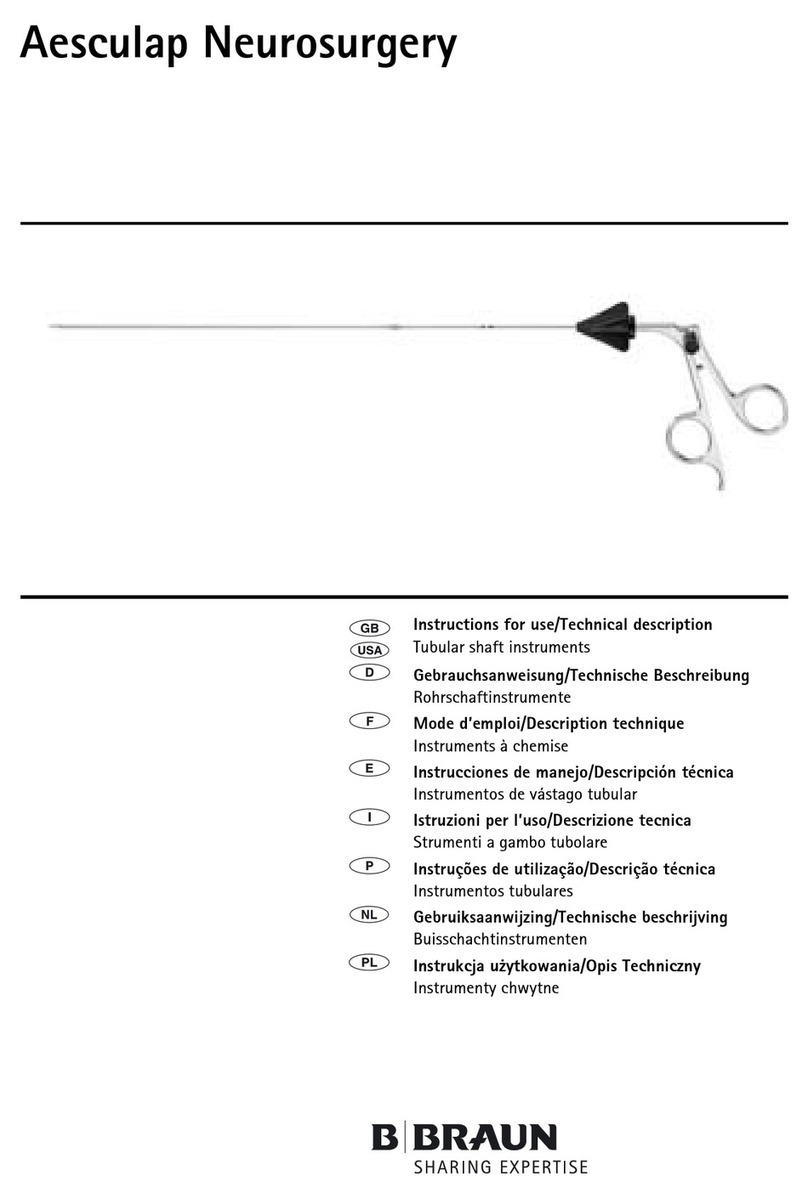

Aesculap Neurosurgery

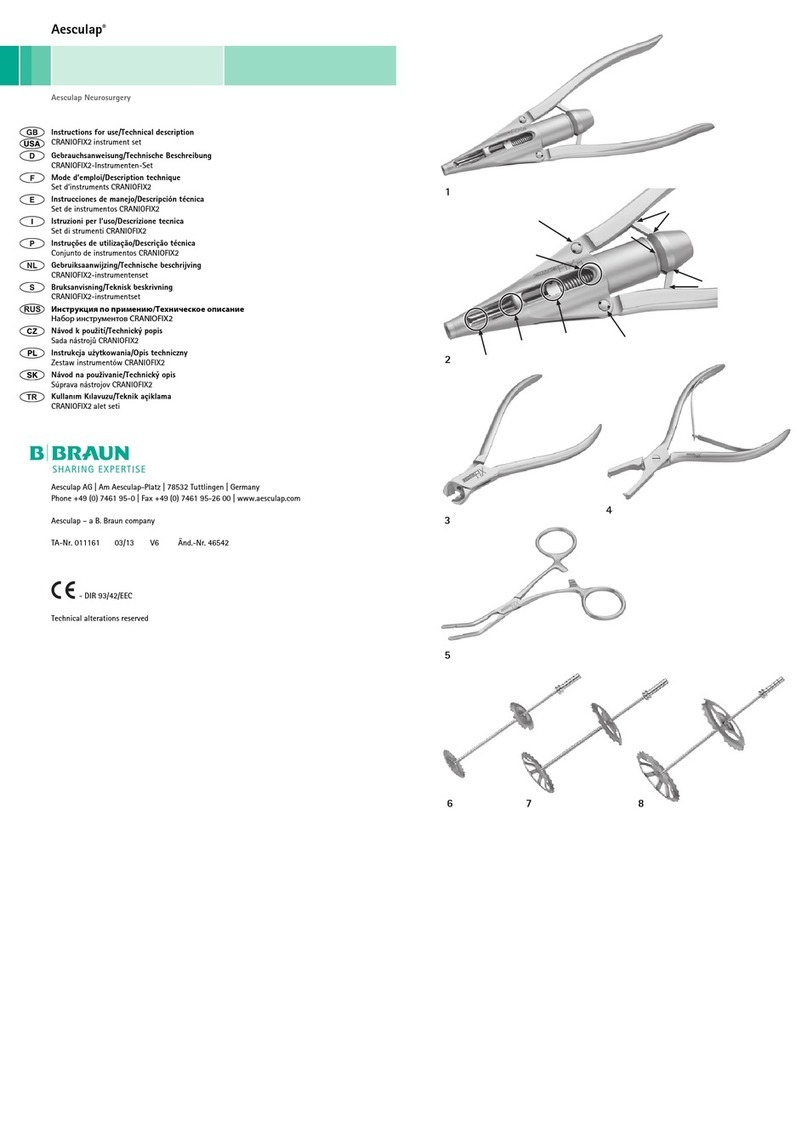

AVM microclip applying forceps

6

General notes

To avoid unnecessary, excessive contamination of the

complete instrument tray during operations, take care

that contaminated instruments are collected

separately and not put back into the instrument tray.

Encrusted or fixated residues from surgery can make

the cleaning process more difficult or ineffective, and

can cause corrosion of stainless steels. To avoid this,

the time interval between application and processing

should not exceed 6 h, and neither fixating pre-

cleaning temperatures >45 °C nor any fixating

disinfecting agents (active ingredient: aldehyde,

alcohol) be used.

Excessive doses of neutralizers or basic detergents can

cause chemical degradation and/or fading and

obliteration of laser inscriptions on stainless steel

surfaces, regarding visual reading and machine-

readability of the inscriptions.

Residues containing chlorine or chlorides e.g. in

surgical residues, medicines, saline solutions and in the

service water used for cleaning, disinfection and

sterilization will cause corrosion damage (pitting,

stress corrosion) and result in the destruction of

stainless steel products. To remove such residues, the

products must be rinsed sufficiently with fully

desalinated water and dried thoroughly.

Only process chemicals that have been tested and

approved (e.g. VAH/DGHM or FDA approval or CE mark)

and which are compatible with the product’s materials

according to the chemical manufacturers’

recommendations may be used for processing the

product. All process parameters specified by the

chemical’s manufacturer, such as temperatures,

concentrations and exposure times, must be strictly

observed. Failure to do so can result in the following

problems:

• Optical deterioration, e.g. fading or discoloration of

titanium or aluminum surfaces. For aluminum, pH

>8 in the application/process can already cause

visible surface changes.

• Material damage, e.g. corrosion, cracks, fracturing,

premature aging or swelling.

¾Do not use process chemicals that cause stress

cracking or brittleness of plastics.

¾For further detailed advice on hygienically safe and

material/value-preserving reprocessing, see

www.a-k-i.org, link to Publications, Red Brochure –

Proper maintenance of instruments.

¾Use suitable cleaning/disinfecting agents if the

product is put away in wet condition. To prevent

foam formation and reduced effectiveness of the

process chemicals: Prior to mechanical cleaning

and disinfecting, rinse the product thoroughly with

running water.