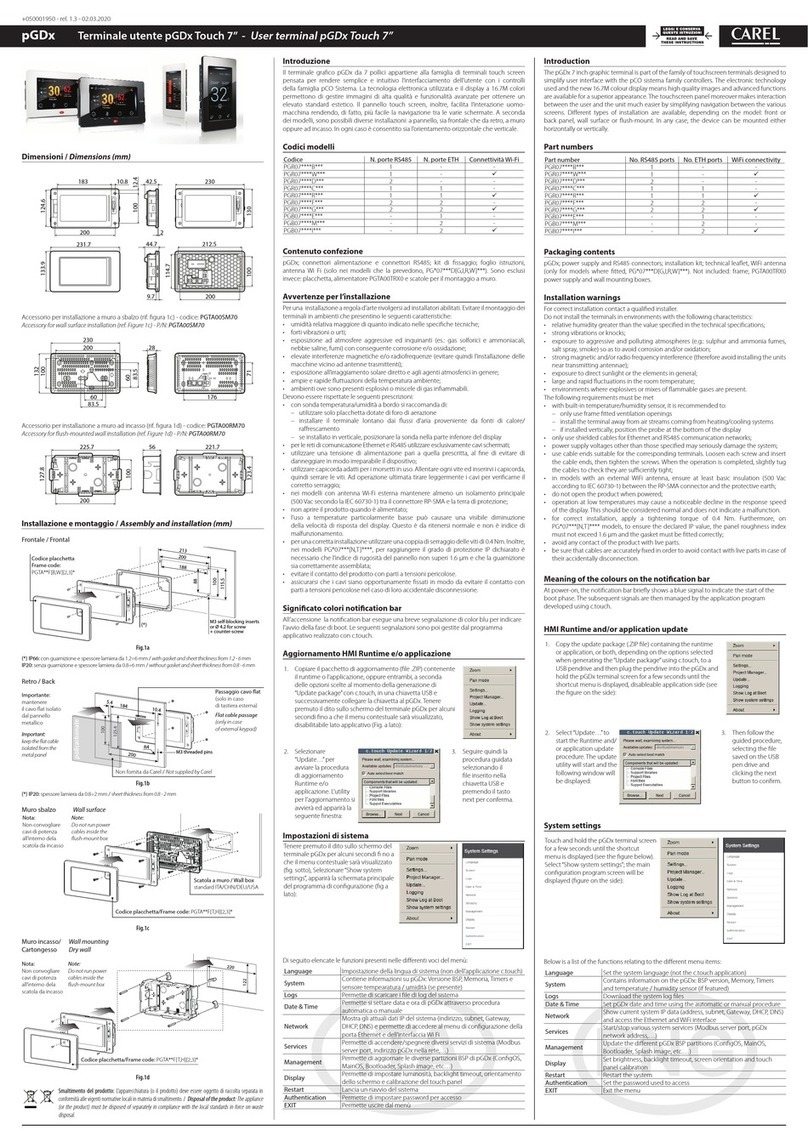

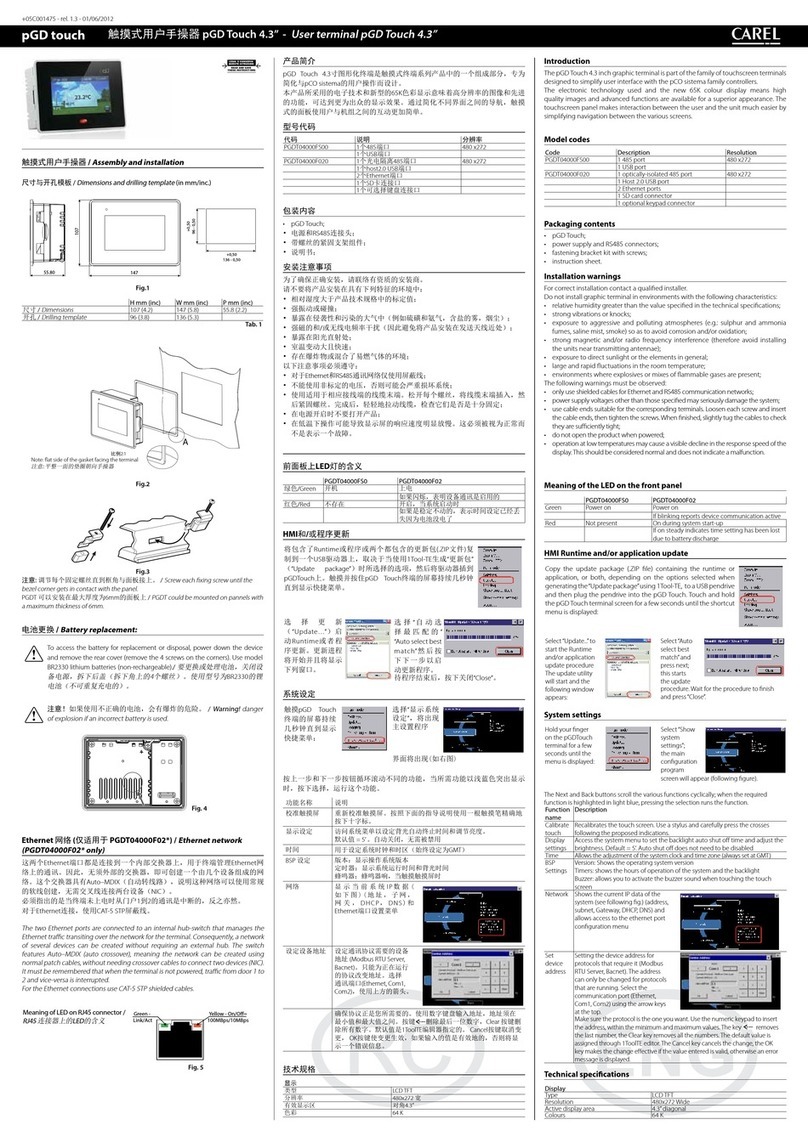

