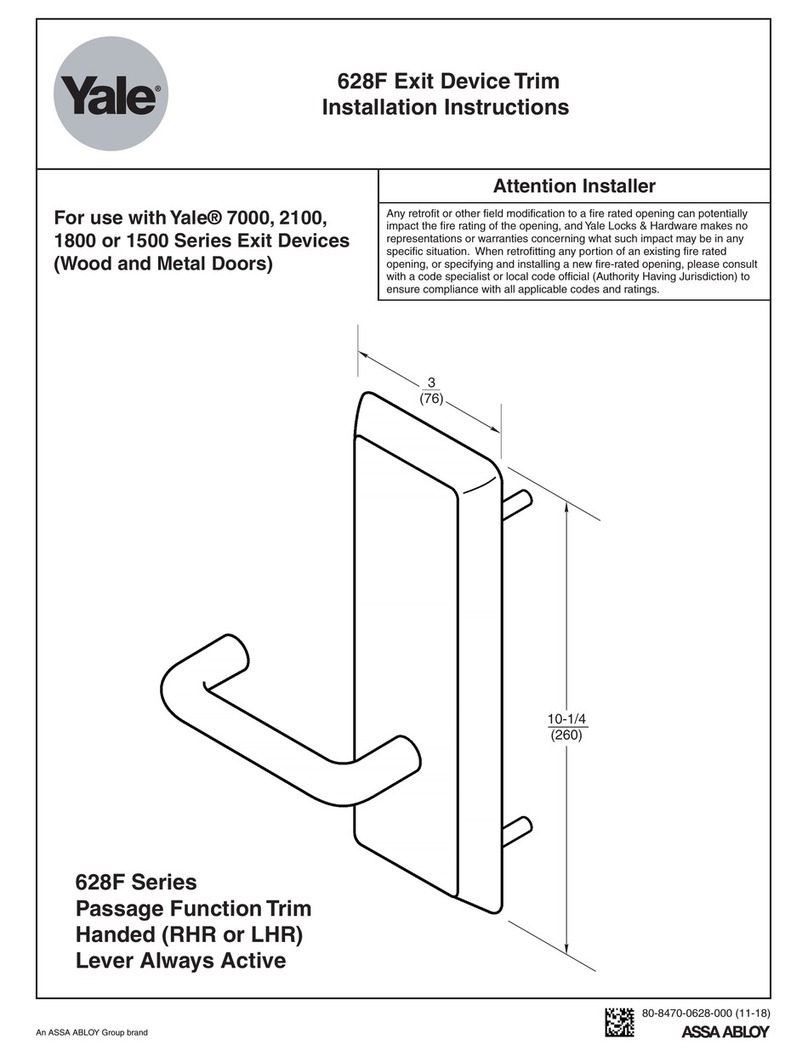

Top Jamb Installation Using 587 Dropplate

Page 3

7

(178)

1/2

(13)

7/8

(22)

5

(127)

1-3/4

(44.5)

1-3/4

(44.5)

C

L

A

Installation Sequence

!

!

!

!

!

!

!

!

!

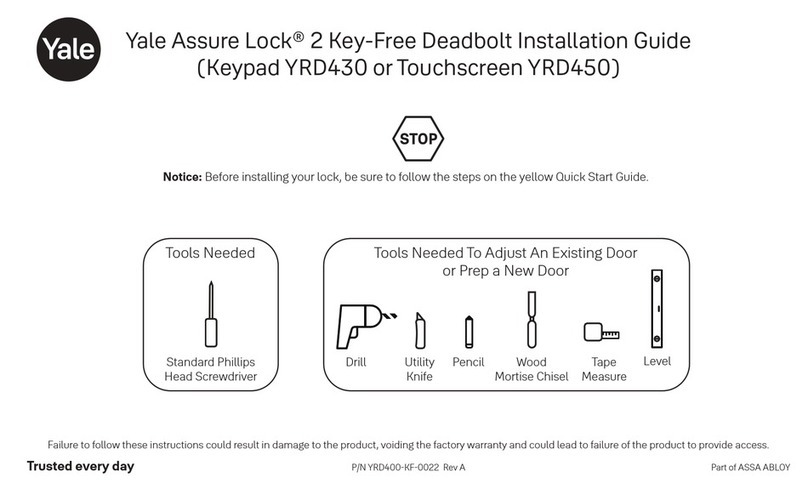

Select door opening angle using template above. Mark 4 holes on

frame face for Dropplate and 2 holes on door for arm shoe.

Prepare door and frame for fasteners. See “Preparation for

Fasteners” at bottom of Page 2.

Mount drop plate to frame.

Install closer to drop plate with “S” and “L” adjustment valves

toward hinge edge of door.

Mount arm shoe to door.

Install main arm onto closer pinion shaft, indexing main arm mark

“S” with pinion flat as shown at right. Fasten with arm screw.

Screw pinion cap onto pinion shaft by hand or with a Phillips

screw driver - DO NOT OVER TIGHTEN.

