FV722 Rev. A 07/23/20

Page 9

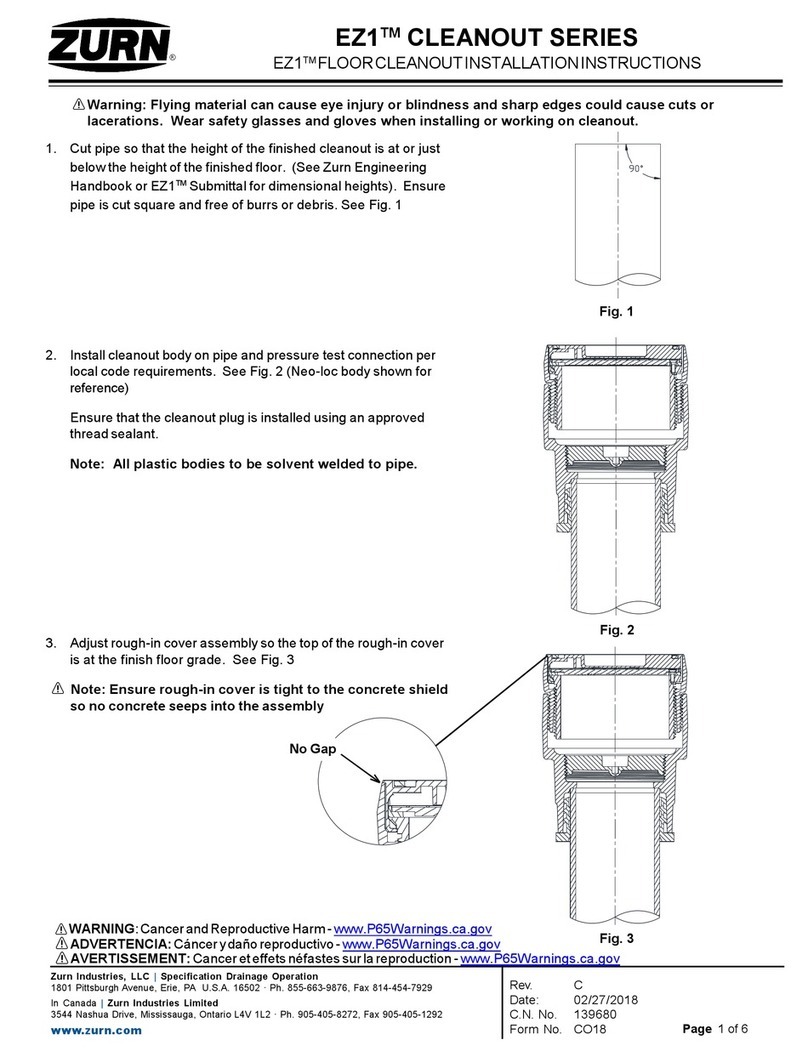

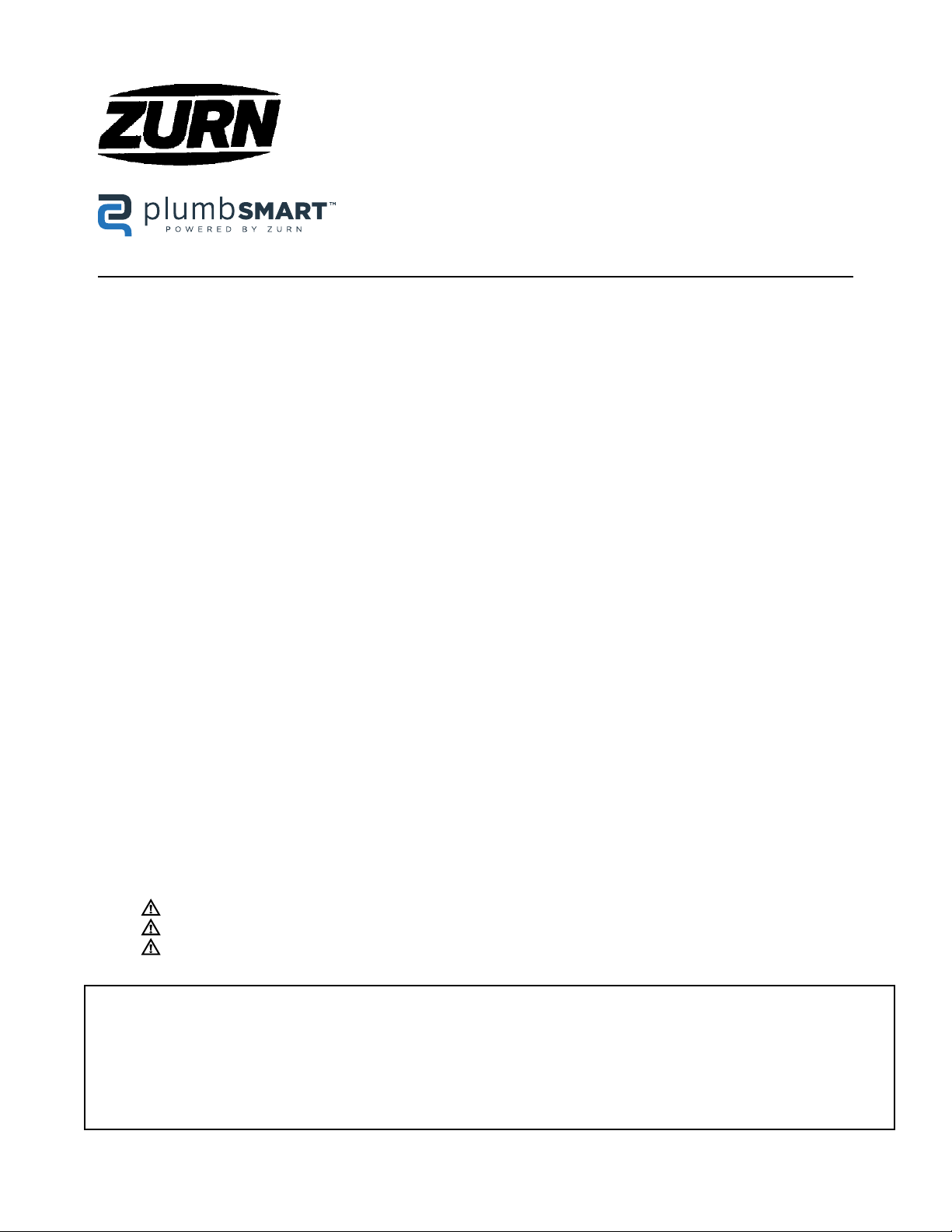