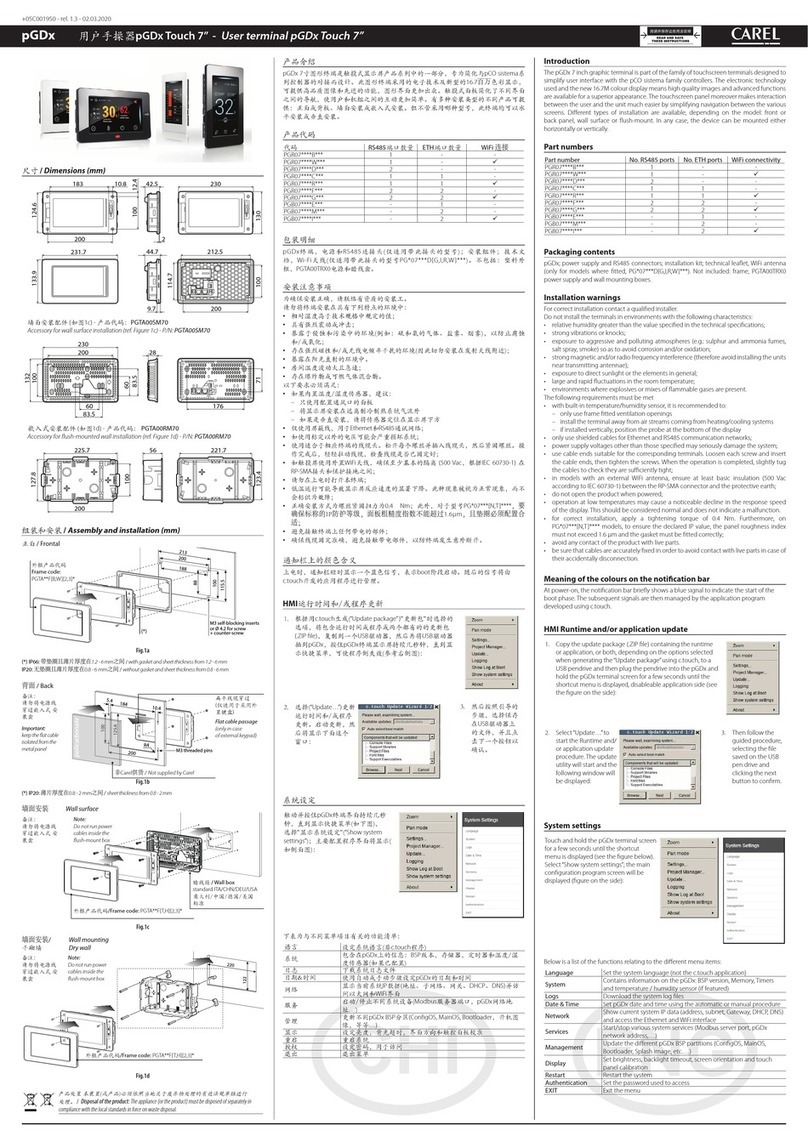

drilling template

A

B

H

LC4mm

0.16”

