<2

RO

VII.

SECTION

1

SERVICE

MANUAL

TABLE

OF

CONTENTS

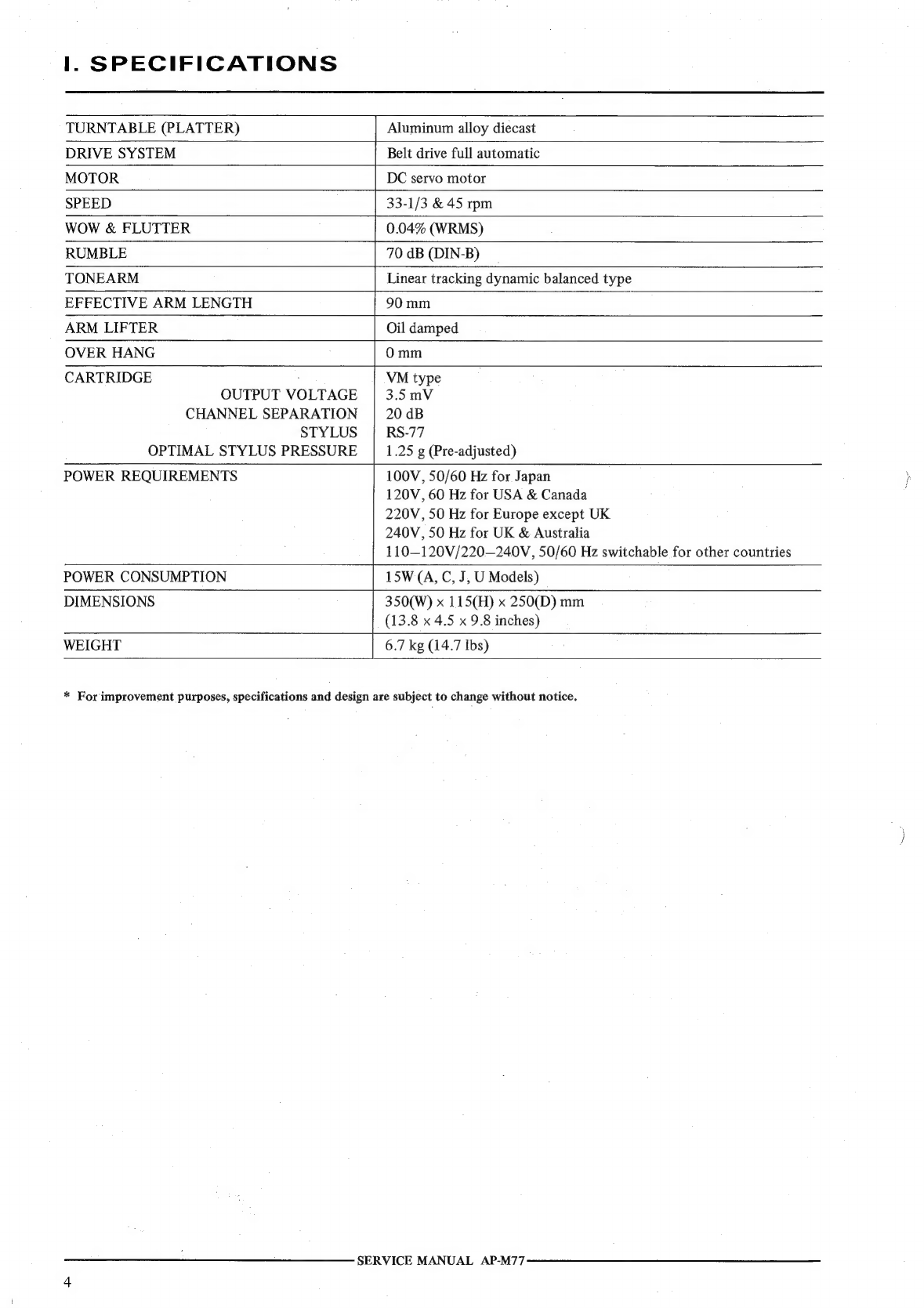

SPECIFICATIONS

.

0...

