AUMA SAEx 25.1 User manual

Control

→Parallel

Profibus

Modbus RTU

Modbus TCP/IP

Foundation Fieldbus

HART

Profinet

Multi-turn actuators

SAEx 25.1 –SAEx 30.1

SAREx 25.1 –SAREx 30.1

Control unit: electronic (MWG)

with actuator controls

ACExC 01.2

Version FM/CSAEx (Class/Division System)

Assembly, operation, commissioningOperation manual

Read operation manual first.

●Observe safety instructions.

●This operation manual is part of the product.

●Store operation manual during product life.

●Pass on manual to any subsequent user or owner of the product.

●Proposition 65:This product may contain one or more substances or chemicals known to the state of

California to cause cancer.

Target group:

This document contains information for the mounting, commissioning, and maintenance staff.

Reference documents:

●Manual (Operation and setting) Actuator controls ACExC 01.2 Parallel

Reference documents can be downloaded from the Internet (www.auma.com) or ordered directly from AUMA

(refer to <Addresses>).

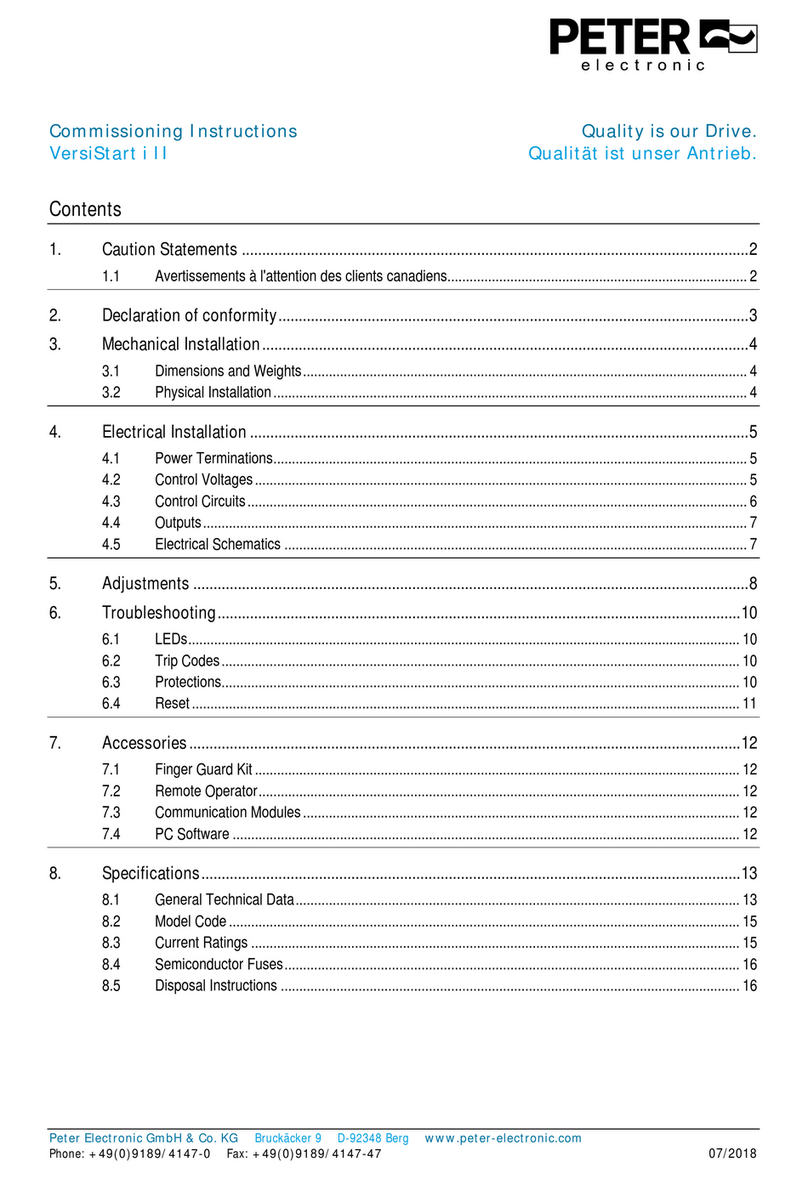

Table of contents Page

51. Safety instructions................................................................................................................. 51.1. Prerequisites for safe handling of the product 51.2. Range of application 61.3. Warnings and notes 61.4. References and symbols

82. Identification........................................................................................................................... 82.1. Short description 92.2. Name tag

