3

CONTENTS

1 Manual use modes ...................................................................................................................................................................4

2 Limitations ................................................................................................................................................................................4

3 Responsibility ...........................................................................................................................................................................4

4 Risks and protections before assembly.................................................................................................................................4

5 Intended use .............................................................................................................................................................................4

6 Precautions ...............................................................................................................................................................................4

7 Package content .......................................................................................................................................................................4

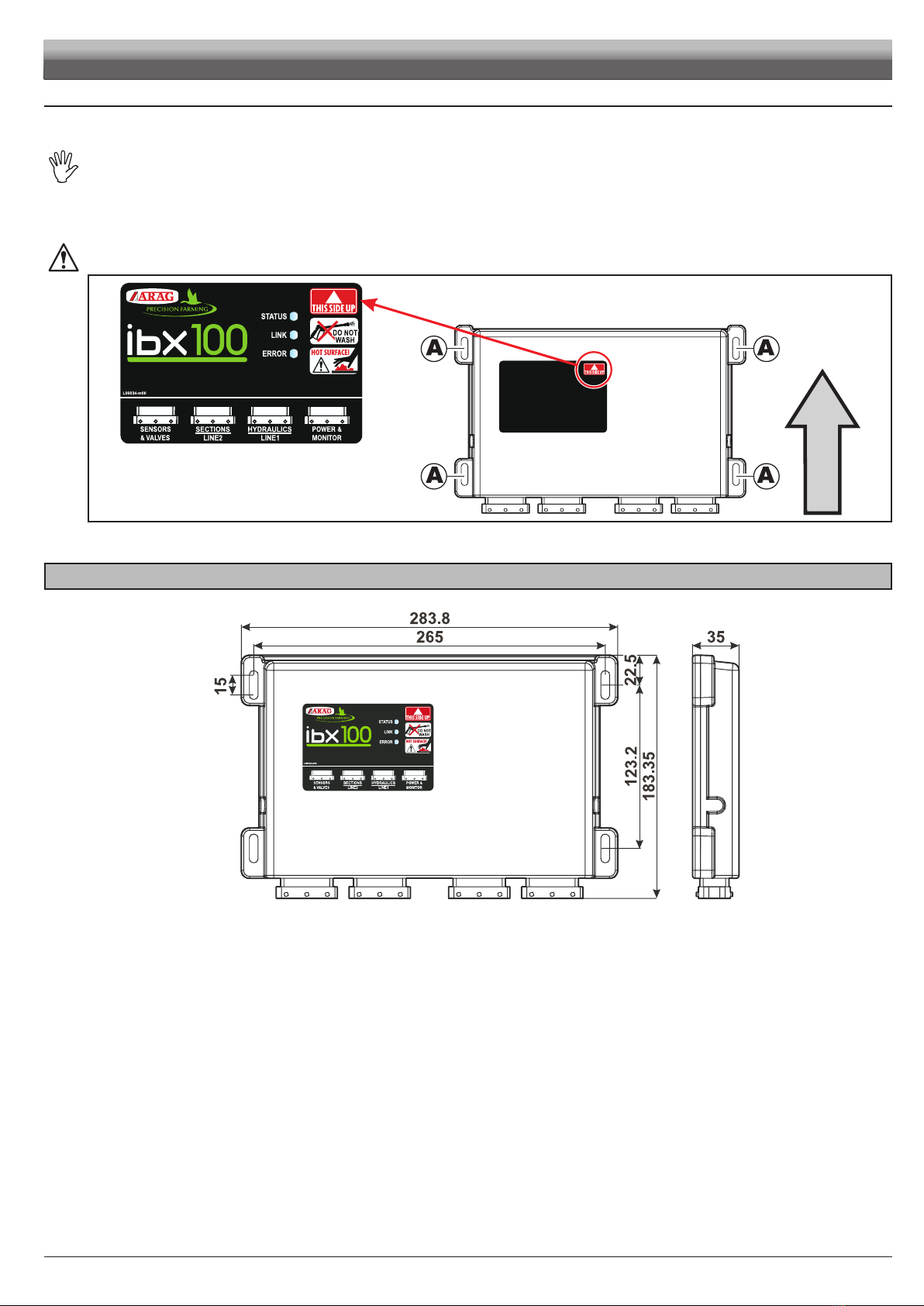

8 Position of farming machine ...................................................................................................................................................5