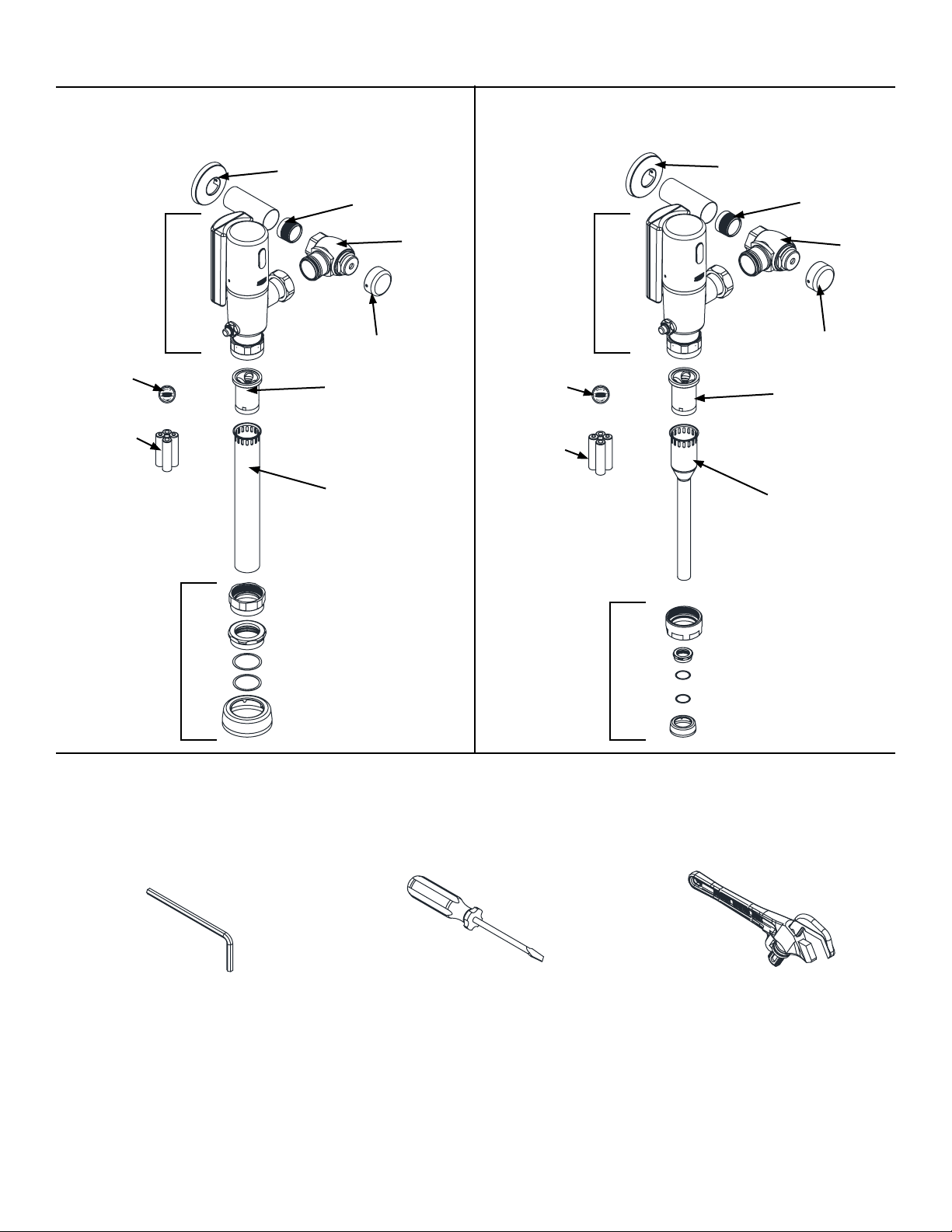

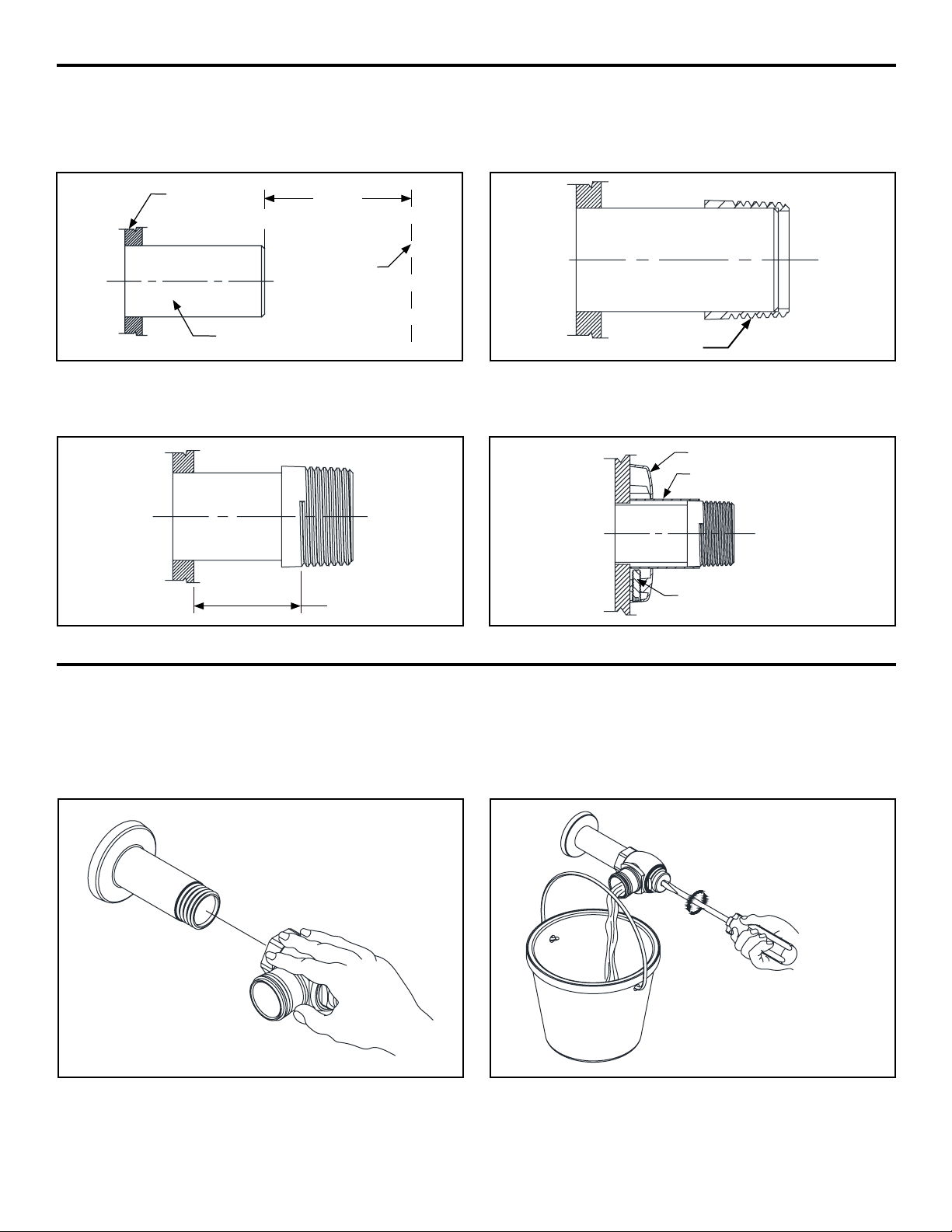

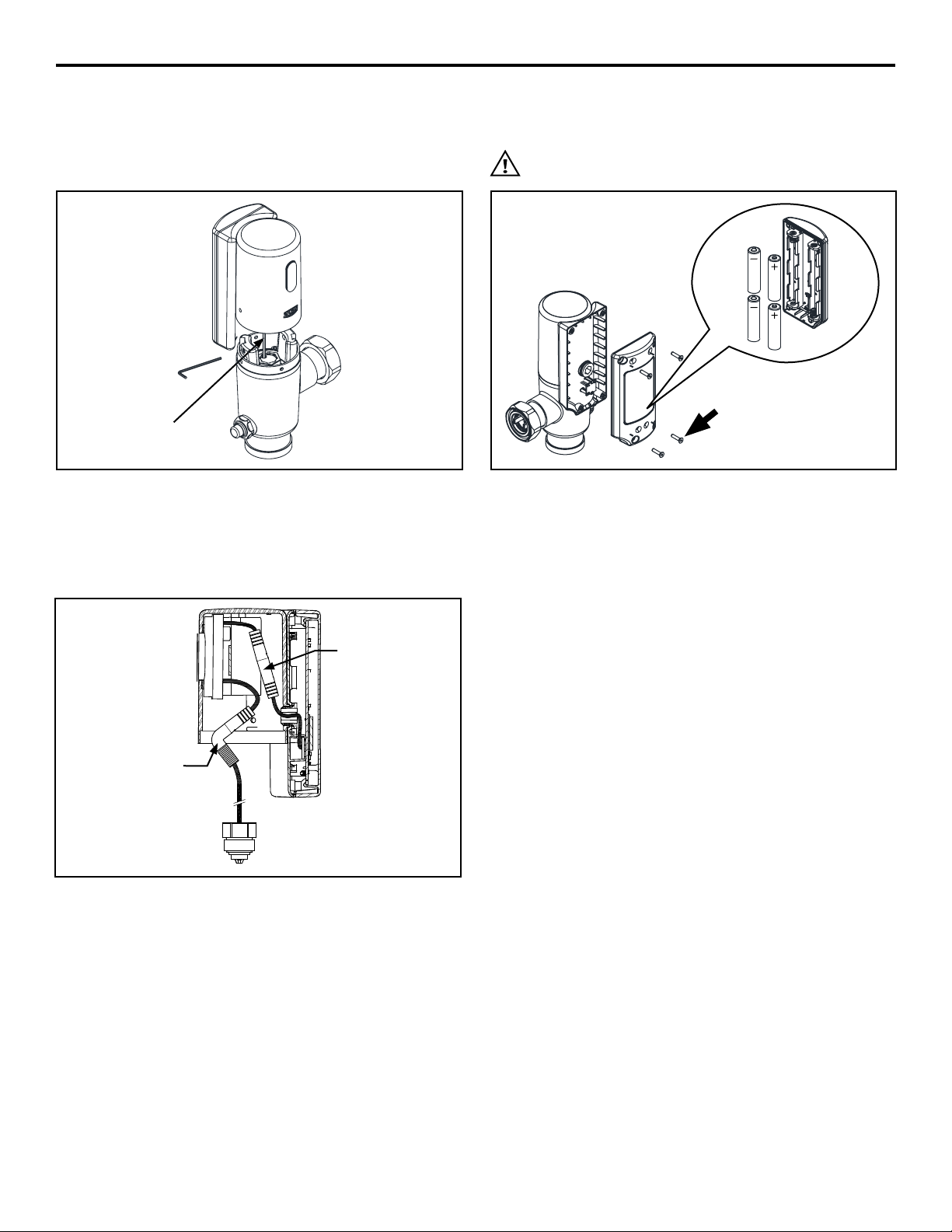

Accessing Piston Kit

1. Turn o water supply and press manual override button to relieve

all water pressure.

2. Remove valve cap to expose ring insert. Using the M3 Allen

Wrench remove the 4 screws and the ring insert.

