C.A. Technologies H2O-CPR User manual

Other C.A. Technologies Paint Sprayer manuals

C.A. Technologies

C.A. Technologies Panther 200H User manual

C.A. Technologies

C.A. Technologies Techline JR User manual

C.A. Technologies

C.A. Technologies Tomahawk TG User manual

C.A. Technologies

C.A. Technologies TOMCAT 100C Troubleshooting guide

C.A. Technologies

C.A. Technologies Panther 200Z User manual

C.A. Technologies

C.A. Technologies CAT-Xpress Troubleshooting guide

C.A. Technologies

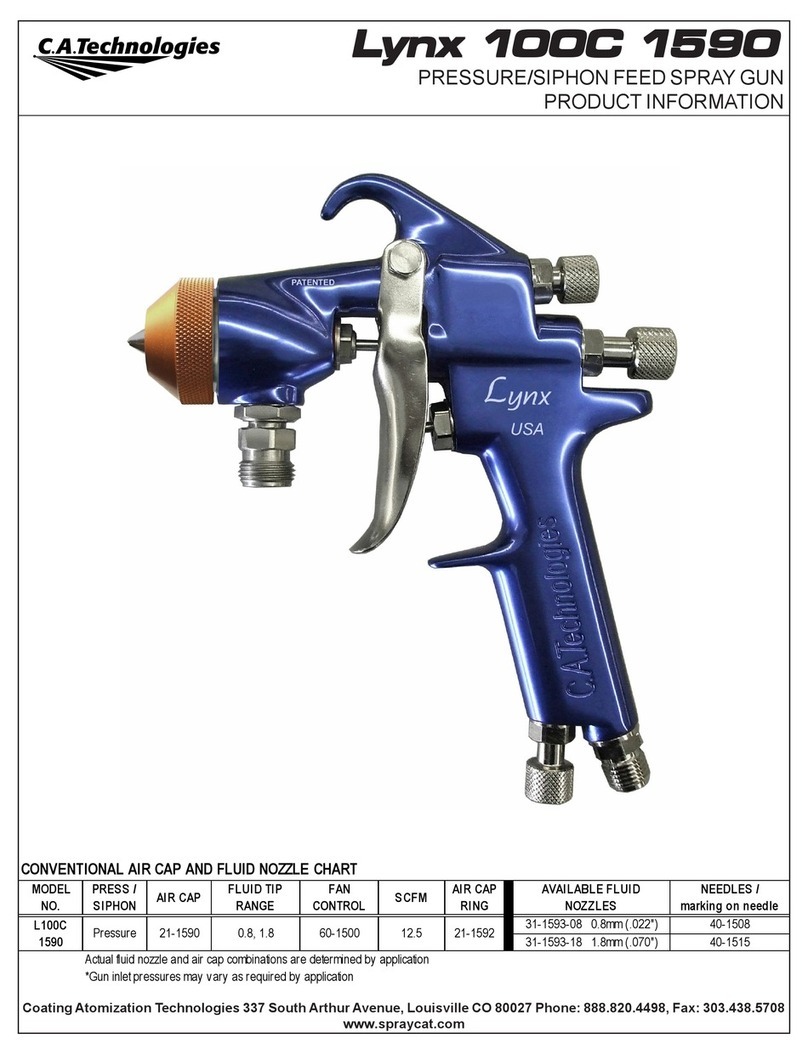

C.A. Technologies Lynx 100C 1590 User manual

C.A. Technologies

C.A. Technologies FE-Line Fine Finish User manual

C.A. Technologies

C.A. Technologies Cougar User manual

C.A. Technologies

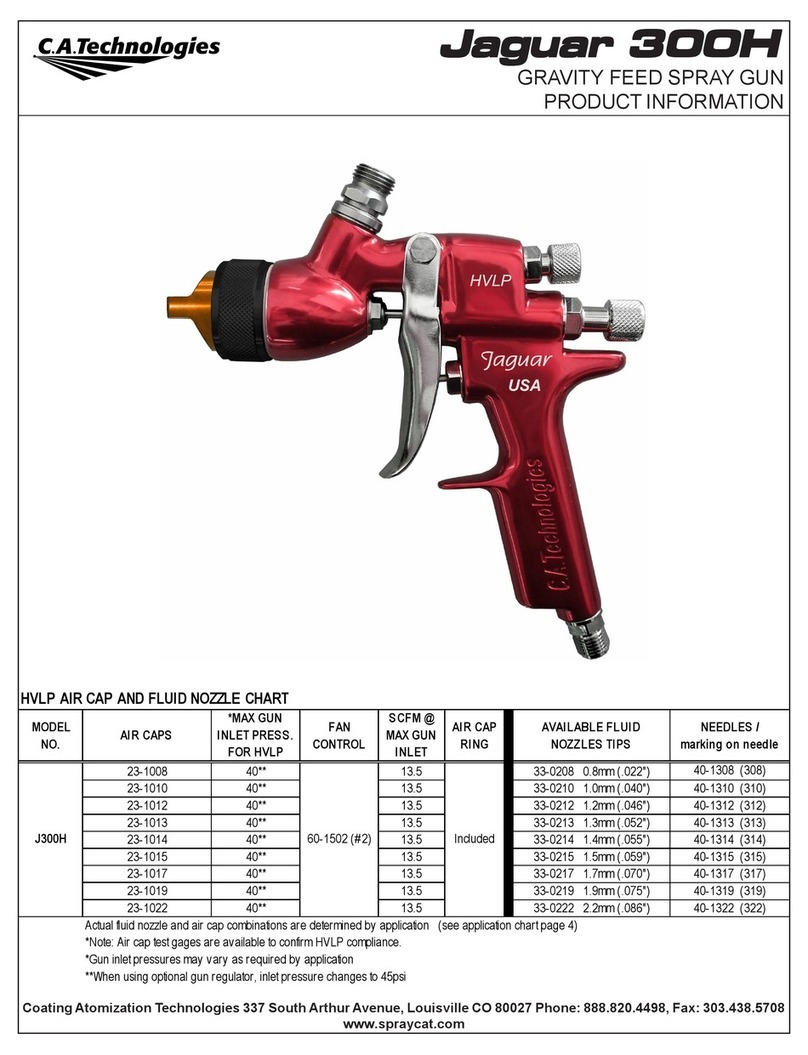

C.A. Technologies Jaguar 300H User manual

