ARTHUR HOLM Dynamic DB2 Installation instructions manual

Other ARTHUR HOLM Monitor manuals

ARTHUR HOLM

ARTHUR HOLM AH17D X2HDGA User manual

ARTHUR HOLM

ARTHUR HOLM AH2 User manual

ARTHUR HOLM

ARTHUR HOLM AH12D 216A User manual

ARTHUR HOLM

ARTHUR HOLM AH 18D3 RHDGA RV User manual

ARTHUR HOLM

ARTHUR HOLM AH15D3 HDGA User manual

ARTHUR HOLM

ARTHUR HOLM AH15D X2HDGA User manual

ARTHUR HOLM

ARTHUR HOLM AH10 DA User manual

ARTHUR HOLM

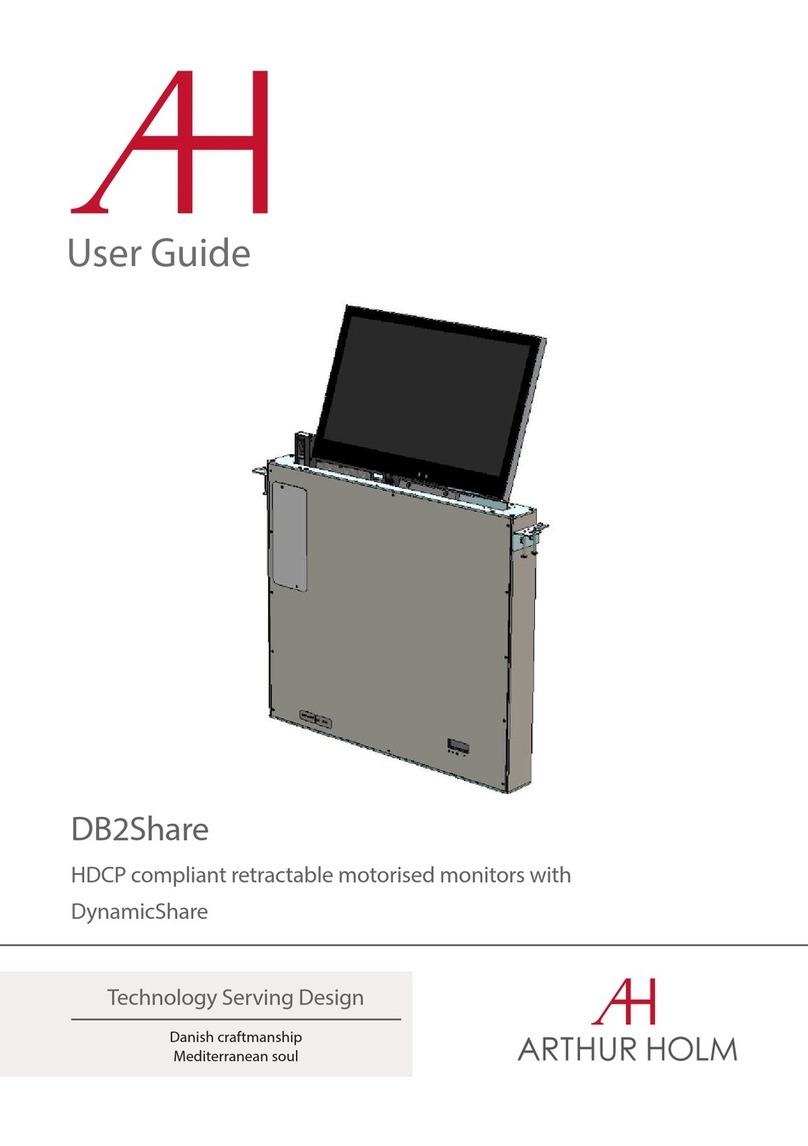

ARTHUR HOLM DB2Share User manual

ARTHUR HOLM

ARTHUR HOLM AH12D 2A User manual

ARTHUR HOLM

