IM CA12E-01E <1>

<6> MEASURE (measurement) / SOURCE (generation) selection switch

Selects MEASURE (measurement) or SOURCE (generation).

<7> Input/output terminals

Used for MEASURE (measurement) and SOURCE (generation) in each range.

<8> 3W input terminal

Used for MEASURE (measurement) in a three-wire connection configuration in the resistance or

RTD range.

<9> Terminal adapter

Attached to the instrument's terminals when measuring a thermocouple signal or when lead wires

are to be connected directly to the terminals.

<10> AC Adapter connection jack

Used to connect an AC adapter (optional).

<11> RJ sensor input connector

When using an external RJ sensor (optional), connect it to this connector.

<12> DIP switches

See Section 7, “Other Features.”

<13> Battery holder

Contains four AA-size batteries. See Section 3, “Replacing Batteries.”

<14> Lead cables for measurement or generation

Used to connect the instrument to the device under measurement/generation.

3. Replacing Batteries

When the

+

-

mark is blinking on the display unit, the batteries are exhausted. Replace them

according to the following procedure:

<1> Check that the power is turned off (disconnect the lead cables).

<2> Slide off the cover at the back of the instrument.

<3> Replace all four batteries with new ones. Insert them according to the polarity directions

shown inside the holder.

<4> After replacing the batteries, return the cover to the original position.

■ Connecting the AC Power (optional)

Before connecting the AC power

Strictly observe the following warnings to avoid electrical shock or damage to the instrument.

WARNING

●Do not use any AC adapter other than the dedicated AC adapter from Yokogawa.

●Before connecting the power cord, check that the supply voltage matches the rated

voltage of the instrument.

●Before connecting the power cord, check that the instrument’s power key is OFF.

Connection procedure:

<1> Check that the [POWER] key of the instrument is off.

<2> Connect the AC adapter (optional) to the instrument’s AC adapter connection jack. (Note that

unless the AC adapter is connected to the power outlet, the power cannot be turned on).

4. Turning the Power On/Off

■ Operating the POWER Key

When the instrument’s power is off, pressing and holding the [POWER] key for more than 1

second causes the power to be turned on. Pressing the key again causes it to be turned off.

When the power is turned on, the instrument starts a self-test and displays “CA12E.” Then the

features selected using the range selection rotary switch and the MEASURE/SOURCE selection

switch start functioning.

• For battery-driven operations, disconnect the AC adapter from the instrument.

■ Automatic Power Off

In the factory setting, all indications start blinking if the instrument has not been operated for about

9.5 minutes. Then, if the instrument is not operated for another 30 seconds, it automatically turns

off. To disable this automatic power off feature, see Section 7, “Other Features.”

If you wish to keep the instrument turned on after the indications start blinking, press the [POWER]

key (or any other key). This causes the blinking to return to normal lighting, without changing the

previous settings.

5. SOURCE (generation)

5.1 Connecting the Output Terminals

<1> Insert the plugs of the supplied lead cables into the output terminals of the instrument.

<2> Connect the clips on the other ends of the cables to the input terminals of the device under

generation.

Lo

3W

Lo Hi

3W

Lo Lo Hi

Lo Hi

3W

(a) Voltage (Thermocouple),

2W Resistance (RTD) OUTPUT (b-1) 3W Resistance (RTD) OUTPUT (b-2) 3W Resistance (RTD) OUTPUT

Lo Lo Hi

Lo

3W

Lo Hi

3W

Lo Lo Hi

<1> Terminal

adapter

<1> Short bar

(supplied)

<2> Terminal

adapter

• When calibrating a resistance temperature detector or a resistance measurement unit in a

three-wire connection configuration, the supplied terminal adapter can be used to achieve a

three-wire connection configuration without shorting the Lo terminal (Fig. b-1). Lo and 3W-Lo

terminals can be shorted (Fig. b-2). Otherwise connect as shown in Fig. a.

1. Safety Precautions

When operating the instrument, strictly observe the precautions below to ensure its correct and safe

operation. If used other than as instructed in this manual, Yokogawa Meters & Instruments Corporation

is not liable for any damage that may result.

■ The following safety symbols are used on the instrument and in the manual:

Danger! Handle with care.

This symbol indicates that the operator must refer to an explanation in the User's Manual in

order to avoid risk of injury or death of personnel or damage to the instrument.

WARNING Indicates a hazard that may result in the loss of life or serious injury of the user unless the

described instruction is abided by.

CAUTION Indicates a hazard that may result in an injury to the user and/or physical damage to the

product or other equipment unless the described instruction is abided by.

NOTE Indicates information that is essential for handling the instrument or, should be noted in order

to familiarize yourself with the instrument’s operating procedures and/or functions.

■Damage to the instrument, personal injury or even death may result from electrical shock or

other factors. To avoid this, follow the precautions below:

WARNING

●Use where gases may be present

Do not operate the instrument in a location where flammable or explosive gas/vapor present. It is

extremely hazardous to operate the instrument in such an atmosphere.

●External connection

If necessary to touch a circuit to make an external connection, turn off the power to that circuit,

ensure there is no voltage, then perform the connection. When replacing the batteries, disconnect the

lead cables in advance.

●Disassembly

Do not disassemble or remodel the instrument yourself. This needs to be done by our service

personnel.

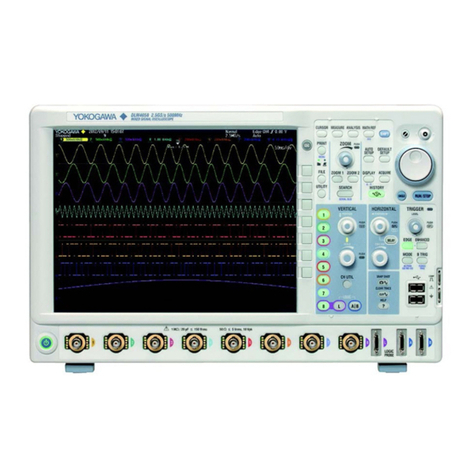

2. Names and Functions of Parts

ON

123 4

<8> Three-wire input

terminal

<3> POWER

key

<4> SHIFT

key

<1> Display unit

<2> Output value

setting keys

<5> Range selection

rotary switch

<10> AC Adapter

connection jack

<7> Voltage/resistance

input and output terminals

<6> MEASURE

(measurement)/

SOURCE

(generation)

selection switch

Side ViewFront View Rear View

(with the rear cover removed)

Red

Black

Black

<12> DIP

switches

<13> Battery

holder

<14> Lead cables

<9> Terminal adapter

<11> RJ sensor

input connector

<1> Display unit

a. MEASURE

Lights up when MEASURE (measurement) is

selected using the selection switch <6>.

b. SOURCE

Lights up when SOURCE (generation) is

selected using the selection switch <6>.

c. CAL

Lights up in the calibration mode.

d. 0/FS

Lights up or blinks when offset or full-scale adjustment is performed in the calibration mode.

e.

+

-

This mark indicates the battery’s status. When lit, it indicates the batteries will soon need

replacing. When blinking, it indicates that they must be replaced (see Section 3, “Replacing

Batteries”).

f. Main Seven Segment

Displays a measured value or an output value.

g. Sub Seven Segment

<PT100 range> When IPTS68 is selected by DIP switch 3, 68 is displayed.

<Thermocouple range> When the U, L, B, or S range is selected using the SHIFT key, the type

of thermocouple is displayed.

<Calibration mode> This mode displays the lower two digits of the measured or generated value.

h. Displays the unit of the range selected.

i. ON

It lights up when the output is turned on in SOURCE mode (signal generation).

j. RJ-ON

It lights up when the reference junction compensation is being calculated in SOURCE mode

(signal generation).

k. JPT100

It lights up when the JPT100 standard is selected in the RTD range (PT100 range). Refer to

Section 5.3 “Generating Resistance or RTD Signal”, 6.3 “Measuring Resistance or RTD Signal”

and 7, “Other Features.”

<2> Output value setting keys

Sets an output value for SOURCE mode (signal generation). The [▲]/[▼] keys are provided under

each digit, whose value is increased or decreased in increments of 1. Carry of the digit is applied

to increasing the value (pressing the [▲] key) when it is 9. Borrow of the digit is applied to decreas-

ing the value (pressing the [▼] key) when it is 0.

<3> POWER key

Turns on/off the power supply. For more information, see Section 4, “Turning the Power On/Off.”

<4> SHIFT key

Selects the type of thermocouple or the resistance temperature detector being selected by the

range selection rotary switch (e.g., thermocouple type: S←→R).

<5> Range selection rotary switch

Selects a range for SOURCE mode (signal generation) or MEASURE mode (measurement).

User’s

Manual CA12E

HANDY CAL

(Temperature Calibrator)

IM CA12E-01E

3rd Edition Sep. 2009 (KP)

Thank you for purchasing the CA12E HANDY CAL. Prior to using, read this User’s Manual carefully to

fully and properly utilize all of the features of this instrument. Also, refer as needed to IM CA12E-02E,

an additional User’s Manual for this instrument.

-1-

MEASURE

SOURCE

ON

+

-

RJ-ON

JPT100

CAL

FS

0

a

b

f c

d

g

ie jk h

■ Notice regarding the Manual

<1> The information contained in this User’s Manual is subject to change without notice.

<2> Every effort has been made to ensure that the information contained herein is accurate.

However, should any concerns, errors, or omissions come to your attention, or if you have any

comments, please contact us.

IM3E-2009.2

Yokogawa Meters & Instruments Corporation

International Sales Dept.

Tachihi Bld. No.2, 6-1-3, Sakaecho, Tachikawa-shi,Tokyo 190-8586 Japan

Phone: 81-42-534-1413, Facsimile: 81-42-534-1426

YOKOGAWA CORPORATION OF AMERICA (U.S.A.)

Phone: 1-800-888-6400 Facsimile: 1-770-254-0928

YOKOGAWA EUROPE B. V. (THE NETHERLANDS)

Euroweg 2, 3825 HD, Amersfoort, THE NETHERLANDS

Phone: 31-88-4641000 Facsimile: 31-88-4641111

YOKOGAWA AMERICA DO SUL LTDA. (BRAZIL)

Phone: 55-11-5681-2400 Facsimile: 55-11-5681-4434

YOKOGAWA ENGINEERING ASIA PTE. LTD. (SINGAPORE)

Phone: 65-6241-9933 Facsimile: 65-6241-2606

YOKOGAWA MEASURING INSTRUMENTS KOREA CORPORATION (KOREA)

Phone: 82-2-551-0660 to -0664 Facsimile: 82-2-551-0665

YOKOGAWA AUSTRALIA PTY. LTD. (AUSTRALIA)

Phone: 61-2-8870-1100 Facsimile: 61-2-8870-1111

YOKOGAWA INDIA LTD. (INDIA)

Phone: 91-80-4158-6000 Facsimile: 91-80-2852-1441

YOKOGAWA SHANGHAI TRADING CO., LTD. (CHINA)

Phone: 86-21-6239-6363 Facsimile: 86-21-6880-4987

YOKOGAWA MIDDLE EAST B. S. C (C) (BAHRAIN)

Phone: 973-17-358100 Facsimile: 973-17-336100

YOKOGAWA ELECTRIC CIS LTD. (RUSSIAN FEDERATION)

Phone: 7-495-737-7868 Facsimile: 7-495-737-7869