Amana ERCF18-UO1B User manual

Other Amana Air Conditioner manuals

Amana

Amana AAC081SRB Service User manual

Amana

Amana APG16 M Series User manual

Amana

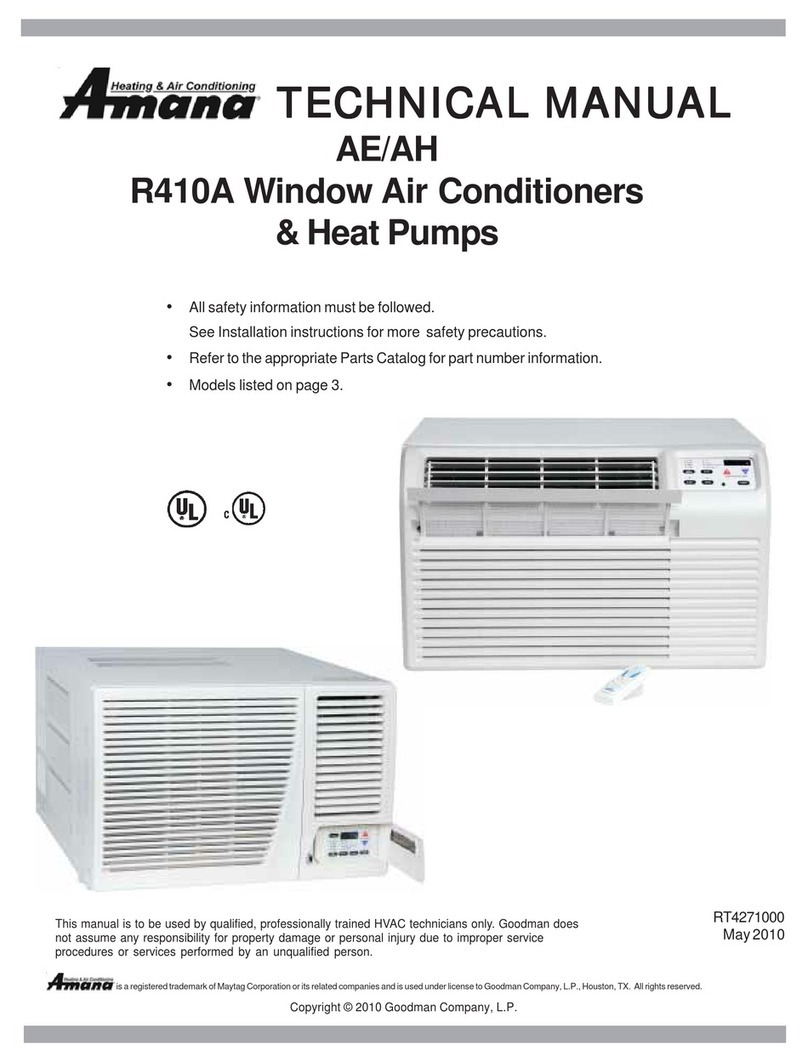

Amana R-410A Service manual

Amana

Amana PTC073E00AXXXAB Owner's manual

Amana

Amana R-410A User manual

Amana

Amana PBC123B00MB Quick start guide

Amana