143. Transport and storage........................................................................................................... 143.1. Transport 153.2. Storage

164. Assembly................................................................................................................................ 164.1. Mounting position 164.2. Handwheel fitting 174.3. Multi-turn actuator: mount to valve/gearbox 174.3.1. Design of output drive type A 174.3.1.1. Stem nut for output drive type A: finish machining 194.3.1.2. Multi-turn actuator with output drive type A:mount 204.3.2. Design of output drive types B and E 204.3.2.1. Multi-turn actuator with output drive type B:mount 214.4. Accessories for assembly 214.4.1. Stem protection tube for rising valve stem

235. Electrical connection............................................................................................................. 235.1. Basic information 255.2. Cable installation for wall bracket and control box 275.3. Electrical connection of actuator 275.3.1. Motor connection (for motors with a nominal current exceeding 25 A) 275.3.1.1. Motor terminal compartment: open 285.3.1.2. Motor cables: connect 295.3.1.3. Motor terminal compartment: close

2

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

Table of contents ACExC 01.2

295.3.2. K electrical connection 305.3.2.1. Terminal compartment: open 315.3.2.2. Cable connection 325.3.2.3. Terminal compartment: close 335.4. Electrical connections of actuator controls 335.4.1. SE electrical connection 345.4.1.1. Terminal compartment: open 355.4.1.2. Cable connection 365.4.1.3. Terminal compartment: close 375.4.2. KE/KES electrical connection 385.4.2.1. Terminal compartment: open 395.4.2.2. Cable connection 405.4.2.3. Terminal compartment: close 405.5. External earth connection 415.6. Accessories for electrical connection 415.6.1. Parking frame

426. Operation................................................................................................................................ 426.1. Manual operation 426.1.1. Manual operation: engage 436.1.2. Manual operation: disengage 436.2. Motor operation 436.2.1. Actuator operation from Local 446.2.2. Actuator operation from remote 446.3. Menu navigation via push buttons (for settings and indications) 456.3.1. Menu layout and navigation 466.4. User level, password 476.4.1. Password entry 476.4.2. Password change 486.5. Language in the display 486.5.1. Language selection

507. Indications.............................................................................................................................. 507.1. Indications during commissioning 507.2. Indications on display 517.2.1. Feedback indications from actuator and valve 537.2.2. Status indications according to AUMA classification 547.2.3. Status indications according to NAMUR recommendation 567.3. Indication lights of local controls 577.4. Optional indications 577.4.1. Mechanical position indication via indicator mark

588. Signals (output signals)......................................................................................................... 588.1. Status signals via output contacts (digital outputs) 588.1.1. Assignment of outputs 588.1.2. Coding the outputs 588.2. Analog signals (analog outputs)

599. Commissioning (basic settings)........................................................................................... 599.1. Heat-up time for low temperature version 599.2. Type of seating: set 609.3. Torque switch setting 629.4. Limit switches: set

3

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

ACExC 01.2 Table of contents

649.5. Test run 649.5.1. Direction of rotation at mechanical position indicator: check 659.5.2. Direction of rotation at hollow shaft/stem: check 659.5.3. Limit switches: check

6710. Commissioning (settings/options in the actuator)............................................................. 6710.1. Switch compartment: open/close 6810.2. Mechanical position indication via indicator mark 6810.2.1. Mechanical position indicator: set 6810.2.2. Gear stage of the reduction gearing: test/set

7111. Corrective action.................................................................................................................... 7111.1. Faults during commissioning 7111.2. Fault indications and warning indications 7511.3. Fuses 7511.3.1. Fuses within the actuator controls 7611.3.2. Fuse replacement 7611.3.2.1. Replace F1/F2 fuses 7611.3.2.2. Test/replace F3/F4 fuses 7711.3.3. Fuses within the control box 7711.3.4. Motor protection (thermal monitoring)

7812. Servicing and maintenance................................................................................................... 7812.1. Preventive measures for servicing and safe operation 7912.2. Disconnection from the mains 7912.2.1. Disconnection from the mains with KES electrical connection 7912.3. Maintenance 8012.4. Disposal and recycling

8113. Technical data......................................................................................................................... 8113.1. Technical data Multi-turn actuators 8213.2. Technical data Actuator controls 8613.3. Technical data Control box

8714. Spare parts............................................................................................................................. 8714.1. Multi-turn actuator SAEx 25.1 –SAEx 35.1/SAREx 25.1 –SAREx 30.1 8914.2. Actuator controls AUMATIC ACExC 01.2 SE 9114.3. Actuator contrtols AUMATIC ACExC 01.2 KES-Exd 9314.4. ExC wall bracket

97Index........................................................................................................................................