Fig1 / 1

Model A B C H L

pGD 7 (“0690) 176 (“0535) 136 (“0177) 45 (“0579) 147 (“0736) 187

Tab 1 / Tab 1

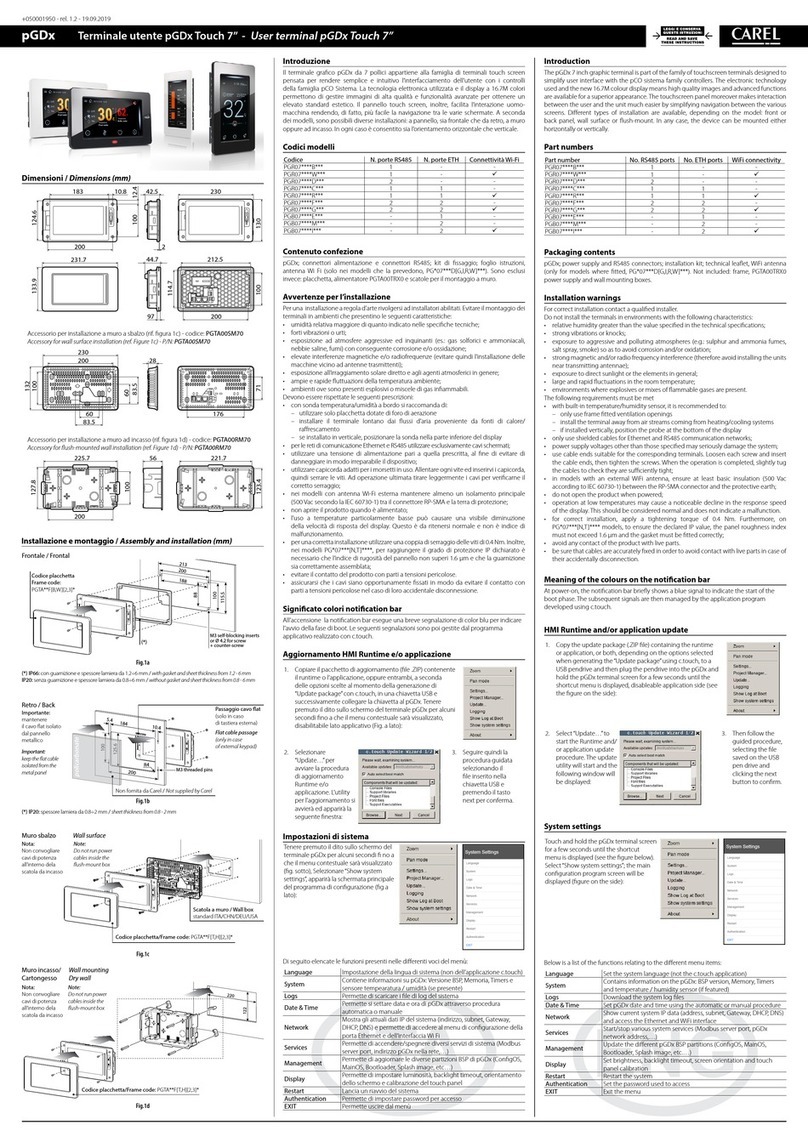

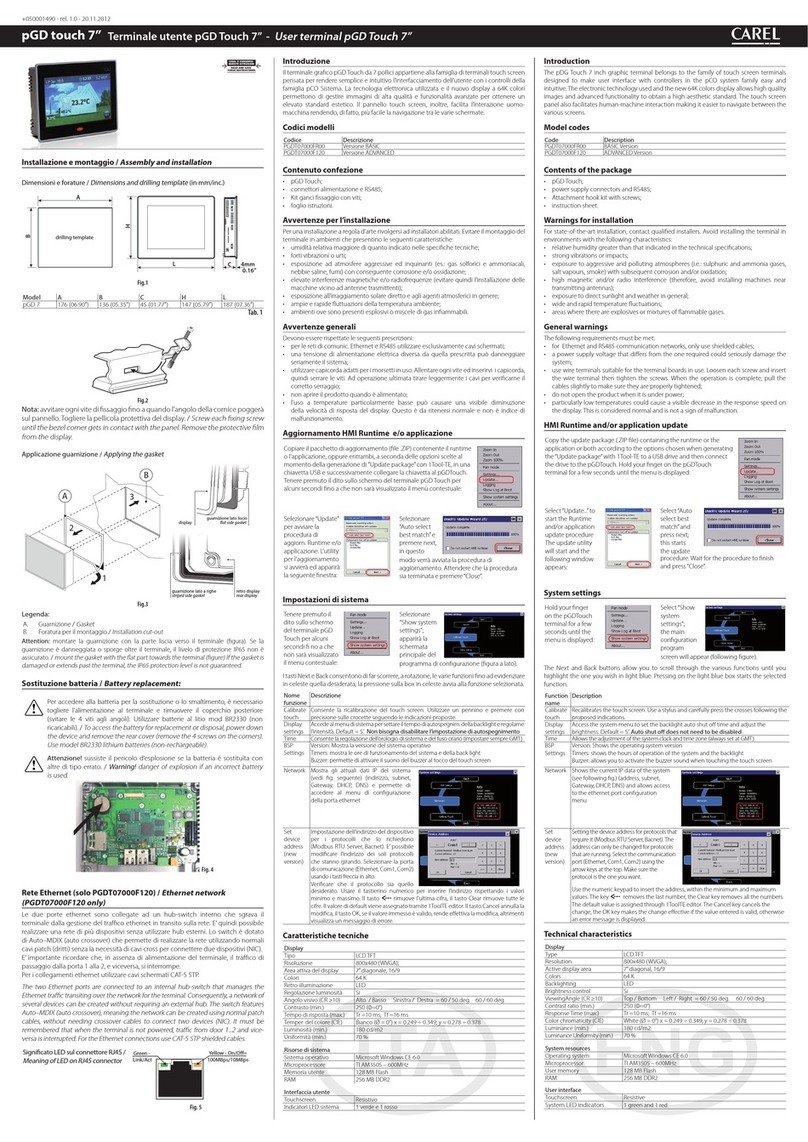

Fig2 / 2

Note: Screw each xing screw until the bezel corner gets in contact with the

/ .panel. Remove the protective lm from the display

A

2

1

3

B

guarnizione lato liscio

flat side gasket

display

guarnizione lato a righe

striped side gasket

retro display

rear display

guarnizione lato liscio

flat side gasket

display

guarnizione lato a righe

striped side gasket

retro display

rear display

Fig3 / 3

Legend /

A Gasket /

B Installation cut-out /

Attention: mount the gasket with the at part towards the terminal (gure) If the gasket is

damaged or extends past the terminal, the IP65 protection level is not guaranteed. /