Amana AP095R User manual

Amana

Amana ASX 14 SEER User manual

Amana

Amana SC-415 Service manual

Amana

Amana ACD105E User manual

Amana

Amana Room Air Conditioner & Heat Pump User manual

Amana

Amana 10M52TA-P1214708R User manual

Amana

Amana PTAC 24" User manual

Amana

Amana AP095R User manual

Amana

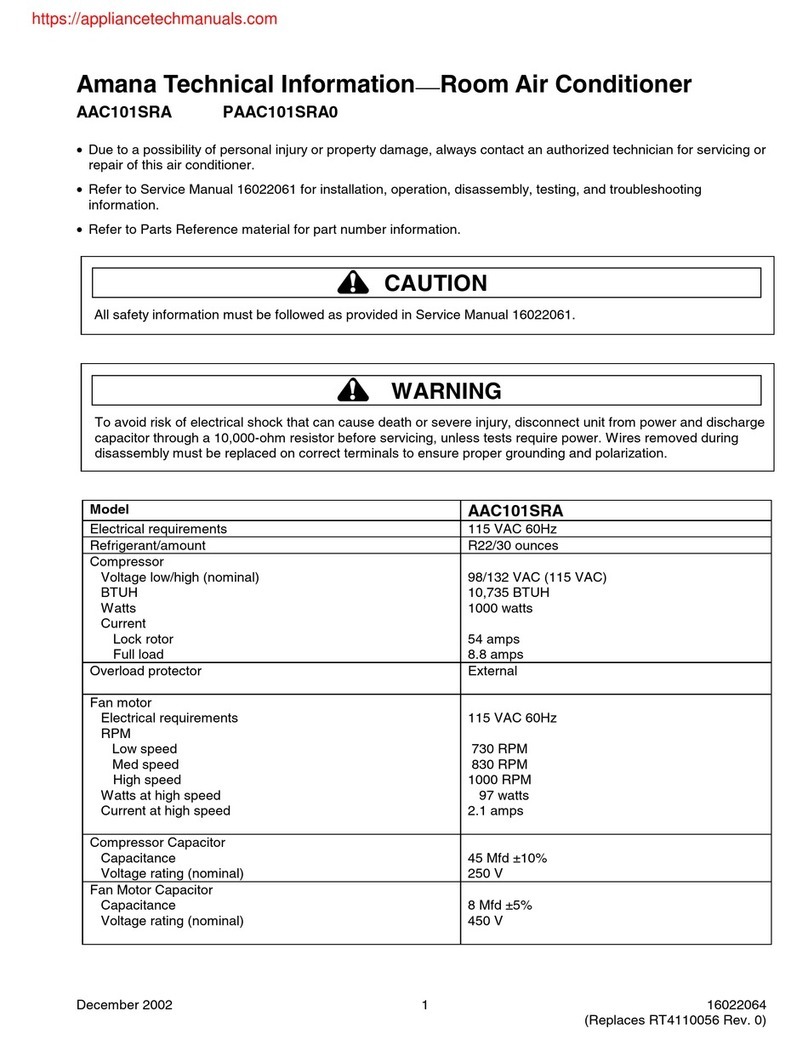

Amana AAC101SRA Service Manual

