SUPERSCAN

USER’S GUIDE

PRESENCE SENSOR

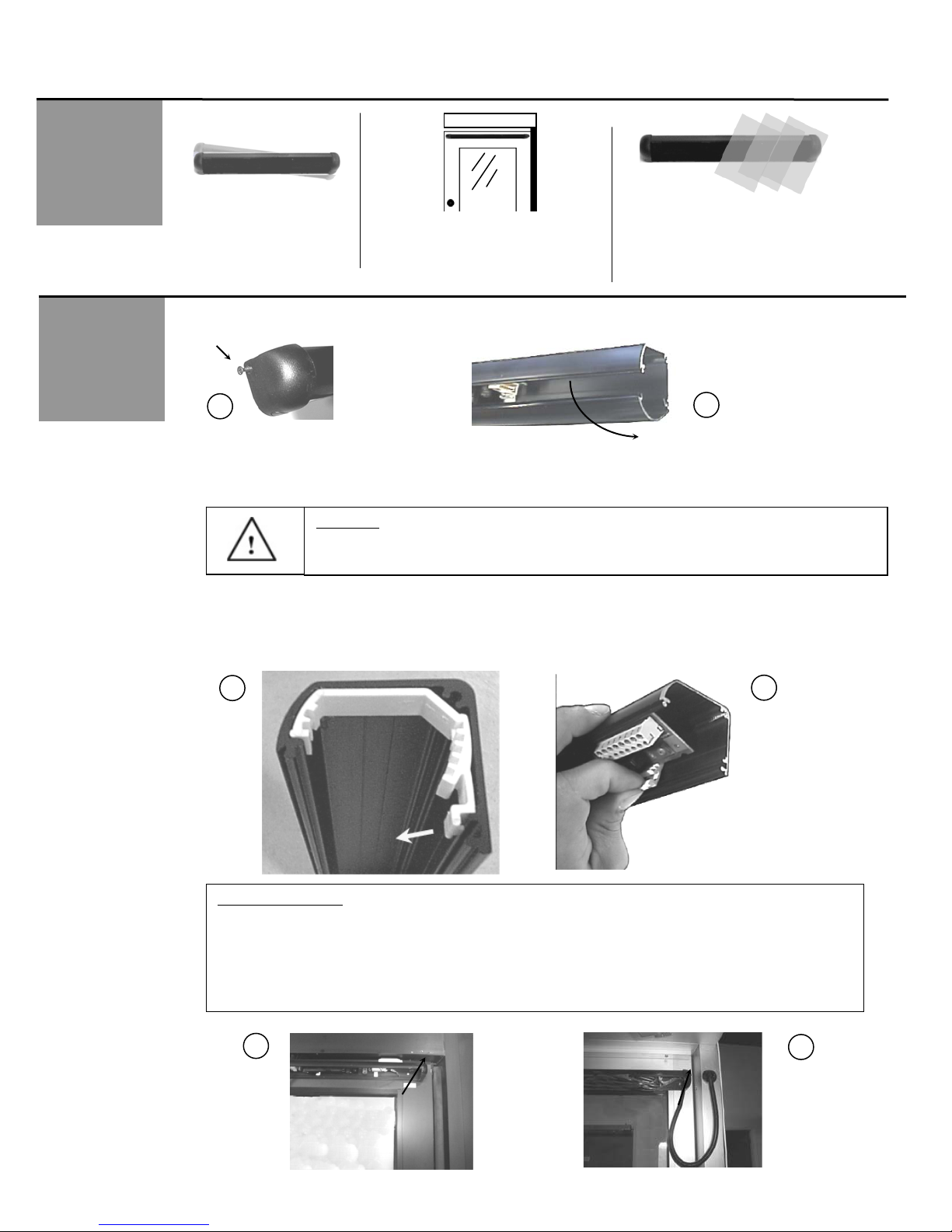

DESCRIPTION The SuperScan (10SSI, 10SSII, 10SSIII) detector is a door-mounted presence detection system that is used on automatic

pedestrian swing doors. The SuperScan can be used on an SMR or non-SMR system. Unlike other door-mounted sensing

devices, the SuperScan's unique electronic architecture allows the detection modules to be mounted near the top of the

