2

corresponds to the mains voltage;

- The mains supply is compable with the appliance's electricity needs and is

correctly grounded.

• In the event of abnormal operaon or the release of odours from the appliance,

turn it o immediately, unplug it from its power supply and contact a professional.

• Before servicing or performing maintenance on the appliance, check that it is

powered o and completely disconnected from the power supply. Moreover,

check that the heang priority (where applicable) is deacvated and that any

other device or accessory connected to the appliance is also disconnected from

the power supply.

• Do not disconnect and reconnect the appliance to the power supply when in

operaon.

• Do not pull on the power cord to disconnect it from the power supply.

• If the power cord is damaged, it must be replaced by the manufacturer, an

authorised representave or a repair facility only.

• Do not perform maintenance or servicing operaons on the appliance with wet

hands or if the appliance is wet.

• Before connecng the appliance to the power supply, check that the connecon

unit or socket to which the appliance will be connected is in good condion and

shows no signs of damage or rust.

• For any component or sub-assembly containing a baery: do not recharge or

dismantle the baery, or throw it into a re. Do not expose it to high temperatures

or direct sunlight.

• In stormy weather, disconnect the appliance from the power supply to prevent it

from suering lightning damage.

• Do not immerse the appliance in water (with the excepon of cleaners) or mud.

WARNINGS CONCERNING APPLIANCES CONTAINING R410A REFRIGERANT

• Do not discharge R410A uid into the atmosphere. This is a uorinated greenhouse

gas, covered by the Kyoto Protocol, with a Global Warming Potenal (GWP) = 2088

(European regulaon EU 517/2014).

• In order to comply with the applicable standards and regulaons in terms of the

environment and installaon, in parcular Decree No. 2015-1790 and/or European

regulaon EU 517/2014, a leak test must be performed on the cooling circuit when

the appliance is rst started and at least once a year. This operaon must be carried

out by a specialist cered to test cooling appliances.

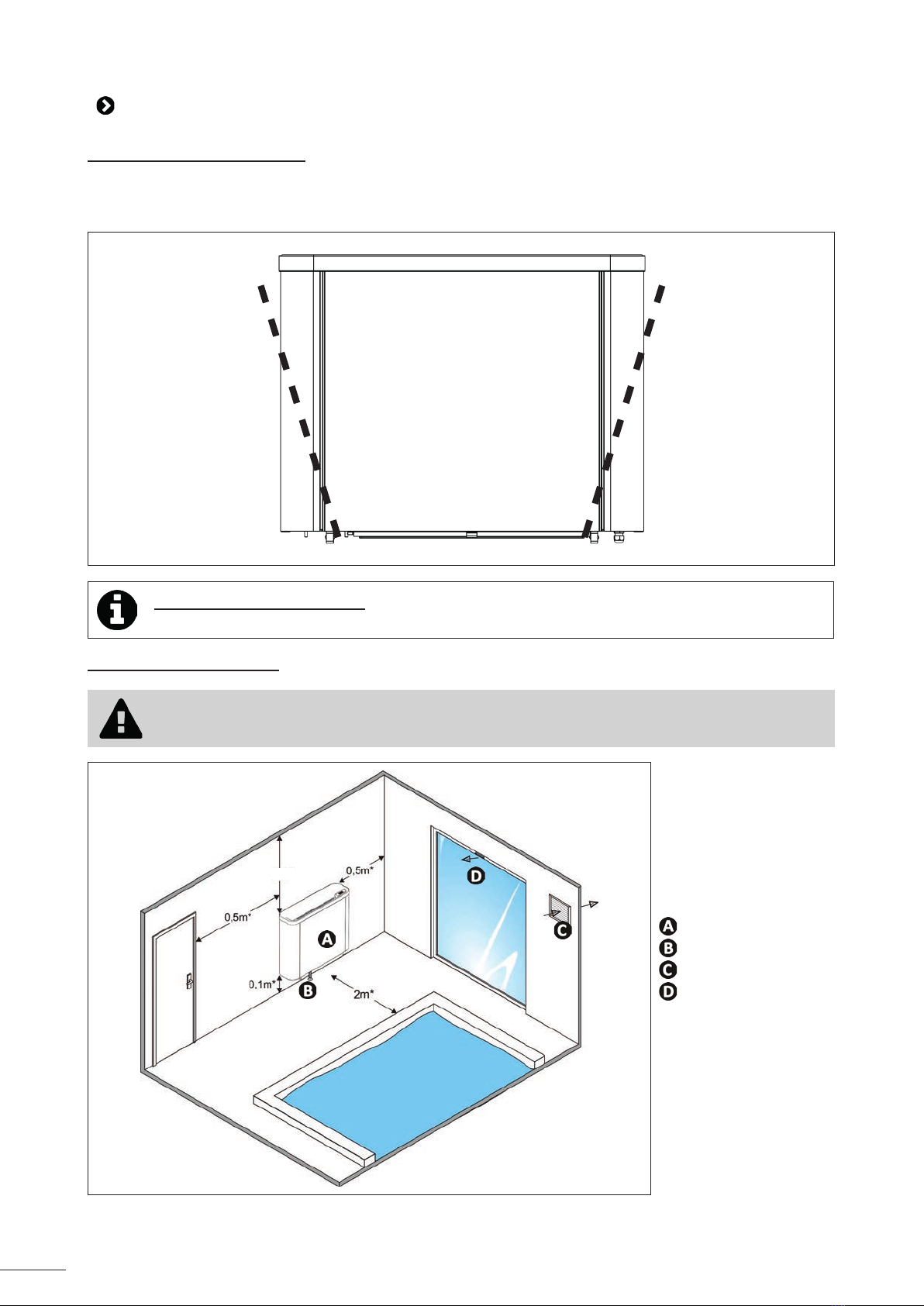

INSTALLATION AND MAINTENANCE

• The appliance may not be installed close to combusble materials, or the air duct

inlet of an adjacent building.

• With some appliances, it is essenal to t a "protecon grid"-type accessory if the

unit is installed in an area with uncontrolled access.

• During installaon, troubleshoong and maintenance, pipes may not be used as

steps: the pipe could break under the weight, spilling coolant and possibly causing

serious burns.

• When servicing the appliance, the composion and state of the heat transfer uid

must be checked, as well as the absence of any traces of coolant.

• During the appliance's annual sealing test in accordance with applicable legislaon,

the high and low pressure switches must be checked to ensure that they are

securely fastened to the cooling circuit and that they cut o the electrical circuit

when tripped.

• During maintenance work, ensure there are no traces of corrosion or oil around

the cooling components.

• Before beginning work on the cooling circuit, stop the appliance and wait for a few

minutes before ng the temperature and pressure sensors. Some elements such

as the compressor and piping may reach temperatures in excess of 100°C and high

pressures with the consequent risk of severe burns.

TROUBLESHOOTING

• All brazing must be carried out by qualied brazers.

• Replacement pipes must always be made of copper in compliance with standard

NF EN 12735-1.

EN