100Addresses...............................................................................................................................

4

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

Table of contents ACExC 01.2

1. Safety instructions

1.1. Prerequisites for safe handling of the product

Standards/directives The end user or the contractor must ensure that all legal requirements, directives,

guidelines, national regulations and recommendations with respect to assembly,

electrical connection, commissioning and operation are met at the place of installation.

Safetyinstructions/warn-

ings All personnel working with this device must be familiar with the safety and warning

instructions in this manual and observe the instructions given. Safety instructions

and warning signs on the device must be observed to avoid personal injury or property

damage.

Qualification of staff Assembly, electrical connection, commissioning, operation, and maintenance must

be carried out exclusively by suitably qualified personnel having been authorized by

the end user or contractor of the plant only.

Prior to working on this product, the staff must have thoroughly read and understood

these instructions and, furthermore, know and observe officially recognized rules

regarding occupational health and safety.

Work performed in hazardous locations is subject to special regulations which have

to be observed.The end user or contractor of the plant are responsible for respect

and control of these regulations, standards, and laws.

Commissioning Prior to commissioning, imperatively check that all settings meet the requirements

of the application. Incorrect settings might present a danger to the application, e.g.

cause damage to the valve or the installation.The manufacturer will not be held

liable for any consequential damage. Such risk lies entirely with the user.

Operation Prerequisites for safe and smooth operation:

●Correct transport, proper storage, mounting and installation, as well as careful

commissioning.

●Only operate the device if it is in perfect condition while observing these instruc-

tions.

●Immediately report any faults and damage and allow for corrective measures.

●Observe recognized rules for occupational health and safety.

●Observe the national regulations.

●During operation, the housing warms up and surface temperatures > 140 °F

(60 °C ) may occur.To prevent possible burns, we recommend checking the

surface temperature using an appropriate thermometer and protective gloves,

prior to working on the device.

Protective measures The end user or the contractor is responsible for implementing required protective

measures on site, such as enclosures, barriers, or personal protective equipment

for the staff.

Maintenance To ensure safe device operation, the maintenance instructions included in this manual

must be observed.

Any device modification requires prior written consent of the manufacturer.

1.2. Range of application

AUMA SAEx 25.1 –SAEx 30.1/SAREx 25.1 –SAREx 30.1 multi-turn actuators are

designed for the operation of industrial valves, e.g.globe valves, gate valves, butterfly

valves, and ball valves.

The devices described below are approved for use in hazardous locations in

compliance with the classification (class, division) as specified on the name tag.The

particular conditions of use are listed on the certificates supplied.

Other applications require explicit (written) confirmation by the manufacturer.

The following applications are not permitted, e.g.:

5

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

ACExC 01.2 Safety instructions

●Industrial trucks

●Lifting appliances

●Passenger lifts

●Service lifts

●Escalators

●Continuous duty

●Buried service

●Continuous submersion (observe enclosure protection)

●Radiation exposed areas in nuclear power plants

No liability can be assumed for inappropriate or unintended use.

Observance of this operation manual is considered as part of the device's designated

use.

This operation manual is only valid for the “clockwise closing”standard version, i.e.

driven shaft turns clockwise to close the valve.For “counterclockwise closing”version,

a supplement must be observed in addition to these operation instructions.

1.3. Warnings and notes

The following warnings draw special attention to safety-relevant procedures in this

operationmanual, eachmarkedbythe appropriate signal word(DANGER,WARNING,

CAUTION, NOTICE).

Indicates an imminently hazardous situation with a high level or risk. Failure

to observe this warning results in death or serious injury.

Indicates a potentially hazardous situation with a medium level of risk.Failure

to observe this warning could result in death or serious injury.

Indicates a potentially hazardous situation with a low level of risk. Failure to

observe this warning could result in minor or moderate injury. May also be

used with property damage.

Potentially hazardous situation. Failure to observe this warning could result

in property damage. Is not used for personal injury.

Safety alert symbol warns of a potential personal injury hazard.

The signal word (here: DANGER) indicates the level of hazard.

1.4. References and symbols

The following references and symbols are used in this manual:

Information The term Information preceding the text indicates important notes and information.