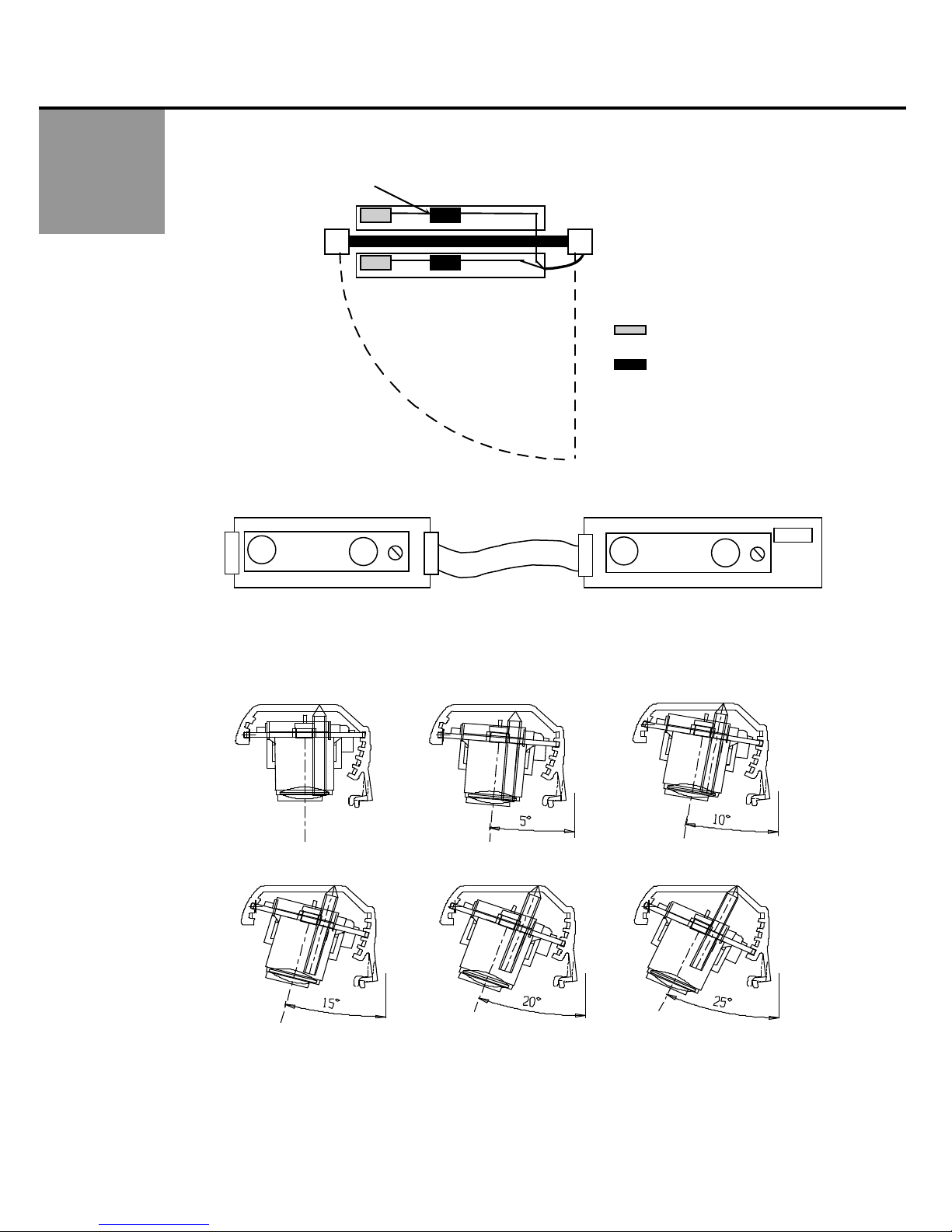

door, out of harm's way. A rotating cam is used for the range adjustment of the detection zone. Width patterns may be

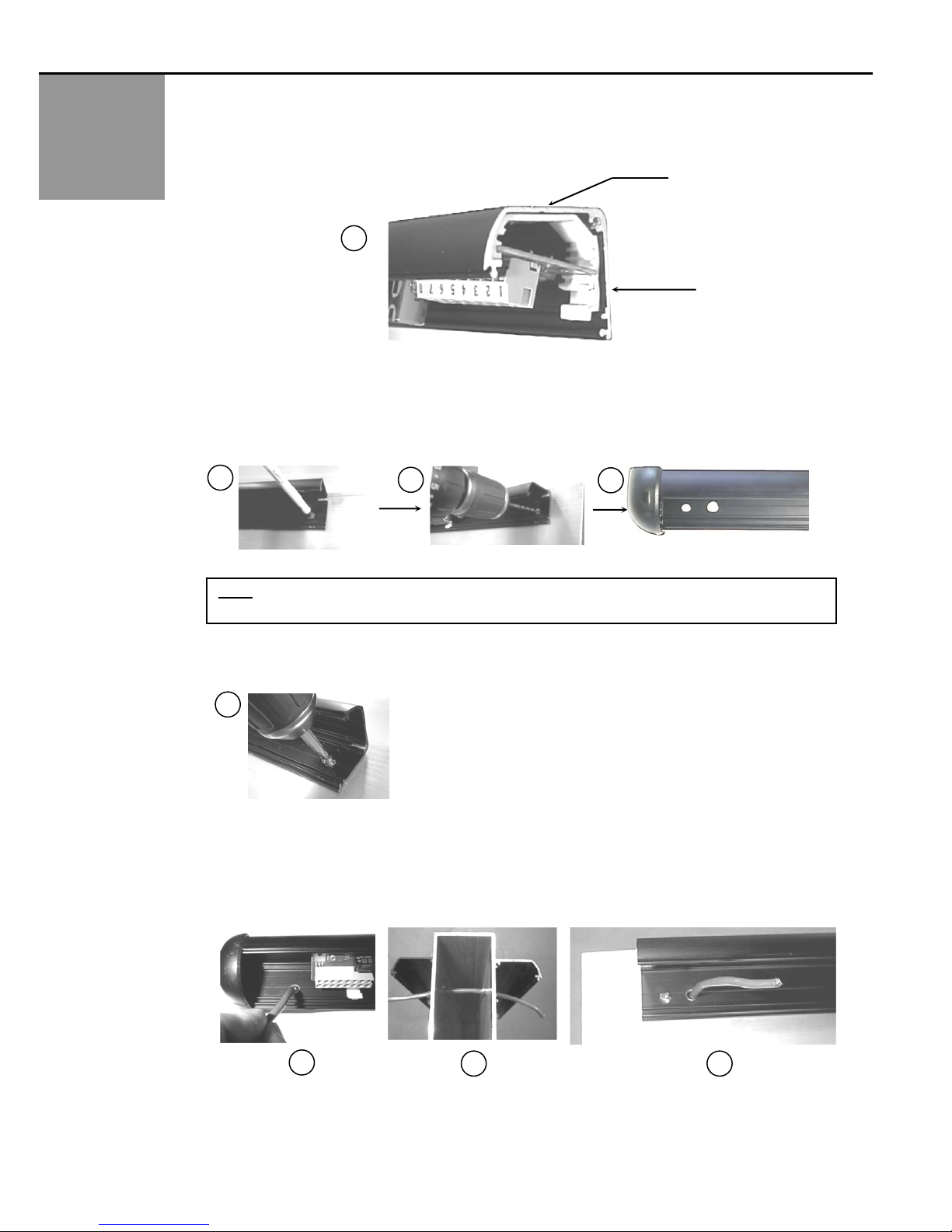

altered by adding slave modules to the master module. These slave modules are simply added by inserting them into the

aluminum extrusion, then connecting them with the attached flat ribbon cable to the next module without interrupting other

modules in the same extrusion. Once installed, the detection zone (in addition to being adjustable for distance) can be

angled independently from the other modules.

