802253UK - Boiling chilled residential installation instructions - Aug 2015 - V2.02 Page 3 of 36

HydroTap®G4 specifications

Installation check list .................................................................................................................... 4

General product features ............................................................................................................. 5

Important safety instructions ........................................................................................................ 6

Warnings and regulatory information ........................................................................................... 7

Major components and accessories............................................................................................. 8

Technical specifications ............................................................................................................... 9

Before installation and site requirements..................................................................................... 10

Installation instructions

Step 1 -

Measure and cut all the tap holes before fitting the taps.

Section 1 - Tap installation.

1.1 - HydroTap®G4 Classic and Elite taps installation ..................................................... 11-13

1.6 - HydroTap®G4 Arc / Cube installation........................................................................ 14-15

1.10 - Mixer tap installation ............................................................................................... 16

1.12- All-in-One tap 'Mains' installation............................................................................. 17-18

1.16- All-in-One tap 'Vented' installation ........................................................................... 19-20

Step 2

- Check for adequate ventilation.

Section 2- Ventilation.

2.1- Ventilation for all models.............................................................................................21

Step 3

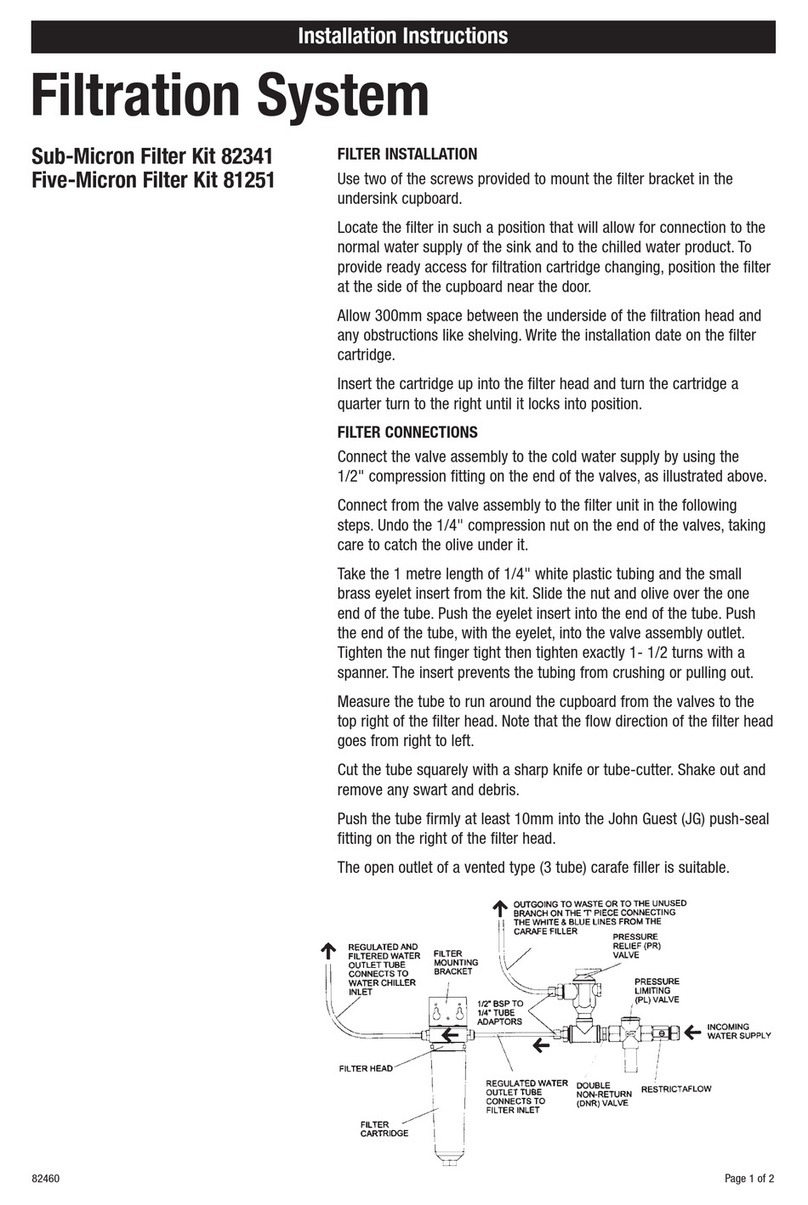

- Install the booster and / or filter / softener (if required).

Section 3 - Booster installation.

3.1- Booster specifications and descriptions..................................................................... 22

3.2- Installation procedure................................................................................................. 23

3.3- Booster installation..................................................................................................... 23

3.4- Braided hose connections.......................................................................................... 24

3.5- Filter / softener installation......................................................................................... 25

Step 4

- Install the Command-CentreTM.

Section 4 - Command-CentreTM installation.

4.1- Check the external bypass valve setting ................................................................... 26

4.2- Fit the mains water supply hose ................................................................................ 26

4.3- HydroTap®G4 models................................................................................................ 27

4.4- HydroTap®G4 and mixer tap combinations................................................................ 28

4.5- All-in-One 'Mains' tap................................................................................................. 29

4.6- All-in-One 'Vented' tap ............................................................................................... 30

Step 5

- Commission the HydroTap®G4.

Section 5 - Commissioning.

5.1- Select language ........................................................................................................ 31

5.2- Filter flush ................................................................................................................. 31

5.3- Flow calibration.......................................................................................................... 31

5.4- Boiling calibration....................................................................................................... 32

5.5- Booster activation ...................................................................................................... 32

5.6- Safety sensor calibration............................................................................................ 32

Trouble shooting

Trouble shooting table.................................................................................................................. 33

End of life disposal....................................................................................................................... 34

Warranty....................................................................................................................................... 35

Contact details ............................................................................................................................. 36

Index