ADTEK AEM-DRB User manual

Table of contents

Other ADTEK Measuring Instrument manuals

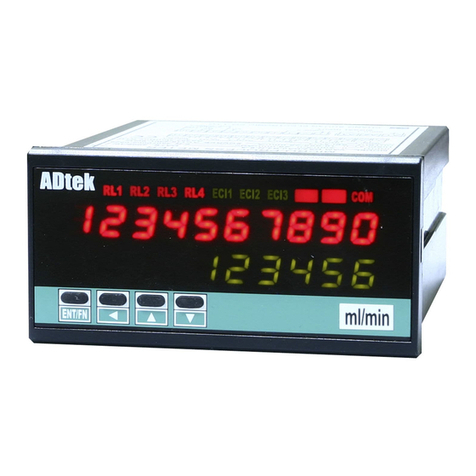

ADTEK

ADTEK CS1-RL User manual

ADTEK

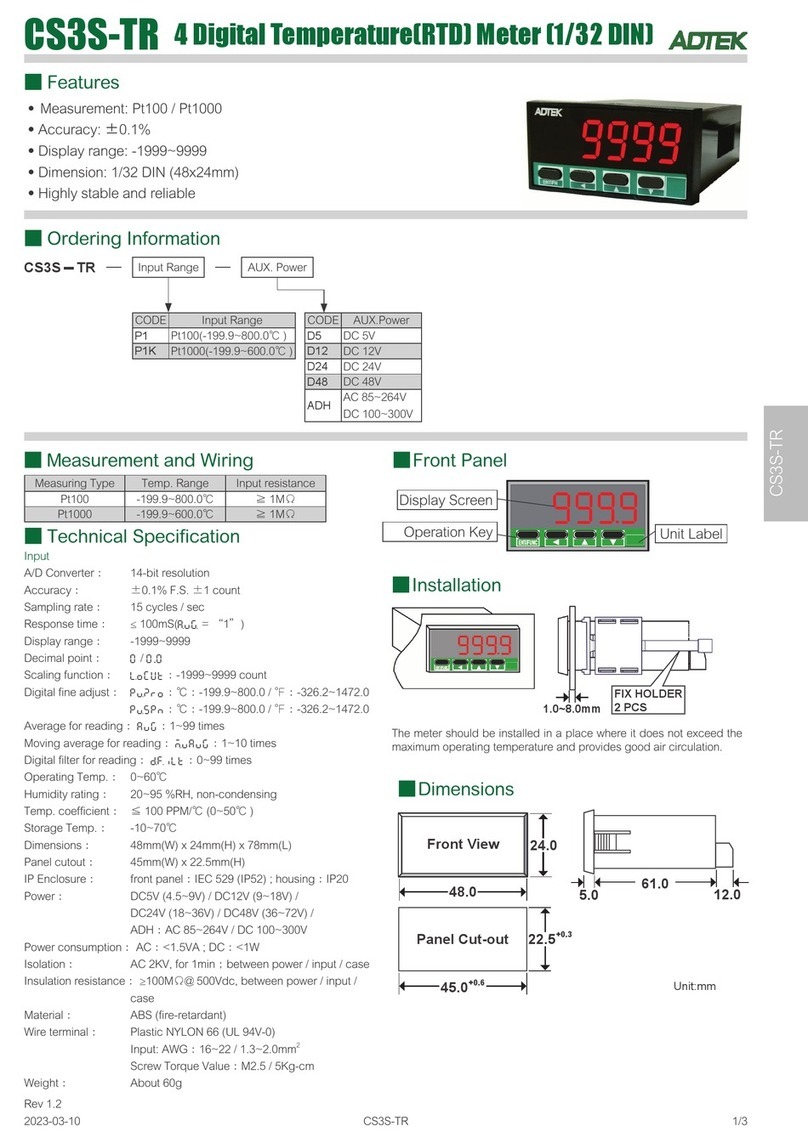

ADTEK CS3S-TR User manual

ADTEK

ADTEK CS2-VA User manual

ADTEK

ADTEK MWH-10A User manual