Symbol for CLOSED (valve closed)

Symbol for OPEN (valve open)

Via the menu to parameter

Describes the menu path to the parameter.When using the push buttons of local

controls, the required parameter can be quickly found on the display. Display texts

are shaded in gray: Display.

Wiring diagram Texts extracted from other documents

Texts extracted from other documents are highlighted in a different font.For example

Wiring diagram.

6

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

Safety instructions ACExC 01.2

➥Result of a process step

Describes the result of a preceding process step.

7

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

ACExC 01.2 Safety instructions

2. Identification

2.1. Short description

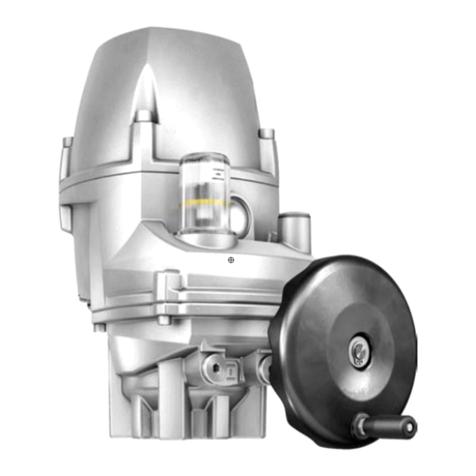

Multi-turn actuator Definition in compliance with MSS SP-102 (EN 15714-2/EN ISO 5210):

A multi-turn actuator is an actuator which transmits to the valve a torque for at least

one full revolution.It is capable of withstanding thrust.

AUMA multi-turn actua-

tor Figure 1: Example, SAEx 25.1 multi-turn actuator

AUMA multi-turn actuators SAEx 25.1 –SAEx 30.1/SAREx 25.1 –SAREx 30.1 are

driven by an electric motor and are capable of withstanding thrust in combination

with output drive type A.For manual operation, a handwheel is provided. Switching

off in end positions may be either by limit or torque seating.Controls are required to

operate or process the actuator signals.

Actuator controls ACExC 01.2 actuator controls are used to operate AUMA actuators and are supplied

ready for use. In combination with SAEx 25.1 –SAEx 30.1/SAREx 25.1 –SAREx

30.1 multi-turn actuators, they may be mounted separately on a wall bracket. For

high nominal motor currents of the actuator, the switchgear of the actuator controls

additionally require a control box.

Figure 2: Actuator controls and control box

[1] Actuator controls

[2] Control box

The functions of ACExC 01.2 actuator controls include standard valve control in

OPEN-CLOSE duty, positioning, process control, logging of operating data right

through to diagnostic functions.

Local controls/

AUMA CDT Operation, setting and display can be performed directly at the actuator controls.

When set to local control, it is possible to

●Operate the actuator via the local controls (push buttons and display) and per-

form settings (contents of these instructions).

●Read in or out data or modify and save settings via AUMA CDT software (ac-

cessory), using a computer (laptop or PC).The connection between computer

and actuator controls is wireless via Bluetooth interface (not included in these

instructions).

8

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

Identification ACExC 01.2

2.2. Name tag

Figure 3: Arrangement of name tags

[1] Actuator name tag

[2] Actuator controls name tag

[3] Motor name tag

[4] Additional tag, e.g.KKS tag (Power Plant Classification System)

[5] Approval tag for hazardous location version

Actuator name tag

Figure 4: Actuator name tag (example)

(= manufacturer logo)

[1] Name of manufacturer

[2] Address of manufacturer

[3] Type designation

[4] Order number (commission number)

[5] Serial number

[6] Speed

[7] Torque range in direction CLOSE

[8] Torque range in direction OPEN

[9] Type of lubricant

[10] Permissible ambient temperature

[11] Can be assigned as an option upon customer request

[12] Enclosure protection

9

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

ACExC 01.2 Identification

Actuator controls name tag

Figure 5: Actuator controls name tag

[1] Type designation

[2] Order number (commission number)

[3] Serial number

[4] Actuator terminal plan

[5] Actuator controls terminal plan

[6] Mains voltage

[7] AUMA power class for switchgear

[8] Permissible ambient temperature

[9] Enclosure protection

[10] Control

Motor name tag

Figure 6: Motor name tag (example)

(= manufacturer logo)

