RF0010: Prox Module

Installation Directions

3. Drill a 3/8” hole for the door position switch (DPS) as required.

Note that the DPS may be positioned as desired, within the

limits of its 12” cable. If necessary (e.g. wood frames), drill a

channel from the DPS to the electric strike to accommodate

the 12” cable. Next drill a matching 3/8” hole in the door and

install the press-fit magnet so it will make contact with the DPS.

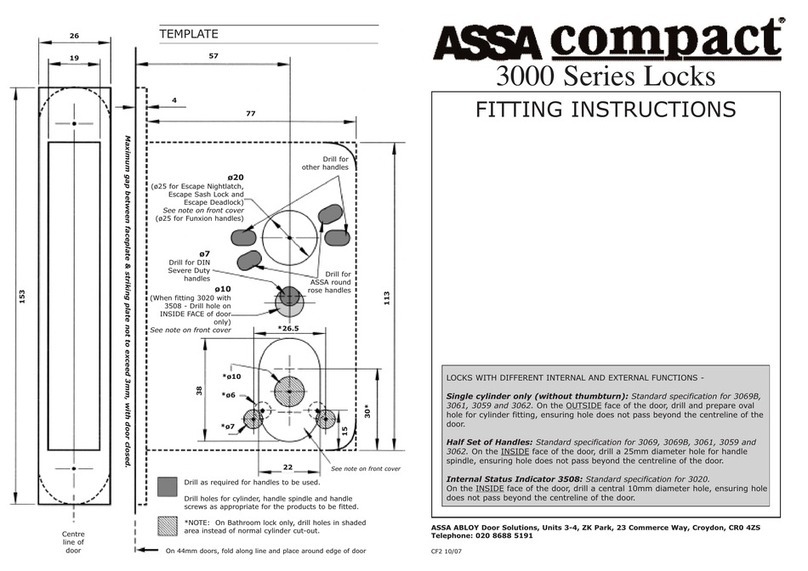

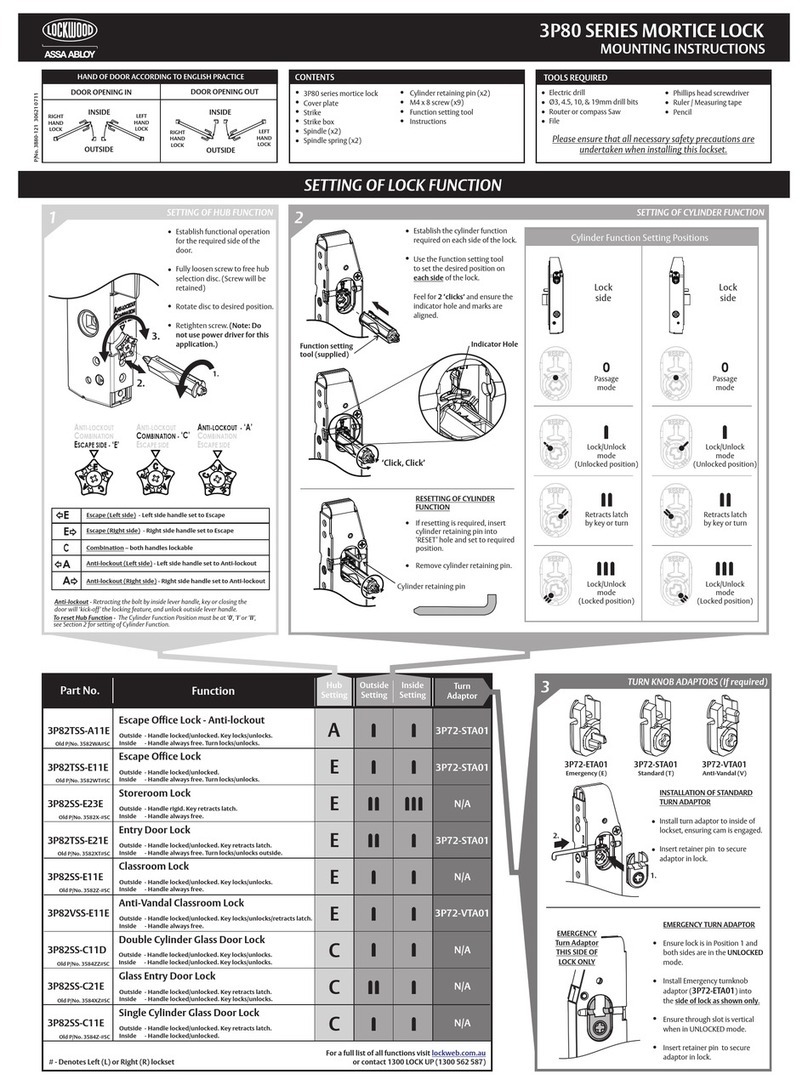

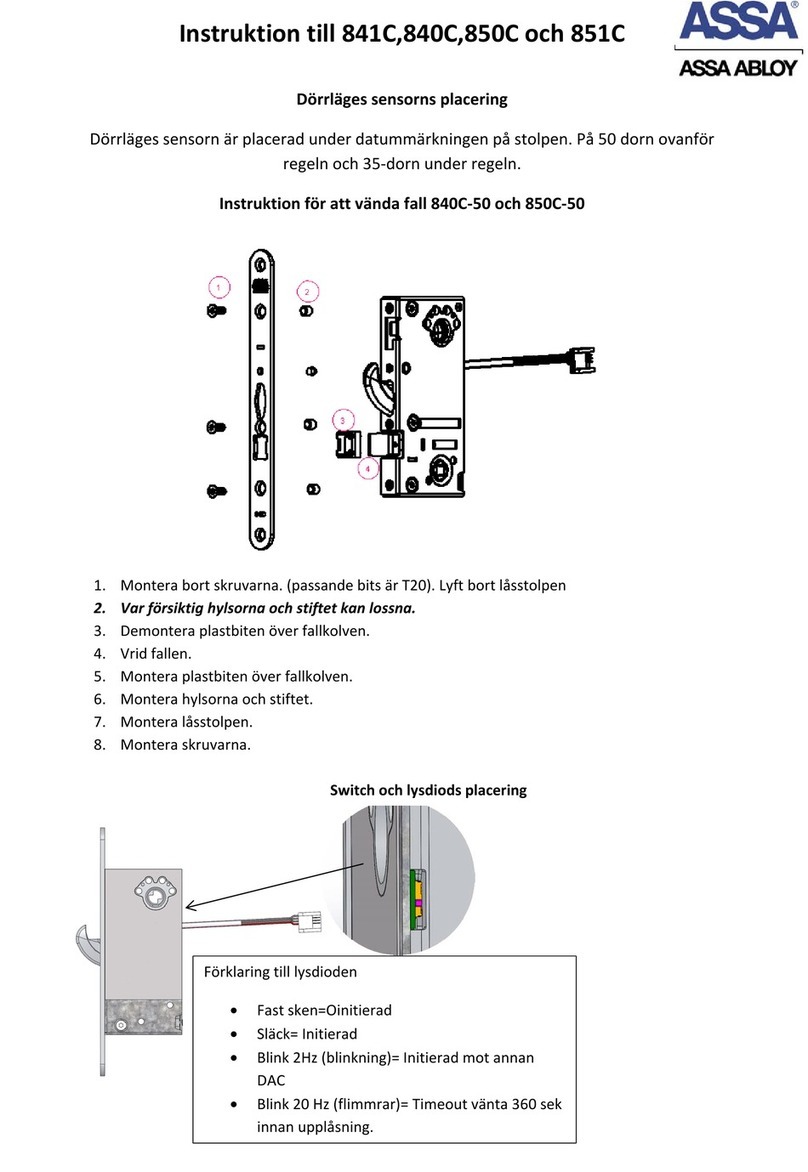

Wire Gauge Diagram

12VDC

100’ or less 24 Gauge

2

Distance In ft, Round Trip

100’ to 200’

200’ to 300’

300’ to 400’

400’ to 500’

22 Gauge

22 Gauge

22 Gauge

20 Gauge

24VDC

24 Gauge

24 Gauge

24 Gauge

22 Gauge

22 Gauge

©2011 HES, Inc.