Each SuperScan module consists of two optics, a transmitter (TX) and a receiver (RX), and functions independently of the

other modules. The transmitter emits an extremely precise beam, which measures approximately 4" in diameter at a

distance of 8'. The receiver, in turn, receives the infrared beam reflected off of the floor. This transmission and reception

forms a detection triangle, which is the basic premise of detection (called triangulation). Should this angle be interrupted,

detection will occur. Detection is NOT based upon the intensity of the beam, and in principle will not be affected by the color

or background of the object that interrupts the angle.

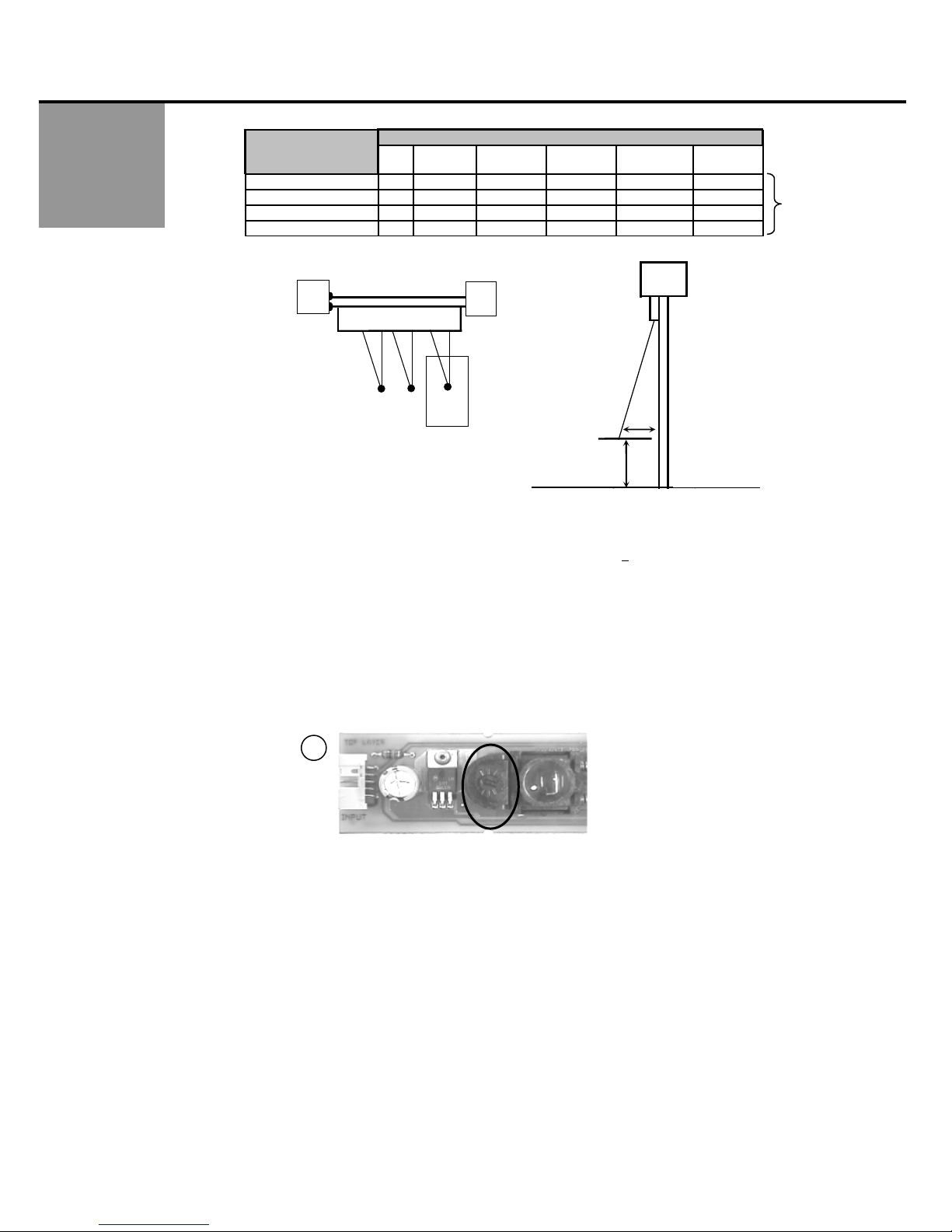

TECHNIC

SPECIFICATIONS DESCRIPTION SPECIFICATION

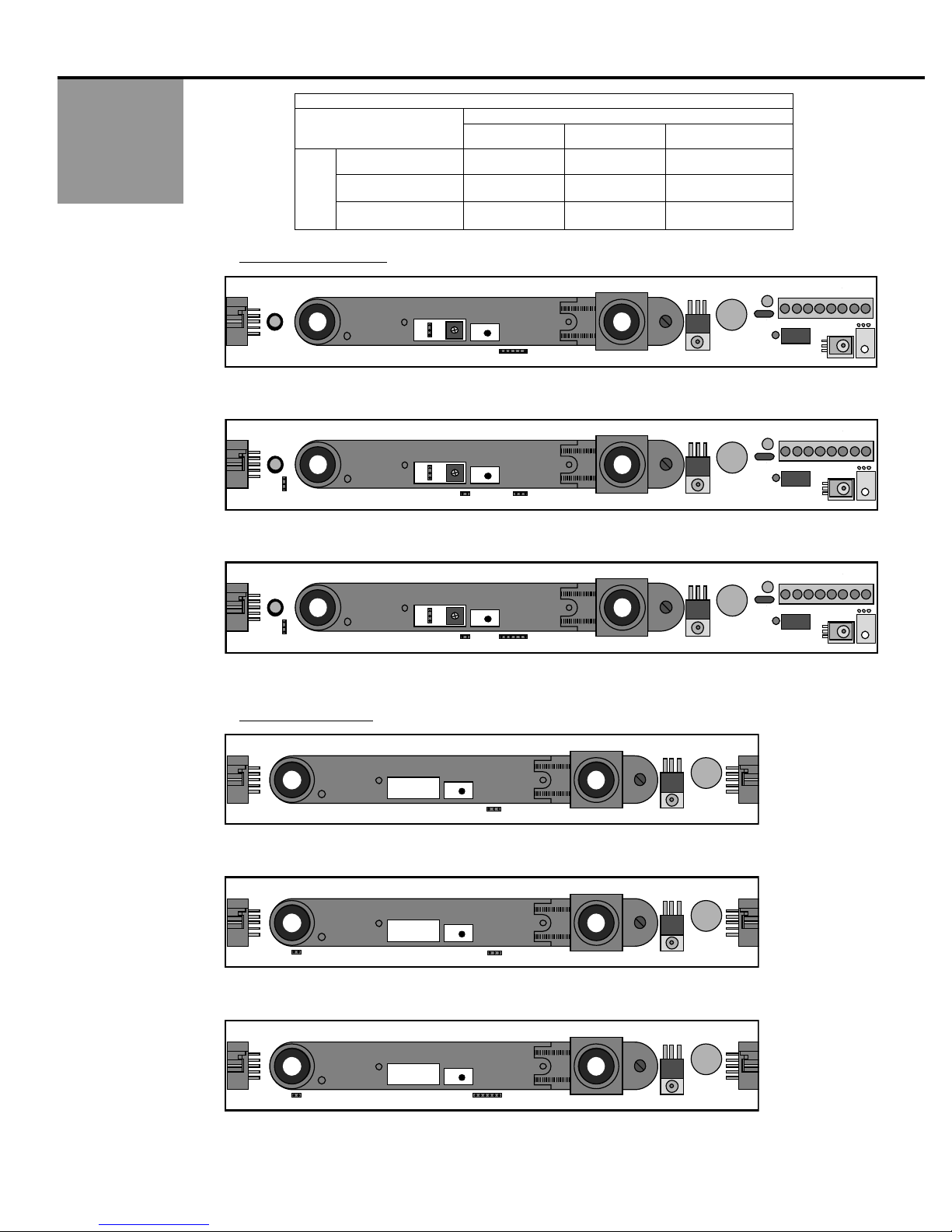

Power Supply 12 to 24 VAC ± 10% / 12 to 24 VDC +10%

Current Consumption:

Master: On = 60 mA max. / Master: Off = 30 mA max.

Slave: On = 40 mA. Max. / Slave: Off = 30 mA max.

Input Inhibit 12 to 24 VAC ± 10%: / 12 to 24 VDC +10% / Inhibited when voltage is applied

SMR Input Data 12-18 VDC: Inhibited when voltage is applied

Output Interface; relay Relay; max. contact rating is 1A @ 30v ( resistive)

Detection Range 0' to 8'

Distance Adjustment 2’ to 8’ / Rotating cam with linear adjustment

Max. Mounting Height 8’

Detection Time < 50 ms

Detection Signal Duration Infinite Presence Detection

Output Hold Time Potentiometer Range: 0.1 to 4.5 seconds.

LED Indications Master: Red LED = Detection

Green LED = Active Output

Slave: Red LED = Detection

Operating Temperature

Range

-30° F to 140° F

PCB Dimensions Master: 10.91" x 1.5"

Slave: 8.75" x 1.5"

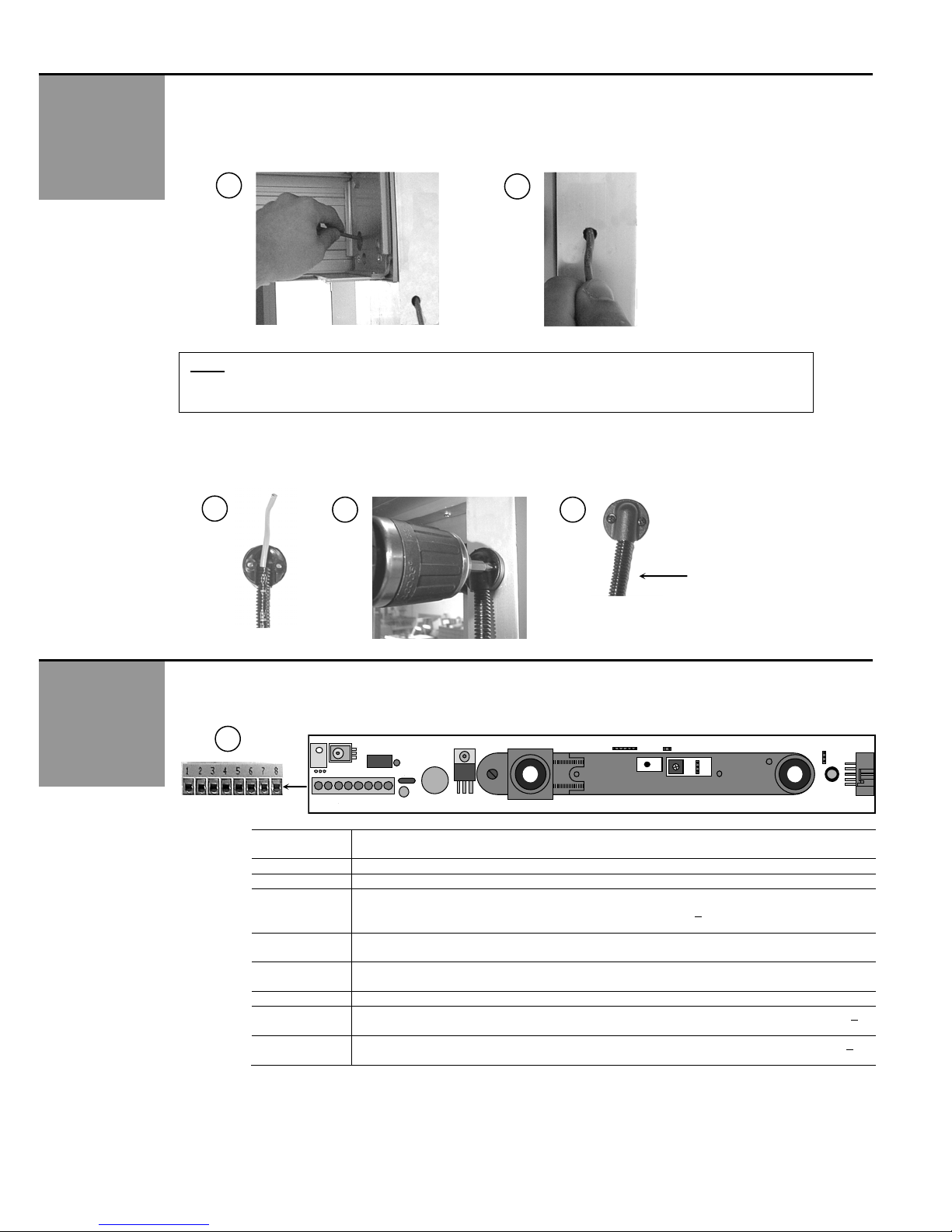

Connection to Door

Controller

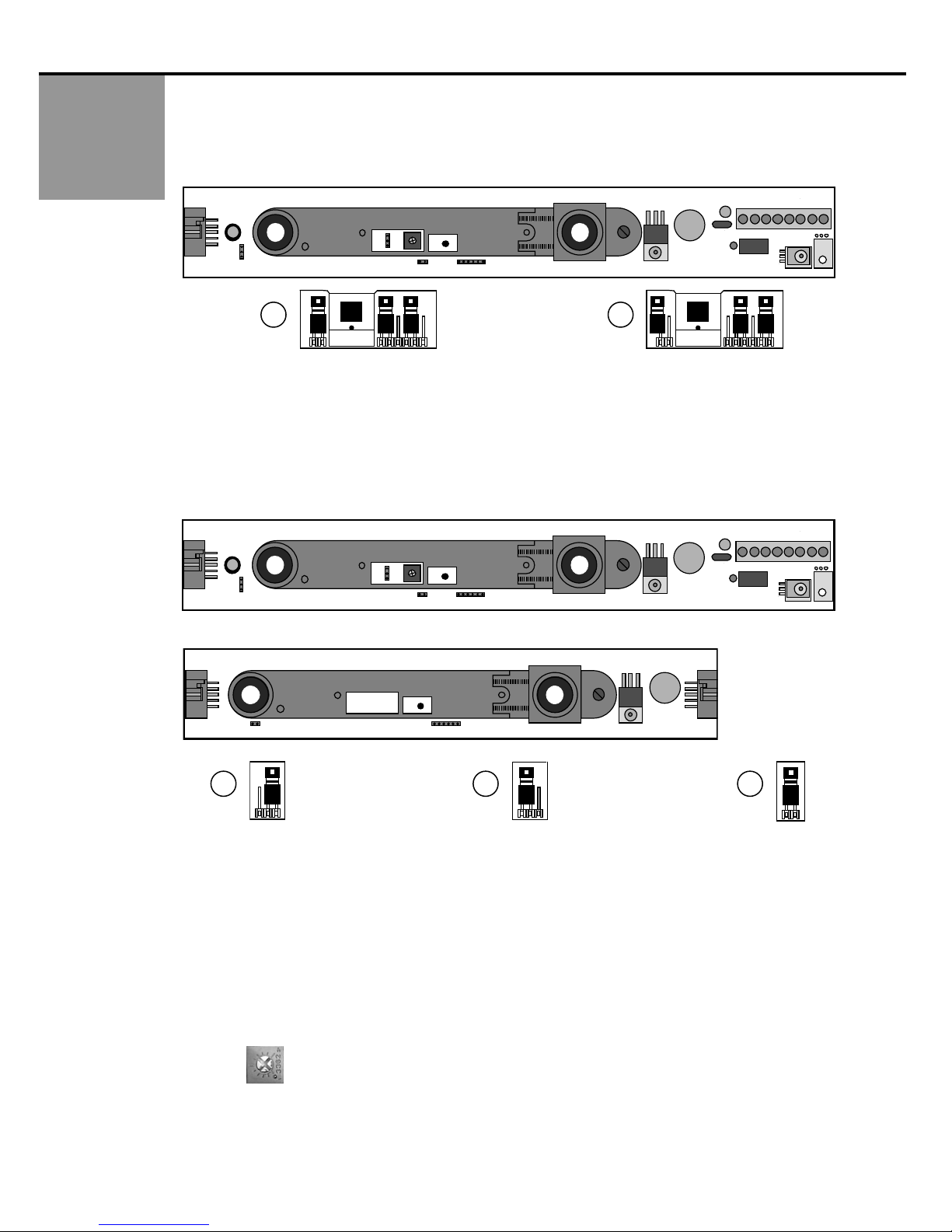

8 Position Screw Terminal on Master PCB

Connection: Master to

Slave

Flat Ribbon Cable With Connectors and Key Lock

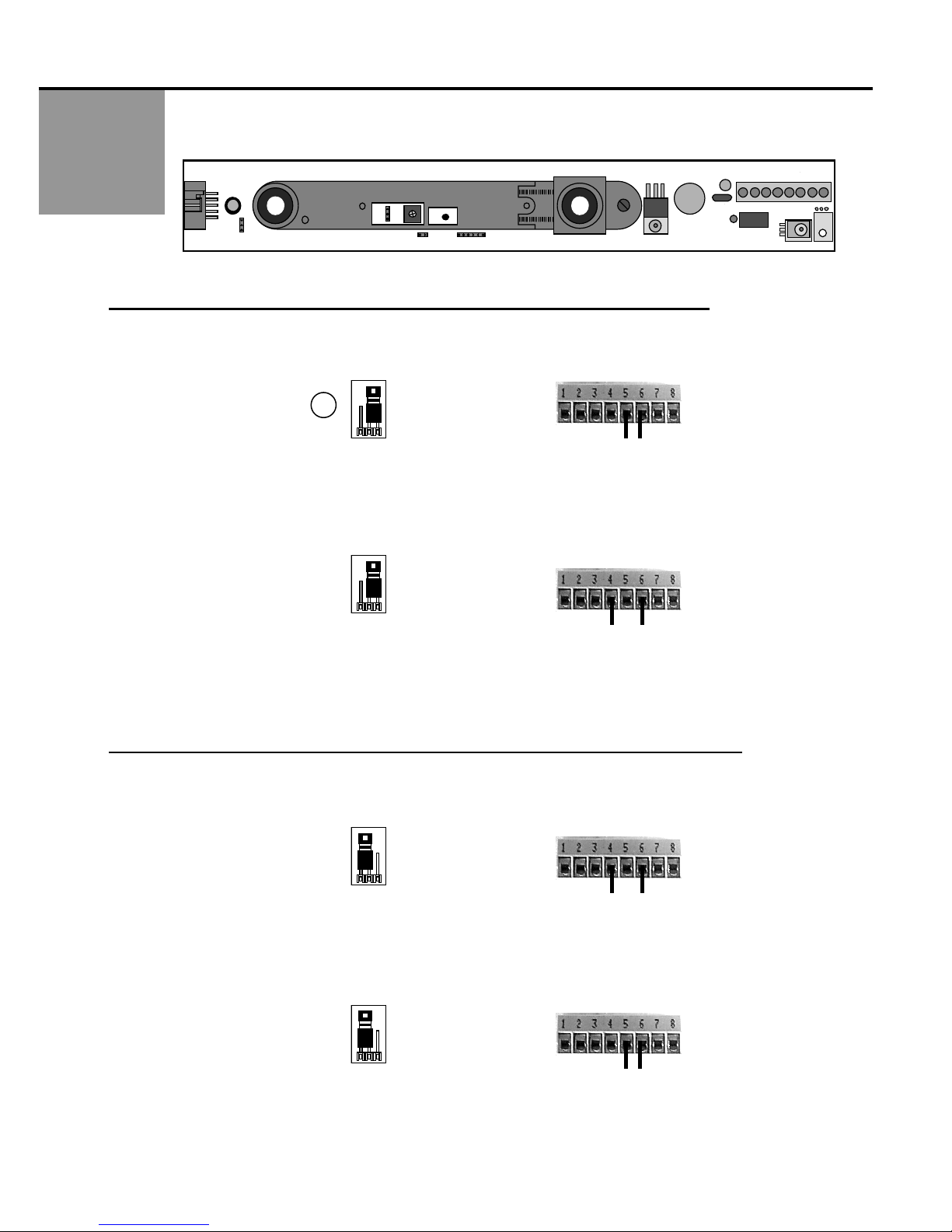

Max. Number of Slaves Standard = 9 / With Monitoring = 8 max.

Functions Selection Detection Mode - NO or NC

Normal Mode or Background Analysis Mode

75.0084.05 20110720 Page 1 of 17

•Shut off all power going to the header before attempting any wiring procedures.

•Maintain a clean & safe environment when working in public areas.

•Constantly be aware of pedestrian traffic around the door area.

•Always stop pedestrian traffic through the doorway when performing tests that may result in unexpected

reactions by the door.

•Always check placement of all wiring and components before powering up to ensure that moving door parts

will not catch any wires and cause damage to equipment.

•Ensure compliance with all applicable safety standards (i.e. ANSI A156.10, 156.27) upon completion of

installation.

