4

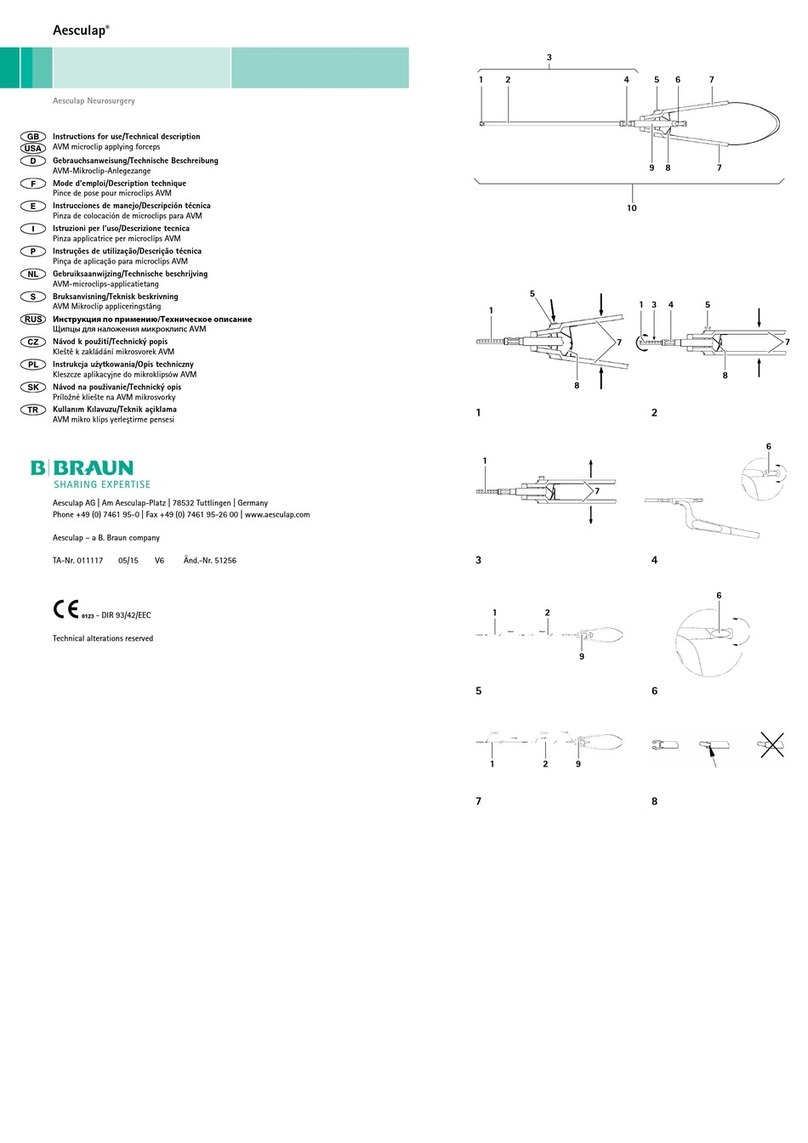

4.3 Operating principle

With the ELAN 4 electro remote foot control GA810 the active applied

part is connected to the control unit without manual control. The coolant

pump is activated or deactivated and the maximum speed and direction of

the applied part is changed.

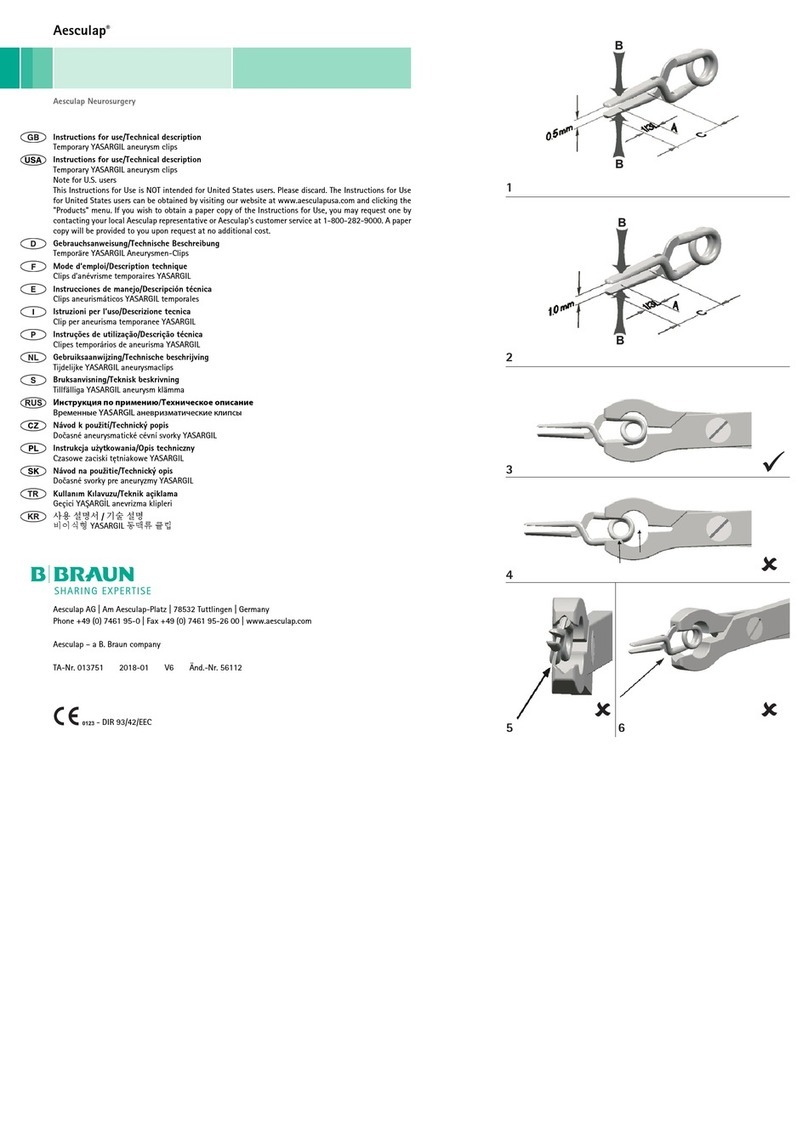

Function button 2:

Rotational direction button for motor 4: Selection of right or left rotation.

Pedal 3: The pedal serves as the actuator for the speed setting of the con-

trol unit. Depending on the actuating path, the speed of the motor can be

selected continuously from 0 to the maximum speed set.

Maximum speed button 5: The maximum speed button is for step-by-step

changes to the set maximum speed on the control device GA800 with full

operation of the pedal.

5. Preparation and setup

Non-compliance with the following instructions will preclude all respon-

sibility and liability in this respect on the part of Aesculap.

►When setting up and operating the product, adhere to

– national regulations for installation and operation,

– national regulations on fire and explosion protection.

5.1 First use

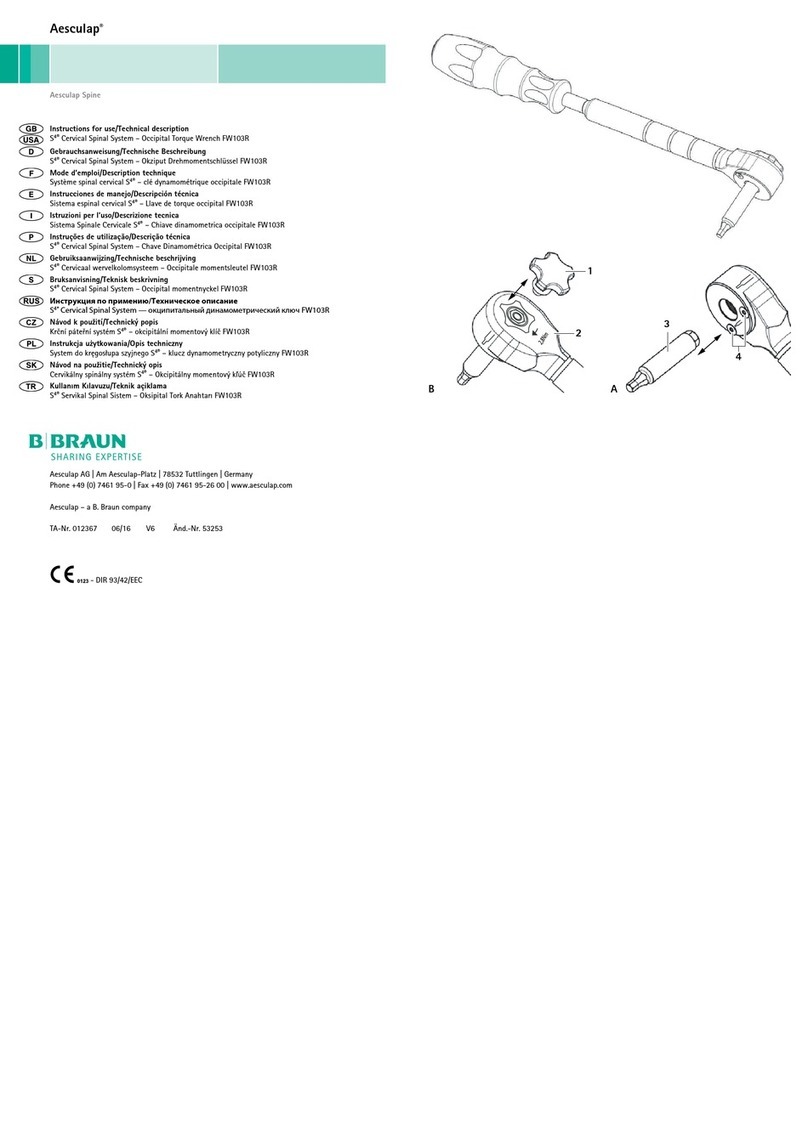

Assembling/disassembling the transport brace

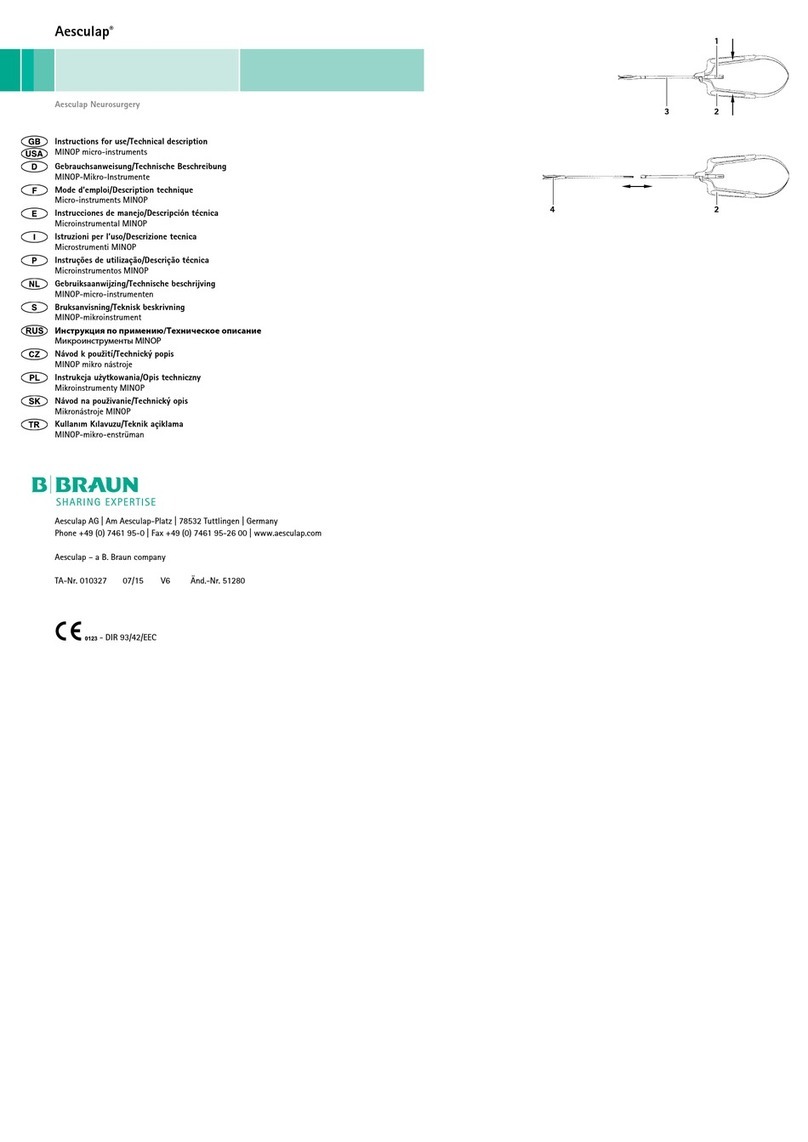

►Insert transport brace 1on one side into the holding receptacle for

transport brace 6, see Fig. A2.

►Widen the transport brace 1and insert it into the other holding recep-

tacle for transport brace 6. Make certain that the transport brace is

correctly mounted.

Note

Disassembly is carried out in the reverse order.

6. Working with the product

How to work with the ELAN 4 electro system and its accessory compo-

nents is described in the instructions for use of the ELAN 4 electro control

unit GA800, see TA014401.

7. Disassembling the pedal for cleaning

►Lift the pedal 3upwards, see Fig. B.

►Remove pedal 3from the guide bolts for pedal 7.

►Remove the pedal 3in an upward direction, see Fig. C.

8. Mounting the pedal (after cleaning)

►Insert pedal 3onto guide bolts for pedal 7, see Fig. B.

►Fold pedal 3down.

9. Processing procedure

9.1 General safety notes

Note

Adhere to national statutory regulations, national and international stan-

dards and directives, and local, clinical hygiene instructions for reprocess-

ing.

Note

For patients with Creutzfeldt-Jakob disease (CJD), suspected CJD, or possi-

ble variants of CJD, observe the relevant national regulations concerning

the reprocessing of products.

Note

It should be noted that successful reprocessing of this medical device can

only be guaranteed following prior validation of the reprocessing method.

The operator/reprocessing technician is responsible for this.

9.2 Reusable products

The life time of the product is limited due to damage, normal wear and

tear, type and duration of use, in addition to the handling, storing and

transporting of the product.

Careful visual and functional testing prior to next use is the best way to

identify a malfunctioning product.

9.3 Preparation before cleaning

►Remove any visible surgical residues as much as possible with a damp,

lint-free cloth.

►Carry out non-fixating/NaCl-free pre-cleaning immediately after use.

Note

The pedal can be removed for cleaning, see Disassembling the pedal for

cleaning.

9.4 Cleaning/disinfection

Product-specific safety instructions for the reprocessing procedure

CAUTION

Damage to, or destruction of the product caused by mechanical clean-

ing/disinfection!

►Only clean and disinfect the product manually.

►Do not sterilize the product under any circumstances.

CAUTION

Damage to the product due to inappropriate cleaning/disinfecting

agents!

►Only use cleaning/disinfecting agents approved for surface clean-

ing. Follow the manufacturer’s instructions for the respective

cleaning/disinfecting agent.

Note

If the product is heavily soiled, Aesculap recommends manual cleaning

including immersion disinfection.

Short actuation Activation/deactivation of the coolant pump.

The pump only works when a motor is running.

Prolonged Pressing Flush function

The pump operates until activation is ended.

Document No.: TA014410 - Version: 1.0 - Document ID: SOP-AIC-5002243 Date/Time Printed/Viewed: 2022-04-13 16:00 (CET)

Effective