3078006.004 rev A

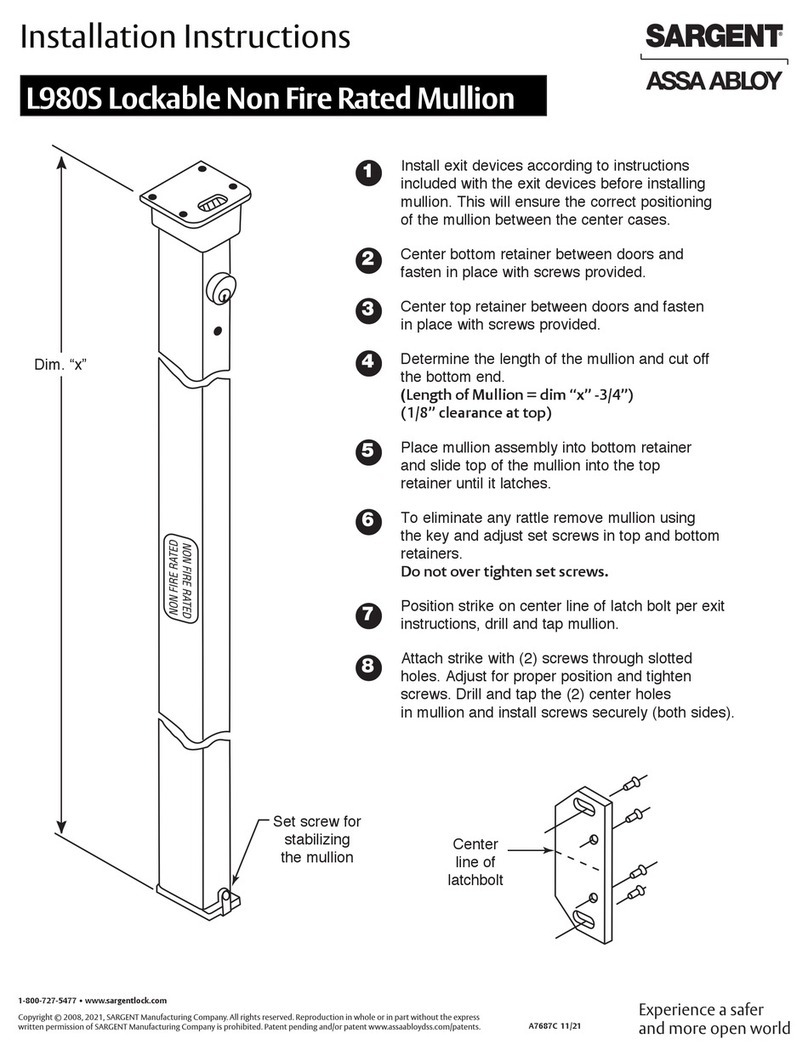

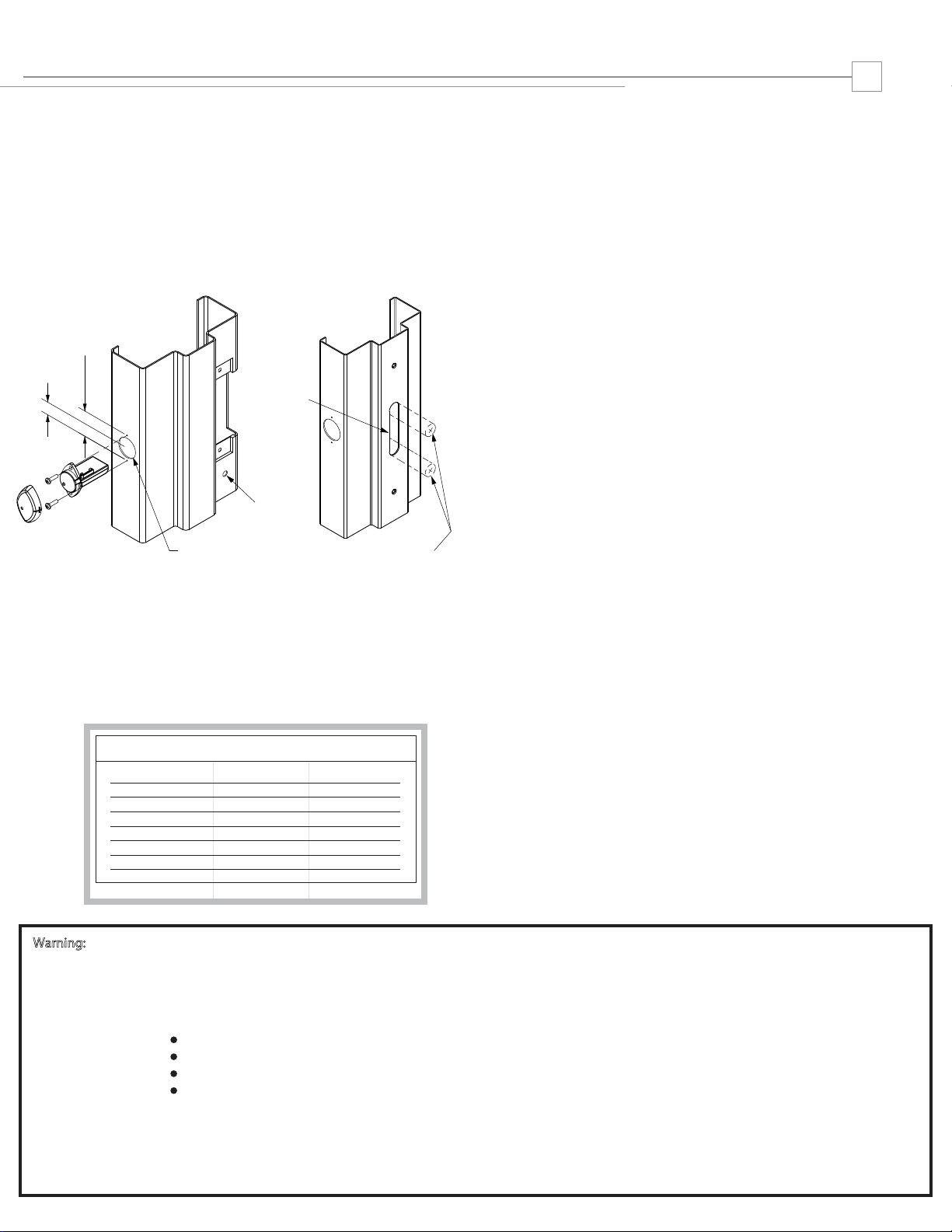

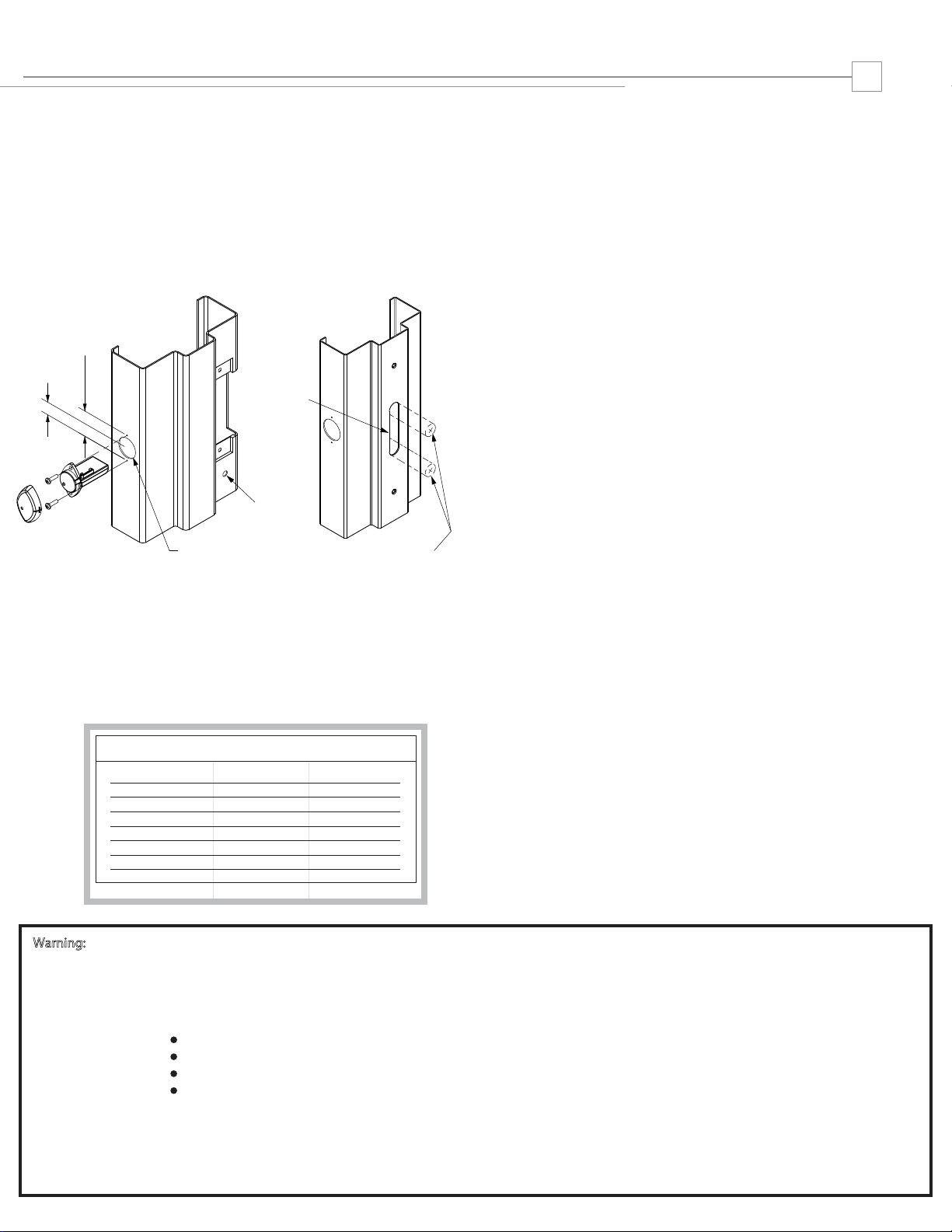

Non-surface mount for

electric strike installation

Surface mount

electric strike installation

Connect Components and Wiring

5. Select the 12V AC/DC pigtail.

6. Verify that the wires running from the control panel are of

adequate wire gauge (see Wire Gauge Diagram below). Connect

the wire leads of the three pigtails provided (items 8, 9, & 10) to

the control panel wiring based on the wiring diagram on page 1

and the appropriate termination at the control panel.

7. Mount the door position switch (DPS) into the frame. Route the

cable back to the electric strike and connect it to the 2 pin connector

