4

Full Description of Switch Functions

PWhile this button is pushed the rate

display will show the input current in mA,

or as a percentage of the instrument

span depending upon how the instrument

has been programmed. When the button

is released the normal display in

engineering units will return. The function

of this push-button may be modified

when alarms are fitted to the instrument.

Down While this button is pushed the

instrument will show the calibrated rate

display with 4mA input - usually zero for

flow applications. When the button is

released the flow rate will again be

displayed.

Up While this button is pushed the

instrument will show the calibrated rate

display with 20mA input. When the

button is released the flow rate will again

be displayed.

EWhile these buttons are pushed the

+Down total display will show the least significant

eight digits of the grand total, and the

grand total annunciator will be activated.

E+Up While these two buttons are pushed the

total display will show the most significant

eight digits of the grand total and the

grand total annunciator will be activated.

Down Resets the tota l display to zero

+Up when these two push-buttons are

operated simultaneously.

Selectable function from programme

menu.

See section 6.15

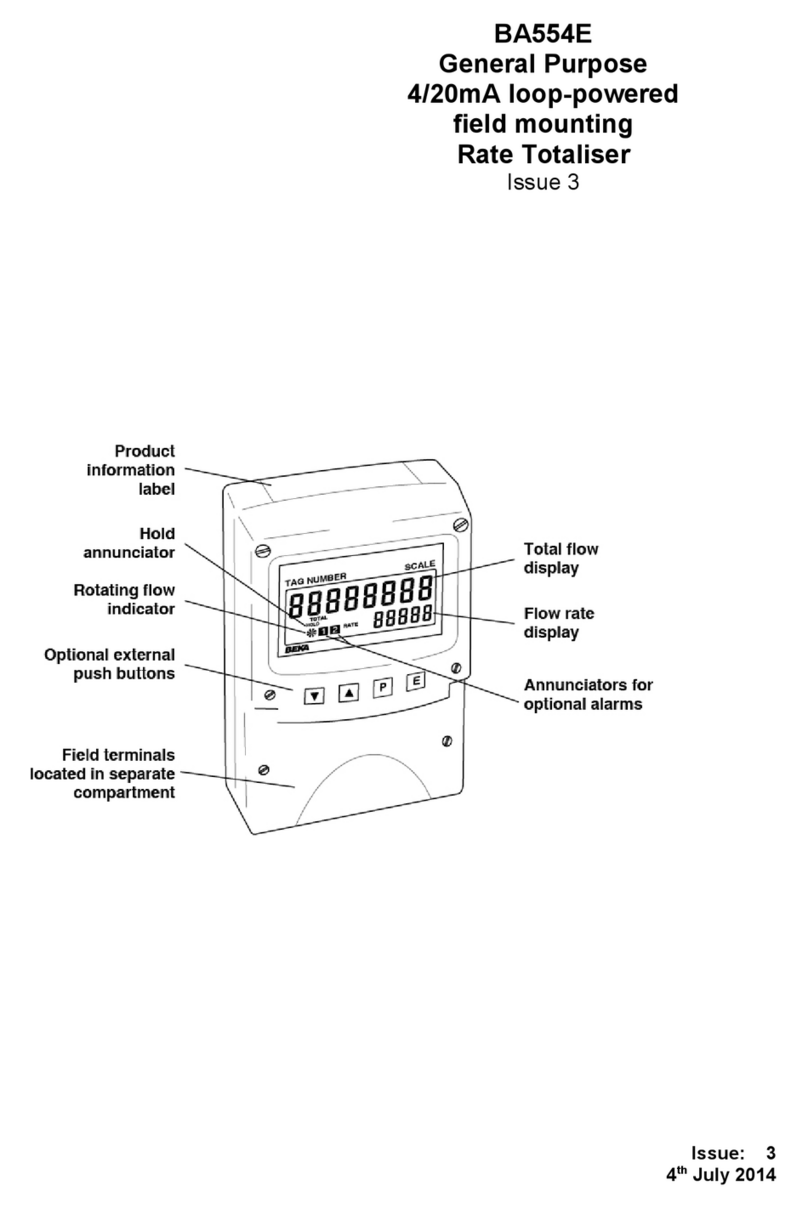

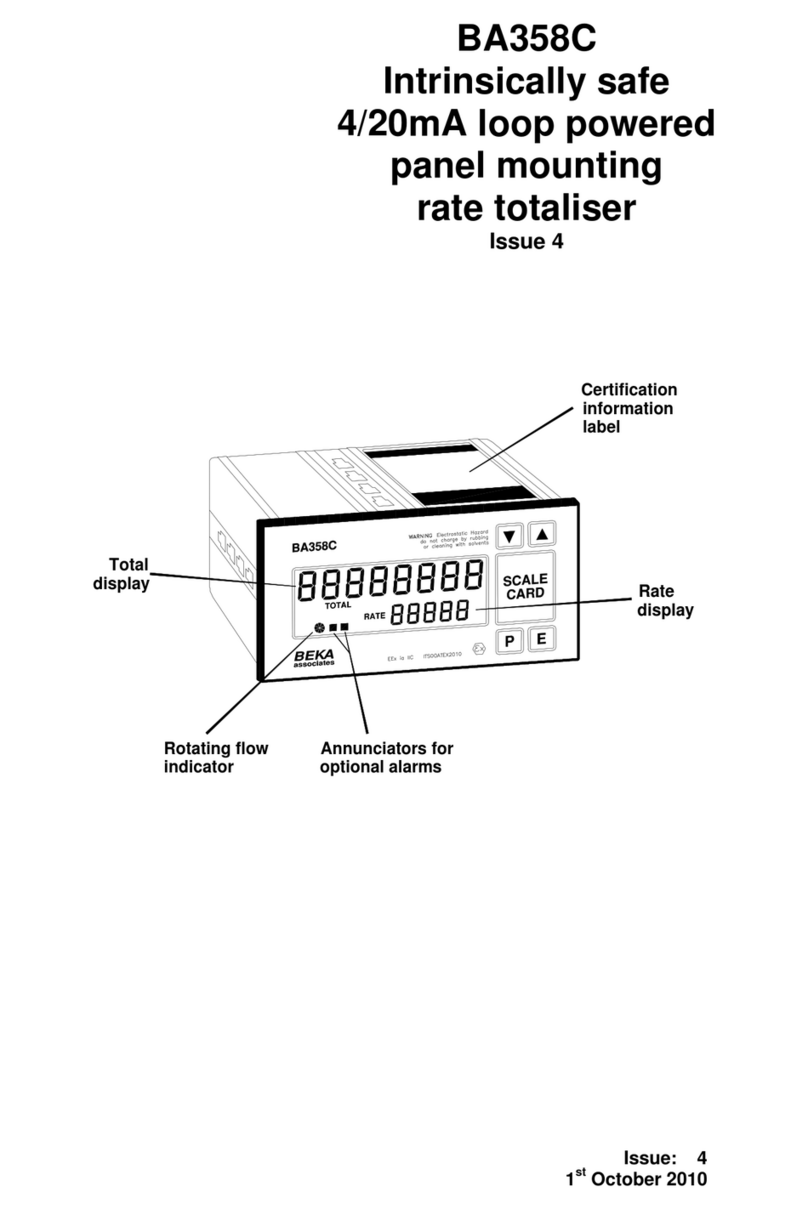

2.2 Displays

The BA354ND has two digital displays and

associated annunciators, plus a flow indicator as

shown on page 1.

Rate Shows the flow rate on the smaller

Display five digit display.

Total Shows the total flow since the

display instrument was last reset on the larger

eight digit display.

Flow This disc in the lower left hand corner

indicator of the display 'rotates' when the input