26

ice

ete

eet

e

nee

e

scene

4

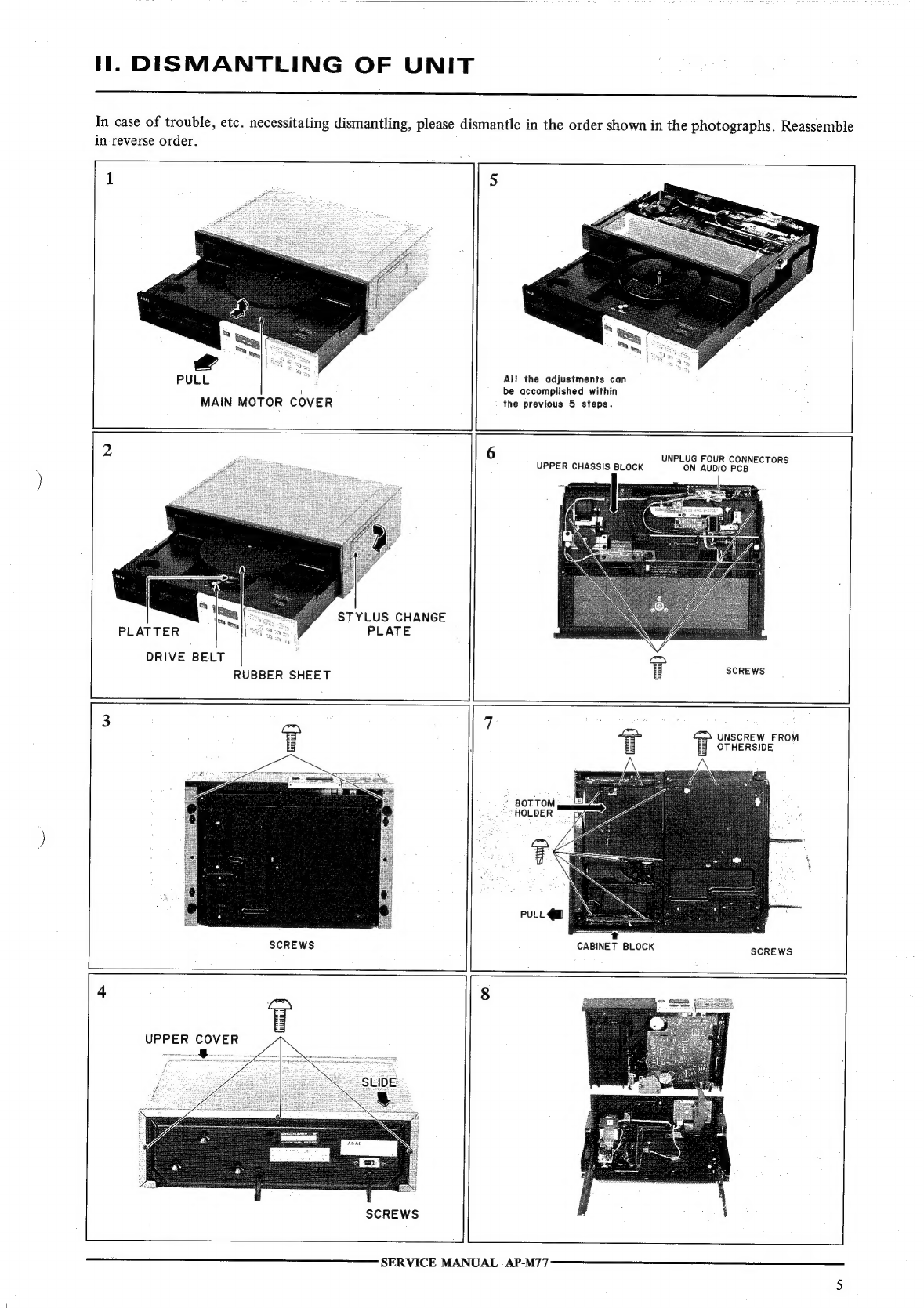

DISMANTLING

OF

UNIT

..

0.0.0...

0.

