- 3 / 50 - BN 09 2671/01/01

CONTENTS

1 INTRODUCTION ............................................................................ 4

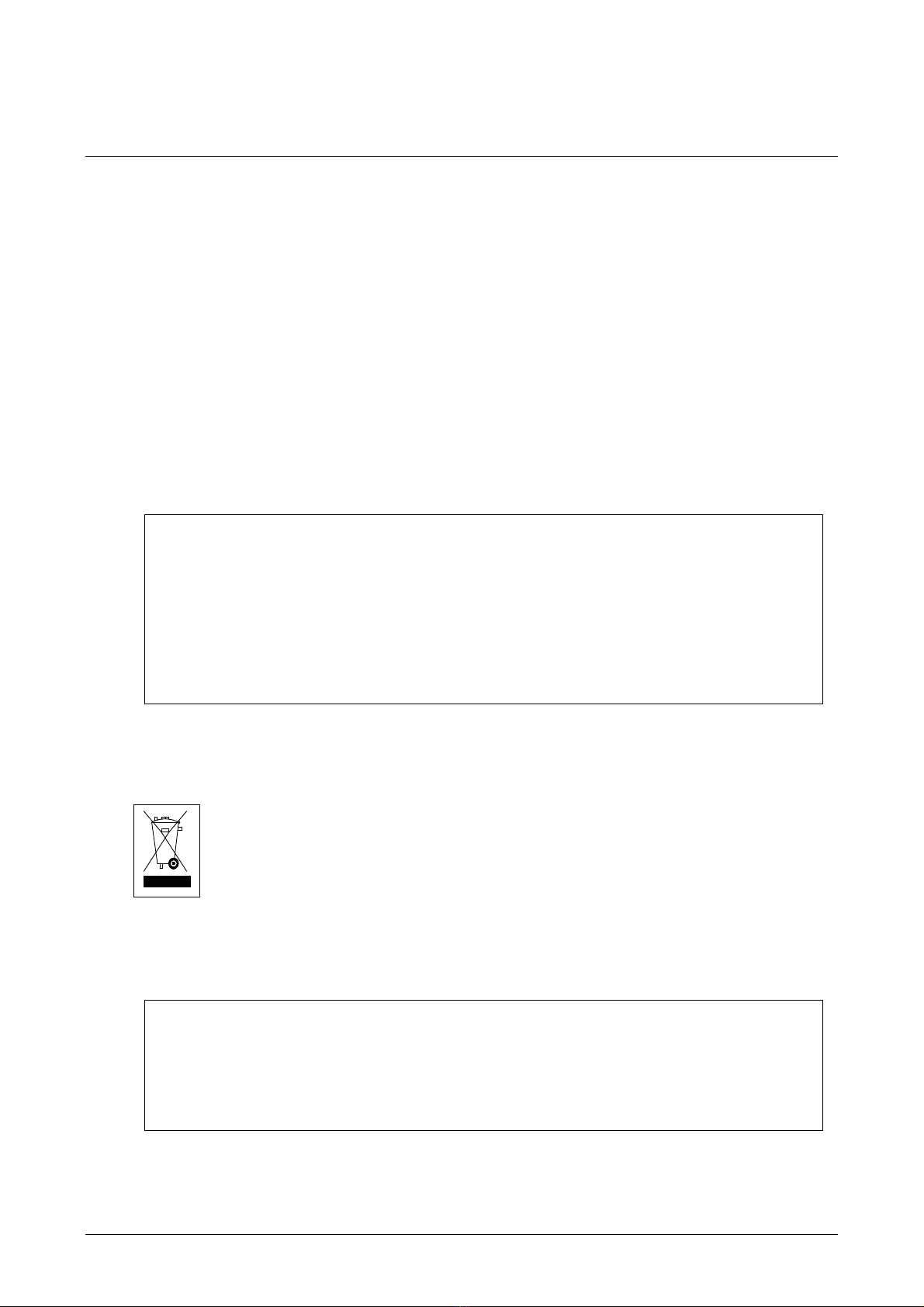

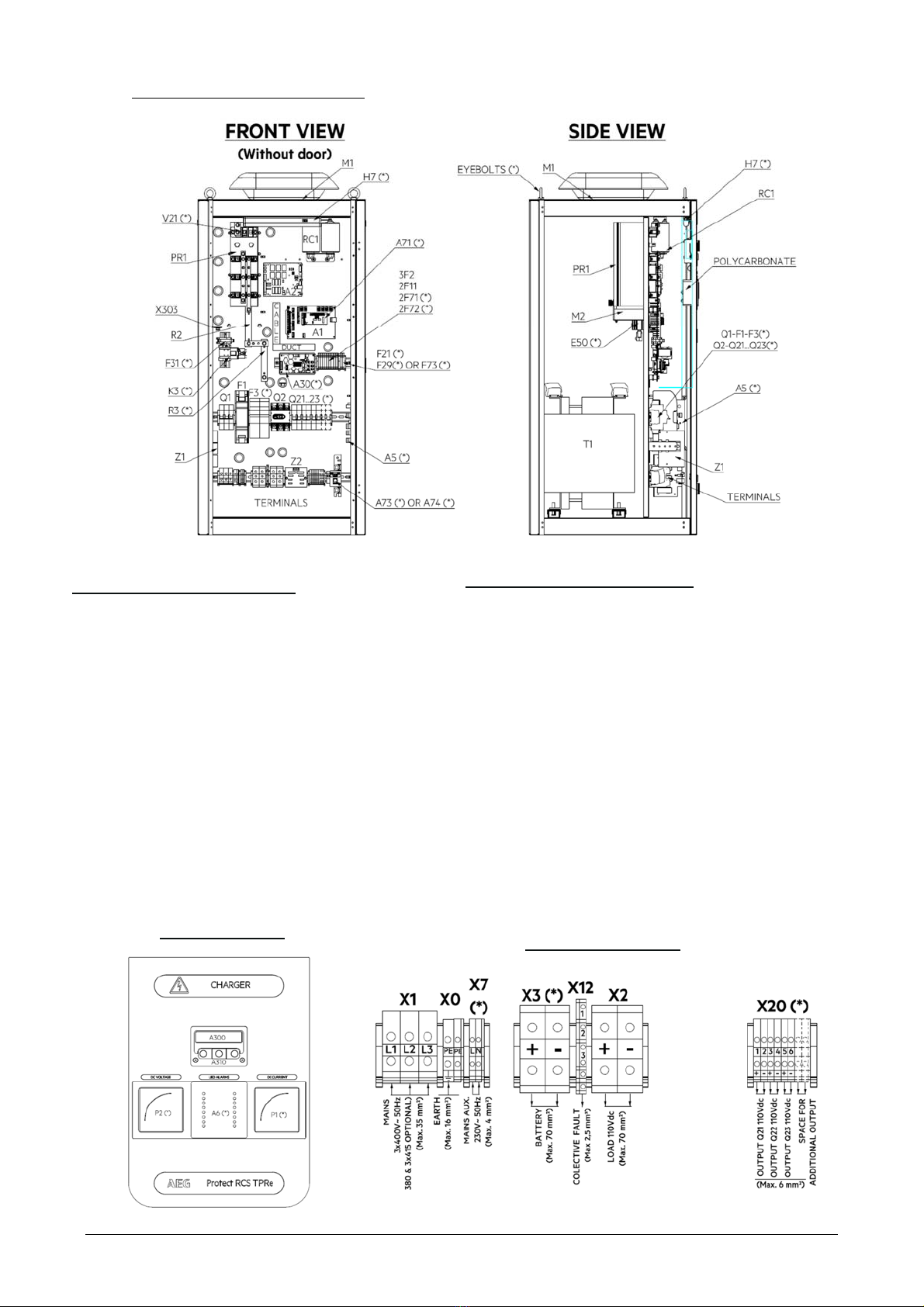

2 PRESENTATION OF THE SYSTEM .............................................. 5

3 INSTALLATION .............................................................................. 7

3.1 HANDLING ............................................................................................... 7

3.2 INSTALLING AND SECURING THE RECTIFIER CHARGER ................. 9

3.3 INSTALLING THE BATTERY ................................................................. 10

3.4 ENVIRONMENTAL REQUIREMENTS (EXCLUDING THE BATTERY) 10

4 CONNECTIONS (refer to the PRODUCT drawing) ...................... 11

4.1 MAINS INPUT CONNECTION ............................................................... 11

4.2 BATTERY CONNECTION ...................................................................... 12

4.3 CONNECTING THE COMMON REMOTE ALARM OUTPUT ................ 12

4.4 CONNECTING THE LOAD .................................................................... 13

5 START-UP (refer to the product drawing) ..................................... 13

5.1 PRELIMINARY CHECKS ....................................................................... 13

5.2 SWITCHING ON ..................................................................................... 14

5.3 START-UP PROCEDURE OF TPRE TD PARALLELED SYSTEMS ..... 15

5.4 BATTERY COMMISSIONING CHARGE ................................................ 15

6 OPERATING INSTRUCTIONS ..................................................... 16

6.1 DEFAULT MENU .................................................................................... 16

6.2 MAIN MENU ........................................................................................... 16

6.3 HUMAN INTERFACE STRUCTURE ...................................................... 18

6.4 STATUS INDICATION DISPLAY ........................................................... 18

6.5 MONITORING FUNCTION ..................................................................... 19

6.6 COMMAND FUNCTION ......................................................................... 22

6.7 CONFIGURATION FUNCTIONS ........................................................... 29

7 FUNCTIONAL DESCRIPTION ..................................................... 34

7.1 OPERATING SEQUENCES ................................................................... 34

7.2 CHARGE MODES .................................................................................. 35

7.3 PRINCIPLE OF OPERATION ................................................................ 35

7.4 "GCAU" GENERIC CONTROL AND ALARM UNIT (A1) ....................... 36

7.5 "TPC" THREE- PHASE CONTROL BOARD (A2) .................................. 36

7.6 DISPLAY BOARD (A300) AND KEYBOARD ASSEMBLY (A310) ......... 37

8 OPTIONS ...................................................................................... 37

8.1 ALARM/SIGNALLING/MEASUREMENT OPTIONS .............................. 37

8.2 COMMUNICATION OPTIONS ............................................................... 39

8.3 LOAD OPTIONS ..................................................................................... 40

8.4 BATTERY OPTIONS .............................................................................. 40

8.5 CABINET OPTIONS ............................................................................... 43

9 PARALLEL OPERATION .............................................................. 44

9.1 REDUNDANT SYSTEM CONFIGURATION .......................................... 44

9.2 PARALLEL SYSTEM CONFIGURATION .............................................. 44

9.3 OPTIONS FOR PARALLEL SYSTEM CONFIGURATIONS .................. 44

10 MAINTENANCE ............................................................................ 45

10.1 PREVENTIVE MAINTENANCE VISIT .................................................... 45

10.2 FAN MAINTENANCE ............................................................................. 46

10.3 CAPACITORS MAINTENANCE ............................................................. 46

11 ELEMENTARY TROUBLESHOOTING ........................................ 46