current exceeds 4mA.

3. TYPE ‘n’ CERTIFICATION

3.1 Certificate of Conformity

ITS Testing and Certification Ltd. (Formerly ERA

Technology Ltd) have issued a Certificate of

Conformity Ex00Y4017 confirming that the

BA354ND complies with the CENELEC standard.

3.2 ATEX certification

The BA354ND complies with the European ATEX

Directive 94/9/EC for Group II, Category 3G

equipment. It has been assessed using the

‘Internal Control of Production procedure specified

in Annex 8 of the Directive. A technical dossier

has been prepared and an EC Declaration of

Conformity BEKA01ATEX0011 has been issued.

The instrument bears the Community Mark and,

subject to local codes of practice, may be installed

in any of the EU member countries, i.e. Austria,

Belgium, Denmark, Finland, France, Germany,

Greece Ireland, Italy, Luxembourg, The

Netherlands, Portugal, Spain, Sweden and the

United Kingdom. ATEX certificates are also

accepted in Norway, Iceland, Liechtenstein and in

Switzerland.

This manual describes installations that comply

with BS EN60079: Part 14 Electrical Installation in

Hazardous Areas. When designing systems for

installation outside the UK, the local Code of

Practice should be consulted.

3.3 Input terminals

Input terminals 1 and 3 may be safely connected in

series with any 4/20mA loop providing that in

normal operation the input current to the

instrument does not exceed 30mA dc.

3.4 Reset terminals

The BA354ND total display may be reset to zero

by connecting a switch between reset terminals

RS1 and RS2. The switch may be located in Zone

2 or in the safe area. The only certification

requirements are that the switch and associated

wiring be able to withstand a 500V rms insulation

test to earth.