8.1 System typical composition..............................................................................................................................................5

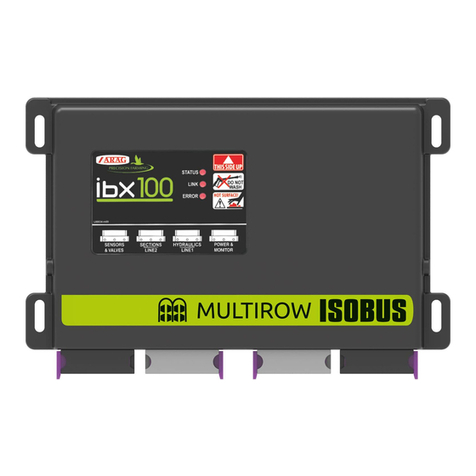

8.2 IBX 100 control unit fixing ................................................................................................................................................7

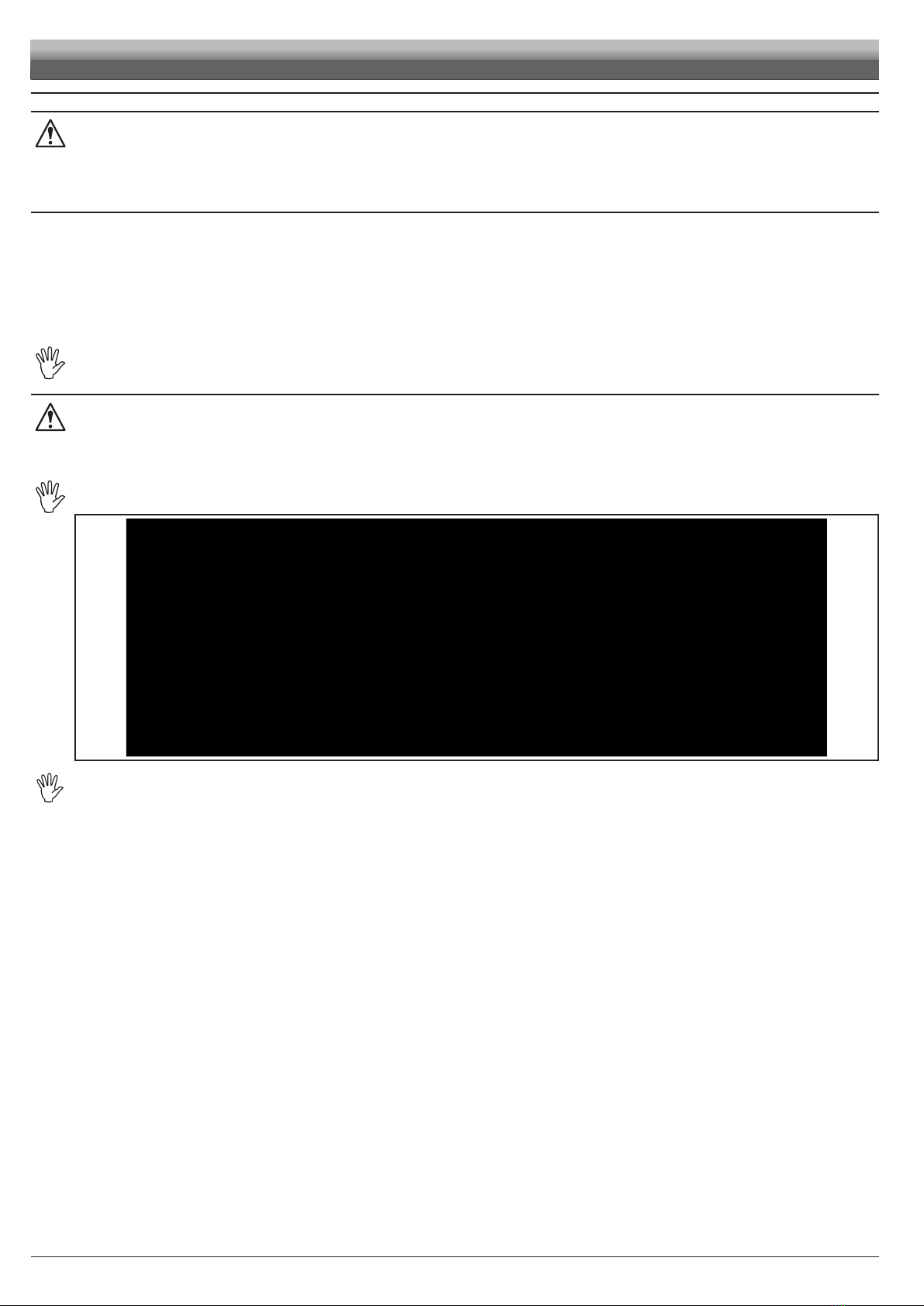

9 Wiring connections ..................................................................................................................................................................8

9.1 General precautions for a correct harness position .........................................................................................................8

9.2 Control unit (ECU) connection .........................................................................................................................................8

9.3 Wiring harness connection ..............................................................................................................................................9