[1] Motor type

[2] Motor article number

[3] Serial number

[4] Type of current, mains voltage

[5] Rated power

[6] Nominal current

[7] Type of duty

[8] Enclosure protection

[9] Motor protection (temperature protection)

[10] Insulation class

[11] Speed

[12] Power factor cos phi

[13] Mains frequency

10

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

Identification ACExC 01.2

Approval tag for hazardous location version

Figure 7: Approval tags for hazardous location version (examples)

[1] Ex-symbol

[2] Classification

Division 1 (frequency or duration of occurrence of hazardous substances)

Class I = Gases, vapors or liquids (groups B, C, D)

Class II = Combustible dusts (groups E, F, G)

Class III = Fibers and Flyings

[3] Range of application

[4] Temperature class / max.surface temperature

[5] Permissible ambient temperature

[6] Certificate number

Descriptions referring to name tag indications

Type designation Figure 8:Type designation (example)

1. Type and size of actuator

2. Flange size

3. Ex marking

Type and size

This manual applies to the following device types and sizes:

●Type SAEx: Multi-turn actuators for open-close duty

Sizes: 25.1, 30.1

●Type SAREx = Multi-turn actuators for modulating duty

Sizes: 25.1, 30.1

11

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

ACExC 01.2 Identification

Ex marking

Table 1:

Marking for explosion protection (example)

1111B33/

Version (actuator with/without actuator controls)

3 = with AUMATIC ACExC actuator controls

3

Electrical connection

1 = Terminal connection type: SE or S

2 = Terminal connection type: KE or K

3 = Terminal connection type: KES-Exd

3

Cover of control unit

B = Without indicator glass

W = With indicator glass

B

Motor heater

1 = Without motor heater

2 = With motor heater

1

Motor insulation class

1 = Insulation class F

2 = Insulation class H

1

Not applicable

Not applicable

1

Motor type

a = AD. orVD.: 3-phase AC motor

1

Order number The product can be identified using this number and the technical data as well as

order-related data pertaining to the device can be requested.

Please always state this number for any product inquiries.

On the Internet at http://www.auma.com> Service >Support >myAUMA, we offer

a service allowing authorized users to download order-related documents such as

wiring diagramsand technical data (bothinGerman andEnglish),inspectioncertificate

and the operation manual when entering the order number.

Actuator serial number Table 2:

Description of serial number (example of 0519MD12345)

UD123451905

Positions 1+2: Assembly in week = week 0505

Positions 3+4:Year of manufacture = 201919

Internal number for unambiguous product identificationUD12345

Wiring diagram actuator Position 9 after TPA: Position transmitter version

I, Q = MWG (magnetic limit and torque transmitter)

AUMA power class for

switchgear The switchgear used in the actuator controls (reversing contactors/thyristors) are

classified according to AUMA power classes (e.g.A1, B1, ....).The power class

defines the max. permissible rated power (of the motor) the switchgear has been

designed for.The rated power (nominal power) of the actuator motor is indicated in

HP [kW] on the motor name tag. For the assignment of the AUMA power classes to

the nominal power of the motor types, refer to the separate electrical data sheets.

For switchgear without assignment to any power classes, the actuator controls name

tag does not indicate the power class but the max. rated power in HP [kW].

12

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

Identification ACExC 01.2

Control Table 3:

Control examples (indications on actuator controls name tag)

DescriptionInput signal

Control voltage 24/48/60V DC for OPEN - CLOSE control via digital inputs

(OPEN, STOP, CLOSE)

24/48/60 V DC

Control voltage 100 –125V DC for OPEN - CLOSE control via digital inputs

(OPEN, STOP, CLOSE)

100 –125 V DC

Control voltage 100 –120V AC for OPEN - CLOSE control via digital inputs

(OPEN, STOP, CLOSE)

100 –120 V AC

Input current for setpoint control via analog input0/4 –20 mA

13

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

ACExC 01.2 Identification

3. Transport and storage

3.1. Transport

For transport to place of installation, use sturdy packaging.

Hovering load!

Death or serious injury.

→Do NOT stand below hovering load.

→Attach ropes or hooks for the purpose of lifting by hoist only to housing and NOT

to handwheel.

→Actuators mounted on valves: Attach ropes or hooks for the purpose of lifting

by hoist to valve and NOT to actuator.

→Actuatorsmountedto gearboxes:Attachropesor hooksforthepurpose oflifting

by hoist only to the gearbox using eyebolts and NOT to the actuator.

