8

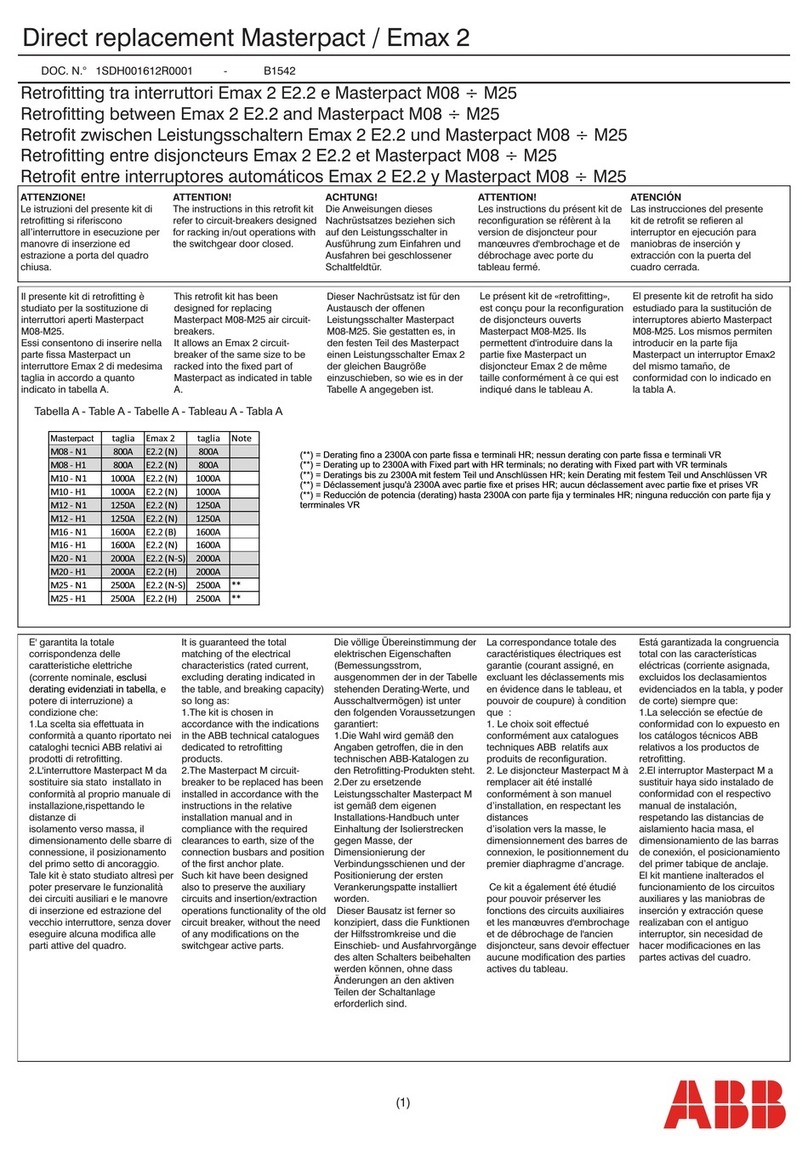

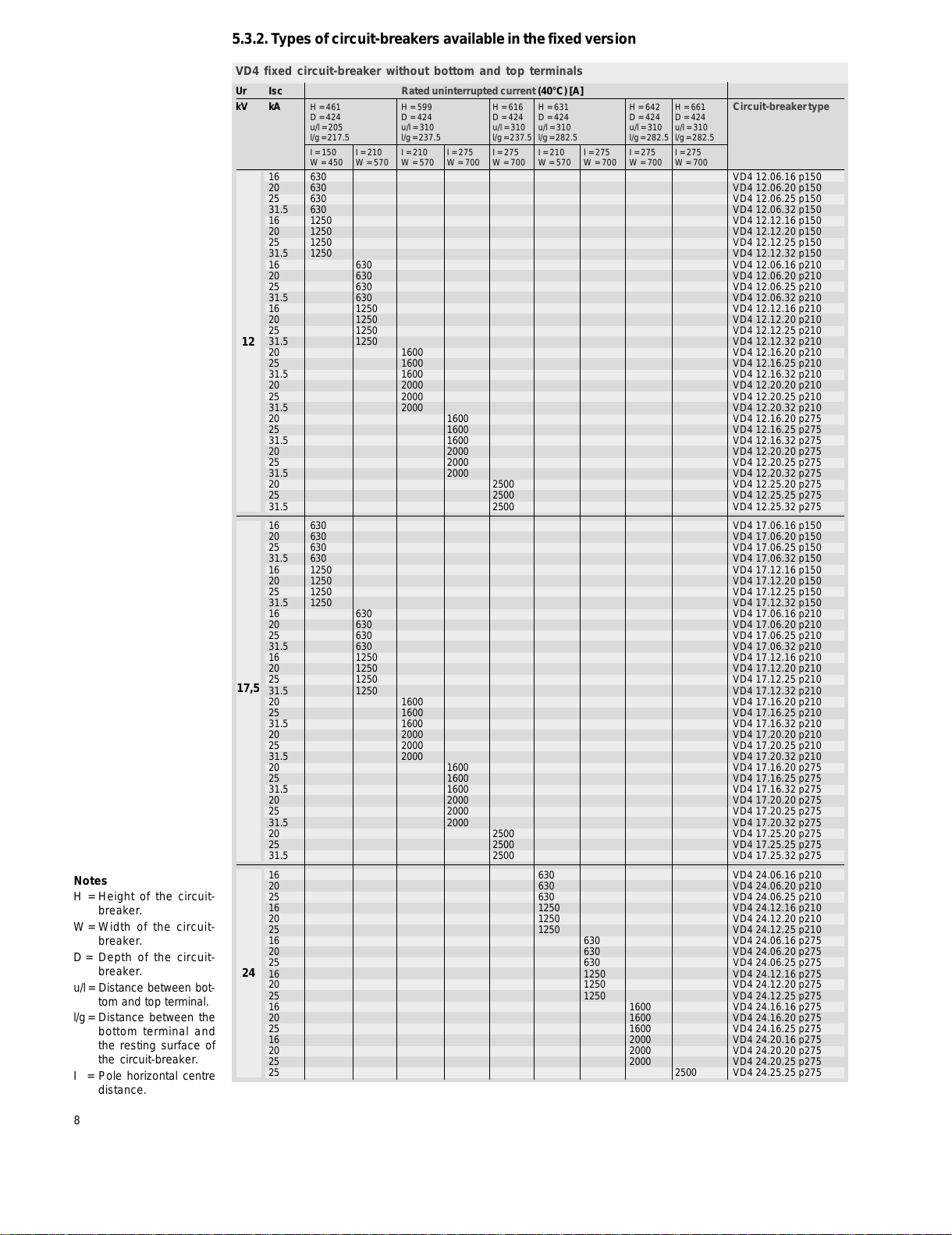

5.3.2. Types of circuit-breakers available in the fixed version

24

VD4 fixed circuit-breaker without bottom and top terminals

17,5

12

Notes

H = Height of the circuit-

breaker.

W = Width of the circuit-

breaker.

D = Depth of the circuit-

breaker.

u/l= Distance between bot-

tom and top terminal.

l/g= Distance between the

bottom terminal and

the resting surface of

the circuit-breaker.

I = Pole horizontal centre

distance.

