Grand Is a 16 digit (15 digit with negative sign)

Total number which is not zeroed when the

total display is zeroed. The Grand Total

is viewed from the operating mode as

two eight digit numbers, it may be reset

to zero from within the configuration

menu or from the operating mode.

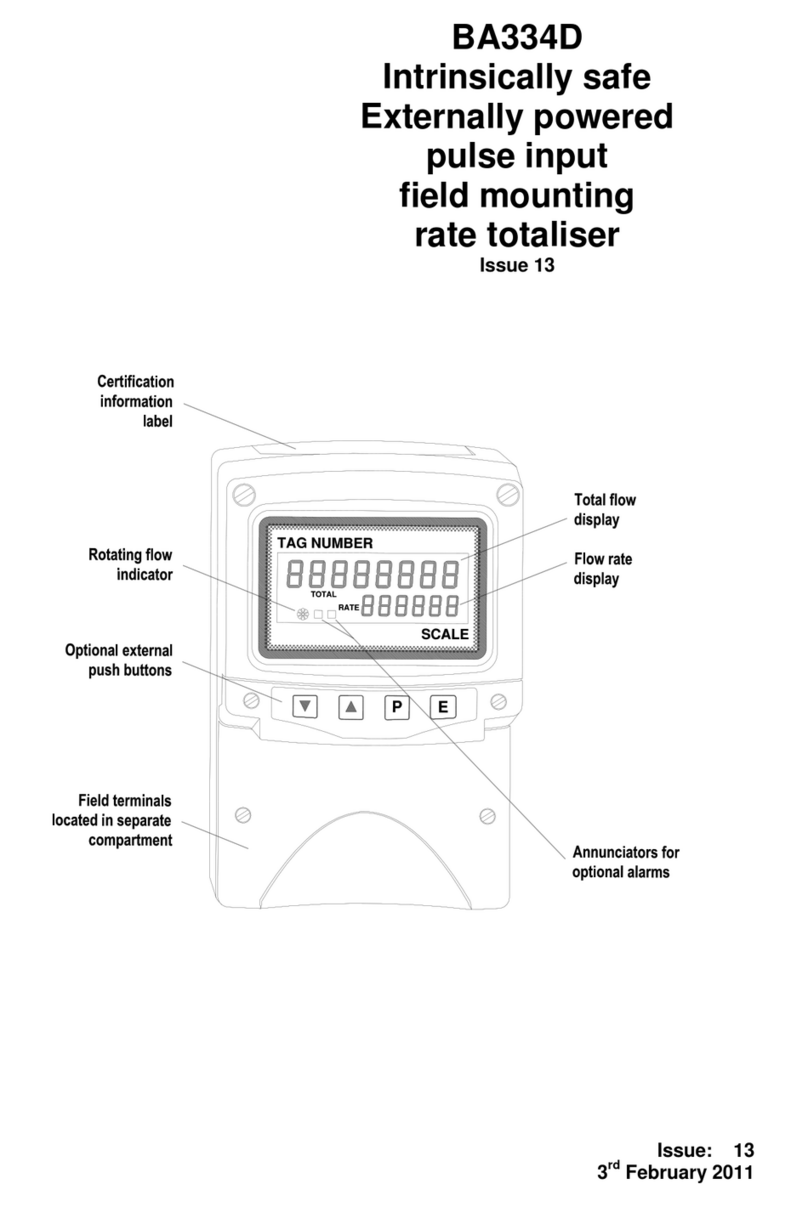

3. INTRINSIC SAFETY CERTIFICATION

The BA35 E rate totaliser has ATEX and IECEx

gas certification plus optional dust certification.

This section of the instruction manual describes

ATEX gas certification. Optional ATEX dust,

IECEx and other approvals are described in

separate appendixes to this manual.

3.1 ATEX gas certification

Notified Body Intertek Testing and Certification Ltd

have issued the BA35 E with an EC-Type

Examination Certificate number

ITS11ATEX27253X. This confirms compliance

with harmonised European standards and it has

been used to confirm compliance with the

European ATEX Directive for Group II, Category

1G equipment, Ex ia IIC T5 Ga Ta = - 0 to

+70ºC. The Rate Totaliser bears the community

mark and subject to local codes of practice may be

installed in any of the European Economic Area

(EEA) member countries. ATEX certificates are

also acceptable for installations in Switzerland.

This section of the instruction manual describes

ATEX installations in explosive gas atmospheres

conforming with EN60079-1 Electrical

Installations in Hazardous Areas. When designing

systems for installation outside the UK the local

Code of Practice should be consulted.

3.2 Zones, gas groups and T rating

The BA35 E Rate Totaliser has been certified

Ex ia IIC T5 Ga. When connected to a suitable

system it may be installed in:

Zone 0 explosive gas air mixture

continuously present.

Zone 1 explosive gas air mixture likely

to occur in normal operation.

Zone 2 explosive gas air mixture not

likely to occur, and if it does

will only exist for a short time.

Be used with gases in groups:

Group A propane

Group B ethylene

Group C hydrogen

In gases that may be used with equipment having

a temperature classification of :

T1 50oC

T2 300oC

T3 200oC

T 135oC

T5 100oC

At ambient temperatures between - 0 and +70oC.

CAUTION installation in Zone 0

When installed in a Zone 0 potentially e plosive

atmosphere requiring EPL Ga apparatus, the

instrument shall be installed such that even in

the event of rare incidents, an ignition source

due to impact or friction between the aluminium

label and iron/steel is e cluded.

No special conditions apply when the indicator is

installed in Zone 1 or in Zone 2.

Note: The specified operating temperature of the

BA35 E is –20 to +70ºC. At temperatures below

–20ºC the instrument will continue to totalise but

the display will not function.

This allows the Rate Totaliser to be installed in all

gas Zones and to be used with most common

industrial gases.

3.3 4/20mA input

The input safety parameters for the /20mA input,

terminals 1 and 3 are:

Ui = 30V dc

Ii = 200mA

Pi = 0.8 W

The maximum equivalent capacitance and

inductance between the two /20mA input

terminals 1 and 3 is:

Ci = 13nF

Li = 16µH

The maximum permitted loop cable parameters

can be calculated by adding these figures to Ci and

Li of other instruments in the loop and subtracting

the totals from the maximum cable capacitance Co

and cable inductance Lo permitted for the Zener

barrier or galvanic isolator powering the loop.

Although the BA35 E does not comply with the

requirements for simple apparatus, the EC-Type

Examination Certificate states that for intrinsic

safety considerations, under fault conditions the

output voltage, current and power at terminals 1 &

3 will not exceed those specified by clause 5.7 of

EN 60079-11 for simple apparatus. This simplifies

the application and intrinsic safety documentation

for a loop into which the BA35 E is connected.

Apart from Ci, the affect of the Rate Totaliser may

be ignored when assessing loop safety.