→Actuators mounted to controls: Attach ropes or hooks for the purpose of lifting

by hoist only to the actuator and NOT to the controls.

→Respect total weight of combination (actuator, actuator controls, gearbox, valve)

→Secure load against falling down, sliding or tilting.

→Perform lift trial at low height and eliminate any potential danger e.g. by tilting.

Figure 9: Example: Lifting the actuator

Table 4:

Weight for ACExC 01.2 actuator controls

Weight approx.lbs [kg]with electrical connection type:

36 [16.5]AUMAExplug/socketconnector with terminal blocks(KES), increased

safety Ex d

Table 5:

Weights of multi-turn actuators SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

with 3-phase AC motors

Weight2)

Motor type1)

Type designation

Actuator approx. lbs [kg]

342 [155]ADX... 90-...SAEx 25.1/

SAREx 25.1 364 [165]ADX... 132-...

430 [195]ADX... 112-...SAEx 30.1/

SAREx 30.1 584 [265]ADX... 160-...

Refer to motor name tag1)

14

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

Transport and storage ACExC 01.2

Indicated weight includes AUMA NORM multi-turn actuator with 3-phase AC motor, electrical con-

nection in standard version, output drive type B1 and handwheel.For other output drive types, heed

additional weights.

2)

Table 6:

Weights output drive type

lbs [kg]Flange size Standard MSS

SP–102 [Option EN ISO 5210]

Type designation

93 [42]FA25 [F25]A 25.2

152 [69]FA30 [F30]A 30.2

Table 7:

Weights output drive type

[kg]Flange size Standard MSS

SP–102 [Option EN ISO 5210]

Type designation

135 [61]FA25 [F25]AF 25.2

227 [103]FA30 [F30]AF 30.2

3.2. Storage

Danger of corrosion due to inappropriate storage!

→Store in a well-ventilated, dry room.

→Protect against floor dampness by storage on a shelf or on a wooden pallet.

→Cover to protect against dust and dirt.

→Apply suitable corrosion protection agent to uncoated surfaces.

Risk of damage due to excessively low temperatures!

→Actuator controls may only be stored permanently down to –22 °F (–30 °C).

→On request, actuator controls may be transported in specific cases and for short

duration at temperatures down to –76 °F (–60 °C).

Long-term storage For long-term storage (more than 6 months), observe the following points:

1. Prior to storage:

Protect uncoated surfaces, in particular the output drive parts and mounting

surface, with long-term corrosion protection agent.

2. At an interval of approx.6 months:

Check for corrosion.If first signs of corrosion show, apply new corrosion protec-

tion.

15

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

ACExC 01.2 Transport and storage

4. Assembly

4.1. Mounting position

The product described in this document can be operated without restriction in any

mounting position.

4.2. Handwheel fitting

Information For transport reason, handwheels with a diameter 15.7”(400 mm) and larger are

supplied separately within the scope of delivery.

Damage at the change-over mechanism due to incorrect assembly!

→Only pivot change-over lever manually.

→Do NOT use extensions as lever for operation.

→First engage manual operation correctly, then mount handwheel.

1. Manually lift the red change-over lever while slightly turning the shaft back and

forth until manual operation engages.

➥Manual operation is properly engaged if the change-over lever can be shifted

by approx. 85°.

Figure 10:

2. Push handwheel over the red change-over lever then onto the shaft.

Figure 11:

3. Release change-over lever (should snap back into initial position by spring ac-

tion, if necessary, push it back manually).

16

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

Assembly ACExC 01.2

4. Secure handwheel using the retaining ring supplied.

Figure 12:

4.3. Multi-turn actuator: mount to valve/gearbox

Corrosion due to damage to paint finish and condensation!

→Touch up damage to paint finish after work on the device.

→After mounting, connect the device immediately to electrical mains to ensure

that heater minimizes condensation.

4.3.1. Design of output drive type A

Figure 13: Output drive type A

[1] Output mounting flange

[2] Stem nut with dog coupling

[3] Valve stem

Output mounting flange [1] with axial bearing stem nut [2] form one unit.Torque is

transmitted to valve stem [3] via stem nut [2].

4.3.1.1. Stem nut for output drive type A: finish machining

This working step is only required if stem nut is supplied unbored or with pilot bore.

Information For exact production version, please refer to the order-related technical data sheet

or AUMA Assistant App.