ADTEK

ADTEK CS2-SG User manual

ADTEK

ADTEK CPM-12D User manual

ADTEK

ADTEK CS2-SG User manual

ADTEK

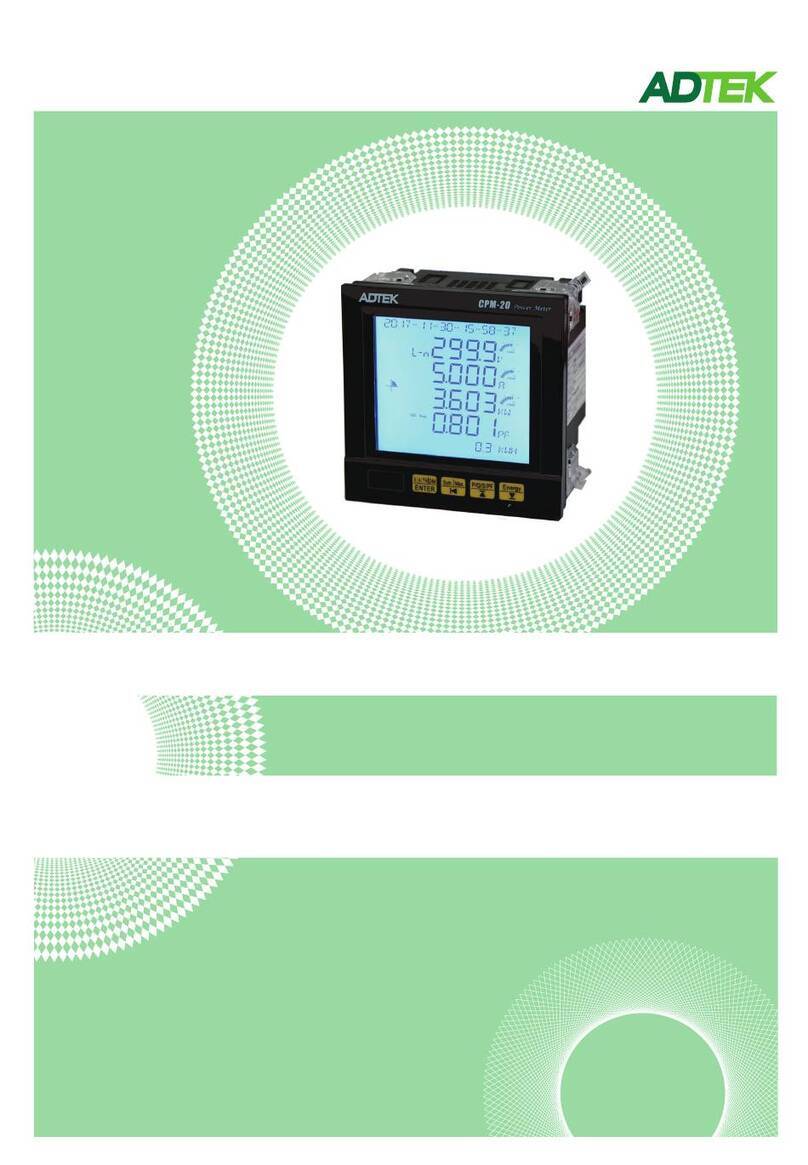

ADTEK CPM-20 Series User manual

ADTEK

ADTEK AFM-8A User manual

ADTEK

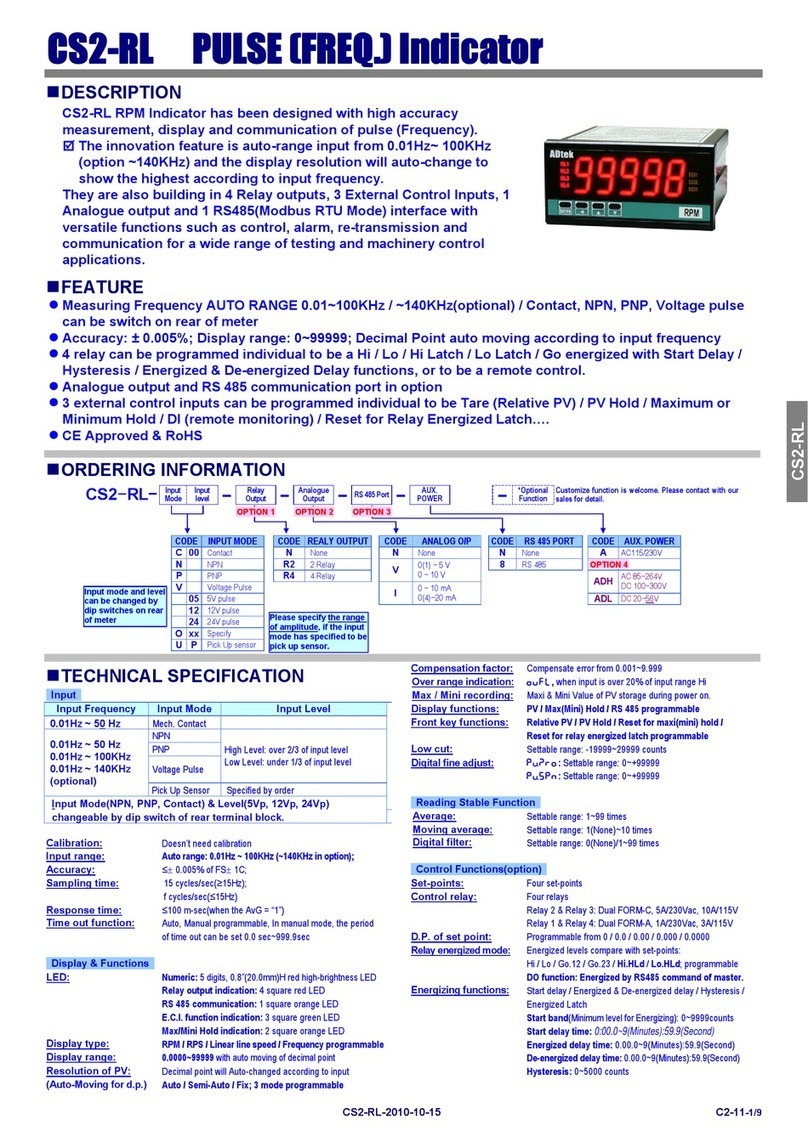

ADTEK CS2-RL User manual

ADTEK

ADTEK CPM-80 Series User manual

ADTEK

ADTEK CPM-12D User manual

ADTEK

ADTEK CS3S VA User manual

ADTEK

ADTEK CM1-TC User manual

ADTEK

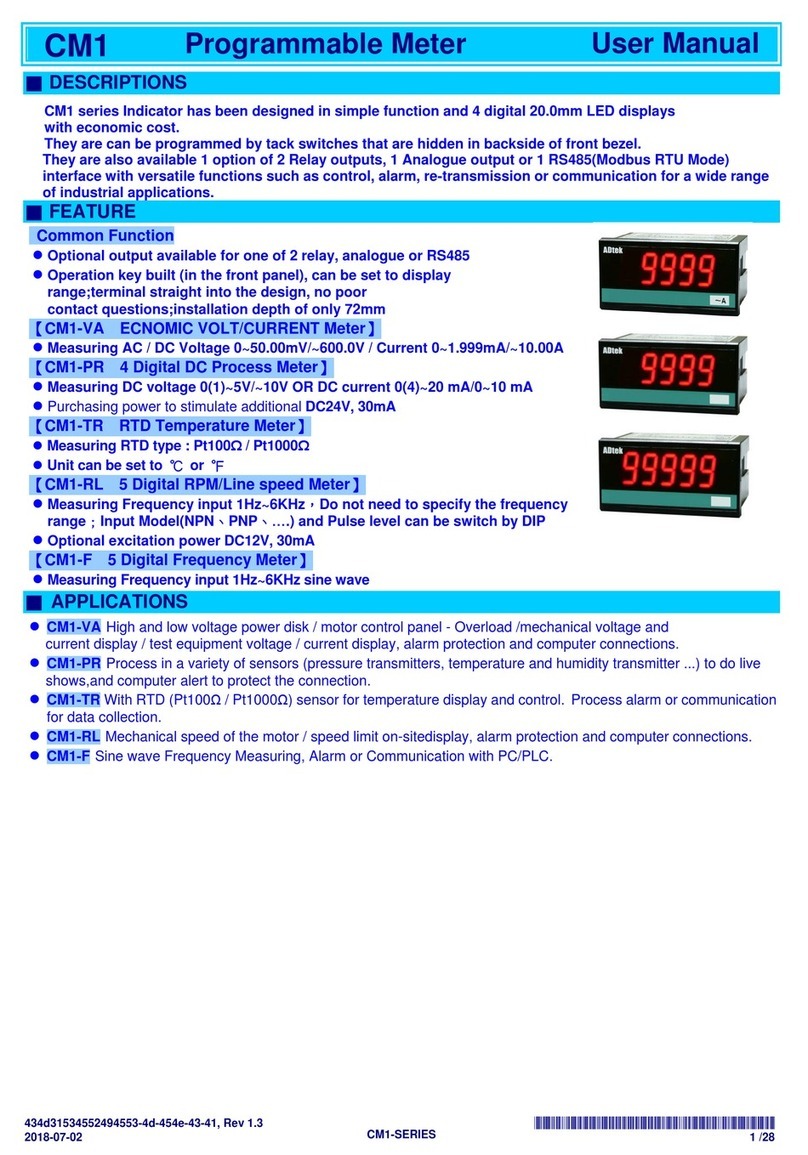

ADTEK CM1 Series User manual

ADTEK

ADTEK MWH-10 User manual

ADTEK

ADTEK MW-5 User manual

ADTEK

ADTEK AEM-DRK User manual

ADTEK

ADTEK CS1-SG User manual

ADTEK

ADTEK CPM-12B User manual

Popular Measuring Instrument manuals by other brands

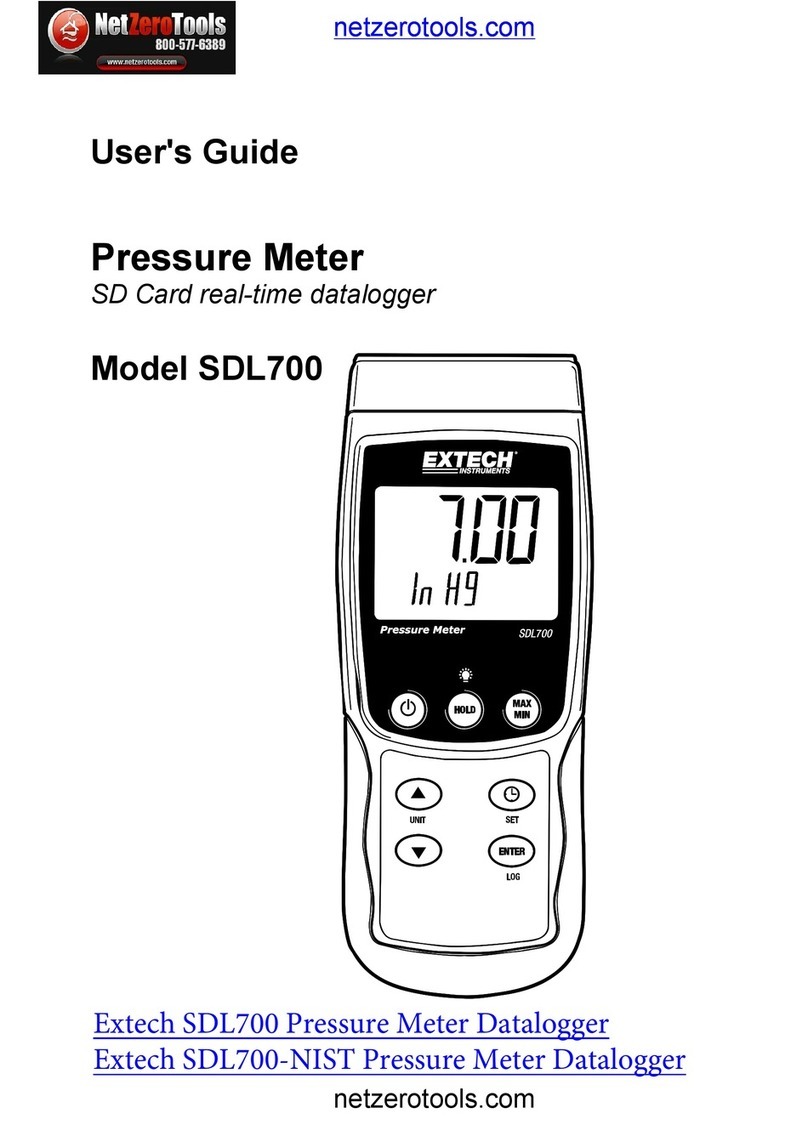

Johnson

Johnson 40-6932 Quick start guides

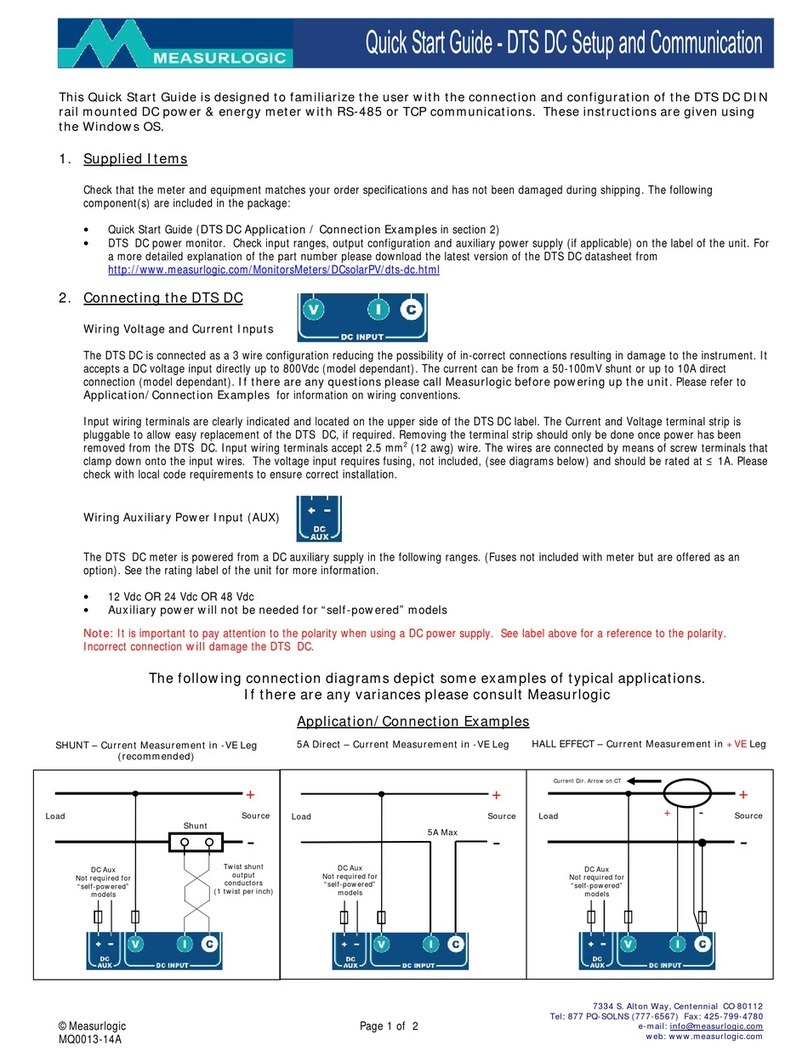

Measurlogic

