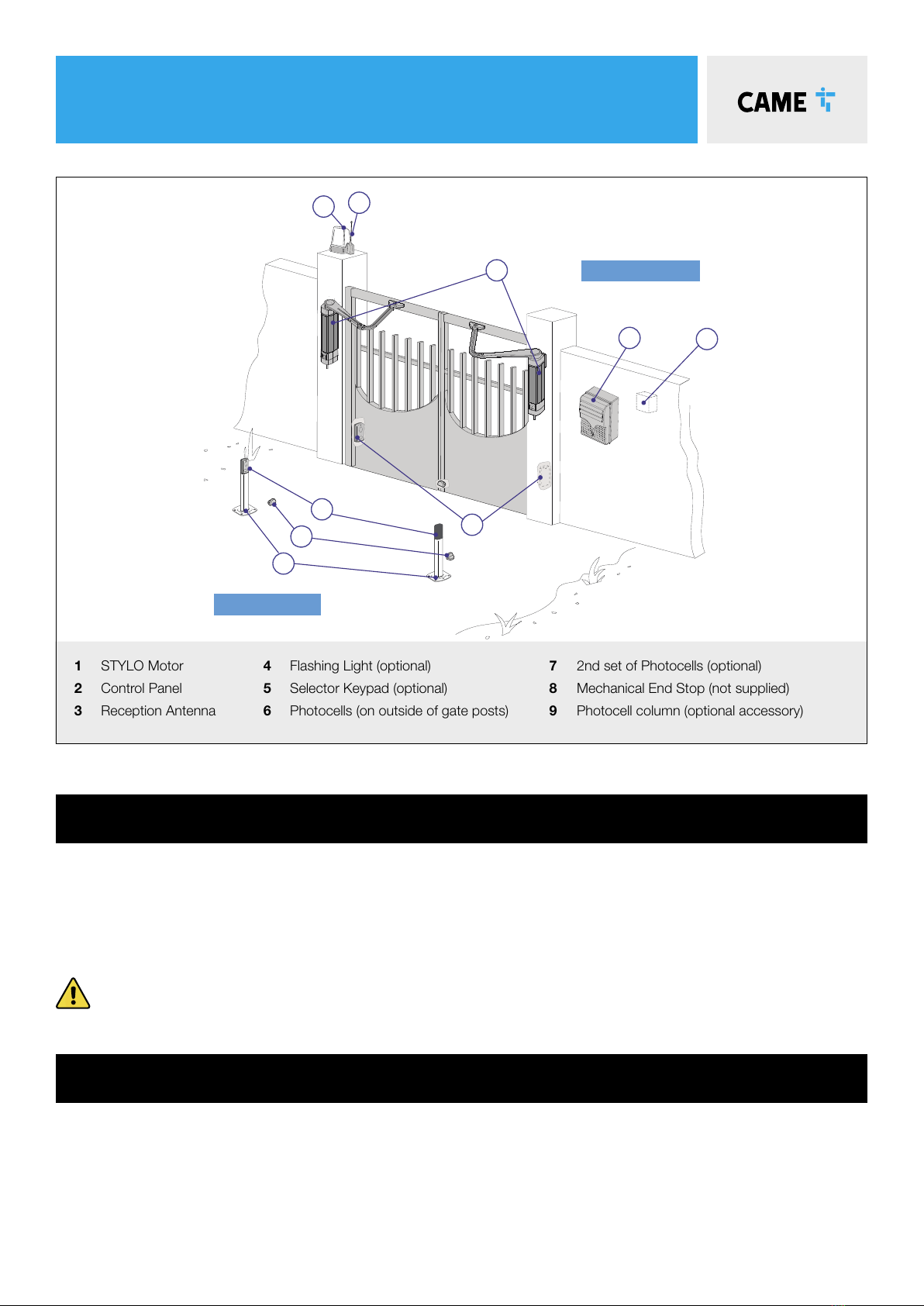

ZL92Z: QUICK START GUIDE

Should the gates not operate as suggested above,

call CAME helpline 0115 921 0430 for technical support.

Important!