of item 12, adapter cable. Connect the 3 pin connector from the

strike to the 3 pin connector of item 12. Connect the remaining 2 pin

connector of item 12 to the 2 pin connector of the RF Prox. The LBM

& DPS are wired in series--a ‘closed’ electrical circuit depicts a closed

door and extended latchbolt into the integrated electric strike.

8. Secure the reader/antenna mounting plate to the frame using

the #6 sheet metal screws provided. Connect the 24” cable to the

reader/antenna, snap the reader/antenna to the reader/antenna

mounting plate and pull the 24” cable through to the Prox Module.

9. Attach all the 8, 4 and 2 pin connectors to the equivalent

pigtail connectors routed from the control panel. Dielectric

grease can be applied to the pigtail electrical terminals if

used in a humid environment.

10. Slide the Prox module through either the access slot or the

electric strike cutout depicted in the illustrations to the left.

11. Install the electric strike unit in the frame as specified in the

specific strike installation instructions.

Testing and Operation

12. When power is supplied, the LED will turn red, while the beeper

beeps 3 times. This sequence indicates the micro-controller is

operating properly.

13. Present a Prox ID card to the reader/antenna. The LED will

turn green, while the beeper beeps once. This indicates that the

card was read successfully. Simultaneously, the keeper will click

open. This indicates that communication between the control

panel and the electric strike is operational.