ARTHUR HOLM Dynamic3Reverse User manual

ARTHUR HOLM

ARTHUR HOLM DynamicX2Talk User manual

ARTHUR HOLM

ARTHUR HOLM AH15D X2HDGA User manual

ARTHUR HOLM

ARTHUR HOLM AH15DCDHD User manual

ARTHUR HOLM

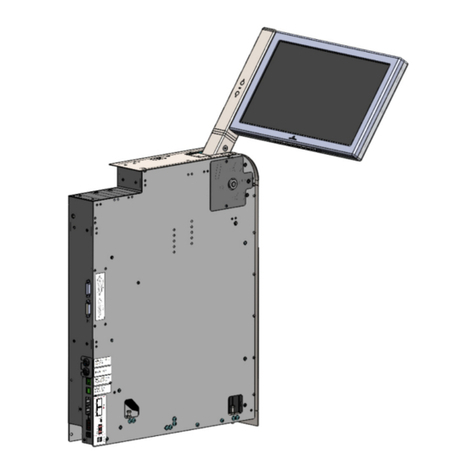

ARTHUR HOLM DynamicX2 AH22DX216DGA User manual

ARTHUR HOLM

ARTHUR HOLM AH24D User manual

ARTHUR HOLM

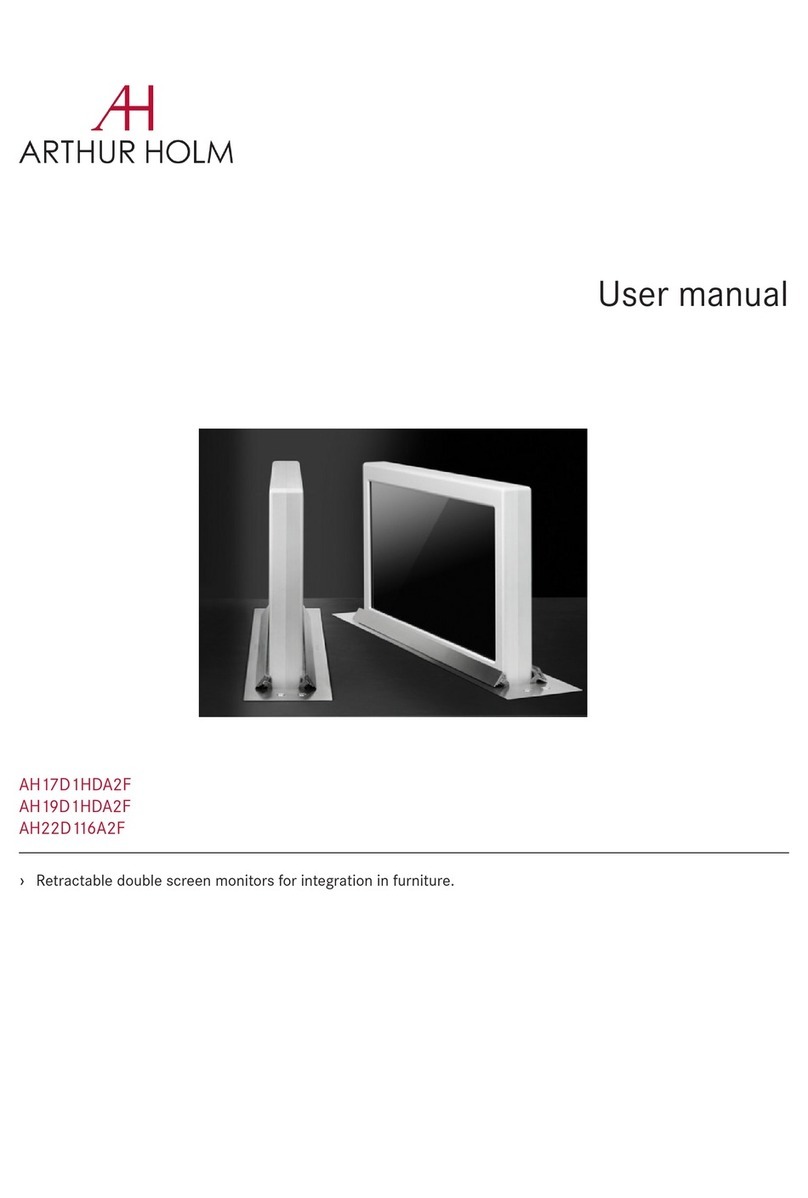

ARTHUR HOLM AH17D1HDA2F User manual

ARTHUR HOLM

ARTHUR HOLM AH24DB2 User manual

ARTHUR HOLM

ARTHUR HOLM AH24DB2 User manual

ARTHUR HOLM

ARTHUR HOLM DB2Share User manual

ARTHUR HOLM

ARTHUR HOLM D1Twin User manual