C.A. Technologies

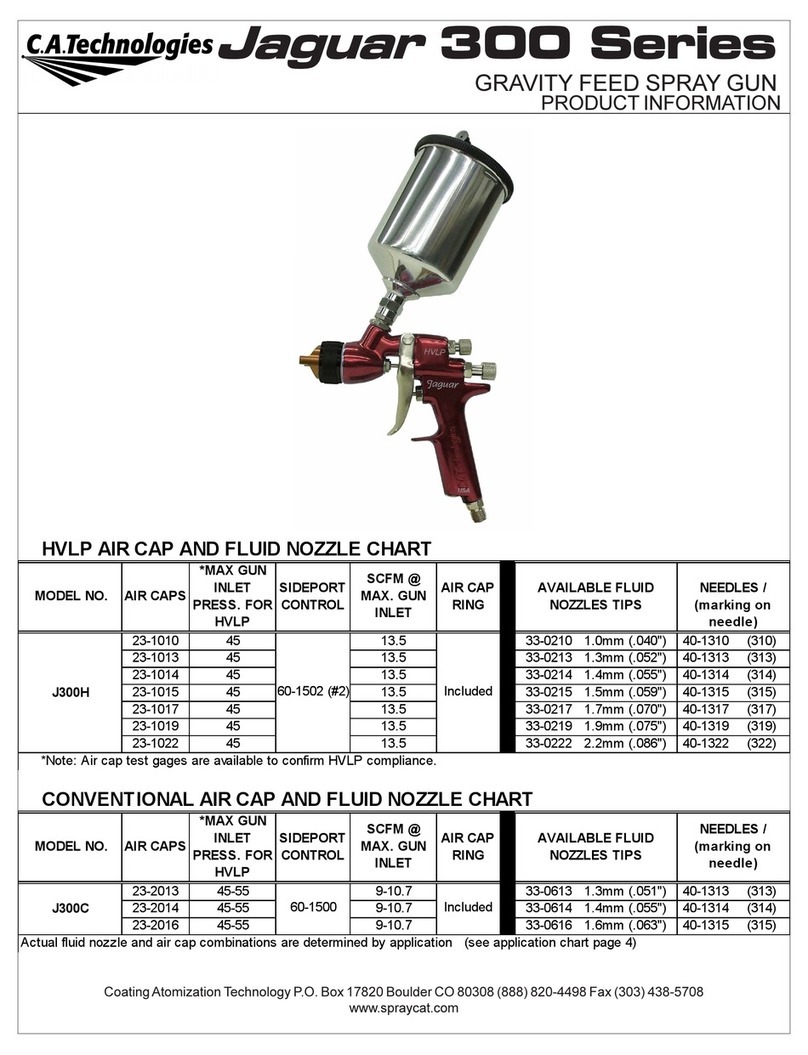

C.A. Technologies Jaguar 300 Series User manual

C.A. Technologies

C.A. Technologies JAGUAR SLP User manual

C.A. Technologies

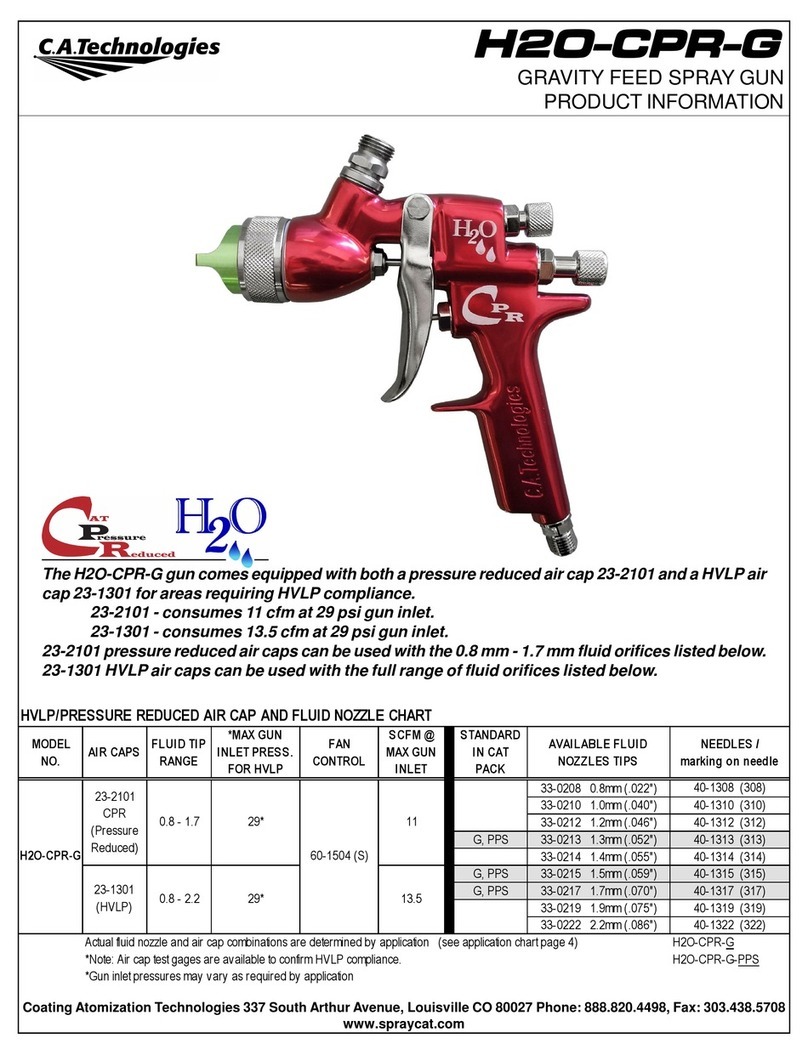

C.A. Technologies H2O-CPR-G User manual

C.A. Technologies

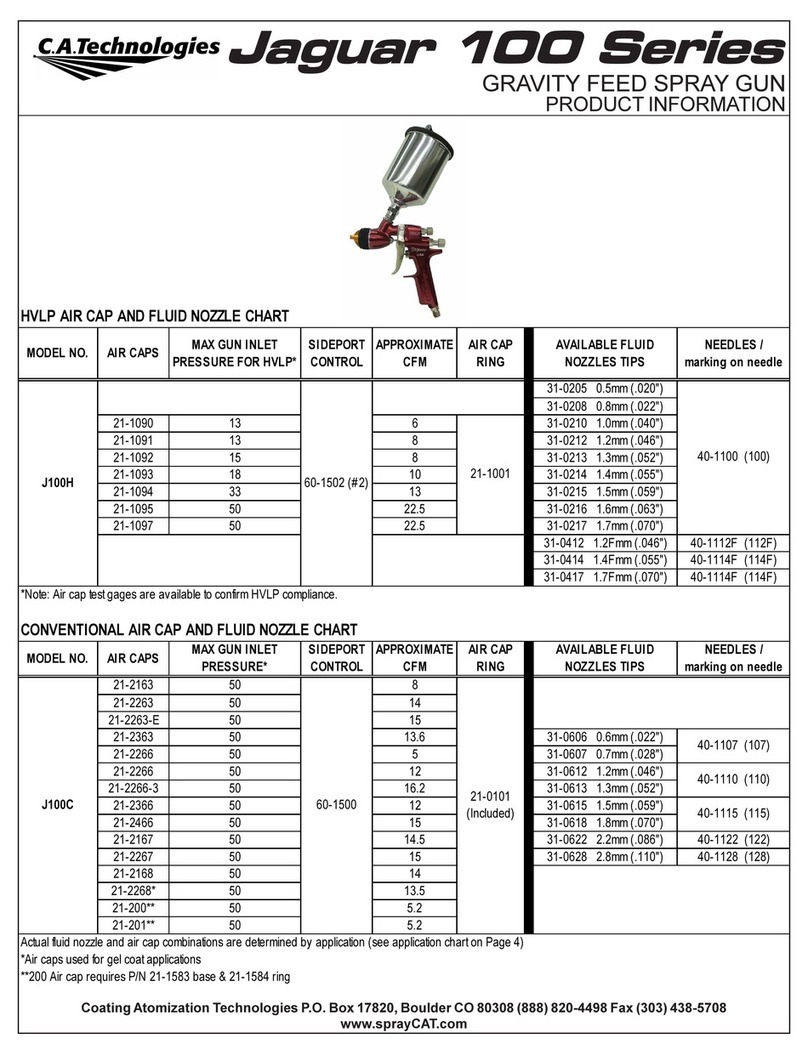

C.A. Technologies Jaguar 100 Series User manual

C.A. Technologies

C.A. Technologies CPR-FE User manual

C.A. Technologies

C.A. Technologies CPR User manual

C.A. Technologies

C.A. Technologies AutoCAT 300C User manual

C.A. Technologies

C.A. Technologies Lynx 300C Troubleshooting guide

C.A. Technologies

C.A. Technologies Lynx 100 Series User manual

C.A. Technologies

C.A. Technologies Lynx 100CVT User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual