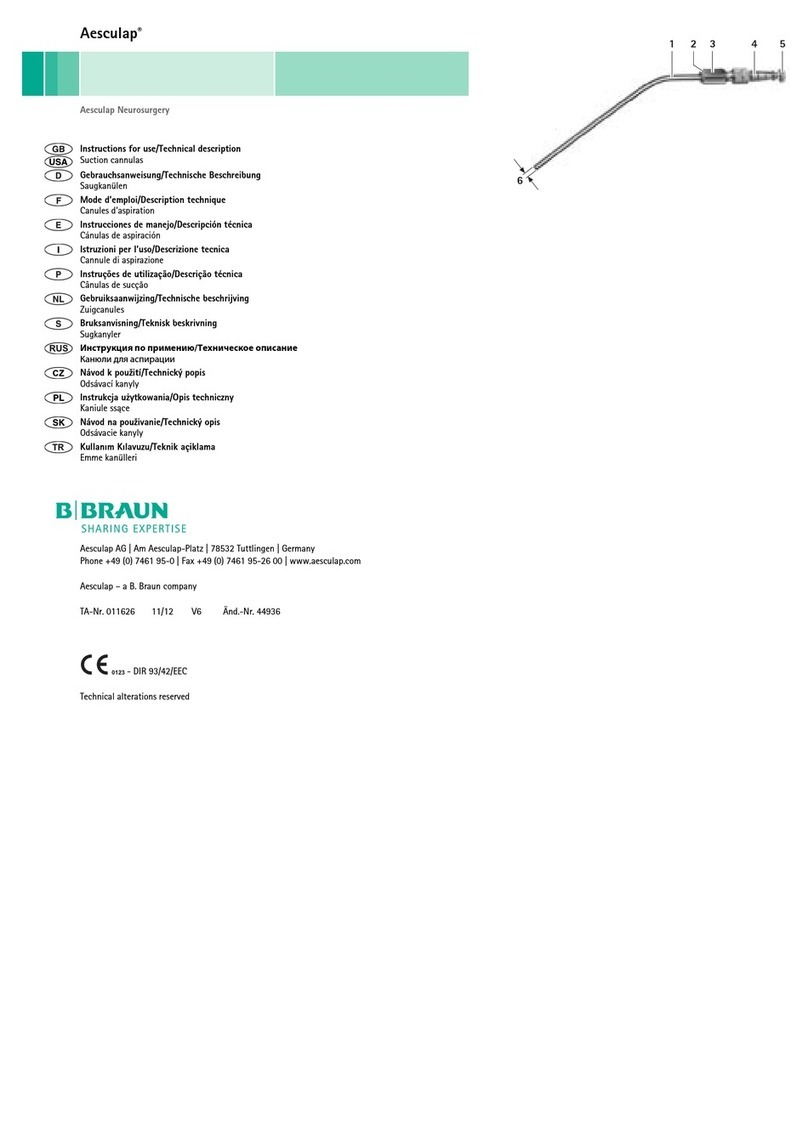

Aesculap Neurosurgery

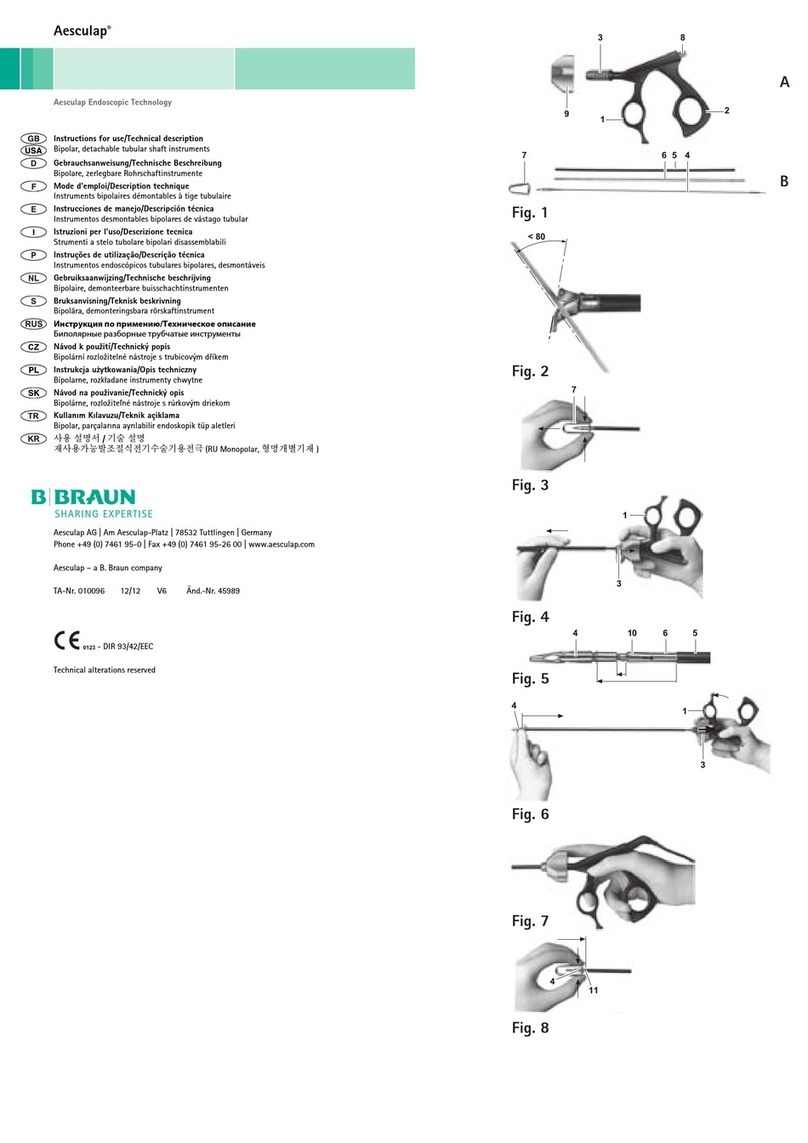

Tubular shaft instruments

6

¾Do not use oxidizing chemicals (e.g. H2O2) for

mechanical cleaning, as these can cause bleaching

or layer loss.

¾Do not use process chemicals that cause stress

cracks or brittleness in plastics.

¾Clean the product immediately after use.

Please see www.a-k-i.org for more detailed informa-

tion on hygienically safe reprocessing which is protec-

tive of materials and retains their value.

¾Use appropriate cleaning/disinfecting agents if the

product is put away in wet condition. To prevent

foam formation and reduced effectiveness of the

process chemicals: Prior to mechanical cleaning

and disinfection, rinse the product thoroughly with

running water.

Preparations at the place of use

¾Disassemble the product immediately after use, as

described in the respective instructions for use.

¾Open up instruments with hinges.

¾Rinse non-visible surfaces such as those in instru-

ments with concealed crevices, lumens or complex

geometries, preferably with distilled water, using a

disposable syringe for instance.

¾Remove any visible surgical residues to the extent

possible with a damp, lint-free cloth.

¾Transport the dry product in a sealed waste con-

tainer for cleaning and disinfection within 6 hours.

Preparation before cleaning

¾Disassemble the product prior to cleaning, see Dis-

