CLEARPOINT S040 - M032

8

english

Installation

CLEARPOINT® lters undergo stringent quality control

procedures in the manufacturing plant and are handed

over to the forwarding agent in a perfect condition. Upon

arrival of the goods, please check for any visible damage

and, where appropriate, insist on a corresponding note

on the delivery receipt. Get in touch immediately with the

forwarding agent and arrange for an assessment of the

damage. The manufacturer is not responsible for any

damage caused during transport.

Positioning:

The housing should be mounted in a vertical position.

Observe the direction of ow which is indicated by an

arrow on the housing.

If the pipe network is aected by vibration, it is recom-

mended to install vibration dampers.

For replacing the lter elements it is necessary to leave

a handling space of 850 mm above the blank ange

(see page 19).

Installation:

The bottom of the lter is double-threaded. It must

therefore be ensured that the bottom is not installed with

the slide facing backwards. For correct installation, the

closed slide should face to the front.

For better lter eciency, it is recommended to install

the device at a preferably cool, but frost-protected point

along the pipe network.

The separation rates and service lives require ltration

using a prelter which is one grade coarser at each level

(exception: coarse lters C series).

The tubing in front of the lter must be clean.

In the case of CLEARPOINT®models supplied with a

BEKOMAT®®condensate drain as a standard, please

observe the instructions in the corresponding documen-

tation. The BEKOMAT®®must be installed using in the

connection set (see page 20).

As far as the version using a oat drain is concerned,

please follow the advice regarding the commen-ce-

ment of operation on page 20.

The condensate must be disposed of in compliance with

the valid legal regulations.

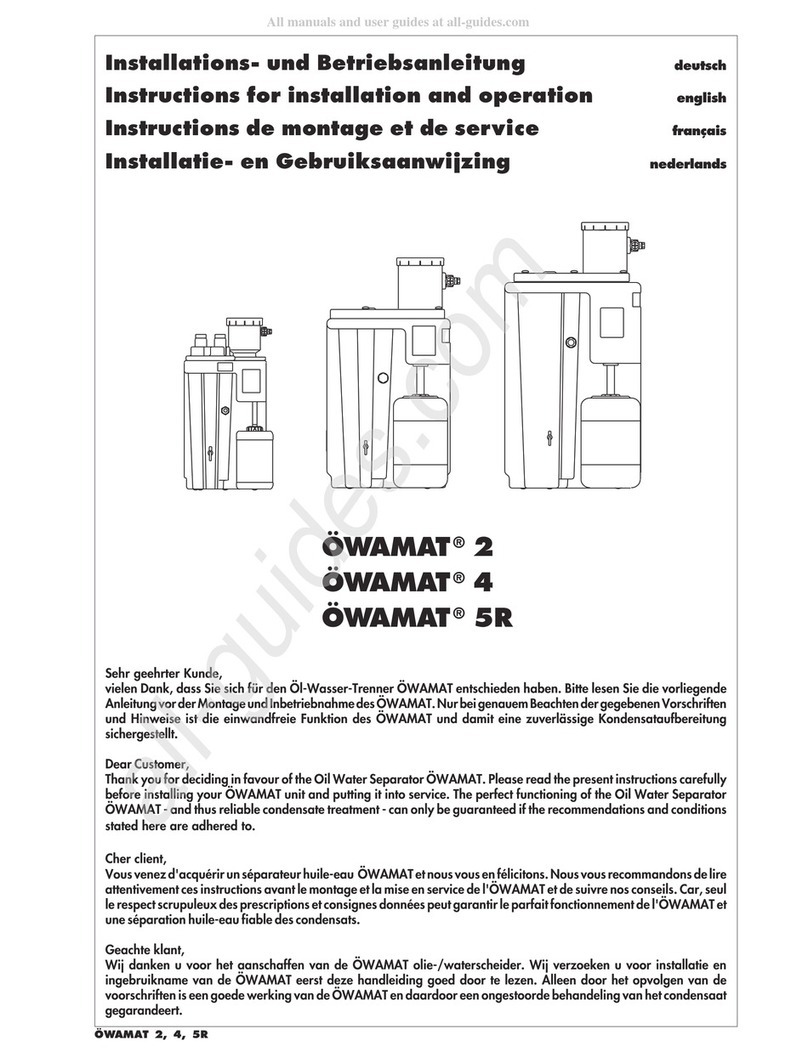

Condensate treatment using an ÖWAMAT®oil-water

separator or a BEKOSPLIT®emulsion splitting plant

represents a particularly economic solution.