()

IP65

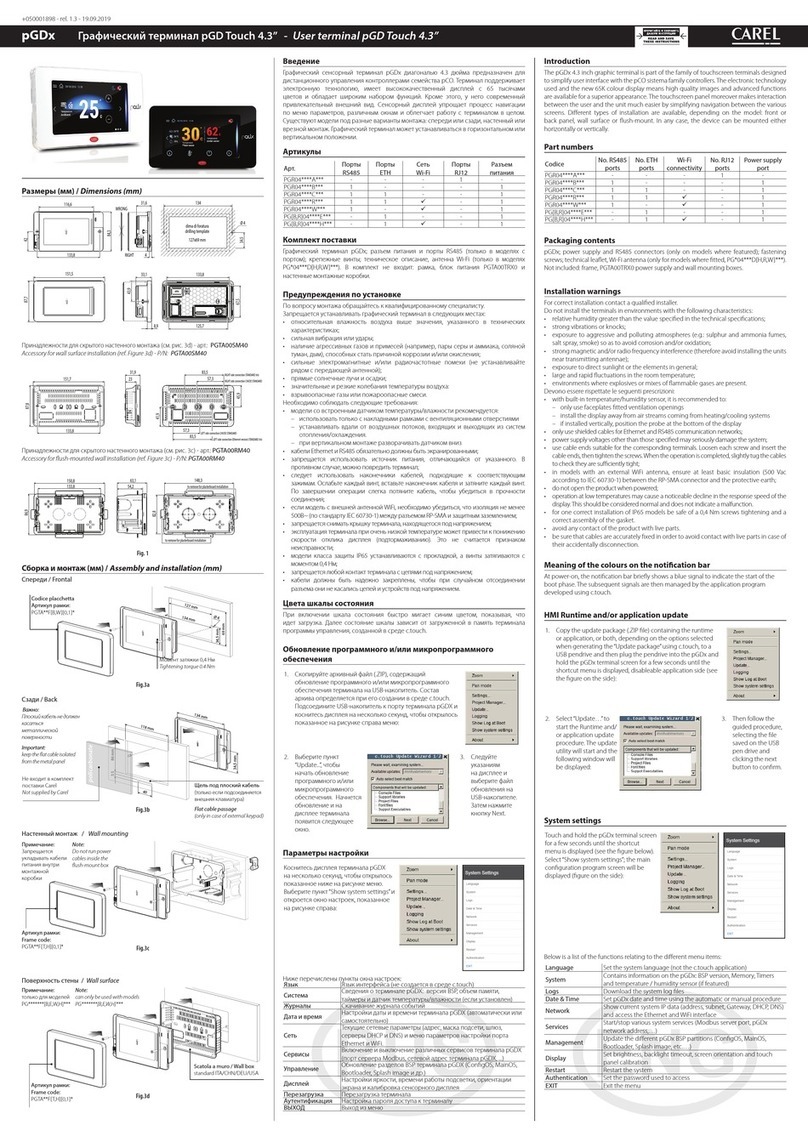

To access the battery for replacement or disposal, power down the device

and remove the rear cover (remove the 4 screws on the corners). Use

/ .(model BR2330 lithium batteries (non-rechargeable

(

) BR2330 (

)

/ Warning! danger of explosion if an incorrect battery is used

!