17

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

ACExC 01.2 Assembly

Figure 14: Output drive type A

[1] Stem nut

[2] Axial needle roller bearing

[2.1] Axial bearing washer

[2.2] Axial needle roller and cage assembly

[3] Spigot ring

How to proceed 1. Remove spigot ring [3] from output drive.

2. Remove stem nut [1] together with axial needle roller bearings [2].

3. Remove axial bearing washers [2.1] and axial needle roller and cage assemblies

[2.2] from stem nut [1].

4. Drill and bore stem nut [1] and cut thread.

5. Clean the machined stem nut [1].

6. Apply sufficient suitable EP multi-purpose grease to axial needle roller and cage

assemblies [2.2] and axial bearing washers [2.1], ensuring that all hollow spaces

are filled with grease.

7. Place greased axial needle roller and cage assemblies [2.2] and axial bearing

washers [2.1] onto stem nut [1].

8. Re-insert stem nut [1] with axial needle roller bearings [2] into output drive.

9. Screw in spigot ring [3] until it is firm against the shoulder.

18

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

Assembly ACExC 01.2

4.3.1.2. Multi-turn actuator with output drive type A: mount

Figure 15: Assembly of output drive type A

[1] Valve stem

[2] Output drive type A

[3] Screws to actuator

[4] Valve flange

[5] Screws to output drive

How to proceed 1. If the output drive type A is already mounted to the multi-turn actuator: Loosen

screws [3] and remove output drive type A [2].

2. Apply a small quantity of grease to the valve stem [1].

3. Place output drive type A on valve stem and turn until it is flush on the valve

flange.

4. Turn output drive type A until alignment of the fixing holes.

5. Fasten screws [5] between valve and output drive type A without completely

tightening them.

6. Fit multi-turn actuator on the valve stem so that the stem nut dogs engage into

the output drive sleeve.

➥The flanges are flush with each other if properly engaged.

7. Rotate multi-turn actuator until alignment of the mounting holes.

8. Reinstall multi-turn actuator with screws [3].

9. Tighten screws [3] crosswise with a torque according to table.

Table 8:

Tightening torques for screws

Tightening torque ft-lb [Nm]M threadsUNC threads

Strength class

A2-808.8

148 [200]158 [214]M165/8”

289 [392]318 [431]M203/4”

1,049 [1,422]1,098 [1,489]M301”

1,830 [2,481]1,913 [2,594]M361 1/4”

10. Turn multi-turn actuator with handwheel in direction OPEN until valve flange

and output drive type A are firmly placed together.

11. Tighten screws [5] between valve and output drive type A crosswise applying

a torque according to table.

19

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

ACExC 01.2 Assembly

4.3.2. Design of output drive types B and E

Figure 16: Output drive type B

[1] Multi-turn actuator flange

[2] For output drive types B/B1/B2 hollow shaft with keyway

[2]* For output drive types B/B1/B2 solid shaft with bore and keyway

[3] Gearbox/valve shaft with parallel key

Information Spigot at valve flanges should be loose fit.

For output drive types B/B1/B2, the connection to the valve or the gearbox is made

by directly placing the multi-turn actuator hollow shaft onto the input shaft of the valve

or gearbox.

For output drive types B3/B4/E, the connection is made via output drive sleeve which

is inserted into the bore of the hollow shaft of the multi-turn actuator and fixed by a

retaining ring.

When exchanging the output drive sleeve, later retrofitting to a different output drive

type is possible

4.3.2.1. Multi-turn actuator with output drive type B: mount

Figure 17: Mounting output drive types B

[1] Multi-turn actuator

[2] Valve/gearbox

[3] Valve/gearbox shaft

How to proceed 1. Check if mounting flanges fit together.

2. Check, if output drive of multi-turn actuator [1] matches the output drive of

valve/gearbox or valve/gearbox valve shaft [2/3].

3. Apply a small quantity of grease to the valve or gearbox stem [3].

20

SAEx 25.1 –SAEx 30.1 / SAREx 25.1 –SAREx 30.1

Assembly ACExC 01.2

Other manuals for SAEx 25.1

3

This manual suits for next models

3

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA SAEx 25.1 User manual

AUMA

AUMA AM 01.1 Manual

AUMA

AUMA SAVEx Series User manual

AUMA

AUMA LE 12.1 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SAVEx 07.2 User manual

AUMA

AUMA SA-UW User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA PROFOX PF-M25 User manual

AUMA

AUMA SG 03.3 Series User manual