Amana

Amana PBC092E00AX User manual

Amana

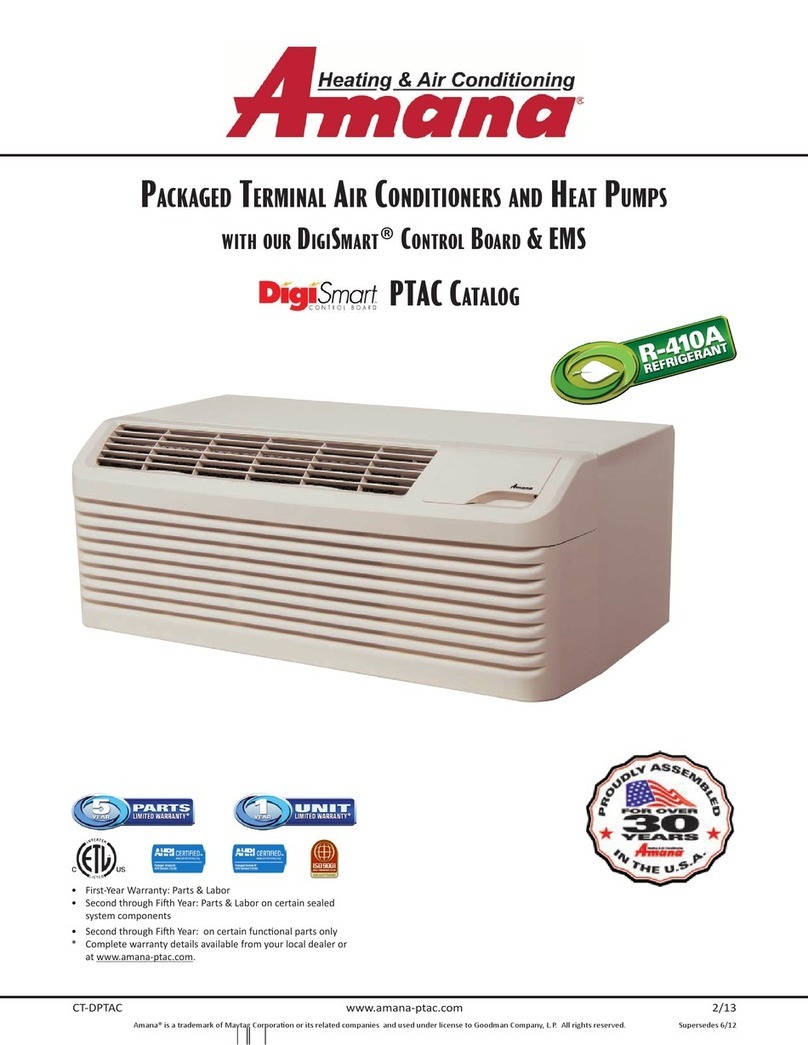

Amana CT-DPTAC Manual

Amana

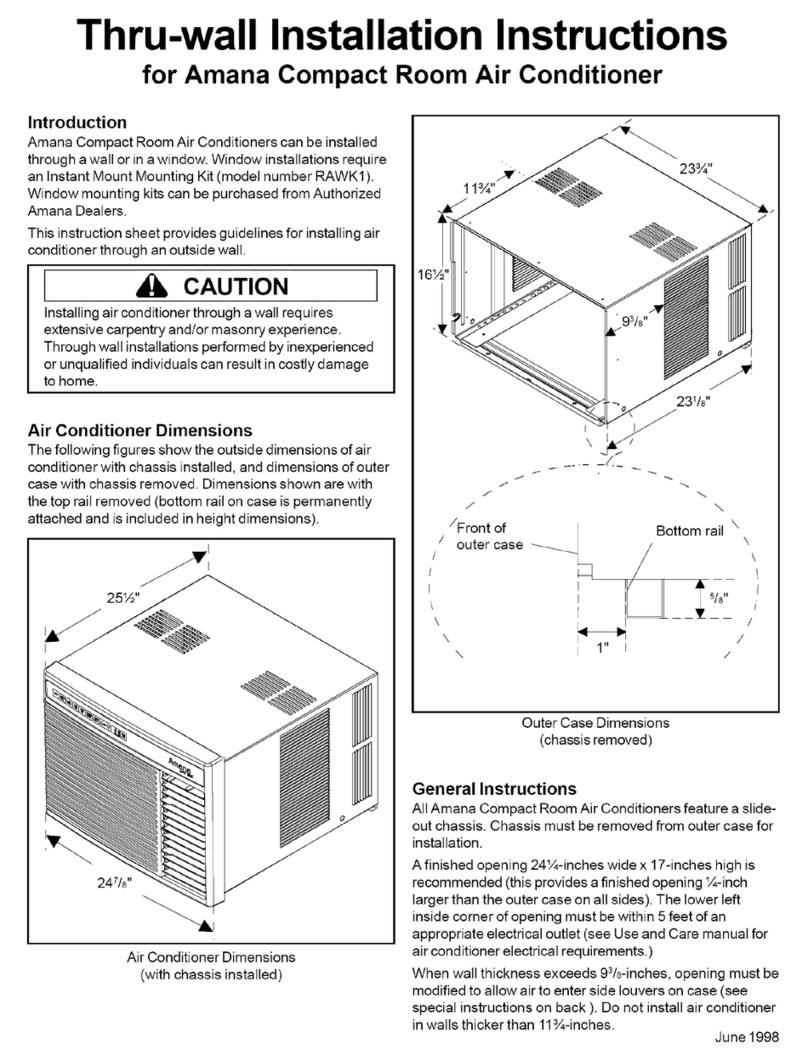

Amana C-Model Assembly instructions

Amana

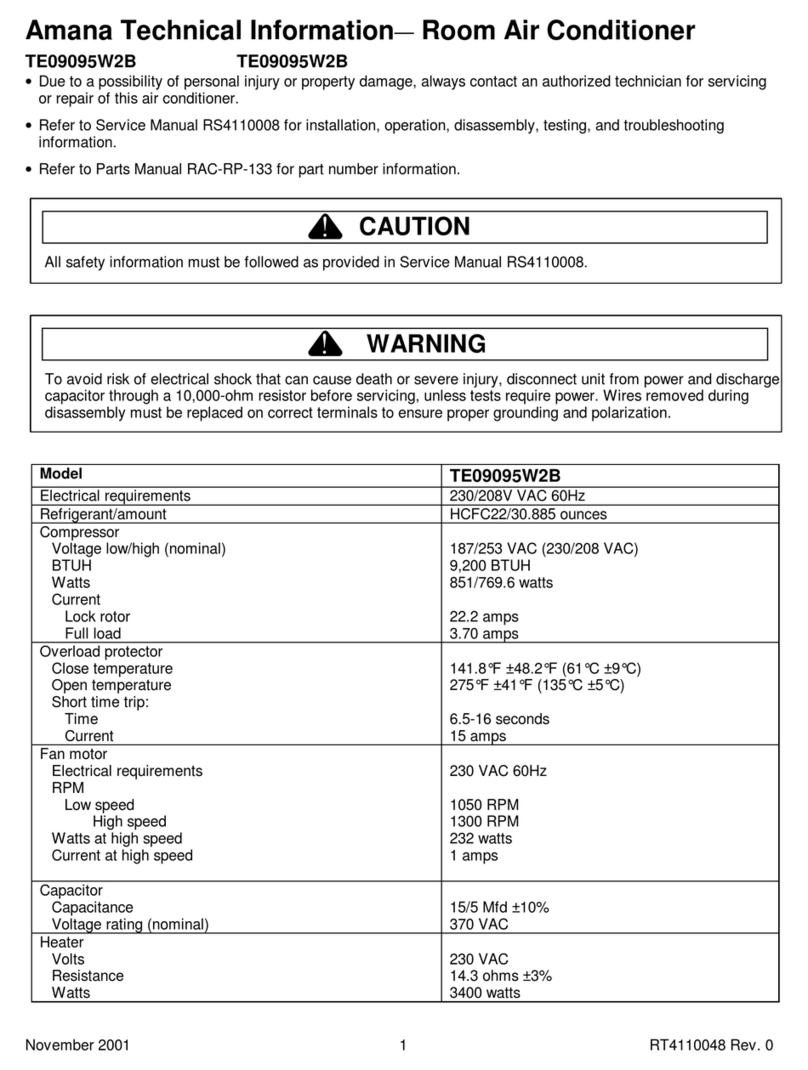

Amana TE09095W2B Manual

Amana

Amana EBCC2400MBM User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions