I.

I.

IV.

VI.

VIL.

Vil.

IX.

SECTION

I

SERVICE

MANUAL

TABLE

OF

CONTENTS

SPECIFICATIONS

.......c.ccsccsssecssseccsssecessscssesecssaeeeseseeersessessnseeeeennees

4

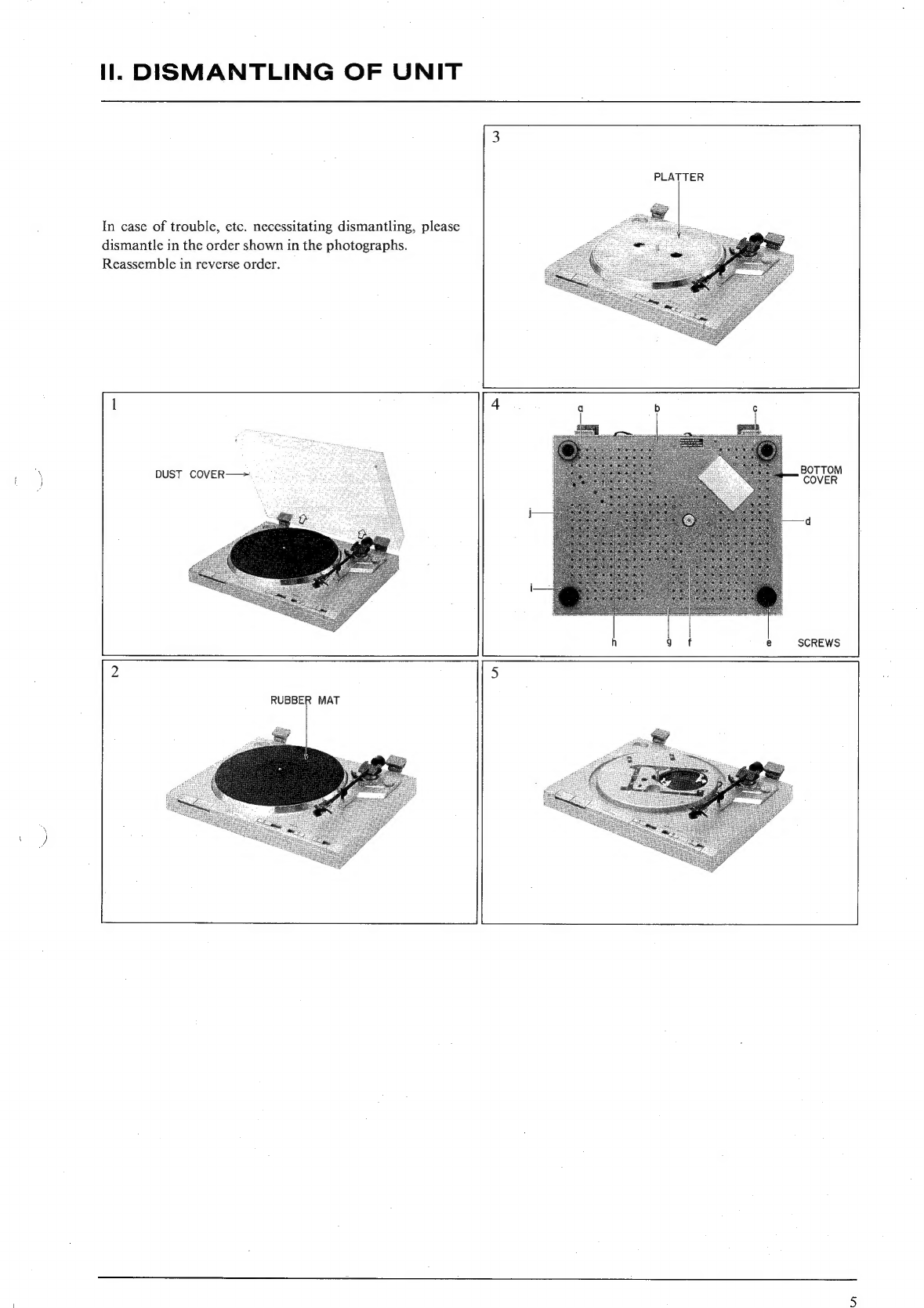

DISMANTLING

OF

UNIT

........ccceceeesecssscecccnscnereceeseeessrsereeseeeeeenes

5

CONTROLS

6

PRINCIPAL

PARTS

LOCATION

.,.....ccccssssssssssesssesssssseseeesecensenees

7

VOLTAGE

AND

CYCLE

CONVERSION

........cssssssssccssrseceeseeeeeseces

8

1.

VOLTAGE

CONVERSION..........ceeceee

obgastadetpindeassvistszacisceaneesee’

8

2.

CYCLE

CONVERSION

..........:cccseescossssssescscerceenssesenseents

seesesesenegens

8

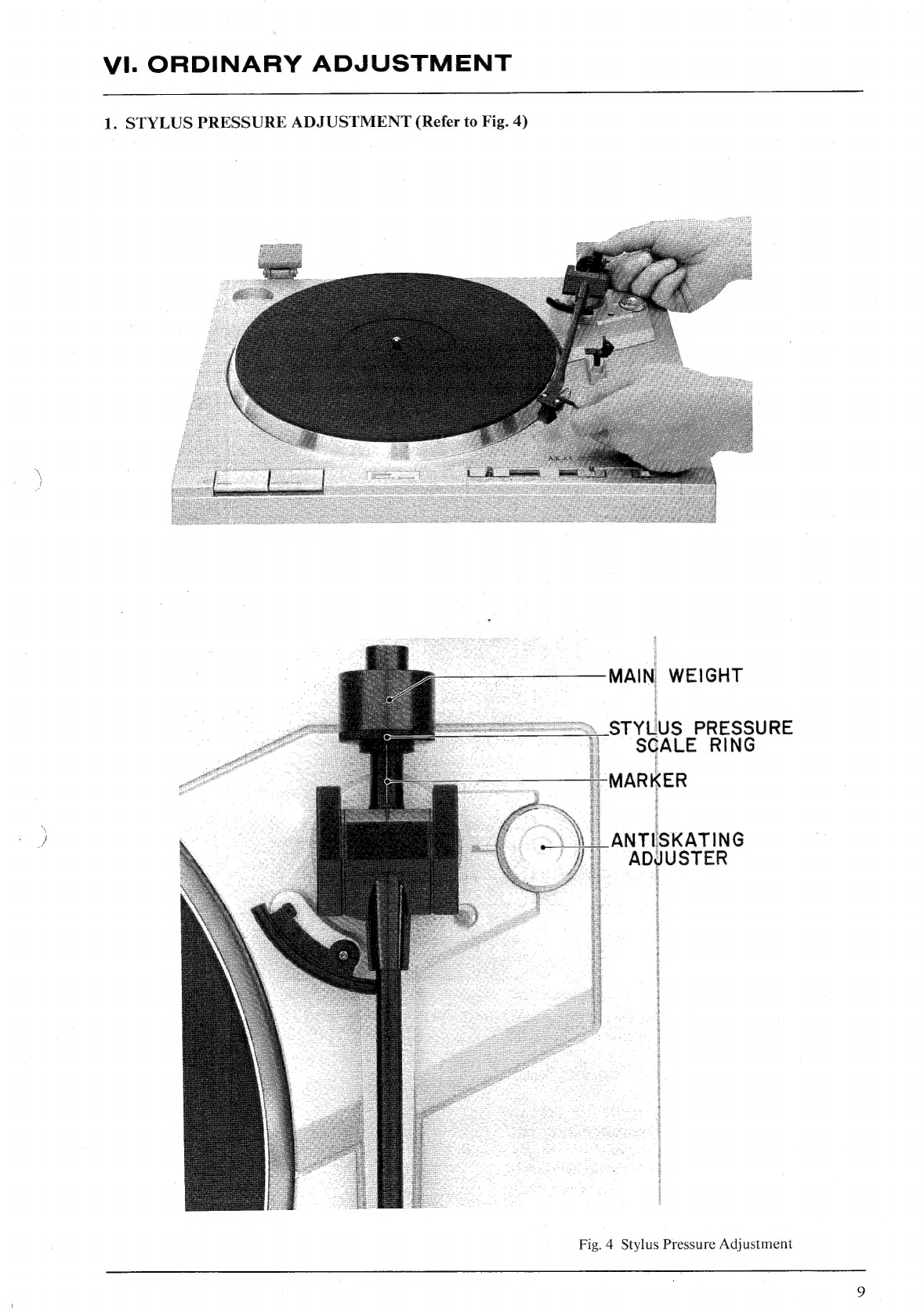

ORDINARY

ADJUSTRMENT

..........:ccsscccssssssreseccerssssreeeeessseneesens

9

1.

STYLUS

PRESSURE

ADJUSTMENT

....ccssesssessecsssesssietsesenees

rexede

9°

2.

OVERHANG

(Not

necessary

for

AP-Q310/€).....

ci

ceeiseesseniesceeeee

10°.

MECHANICAL

ADJUSTMENT.

........cssccsscccscssscesesescsereesessensesenees

11

1.

TONE

ARM

LIFTER

ADJUSTMENT

.....cccesssssessssstssssseesssssesssses

11

2.

TONE

ARM

BRAKE

ADJUSTMENT

.0.....eeeccceescceseteeeettseeeneeees

12

3.

-LEAD-IN/LEAD-OUT

ADJUSTMENT

0.0...

.cceeeeceeeesreeeeeeneeee

13

'

4,

RETURN

PLUNGER

POSITION

ADJUSTMENT...

13

ELECTRICAL

ADJUSTMENT

...........cssccsssssssccctecccsssserecseteeseeeeee

wee

14

1.

OFF-SET

VOLTAGE

ADJUSTMENT

(VR2,

3)

AND

TORQUE

DIFFERENCE

ADJUSTMENT

(VRI)......

eee

14

2.

WOW

AND

FLUTTER

CONFIRMATION

.........ceesseseesseeeeeeee

14

CLASSIFICATION

OF

VARIOUS

P.C

BOARDS

..........cessssccesseess

15

1.

P.C

BOARD

TITLES

AND

IDENTIFICATION

NUMBERS......

[Se

2.

COMPOSITION

OF

VARIOUS

P.C

BOARDS

oe

eeeeeceeeceeees

16

For

basic

adjustments,

measuring

methods,

and

operating

principles,

refer

to

GENERAL

TECHNICAL

MANUAL.