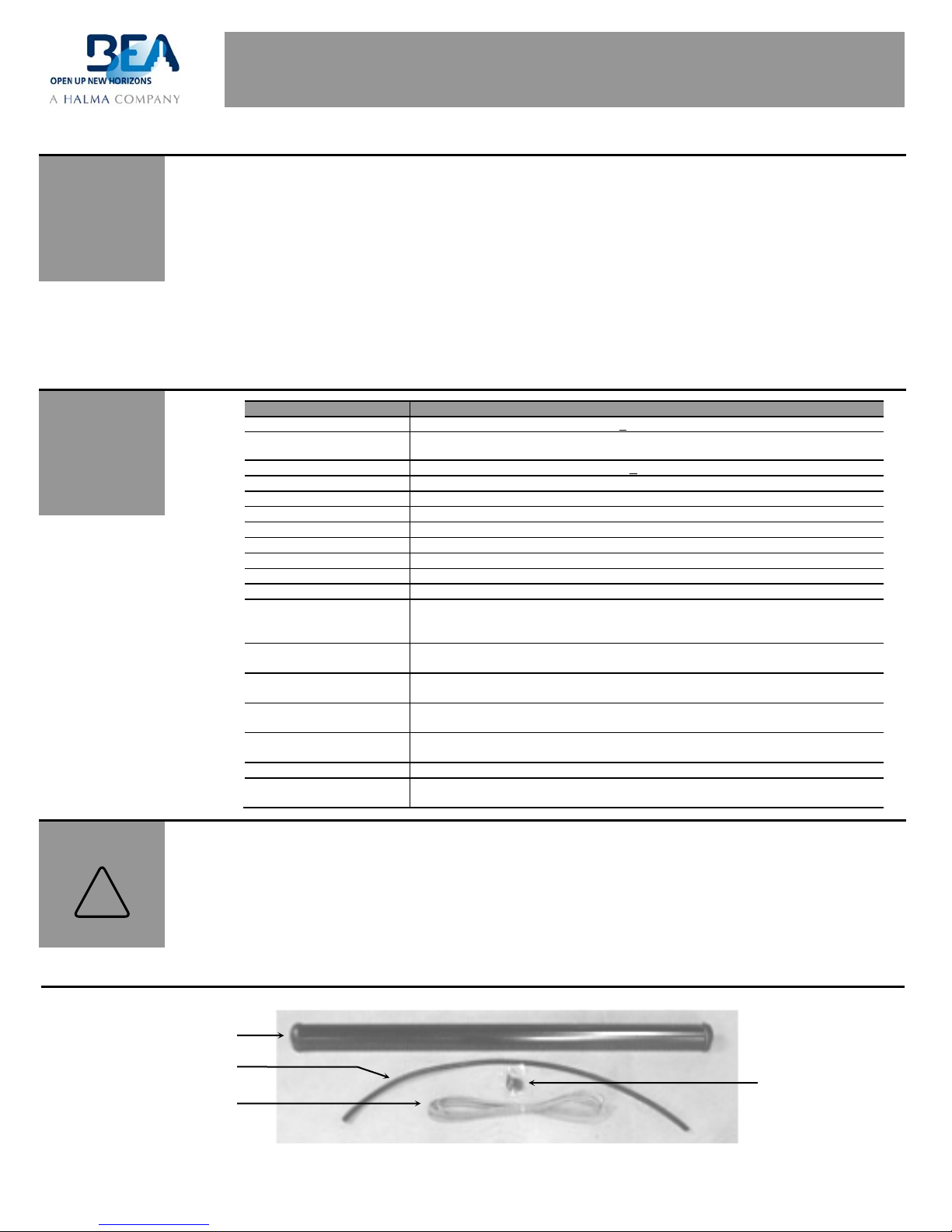

SAFETY

PRECAUTIONS

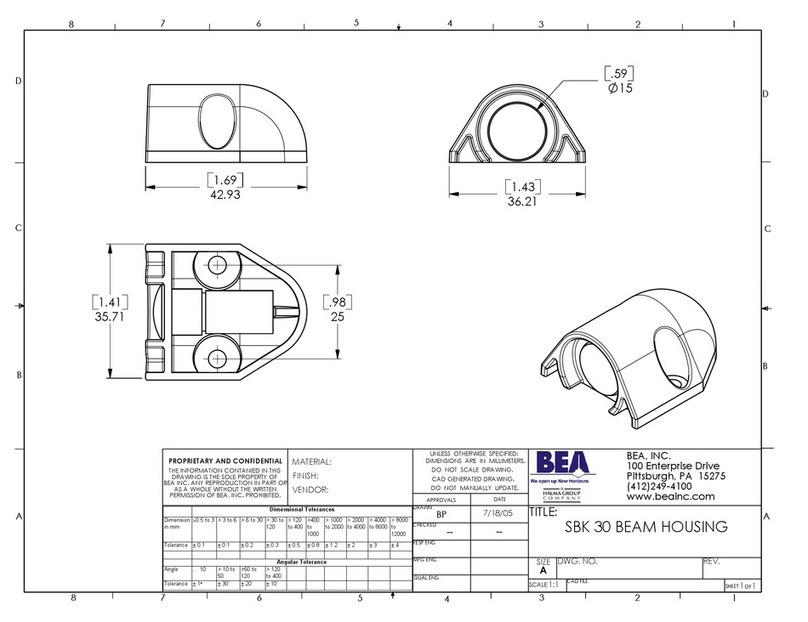

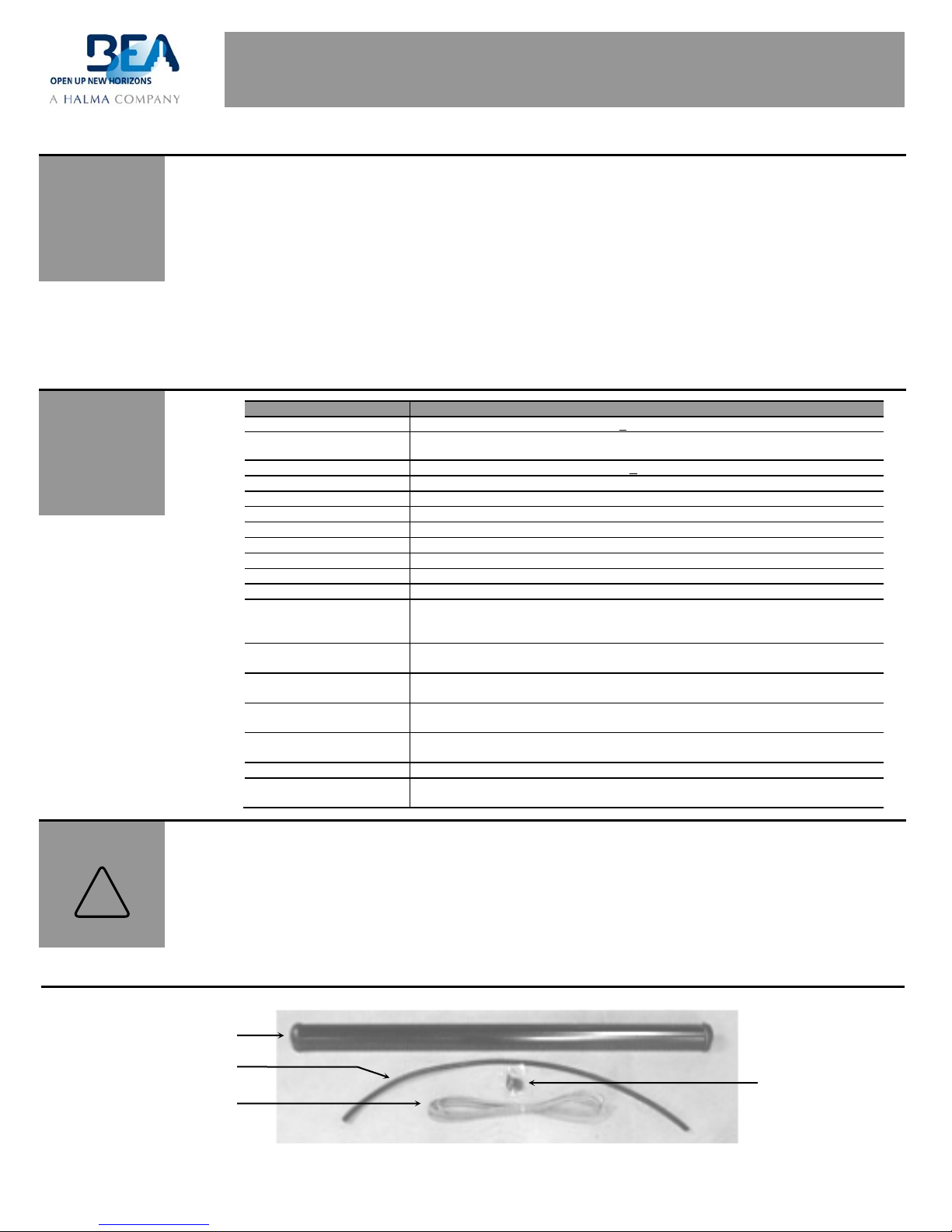

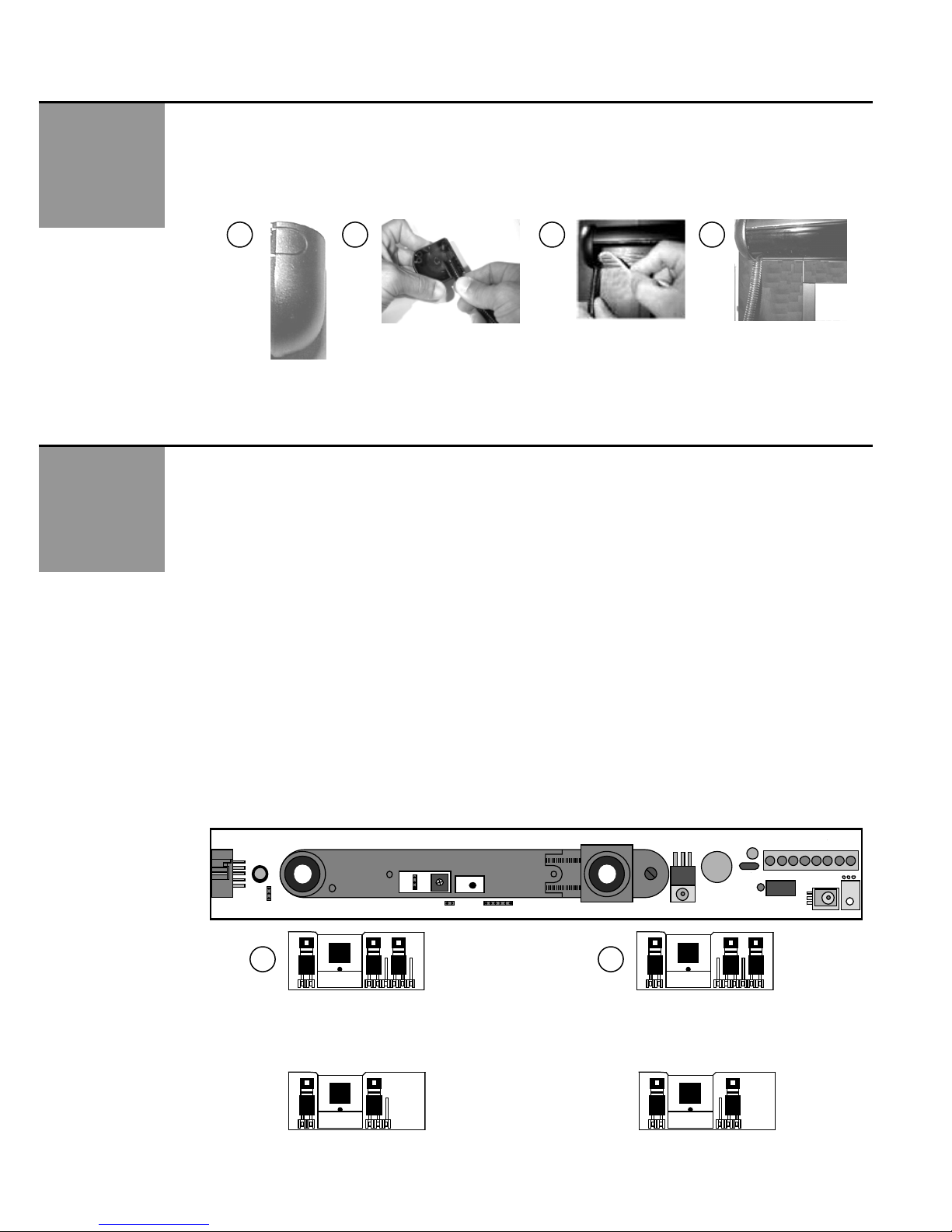

Jamb Hole Cover

SuperScan Assembly

Wire Transfer Sheath

8-Wire Cable