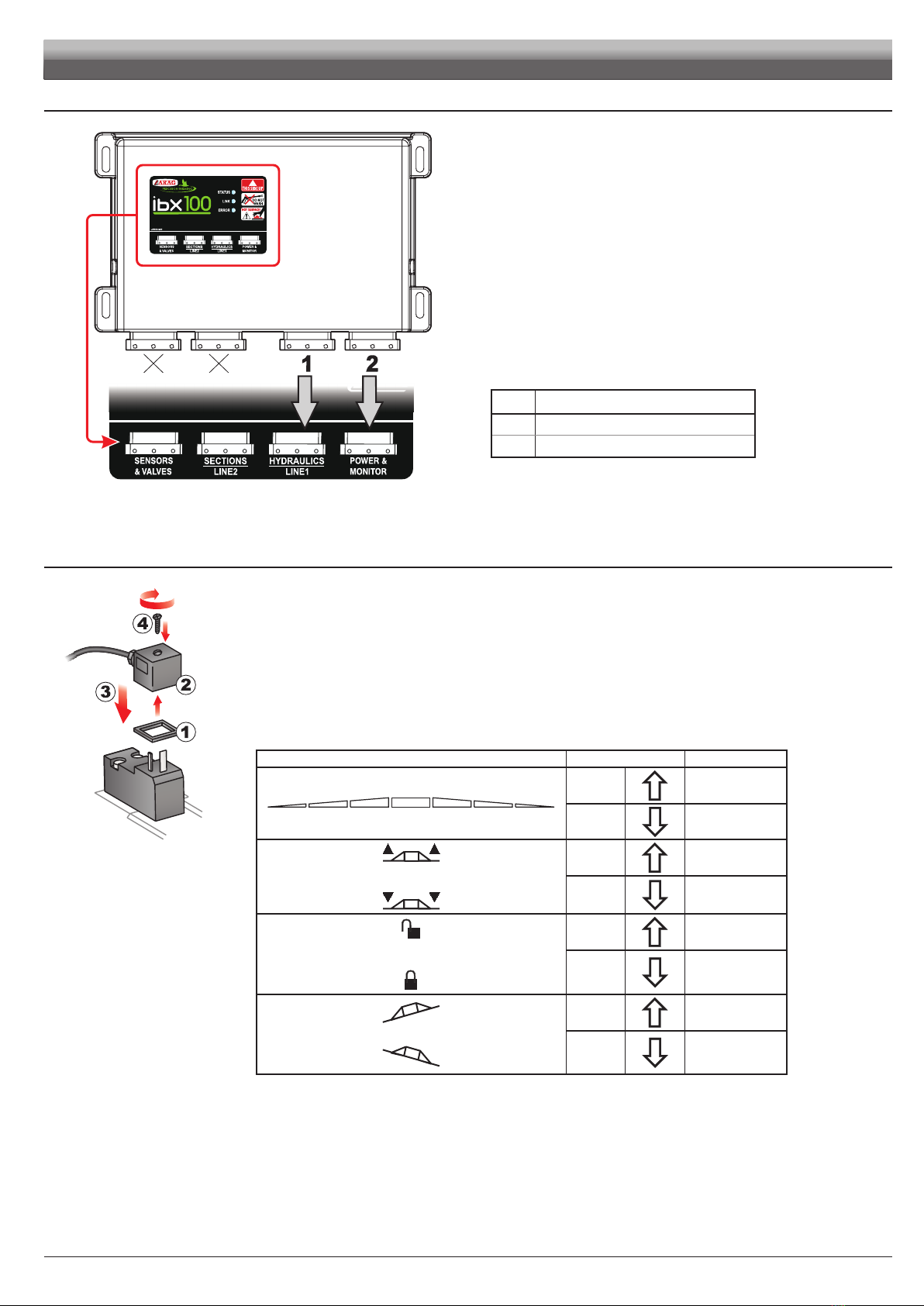

9.4 Hydraulic valve connection ..............................................................................................................................................9

10 ISOBUS system cable connection ........................................................................................................................................10

10.1 Connection of in-cab cable ............................................................................................................................................10

10.2 Connection of ISOBUS cable.........................................................................................................................................10

11 “OBJECT POOL” loading .......................................................................................................................................................11

12 Hydraulic controls ..................................................................................................................................................................11

13 Control layout .........................................................................................................................................................................12

14 MENU ....................................................................................................................................................................................13

14.1 Settings..........................................................................................................................................................................14

14.1.1 AUX configuration: SWITCH BOX............................................................................................................................................. 14

14.1.2 AUX configuration: Joystick ...................................................................................................................................................... 15

14.1.3 Hydraulic functions................................................................................................................................................................... 15

14.2 User level.......................................................................................................................................................................16

14.2.1 Entering the PIN number.......................................................................................................................................................... 16

14.2.2 Removing the PIN number ....................................................................................................................................................... 17

14.3 System status ................................................................................................................................................................18

14.3.1 License Registration................................................................................................................................................................. 18

14.3.2 Restart ECU.............................................................................................................................................................................. 19

14.3.3 Delete OP ................................................................................................................................................................................. 19

14.4 Backup management.....................................................................................................................................................20

14.4.1 Create backup.......................................................................................................................................................................... 20

14.4.2 Restore backup ........................................................................................................................................................................ 20

14.4.3 Reset to Arag factory defaults .................................................................................................................................................. 21

15 JOYSTICK: Arag DEFAULT functions ....................................................................................................................................22

15.1 Joystick Explorer ............................................................................................................................................................22

15.2 Joystick Explorer 2 .........................................................................................................................................................23

16 Maintenance / diagnostics / repairs ......................................................................................................................................24

16.1 Cleaning rules................................................................................................................................................................24

16.2 LED status key...............................................................................................................................................................24

16.3 Troubleshooting..............................................................................................................................................................24

17 Technical data.........................................................................................................................................................................25

18 End-of-life disposal ................................................................................................................................................................25

19 Guarantee terms .....................................................................................................................................................................25

20 EU declaration of conformity.................................................................................................................................................25