ccc

eee

eee

5

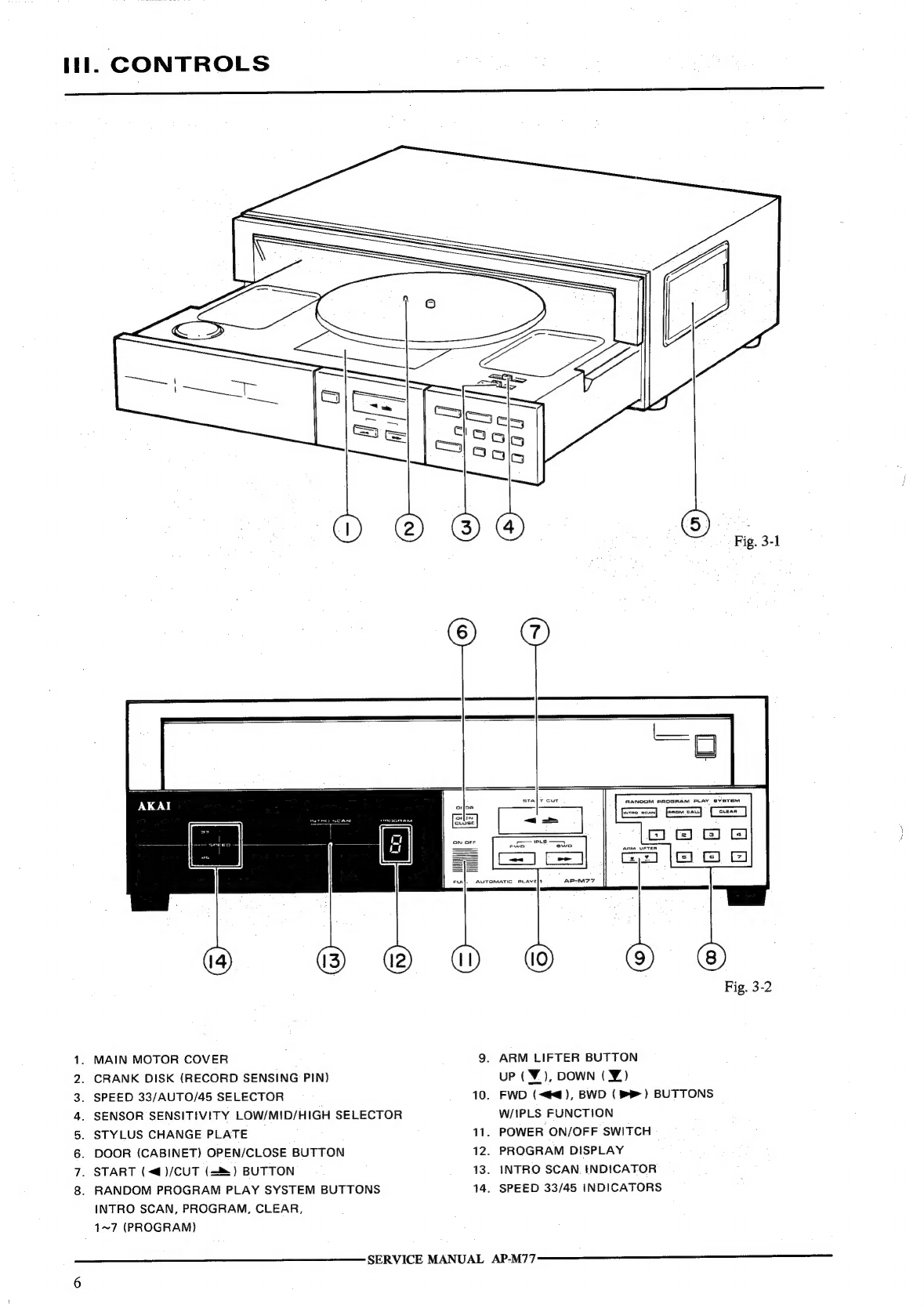

CONTROES

50555

esraiend

eh

ese

Sens

PS

aE

eh

ac

cca

nels

Geka

oR

Botan

6

PRINCIPAL

PARTS

LOCATION

..............

0.00000

cece

eens

7

DESCRIPTION

OF

MISCELLANEOUS

OPERATIONS

..............

9

5-1

OUTLINE

OF

AP-M77

FUNCTIONS................0000055

9

5-2

SPECIFICATION

OF

VARIOUS

KEY

OPERATIONS

...........

9

5-3.

SPECIFICATION

OF

VARIOUS

LEDS

...............0.....

12

54

SPECIFICATION

OF

COMMON

BUS

...................05.

12

5-5

TIMING

OF

VARIOUS

OPERATIONS

..............0..0005

13

ADJUSTMENTS:

20

oo

oii

G20

6001

wane

Pare

ge

Sid

lee

aed

inl

Clee

ae

pce

ie

19

6-1

ORDINARY

MECHANICAL

ADJUSTMENTS

.................

19

6-2

ELEVATION

ARM

POSITION

ADJUSTMENT.................

19

6-3

POSITION

SENSOR

SENSITIVITY

ADJUSTMENT

............

20

6-4

OFF-SET

VOLTAGE

ADJUSTMENT...................0005

20

6-5

TRACKING

SENSOR

SENSITIVITY

ADJUSTMENT

...........

21

6-6

MUSIC

INTERVAL

SENSOR

SENSITIVITY

ADJUSTMENT

......

21

6-7

SPEED

ADJUSTMENT..................

“dh

gdh

Mifesiungs

Mace

is

once

21

6-8

LEAD-IN

POSITION

ADJUSTMENT

..........0.........000.

21

6-9

PLAY

SW

(SW902)

POSITION

ADJUSTMENT

...............

22

6-10

CLOSE

CHASSIS

(FOR

CLOSE

SW:

SW2

on

LIMIT

PCB)

POSITION

ADJUSTMENT.......

22

P.C

BOARD

TITLES

AND

IDENTIFICATION

NUMBERS

...........

22

For

basic

adjustments,

measuring

methods,

and

operating

principles,

refer

to

GENERAL

TECHNICAL

MANUAL.

SERVICE

MANUAL

AP-M77