Assa Abloy Sargent 9700 Instruction Manual

Other Assa Abloy Lock manuals

Assa Abloy

Assa Abloy Abloy EL590 User manual

Assa Abloy

Assa Abloy Sargent IN100 User manual

Assa Abloy

Assa Abloy 1048.10 Guide

Assa Abloy

Assa Abloy OneSystem 519N User manual

Assa Abloy

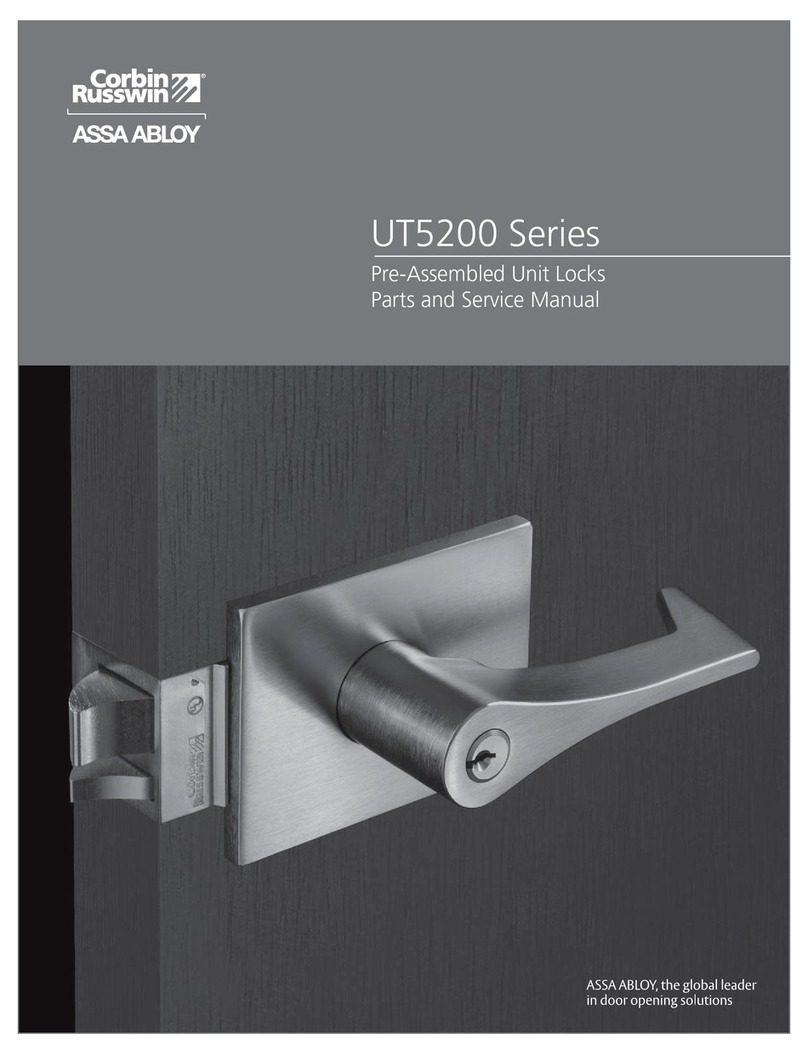

Assa Abloy Corbin Russwin UT5200 Series Quick start guide

Assa Abloy

Assa Abloy Yale Smart Latch User manual

Assa Abloy

Assa Abloy Corbin Russwin BLSS ML2000 Series User manual

Assa Abloy

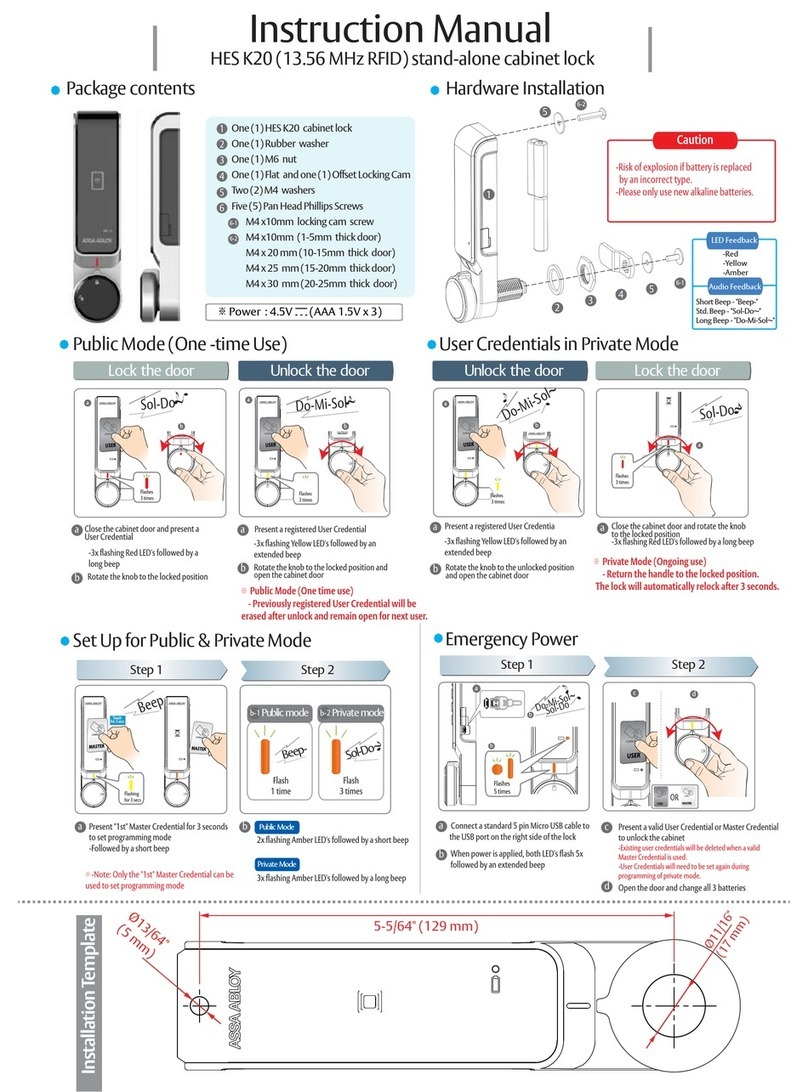

Assa Abloy HES K20 User manual