Ensure the wiring is complete (refer to the wiring diagram) & any required physical stops are set before

commencing with programming Tick

1. Power on the control panel

2. Press and hold the button for 2 seconds to access programming. ( F1 appears on the display).

3. Disable total stop – F1 – O

4. Disable safety inputs – F2& F3– O

5. Disable safety test – F5– O

6. Set the number of motors – F46– 0

7. Set the motor type – A1 – 2

CAUTION, Ensure the gate movement area is clear of all obstructions

8. Check the motor direction A2– 1

For motor 2, press and hold

The gate should open, if not reverse the motor cables for motor 2 (Connections M2, N2)

Leave the gate in the halfway position.

For motor 1, press and hold

The gate should open, if not reverse the motor cables for motor 1 (Connections M1, N1)

Leave the gate in the halfway position.

9. Setup the Encoder A3– 1

10. The Gates will now perform a close and open cycle.

12. Exit the programming using the button.

13. Check the gate operation by pulsing across connections 2 & 7, the gate will close

Please refer to the main manual for:

Changing automatic closing time, adjusting encoder settings if required

Safety inputs should now be configured and the gate force tested as required.

Please refer to the full manual to complete the commissioning.

The installation must be carried out

by skilled and qualified personnel

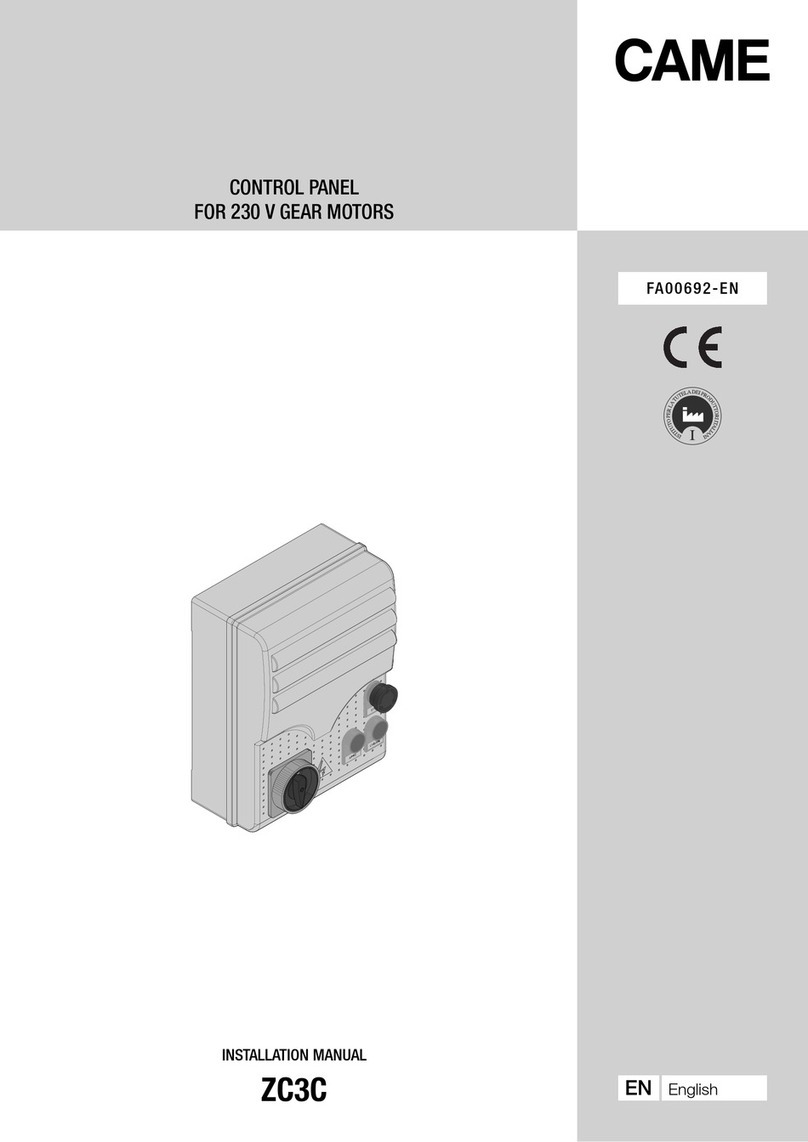

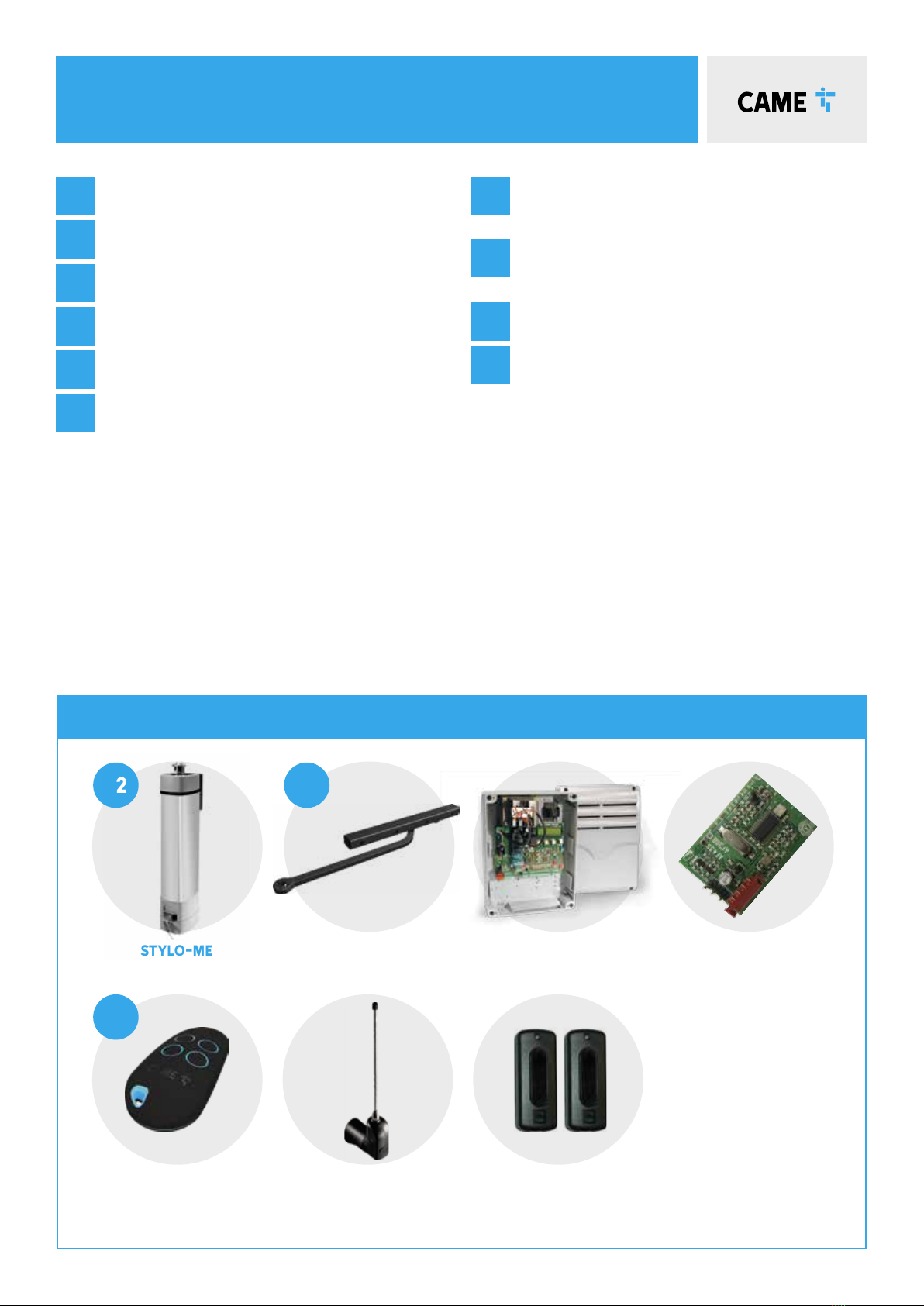

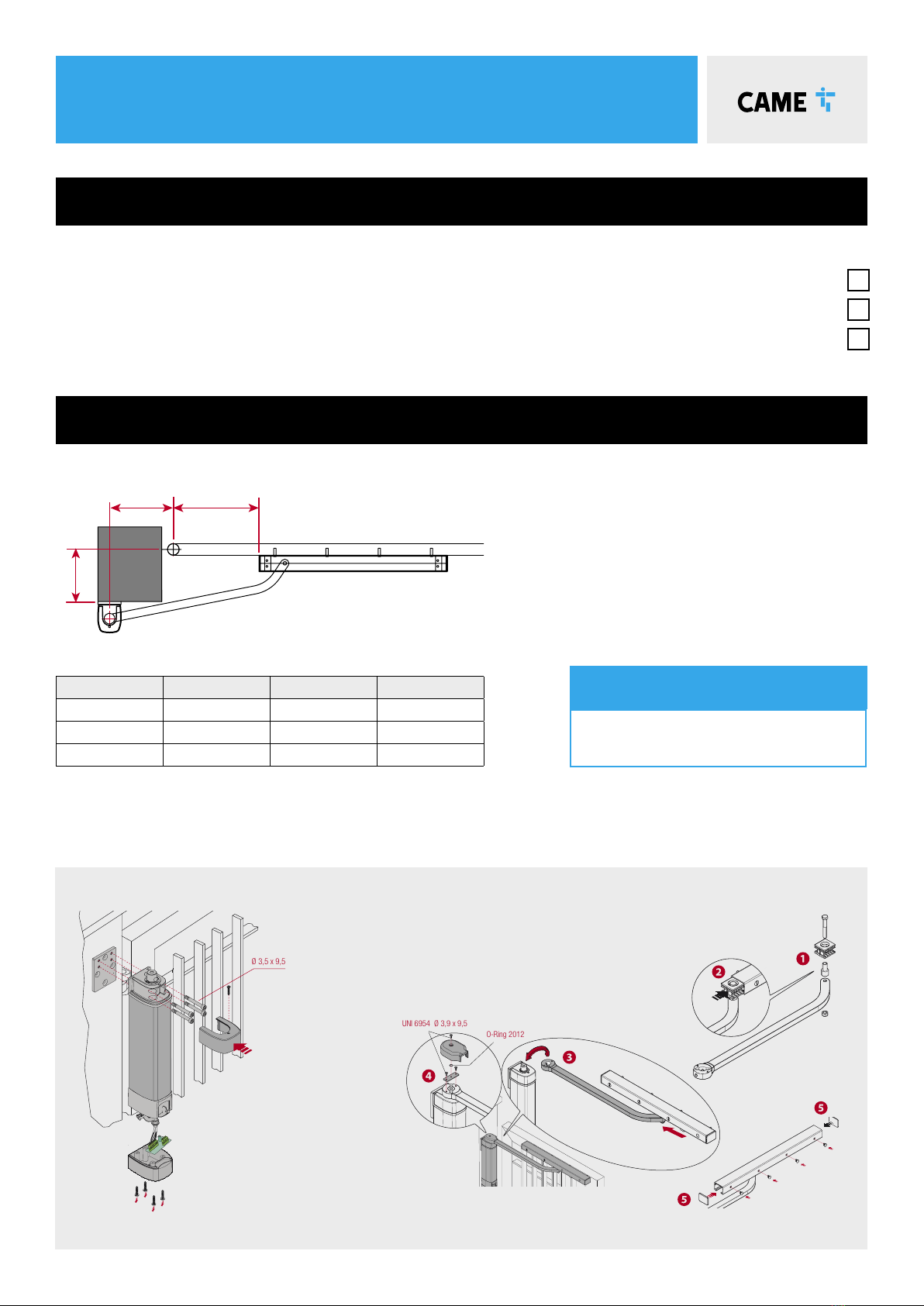

button - used to perform the following operations:

• Exit the menu

• Delete the changes

• Go back to the previous screen

buttons - used to perform the following operations:

• Navigate the menu

• Increase or decrease values

button - used to perform the following operations

• Access menus

• Confirm a choice

1

2

3

1 2 3