3. Remove the remaining 2 screws and the solenoid ange.

4. Remove the piston kit from the valve body and inspect for

damage to the seals or debris in the orice. Excessive build up

of debris may occur on lter screen.

• Do not use any abrasive or chemical cleaners to clean the ushometer.

• ONLY use mildly warm soapy water, and then wipe the device dry with a clean/soft towel or cloth.

• Upon cleaning other areas of the restroom, be sure the sensor lenses are protected from other cleaning chemicals/solvents to

prevent potential damages to the sensor and/or electronics.

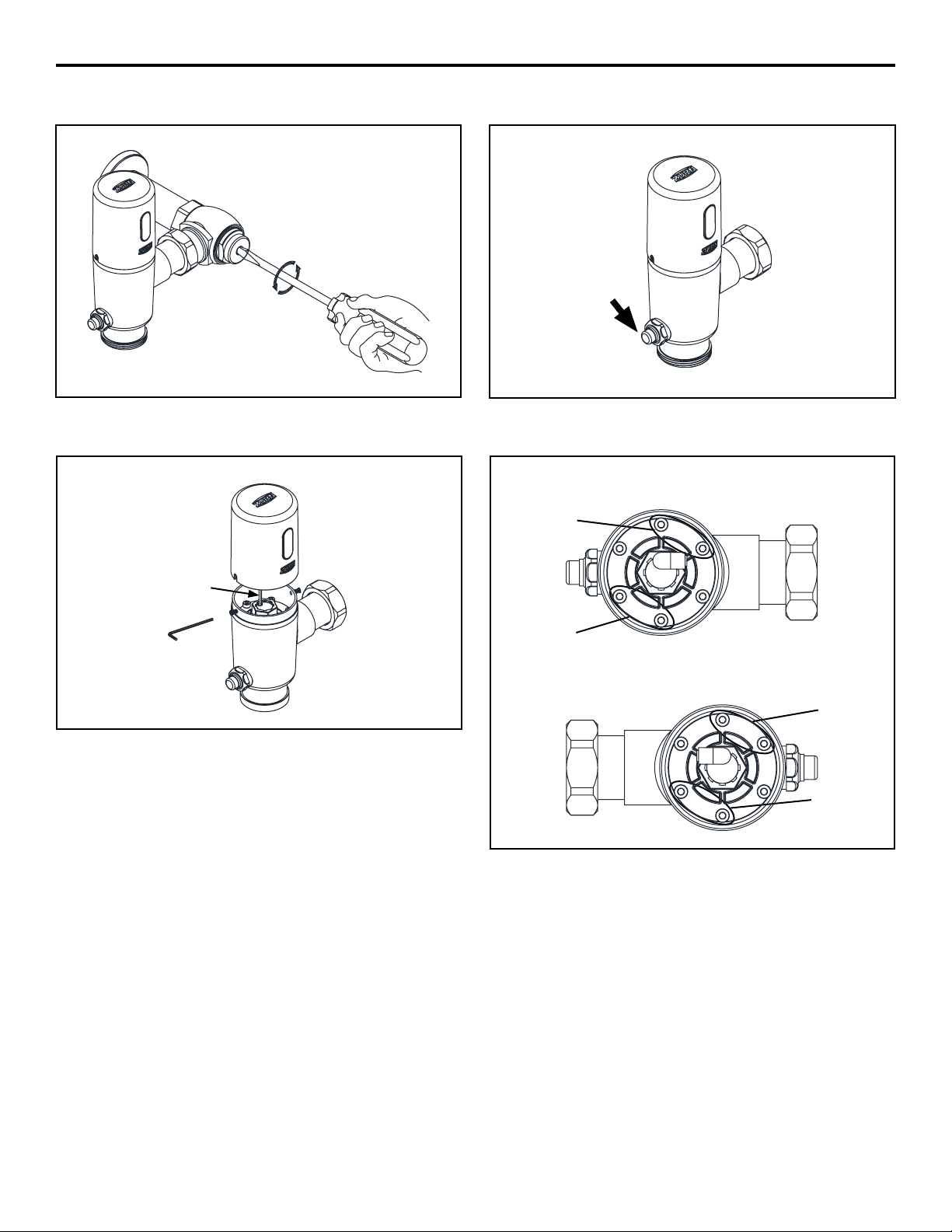

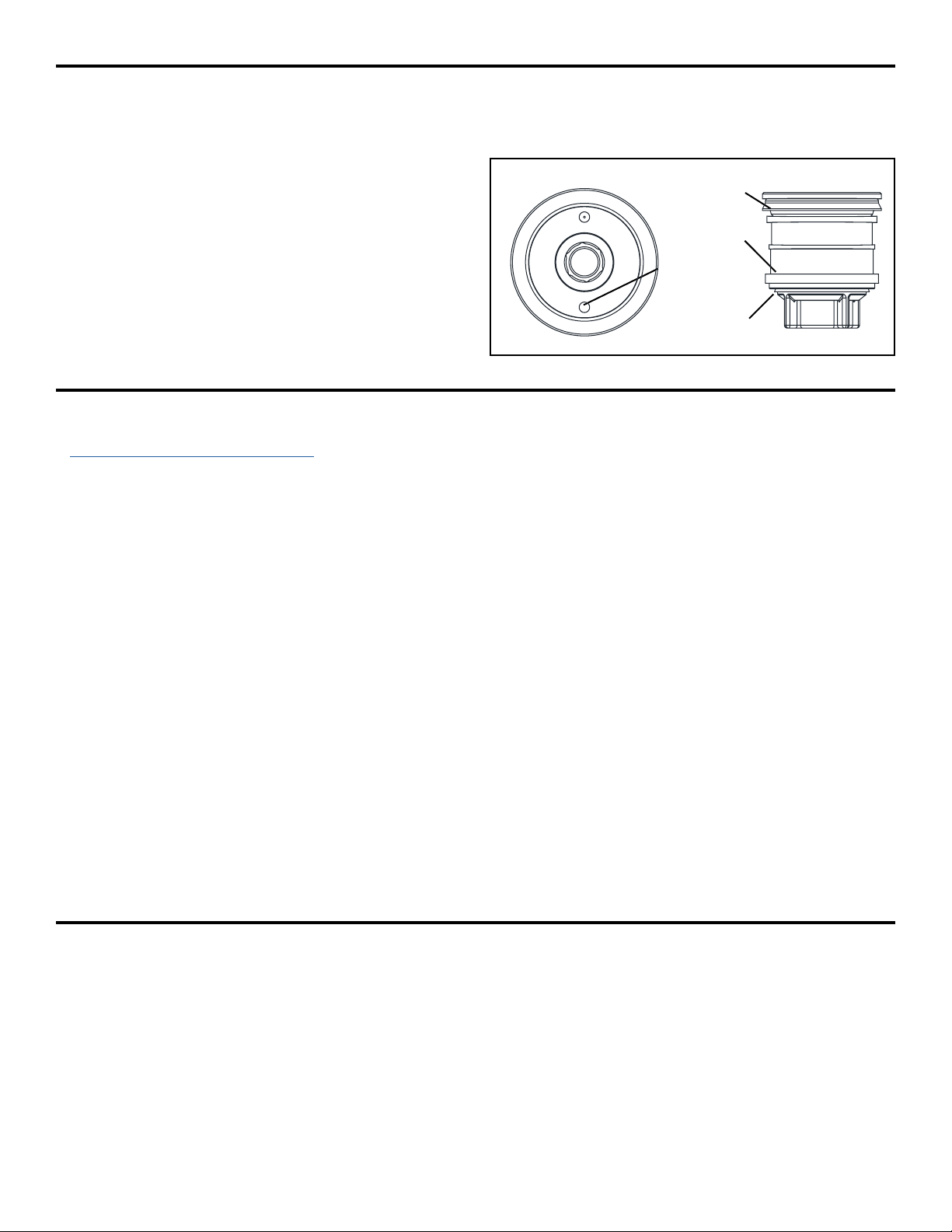

Cup Seal

Face Seal

Orice

Filter

Screen

Care and Cleaning Instruction

Gateway Instruction

You can request your Ethernet or LTE gateway by visiting

Zurn.com/plumbsmart-gateway-request

or call Zurn Customer Care at 1-844-987-6737

Step 1. Request Gateway:

Step 2. Cabling, Powering and Connecting Your Device:

1. Connect one end of the RJ45 Ethernet cable (supplied) to the

gateway’s Ethernet port and plug the cable’s other end into the

nearest wall port of the building’s Ethernet network.

2. Connect the power supply to the power jack.

3. Wait for status LED to go from ON to double ash every second,

the LoRa LED to turn ON solid, and the cell LED (if LTE enabled)

to ash once every 3 seconds. Should take around 1-2 minutes

depending on location. Your gateway is now ready to transmit

data from your Zurn connected product.

4. Zurn Gateways have been set to DHCP by default. Please

consult local IT support for possible additional access

requirements for your network.

Step 3. Determining general Location for the Zurn Gateway:

• Select a location central to all devices to be connected to this

gateway. Place the gateway as high as possible, such as near

the top of a wall.

• Avoid obstructions. Thick walls and reective surfaces, such

as metal, weaken the signal between the gateway and other

devices.

• The LoRa antenna is an omni-directional antenna, but for best

results, mount the device so the LoRa antenna is in a vertical

position near the top of a wall. We recommend conducting a site

survey to test the signal strength in dierent locations before

you mount the device.

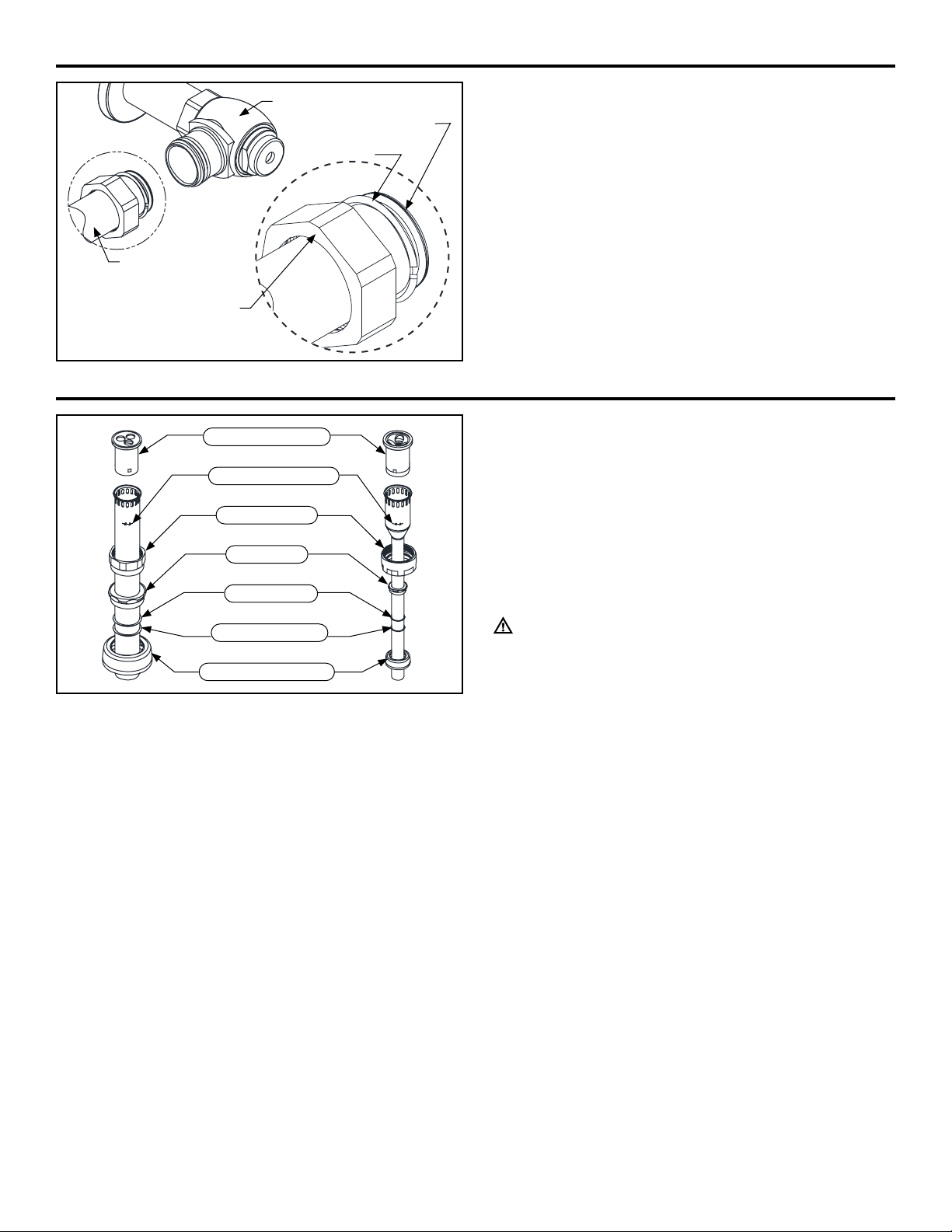

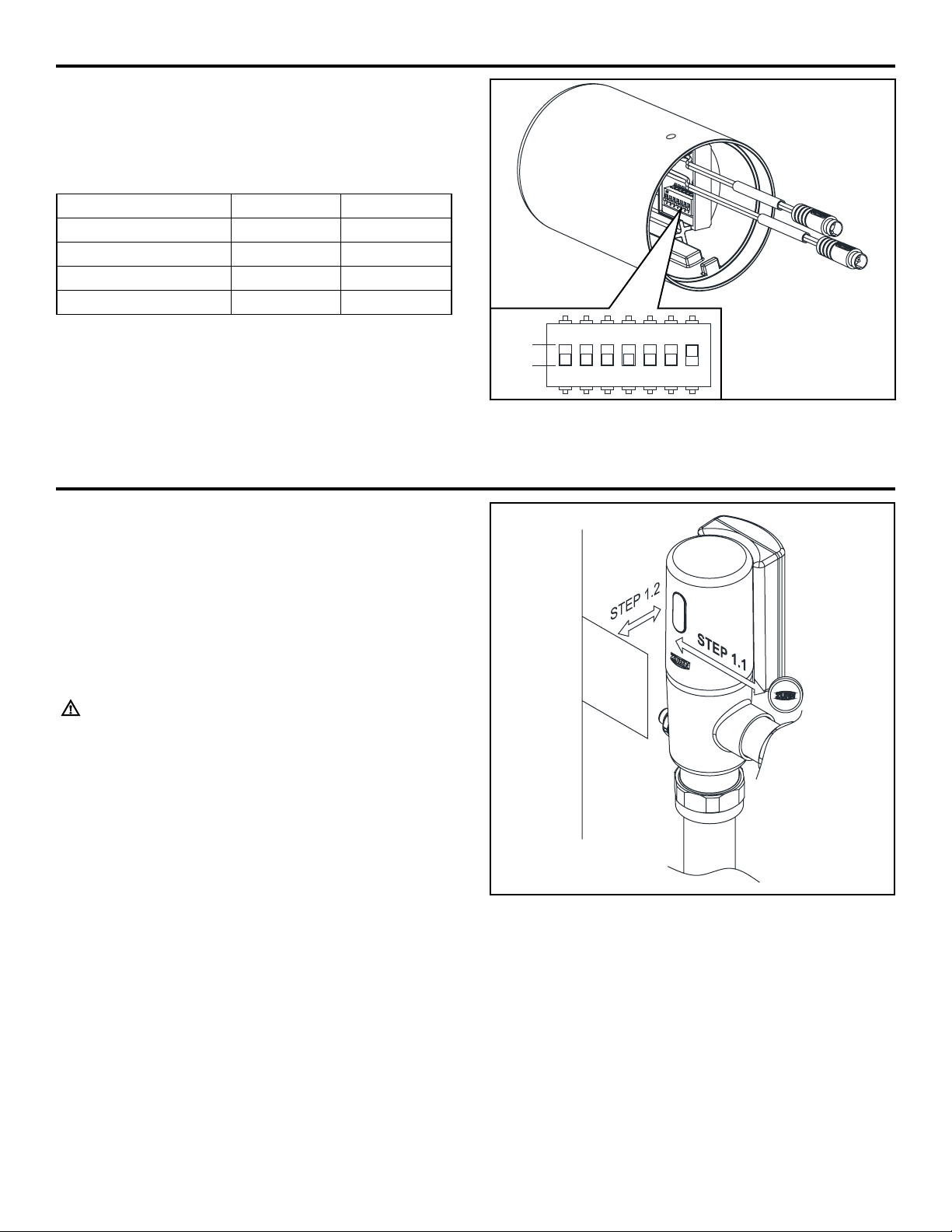

Step 4. Mounting the Zurn Gateway:

The device ships with a mounting bracket. You will also need:

• Four #6 screws with anchors

• Screwdriver

• Drill

1. Determine where you want to mount the device.

2. Mark where you want the screws to go.

3. Drill holes for the screws and insert anchors.

4. Place the mounting bracket and secure it with screws.

5. Attach the device to the bracket and rotate to lock into place.

Register in plumbSMART

NOTE: Instructions below are duplicated from registration card supplied with monitor

1. Install Zurn Connected Product(s)

2. Install Zurn Gateway per the Gateway Instructions Manual

3. Request plumbSMART Administrator Account at 844-987-6737

4. Zurn creates your Enterprise Account for you! (You will be required to identify your building location, number of oors, and number

of rooms.)

5. Log in to plumbsmart.zurn.com

6. Register each Connected Product in plumbSMART (Watch How-To Videos to Get Started. Located in the support section inside the

portal.)

7. Now, Relax. You’re Connected.