Aesculap Spine

S

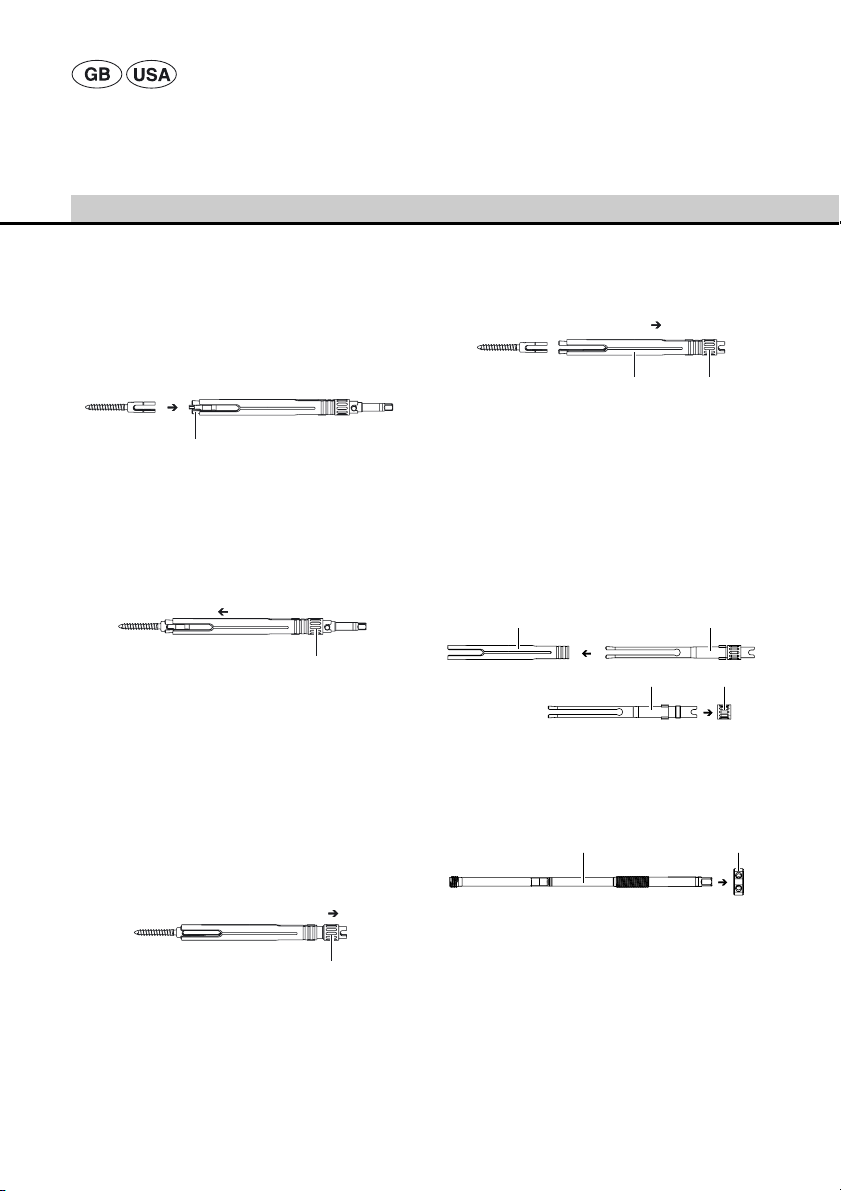

percutaneous instruments

6

General information

To prevent increased contamination of loaded instru-

ment trays during use, please ensure that contami-

nated instruments are collected separately and not

returned to the instrument tray.

Dried or affixed surgical residues can make cleaning

more difficult or ineffective and lead to corrosion of

stainless steel. Consequently, the time interval

between application and processing should not exceed

6 hours, pre-cleaning fixating temperatures >45 °C

should not be used, and no fixating disinfectants (con-

taining aldehydes/alcohols) should be used.

Excessive measures of neutralizing agents or basic

cleaners may result in a chemical attack and/or to fad-

ing and the laser marking becoming unreadable visu-

ally or by machine for stainless steel.

Residues containing chlorine or chloride - e.g. in surgi-

cal residues, drugs, saline solutions and water for

cleaning, disinfection and sterilization - may cause

corrosion damage to stainless steel (pinholing, stress

corrosion), thus rendering the products unusable.

These must be removed by rinsing thoroughly with

demineralized water and then drying.

Only use process chemicals that have been tested and

approved (with VAH, DGHM or FDA approval, for

instance, or feature a CE mark) and are recommended

by the chemical manufacturer as being compatible

with the materials. All the chemical manufacturer's

application specifications regarding temperature, con-

centration and contact time should be strictly

observed. Failure to do so can result in the following

problems:

• Visible changes to materials e.g. fading or changes

in the color of titanium or aluminum. As regards

aluminum, visible changes to the surface may

already occur at a pH level of >8 in the application/

working solution.

• Material damage such as corrosion, cracks, frac-

tures, premature deterioration or swelling.

¾Do not use process chemicals that cause stress

cracks or brittleness in plastics.

¾Clean the product immediately after use.

Please see www.a-k-i.org for more detailed informa-

tion on hygienically safe reprocessing which is protec-

tive of materials and retains their value.

¾Use suitable cleaning/disinfecting agents if the

product is put away in a wet condition. To prevent

foam formation and reduced effectiveness of the

process chemicals: Prior to mechanical cleaning

and disinfection, rinse the product thoroughly with

running water.