Ur Isc Rated uninterrupted current (40°C) [A]

kV kA H = 461 H = 599 H = 616 H = 631 H = 642 H = 661 Circuit-breakertype

D = 424 D = 424 D = 424 D = 424 D = 424 D = 424

u/l=205 u/l=310 u/l=310 u/l= 310 u/l = 310 u/l=310

l/g=217.5 l/g=237.5 l/g=237.5 l/g=282.5 l/g=282.5 l/g=282.5

I = 150 I = 210 I = 210 I = 275 I = 275 I = 210 I = 275 I = 275 I = 275

W = 450 W = 570 W = 570 W = 700 W = 700 W = 570 W = 700 W = 700 W = 700

16 630 VD4 12.06.16 p150

20 630 VD4 12.06.20 p150

25 630 VD4 12.06.25 p150

31.5 630 VD4 12.06.32 p150

16 1250 VD4 12.12.16 p150

20 1250 VD4 12.12.20 p150

25 1250 VD4 12.12.25 p150

31.5 1250 VD4 12.12.32 p150

16 630 VD4 12.06.16 p210

20 630 VD4 12.06.20 p210

25 630 VD4 12.06.25 p210

31.5 630 VD4 12.06.32 p210

16 1250 VD4 12.12.16 p210

20 1250 VD4 12.12.20 p210

25 1250 VD4 12.12.25 p210

31.5 1250 VD4 12.12.32 p210

20 1600 VD4 12.16.20 p210

25 1600 VD4 12.16.25 p210

31.5 1600 VD4 12.16.32 p210

20 2000 VD4 12.20.20 p210

25 2000 VD4 12.20.25 p210

31.5 2000 VD4 12.20.32 p210

20 1600 VD4 12.16.20 p275

25 1600 VD4 12.16.25 p275

31.5 1600 VD4 12.16.32 p275

20 2000 VD4 12.20.20 p275

25 2000 VD4 12.20.25 p275

31.5 2000 VD4 12.20.32 p275

20 2500 VD4 12.25.20 p275

25 2500 VD4 12.25.25 p275

31.5 2500 VD4 12.25.32 p275

16 630 VD4 17.06.16 p150

20 630 VD4 17.06.20 p150

25 630 VD4 17.06.25 p150

31.5 630 VD4 17.06.32 p150

16 1250 VD4 17.12.16 p150

20 1250 VD4 17.12.20 p150

25 1250 VD4 17.12.25 p150

31.5 1250 VD4 17.12.32 p150

16 630 VD4 17.06.16 p210

20 630 VD4 17.06.20 p210

25 630 VD4 17.06.25 p210

31.5 630 VD4 17.06.32 p210

16 1250 VD4 17.12.16 p210

20 1250 VD4 17.12.20 p210

25 1250 VD4 17.12.25 p210

31.5 1250 VD4 17.12.32 p210

20 1600 VD4 17.16.20 p210

25 1600 VD4 17.16.25 p210

31.5 1600 VD4 17.16.32 p210

20 2000 VD4 17.20.20 p210

25 2000 VD4 17.20.25 p210

31.5 2000 VD4 17.20.32 p210

20 1600 VD4 17.16.20 p275

25 1600 VD4 17.16.25 p275

31.5 1600 VD4 17.16.32 p275

20 2000 VD4 17.20.20 p275

25 2000 VD4 17.20.25 p275

31.5 2000 VD4 17.20.32 p275

20 2500 VD4 17.25.20 p275

25 2500 VD4 17.25.25 p275

31.5 2500 VD4 17.25.32 p275

16 630 VD4 24.06.16 p210

20 630 VD4 24.06.20 p210

25 630 VD4 24.06.25 p210

16 1250 VD4 24.12.16 p210

20 1250 VD4 24.12.20 p210

25 1250 VD4 24.12.25 p210

16 630 VD4 24.06.16 p275

20 630 VD4 24.06.20 p275

25 630 VD4 24.06.25 p275

16 1250 VD4 24.12.16 p275

20 1250 VD4 24.12.20 p275

25 1250 VD4 24.12.25 p275

16 1600 VD4 24.16.16 p275

20 1600 VD4 24.16.20 p275

25 1600 VD4 24.16.25 p275

16 2000 VD4 24.20.16 p275

20 2000 VD4 24.20.20 p275

25 2000 VD4 24.20.25 p275

25 2500 VD4 24.25.25 p275