Fig4 / 4

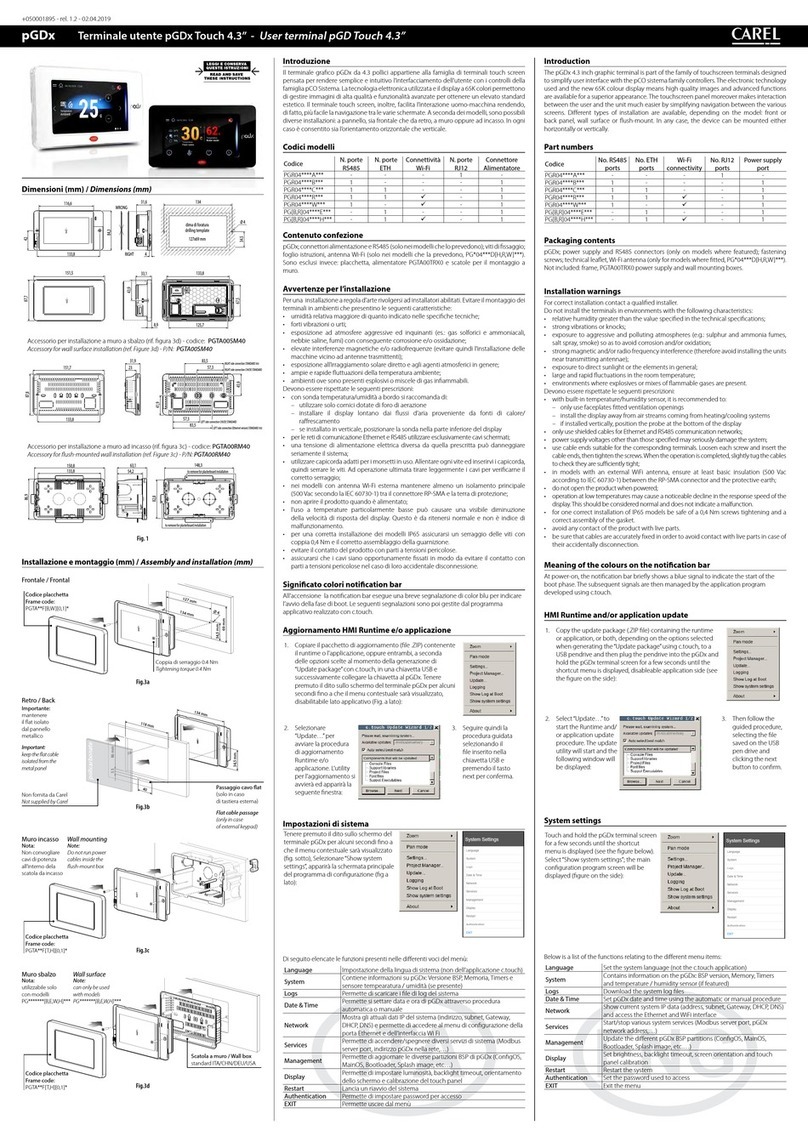

07000F120

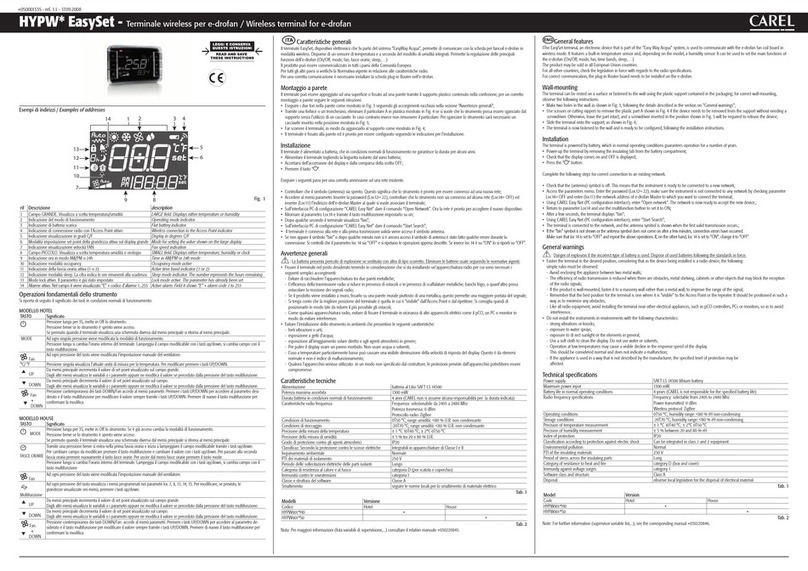

The two Ethernet ports are connected to an internal hub-switch that manages the

Ethernet trac transiting over the network for the terminal. Consequently, a network of

several devices can be created without requiring an external hub. The switch features

Auto–MDIX (auto crossover), meaning the network can be created using normal patch

cables, without needing crossover cables to connect two devices (NIC). It must be

remembered that when the terminal is not powered, trac from door 1...2 and vice-

versa is interrupted. For the Ethernet connections use CAT-5 STP shielded cables.

hub-switch

() ( ) Auto-MDIX

(NIC)