Function

Filter C, F, S and R(x)

Solid particles are separated by impact and inertia ef-

fect, oil and water aerosols by coalescence eect. Due

to gravity, ltered out liquid particles gather in the lower

part of the lter housing from where they are discharged

either manually or automatically. With coalescence lters

the direction of ow through the lter element is from the

inside to the outside; with dust lters the ow moves from

outside to the inside.

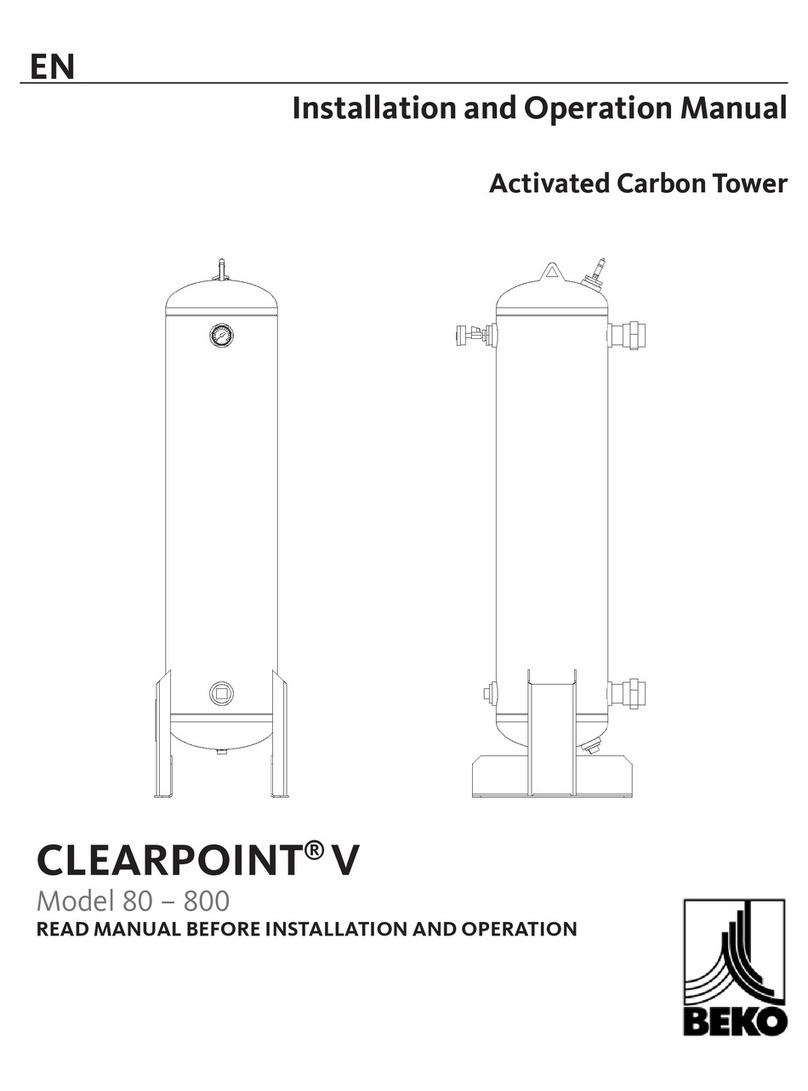

Activated carbon lter A

The ow through the activated carbon bed proceeds

from the inside to the outside. Oil vapours and odours

are adsorbed on the activated carbon. The carbon is

incorporated into a binding fabric which ensures the

reliable retention of dust particles.

Economic efciency of lters

Surface and depth lters

series C, F, S and R(x)

In the course of time, particles accumulate in the ltration

medium and reduce the space available for ow. Conse-

quently, the ow resistance will gradually increase, which

is indicated on the dierential pressure gauge.

It is recommended to replace the lter elements at a

dierential pressure of 0.4 bar or at least once a year,

whichever comes rst. If the element replacement is

delayed any longer, the economic eciency will suer

since the higher dierential pressure has to be com-

pensated by the upstream compressor. This will push

up the electricity consumption and lead to greater wear

on the compressor.

Activated carbon lter, series A

In order to prolong the service life of the elements, the

residual moisture of the inowing gas should not exceed

80 %. The capacity of the elements will be exhausted

after 6 months at the latest so that the element should

then be replaced.

The nominal diameters of the pipes should be as uni-

form as possible in order to avoid creating additional

ow resistance. Reduced pipe sections should only be

installed where required for the partial-ow outlets (ring,

connecting or supply lines).