Measurlogic DTS DC quick start guide

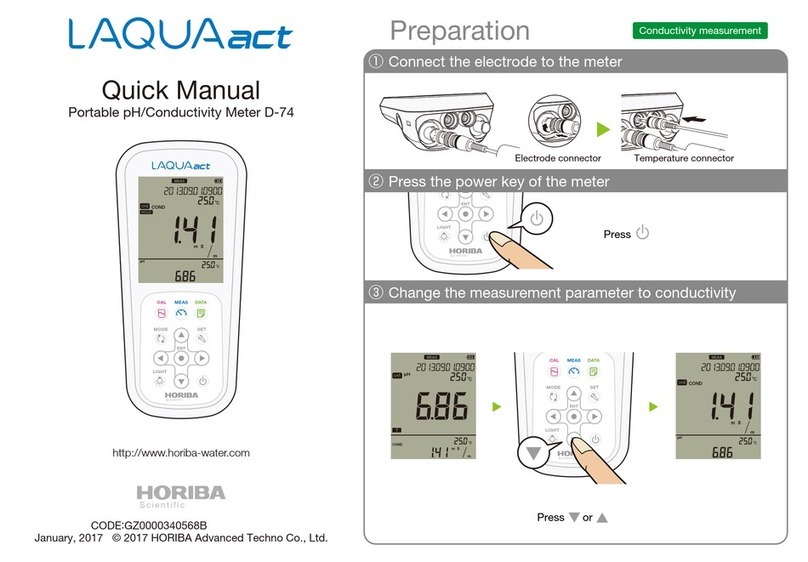

horiba

horiba LAQUAact D-74 Quick manual

delta-mobrey

delta-mobrey Sentry Series Installation, operation & maintenance instructions

Teledyne

Teledyne T3LCR1002 user manual

Hubner

Hubner Cobolt 06-01 Series owner's manual