Assa Abloy

Assa Abloy OneSystem 509N Installation guide

Assa Abloy

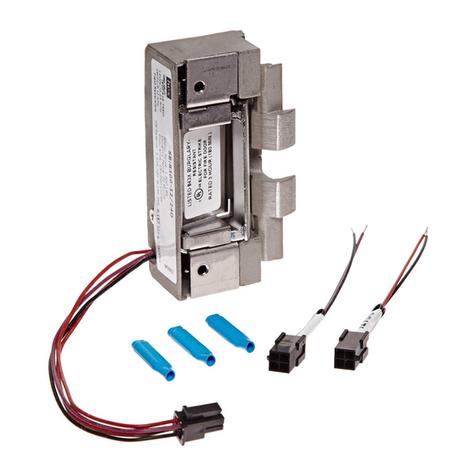

Assa Abloy hes 8000 Series User manual

Assa Abloy

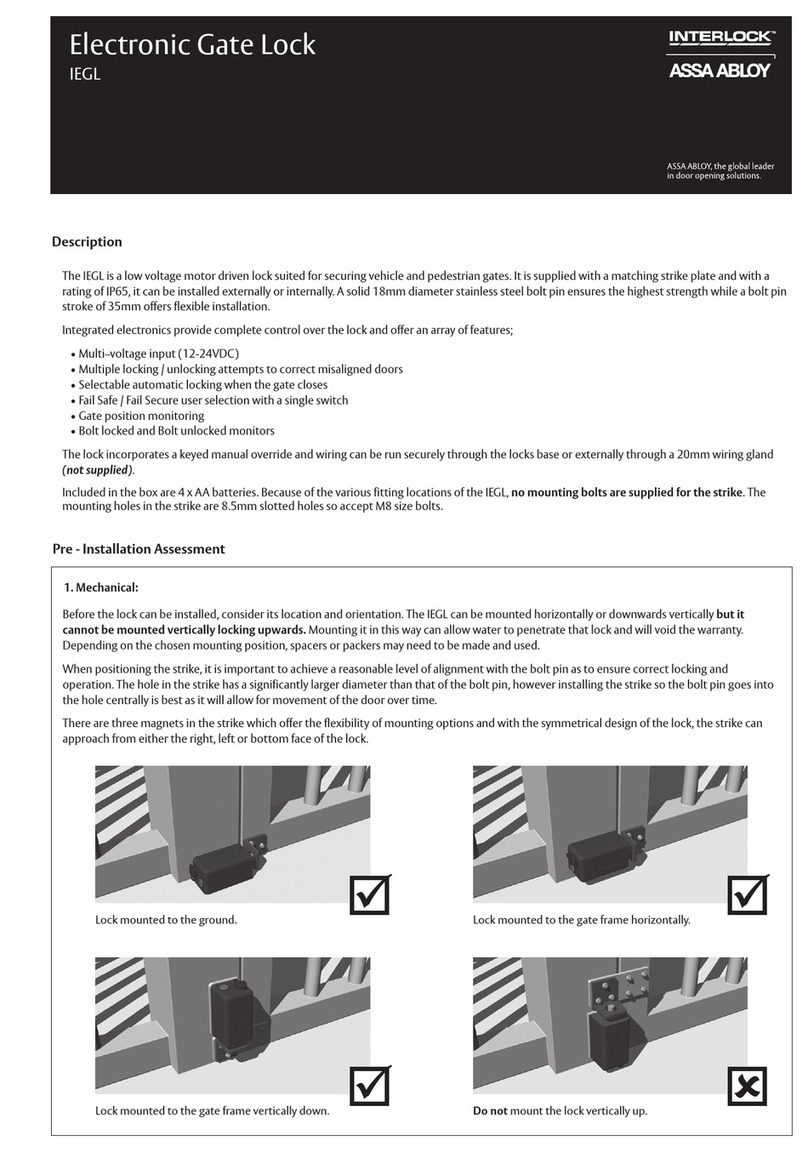

Assa Abloy Interlock IEGL User manual

Assa Abloy

Assa Abloy Securitron SAM User manual