Adjust closer.

!251 or 251BF Models Only. Set closing power using “Power

Adjustment Chart” at bottom of Page 2.

Open door to allow connecting rod to be inserted into arm slide.

Insert rod and close door. Preload main arm by rotating away

from hinge until forearm is perpendicular (at 90° angle) to door.

Secure with forearm screw.

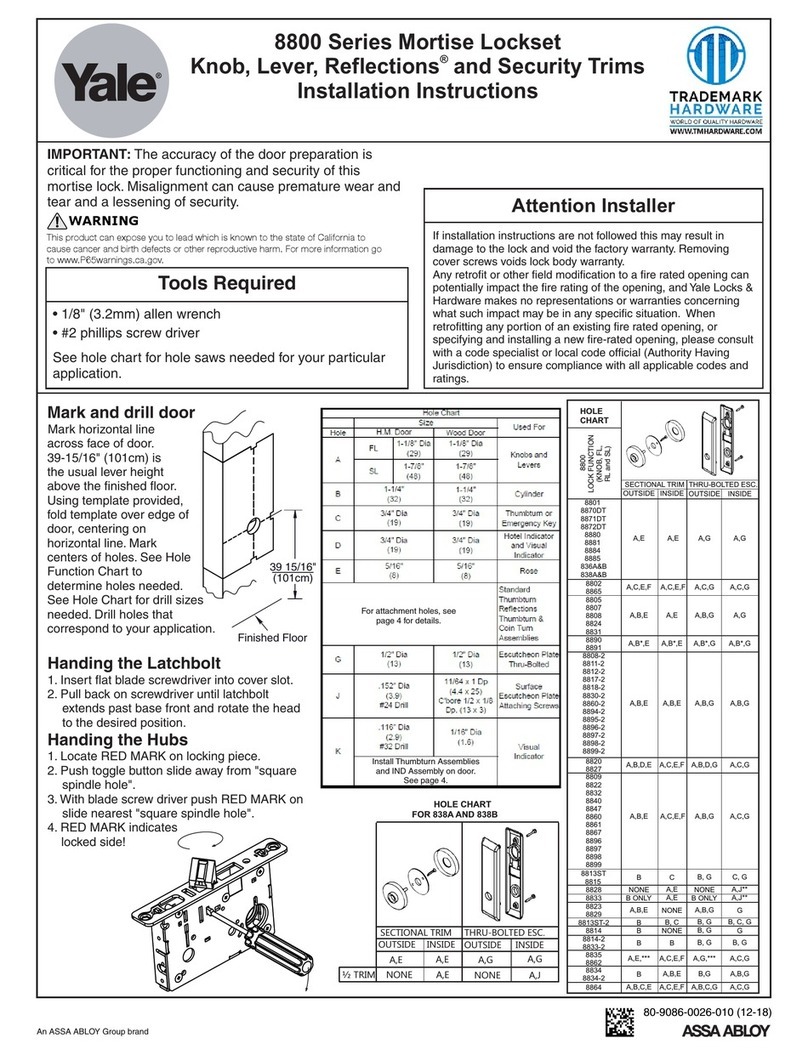

Door Closer Adjustment (Continued)

“DA” suffix (Delayed Action) is an optional feature.

A separate instruction will be packed with these instructions showing valve locations and adjustment procedures.

Closing Speed Control

CAUTION:

DO NOT BACK VALVES OUT OF

CLOSER OR A LEAK WILL

RESULT

Attention: Adjust Closing Speed

Time to between 4 to 7 seconds

from 90°. Use of the door by

handicapped, elderly or small

children may require greater

closing time.

Standard Closing Cycle

CLOSED

S

W

E

E

P

L

A

TC

H

10°

Unit Adjustment

Closing Speed Controls (Figure 1)

!

!

Valve “S” controls sweep range.

Valve “L” controls latch range.

Opening Door Control

Opening Cycle

O

P

E

N

I

N

G

Opening Door Control

!Backcheck (”BC”) valve controls the hydraulic resistance to door

opening in backcheck range. NEVER close this valve completely

– it is not to provide a positive stop.

B

A

C

K

C

H

E

C

K

Template

Hinge or Pivot

Side Elevation

Typical Installation

Right Hand Door

Left Hand Door

Figure 2

Figure 1

CAUTION:

DO NOT BACK VALVES OUT OF

CLOSER OR A LEAK WILL

RESULT

• Do not scale drawing.

• Left hand door shown.

• Dimensions are in inches (mm).

Opening

To 100°

101° to 120°

121° to 180°

Dimension A

inches

8-1/2

7

4-1/2

mm

216

177.8

114

* Door/Wall/Hardware/Jamb

conditions permitting

Optional

“BC”

Valve

“S” & “L”

Valves Power

Adjustment

Screw

Preload Preload

Pinion Flat

“S” & “L”

Valves

1

2

3

4

Z

Y

S

Pinion Flat

1

2

3

4

Z

Y

S

4

(101.6)

1-1/2

(38.1)