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help

Warning: Changes or modification to this device not expressly approved by HES, Inc., could void the user’s authority to operate the equipment.

NOTE: This equipment has been tested and found to comply within the limits for a class [B] digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on. The user is encouraged to try to correct the interference by one or more of the

following measures:

This class [B] digital apparatus meets all requirements of the Canadian Interference Causing Equipment Regulations.

Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation. Cet appareillage numérique de la classe [B] répond à toutes les exigences de

l’inerférencé canadienne causant des réglements d’équipement. L’opération est sujette aux deux conditions suivantes: (1) ce dispositif peut ne pas causer

l’interférence nocive, et (2) ce dispositif doit accepter n’importe quelle interférence reçue, y compris l’interférence quipeut causer ’opération peu désirée.

Prepare Frame and Strike

1. Prepare door jamb per the Installation Instructions provided

with the electric strike.

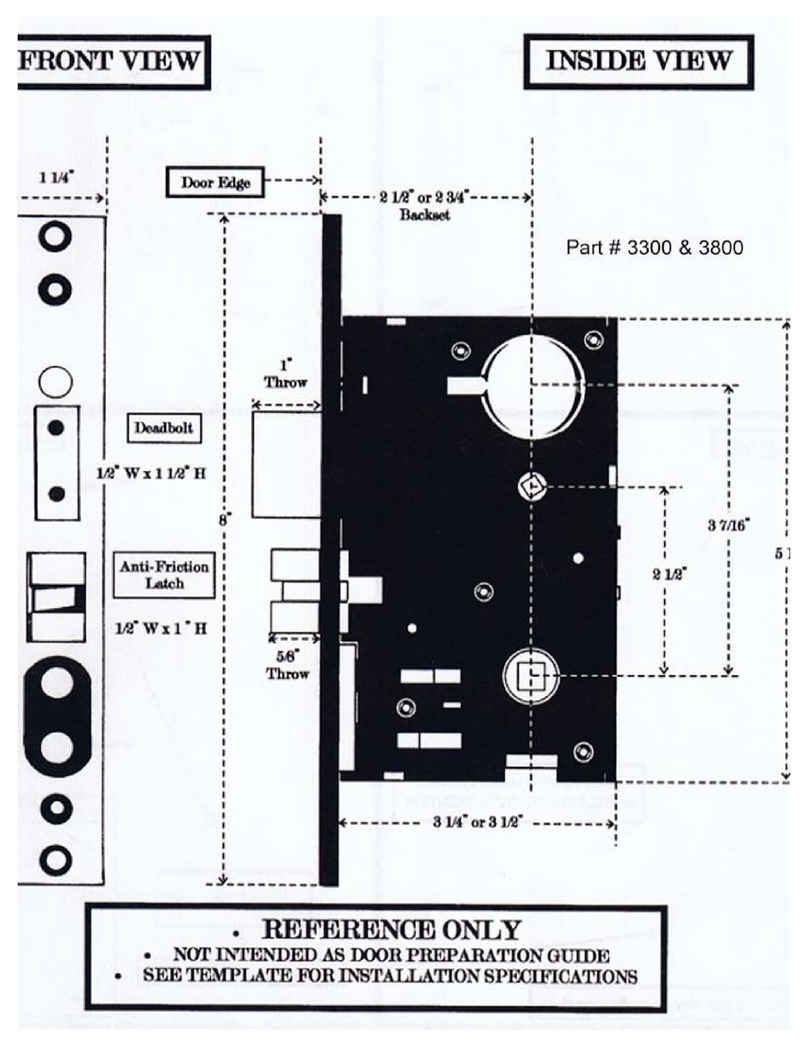

2. On the outside side of the frame drill a 1” diameter hole for

reader/antenna install per the image below. The reader/

antenna may be positioned as desired, within the limits of

the 24” cable connected to the Prox Module.

1-5/16” [33]

5/8” [16]

1” [25]

DPS: 3/8” [10]

Cut

between

holes to

make this

slot

See 9400,9500/9600

installation instructions

for these wire hole locations