2 1

CAT-5 STP

Meaning of LED on RJ45 connector

RJ45 LED

Link/Act

100MBps/10MBps

Fig5 / 5

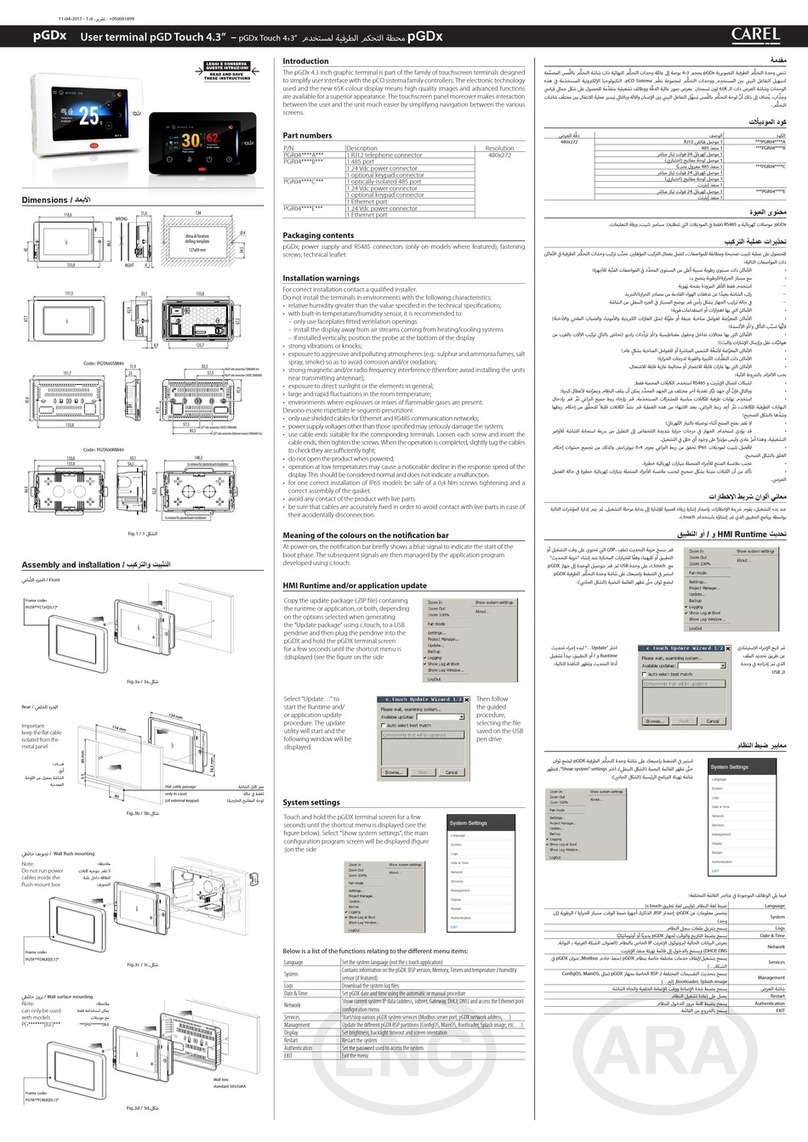

User terminal pGD Touch 7” – 7” pGD Touch 7”

+050001493 - rel. 1.0 - 20.11.2012

Introduction

The pDG Touch 7 inch graphic terminal belongs to the family of touch screen terminals

designed to make user interface with controllers in the pCO system family easy and

intuitive. The electronic technology used and the new 64K colors display allows high

quality images and advanced functionality to obtain a high aesthetic standard. The touch

screen panel also facilitates human-machine interaction making it easier to navigate

between the various screens.

Model codes

Code Description

PGDT07000FR00 BASIC Version

PGDT07000F120 ADVANCED Version

Contents of the package

• pGD Touch;

• power supply connectors and RS485;

• Attachment hook kit with screws;

• instruction sheet.

Warnings for installation

For state-of-the-art installation, contact qualied installers. Avoid installing the terminal in

environments with the following characteristics:

• relative humidity greater than that indicated in the technical specications;

• strong vibrations or impacts;

• exposure to aggressive and polluting atmospheres (i.e.: sulphuric and ammonia gases,

salt vapours, smoke) with subsequent corrosion and/or oxidation;

• high magnetic and/or radio interference (therefore, avoid installing machines near

transmitting antennas);

• exposure to direct sunlight and weather in general;

• wide and rapid temperature uctuations;

• areas where there are explosives or mixtures of ammable gases.

General warnings

The following requirements must be met:

• for Ethernet and RS485 communication networks, only use shielded cables;

• a power supply voltage that diers from the one required could seriously damage the

system;

• use wire terminals suitable for the terminal boards in use. Loosen each screw and insert

the wire terminal then tighten the screws. When the operation is complete, pull the

cables slightly to make sure they are properly tightened;

• do not open the product when it is under power;

• particularly low temperatures could cause a visible decrease in the response speed on

the display. This is considered normal and is not a sign of malfunction.

