1. Disclaimer........................................................................................ 4

2. Introduction...................................................................................... 5

2.1. Improvement Policy................................................................. 5

2.2. Notice....................................................................................... 5

2.3. Standards and Regulations ..................................................... 5

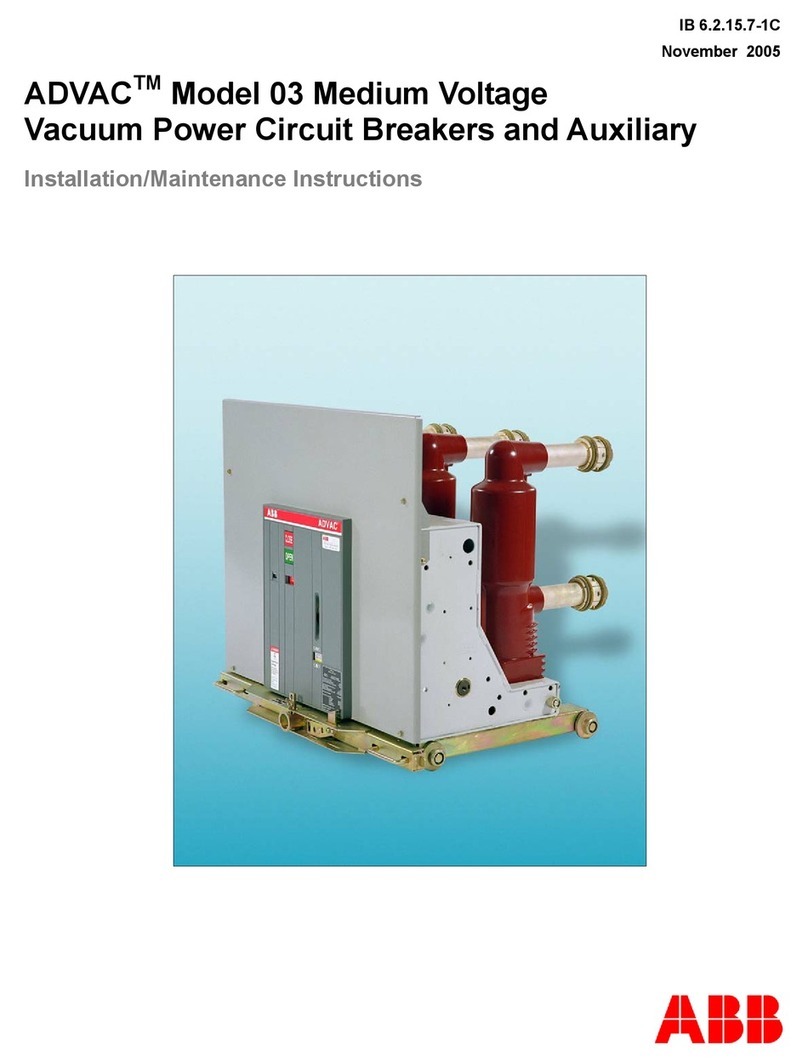

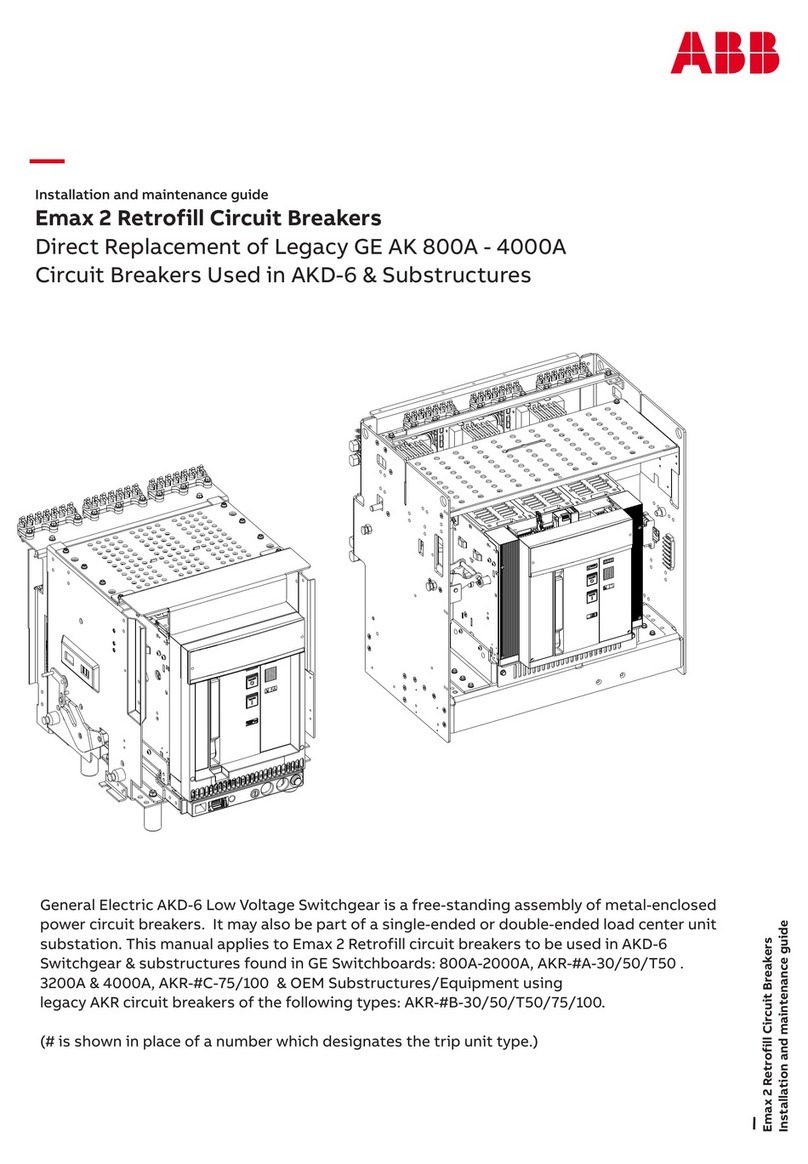

3. Product Description ......................................................................... 6

3.1. Apparatus ................................................................................ 6

3.2. Identification........................................................................... 11

4. Safety Precautions ........................................................................ 13

4.1. Warning Notice...................................................................... 13

4.2. Personnel Requirements ....................................................... 13

5. Transport & Storage...................................................................... 14

5.1. Storage .................................................................................. 14

5.2. Transport ............................................................................... 15

5.3. Goods Acceptance and Visual Inspection............................. 15

5.4. Handling of transport damage ............................................... 15

6. Technical Data .............................................................................. 16

6.1. Electrical Data Pole ............................................................... 16

6.2. MABS Control Card ............................................................... 17