Assa Abloy

Assa Abloy Sargent Passport 1000 Series User manual

Assa Abloy

Assa Abloy Effeff 809M User manual

Assa Abloy

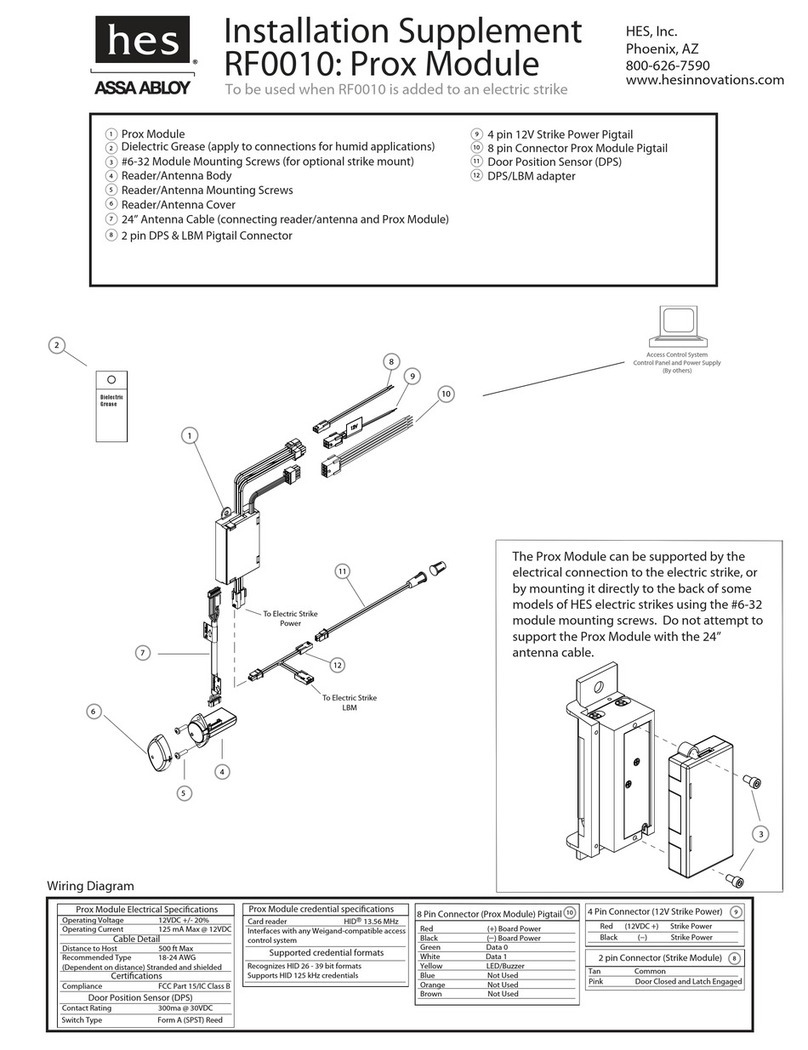

Assa Abloy hes RF0010 Owner's manual

Assa Abloy

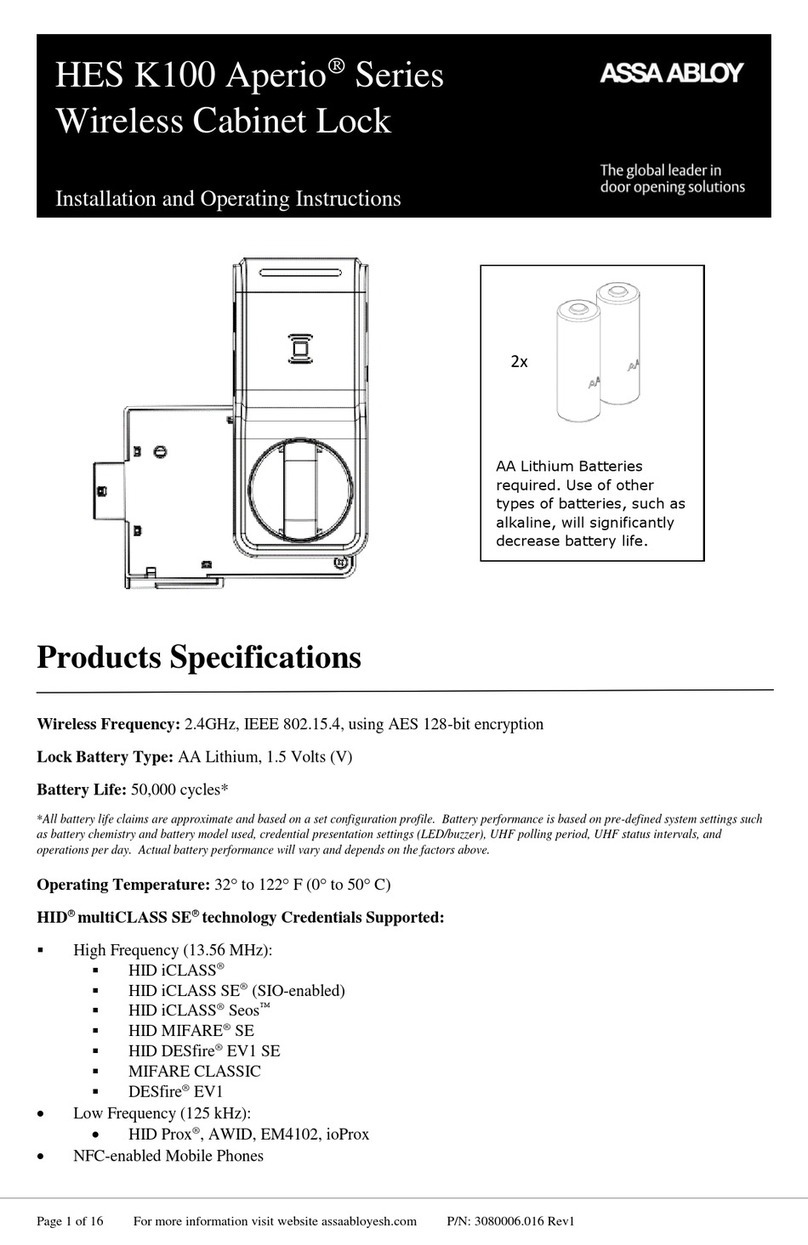

Assa Abloy Aperio Series User manual