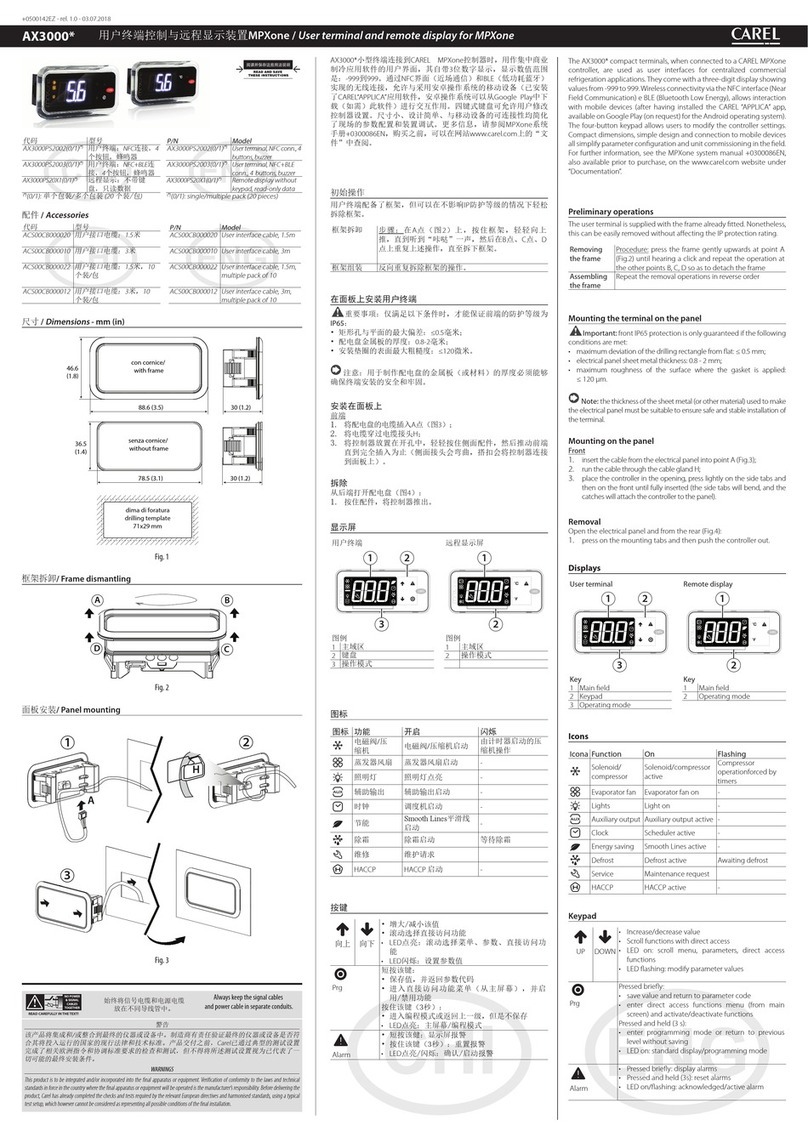

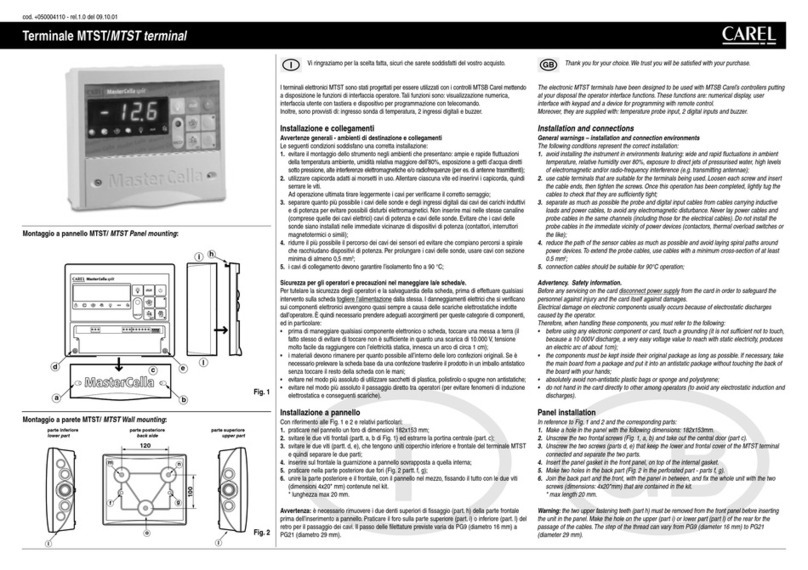

HMI Runtime and/or application update

Copy the update package (.ZIP le) containing the runtime or the

application or both according to the options chosen when generating

the “Update package” with 1Tool-TE to a USB drive and then connect

the drive to the pGDTouch. Hold your nger on the pGDTouch

:terminal for a few seconds until the menu is displayed

Select “Update...” to

start the Runtime

and/or application

update procedure

The update utility

will start and the

following window

:appears

Select “Auto

select best

match” and

;press next

this starts

the update

procedure. Wait for the procedure to nish

.“and press “Close

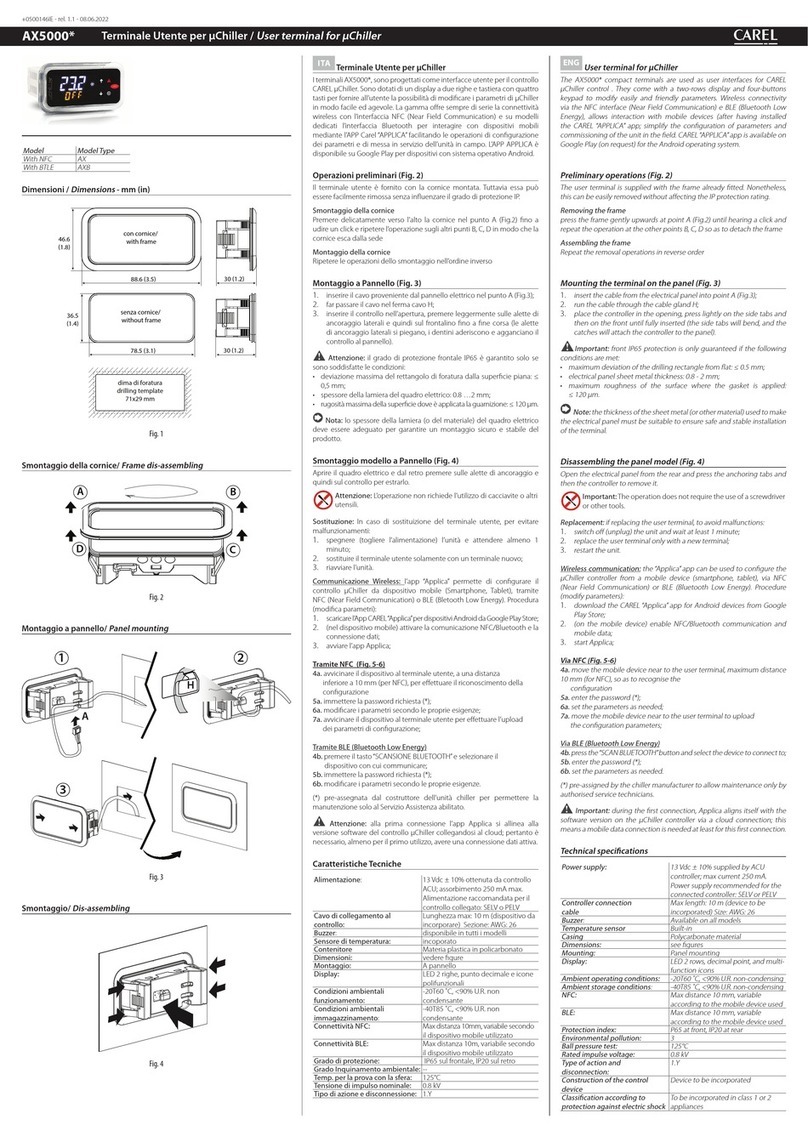

System settings

Hold your nger

on the pGDTouch

terminal for a few

seconds until the

:menu is displayed

Select “Show

system

settings”;

the main

conguration

program

.(screen will appear (following gure

The Next and Back buttons allow you to scroll through the various functions until you

highlight the one you wish in light blue. Pressing on the light blue box starts the selected

function.

Function

name Description

Calibrate

touch

Recalibrates the touch screen. Use a stylus and carefully press the crosses following the

proposed indications.

Display

settings

Access the system menu to set the backlight auto shut o time and adjust the

brightness. Default = 5’. Auto shut o does not need to be disabled

Time Allows the adjustment of the system clock and time zone (always set at GMT)

BSP

Settings

Version: Shows the operating system version

Timers: shows the hours of operation of the system and the backlight

Buzzer: allows you to activate the buzzer sound when touching the touch screen

Network Shows the current IP data of the system

(see following g.) (address, subnet,

Gateway, DHCP, DNS) and allows access

to the ethernet port conguration

menu

Set

device

address

(new

version)

Setting the device address for protocols that

require it (Modbus RTU Server, Bacnet). The

address can only be changed for protocols

that are running. Select the communication

port (Ethernet, Com1, Com2) using the

arrow keys at the top. Make sure the

protocol is the one you want.

Use the numeric keypad to insert the address, within the minimum and maximum

values. The key removes the last number, the Clear key removes all the numbers.

The default value is assigned through 1ToolTE editor. The Cancel key cancels the

change, the OK key makes the change eective if the value entered is valid, otherwise

an error message is displayed.

Technical characteristics

Display

Type LCD TFT

Resolution 800x480 (WVGA);

Active display area 7” diagonal, 16/9

Colors 64 K

Backlighting LED

Brightness control Si

ViewingAngle (CR ≥10) Top / Bottom Left / Right = 60 / 50 deg. 60 / 60 deg.

Contrast ratio (min.) 250 (Φ=0°)

Response Time (max.) Tr =10 ms; Tf =16 ms

Color chromaticity (CIE) White (Ø = 0°) x = 0.249 ÷ 0.349; y = 0.278 ÷ 0.378

Luminance (min.) 180 cd/m2

Luminance Uniformity (min.) 70 %

System resources

Operating system Microsoft Windows CE 6.0

Microprocessor TI AM3505 – 600MHz

User memory 128 MB Flash

RAM 256 MB DDR2

User interface

Touchscreen Resistive

System LED indicators 1 green and 1 red

pGD touch 7”

7 pGD Touch

pCO Sistema

64K

PGDT07000FR00BASIC PGDT07000F120ADVANCED

•;pGD Touch •;RS485 •;

•

•

•

• / (

) •(

) /

•

•

•

•; RS485

•

•

•

•

(ZIP )

pGDTouch USB 1Tool-TE " "

pGDTouch

() "Update"

/ Runtime

Auto select best”

,next “match

"Close"

()

pGDTouch

Show system”

;“settings

(

)

Back Next

Calibrate

touch

Display

settings

‘Default = 5

Time

(GMT )

BSP

Version

Timers

Buzzer

Network) IP

(DHCP, DNS , ,) (

Set device

address

)

(

Modbus RTU Server,)

(Bacnet

(Ethernet, Com1, Com2)

Clear ,

- OK , Cancel 1ToolTE editor

-

LCD TFT (800x480 (WVGA 9 / 16 , 7 64 K LED (10≤ ) 60 / 60 50 / 60 =

/ / (

) (0°= ) 250 ( )

16= ;

10= ( ) x = 0249 ÷ 0349; y = 0278 ÷ 0378 (0° = ) (

)

/ 180 (

) 70

Microsoft Windows CE 60 () TI AM3505 – 600MHz

128 MB Flash ()

DDR2 256

"Touchscreen" LED

1

1

(*) 1

RJ45 - 100/Auto-MDIX 10 (*) 2

RJ45 - 100/Auto-MDIX 10 USB

1 > ,

500 -

A (USB)

- 20 (**) 1

5,08

- 115 RS485

2

115 RS485

5,08

PGDT07000F120 (**) - PGDT07000F120 (*)

SELV CIRCUIT TNV

SVG 10