6.3. Weights and Dimensions....................................................... 23

6.4. Operating Conditions............................................................. 23

6.5. Torques for tightening screws and nuts................................. 23

6.6. Interfaces............................................................................... 23

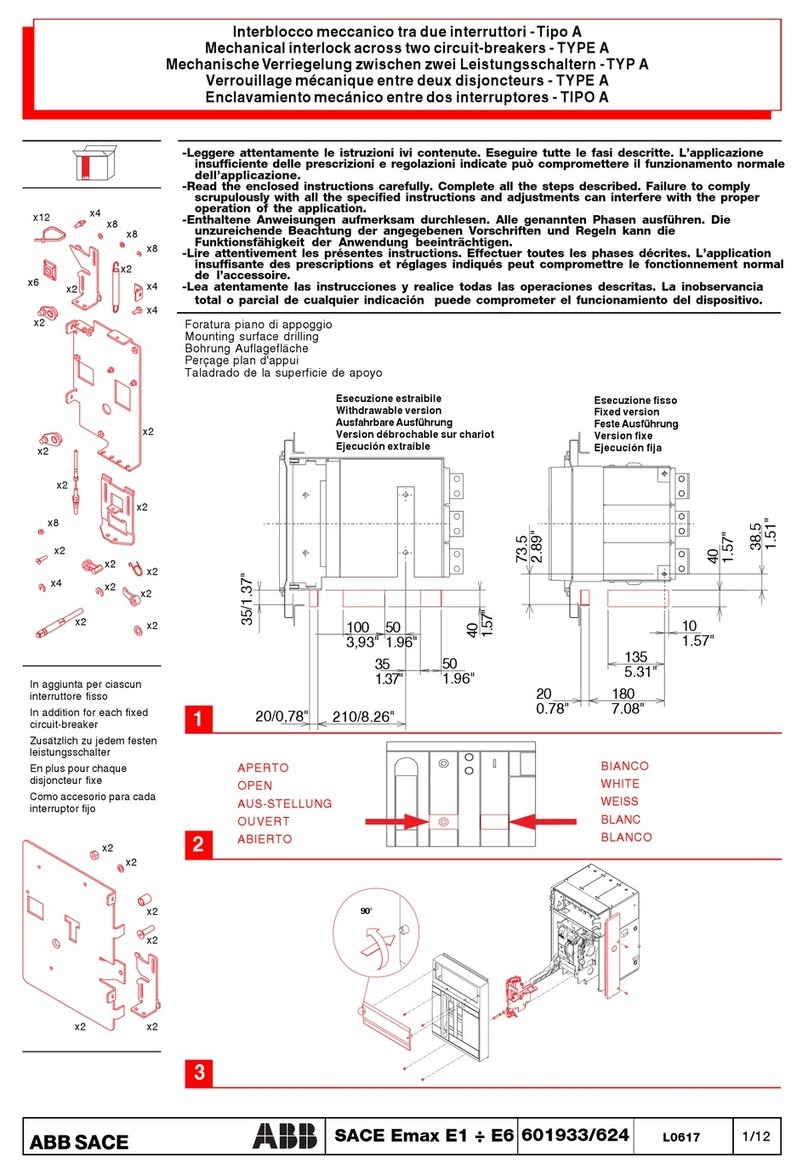

7. Assembly & Commissioning.......................................................... 24

7.1. Unpacking the Material.......................................................... 24

7.2. Assembly / Installation........................................................... 24

7.3. Commissioning...................................................................... 27

8. Maintenance.................................................................................. 29

8.1. General.................................................................................. 29

8.2. Inspection .............................................................................. 29

9. Disposal......................................................................................... 32

10.Customer Service.......................................................................... 32

10.1. Procedure............................................................................ 32

10.2. Packaging ........................................................................... 32

10.3. Spare Parts ......................................................................... 33

11.Troubleshooting............................................................................. 33

12.Customer feedback file ................................................................. 35

ABB in the railways – Medium Voltage products

Product Family : FSK II S +

Operating and Maintenance Manual