Assa Abloy

Assa Abloy SARGENT Profile LK Series Installation manual

Assa Abloy

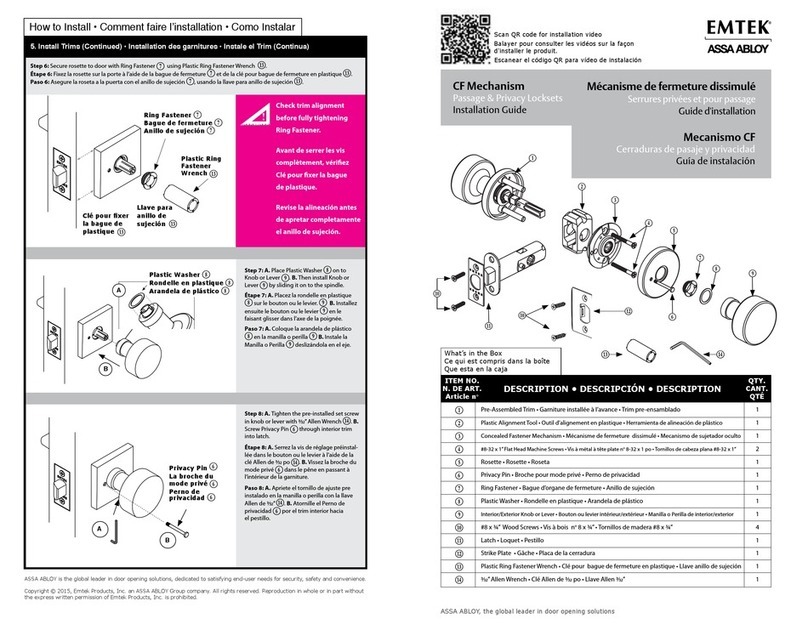

Assa Abloy EMTEK CF Mechanism User manual

Assa Abloy

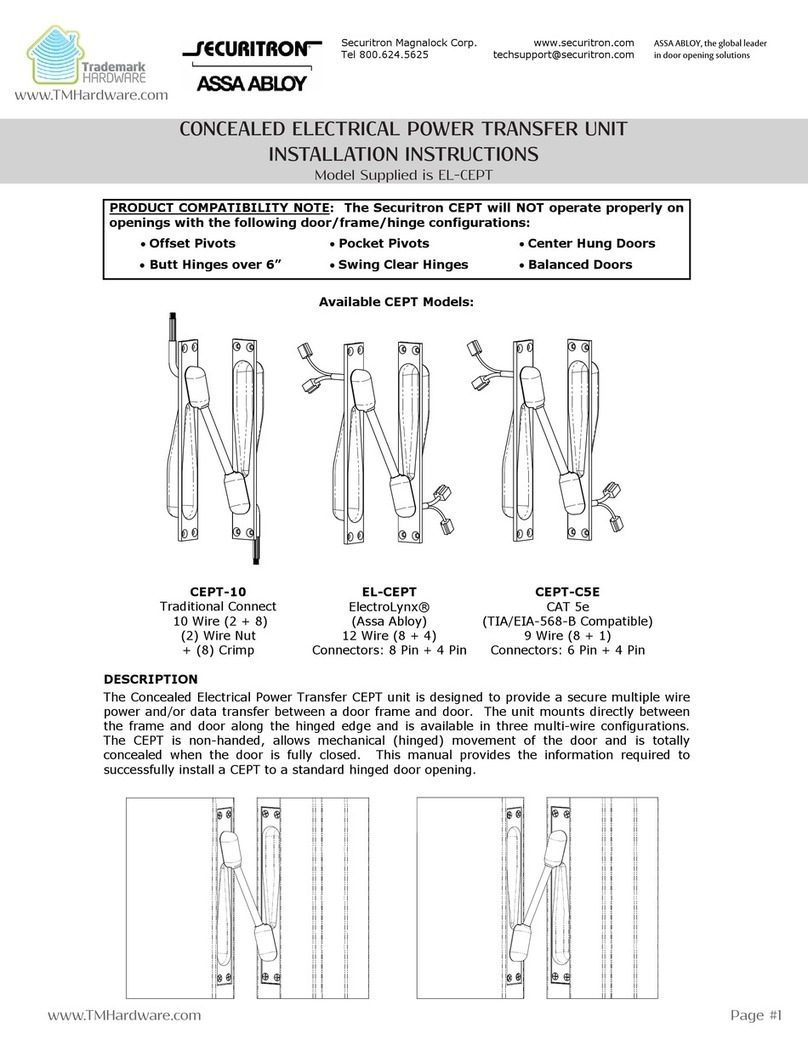

Assa Abloy SECURITRON CEPT-10 User manual

Assa Abloy

Assa Abloy 3090 Guide