assembly.

Cleaning/disinfection

¾Carry out ultrasound cleaning:

– as an effective mechanical supplement to manual

cleaning/disinfection.

– as a pre-cleaning procedure for products with

encrusted residues, in preparation for mechanical

cleaning/disinfection.

– as an integrated mechanical support measure for

mechanical cleaning/disinfection.

– for additional cleaning of products with residues

left after mechanical cleaning/disinfection.

¾Clean and disinfect microsurgical products

mechanically if they can be placed securely in the

machine or on the positioning aids.

Manual cleaning/disinfection

¾Keep working tips open for cleaning.

¾When cleaning instruments with movable hinges,

ensure that these are in an open position and, if

applicable, move the joint while cleaning.

¾Prior to manual disinfecting, allow water to drip off

for a sufficient length of time to prevent dilution of

the disinfecting solution.

¾After manual cleaning/disinfection, check visible

surfaces visually for residues.

¾Where necessary, repeat the cleaning process.

CAUTION

Damage to the product due to

inappropriate cleaning/disinfecting

agents and/or excessive tempera-

tures!

¾Use cleaning and disinfecting

agents approved for aluminum,

plastics, and high-grade

steel, for example, according to

the manufacturer's instructions.

¾Observe specifications regarding

concentration, temperature and

exposure time.