CAREL Industries HQs

Via dell’Industria, 11 - 35020 Brugine - Padova (Italy)

Tel. (+39) 0499716611 – Fax (+39) 0499716600 – www.carel.com – e-mail: carel@carel.com +0500142EZ - rel. 1.0 - 03.07.2018

CAREL保留在未事先通知的情况下对产品进行变更的权利。

CAREL reserves the right to modify its products without notice.

IMPORTANT WARNINGS

The CAREL product is a state-of-the-art product, whose operation is specied in the

technical documentation supplied with the product or can be downloaded, even prior to

purchase, from the website www.carel.com. - The client (builder, developer or installer

of the nal equipment) assumes every responsibility and risk relating to the phase of

conguration the product in order to reach the expected results in relation to the specic

nal installation and/or equipment. The lack of such phase of study, which is requested/

indicated in the user manual, can cause the nal product to malfunction of which CAREL can

not be held responsible. The nal client must use the product only in the manner described

in the documentation related to the product itself. The liability of CAREL in relation to its own

product is regulated by CAREL’s general contract conditions edited on the website www.

carel.com and/or by specic agreements with clients.

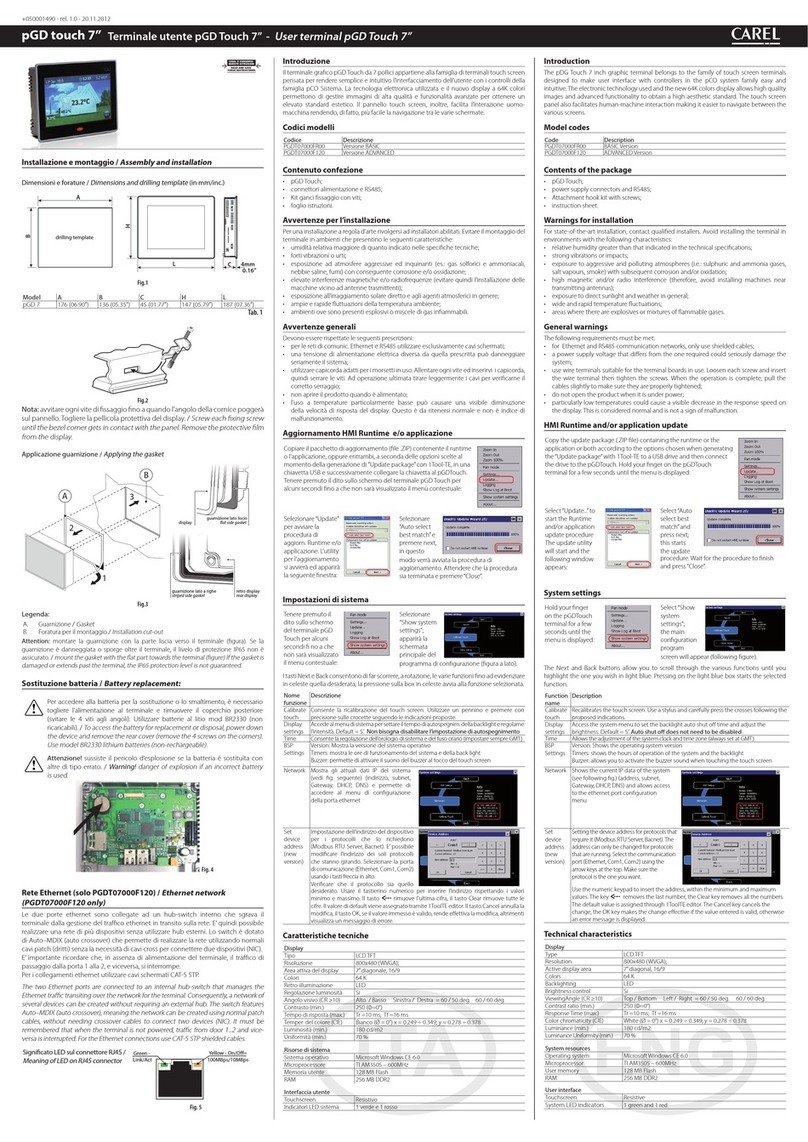

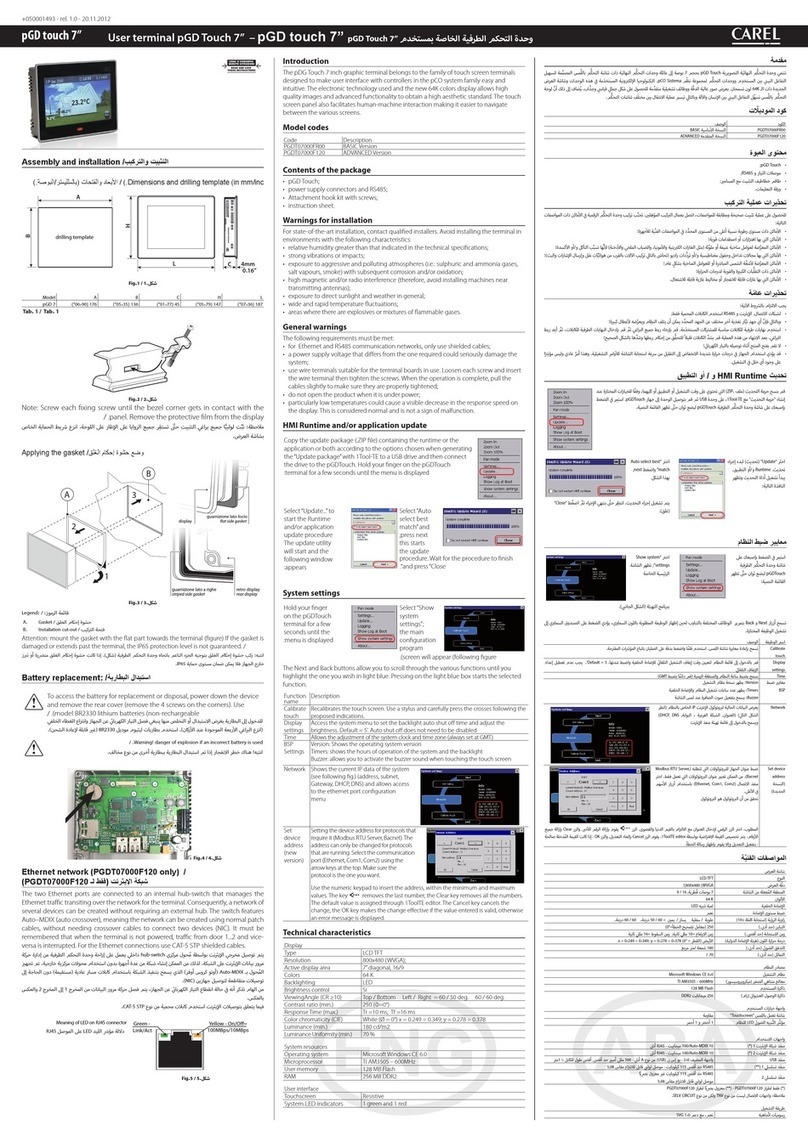

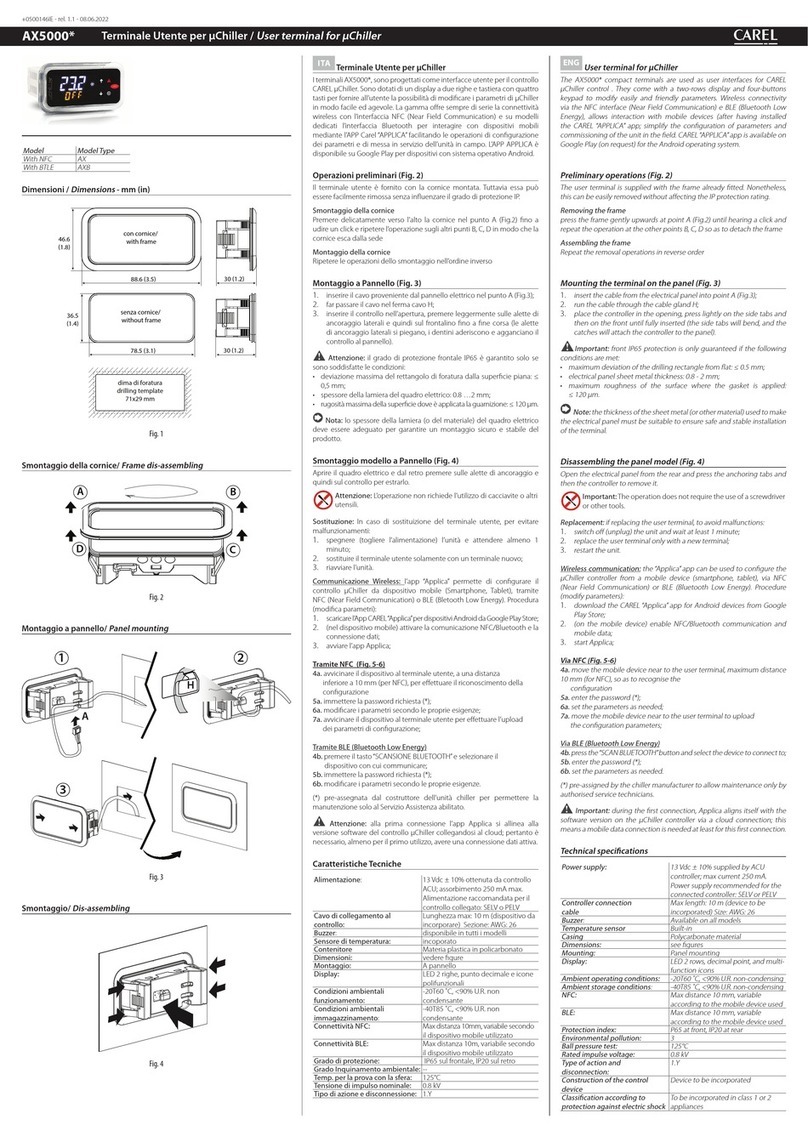

拆卸/ Dismantling

1

Fig. 4

更换 Replacing

如需更换用户终端,为避免发生故障:

1. 关掉该装置的电源;

2. 更换用户终端;

3. 重新启动装置。

In case of replacing the user terminal, to

avoid malfunctions:

1. switch o (unplug) the unit;

2. replace the user terminal;

3. restart the unit.

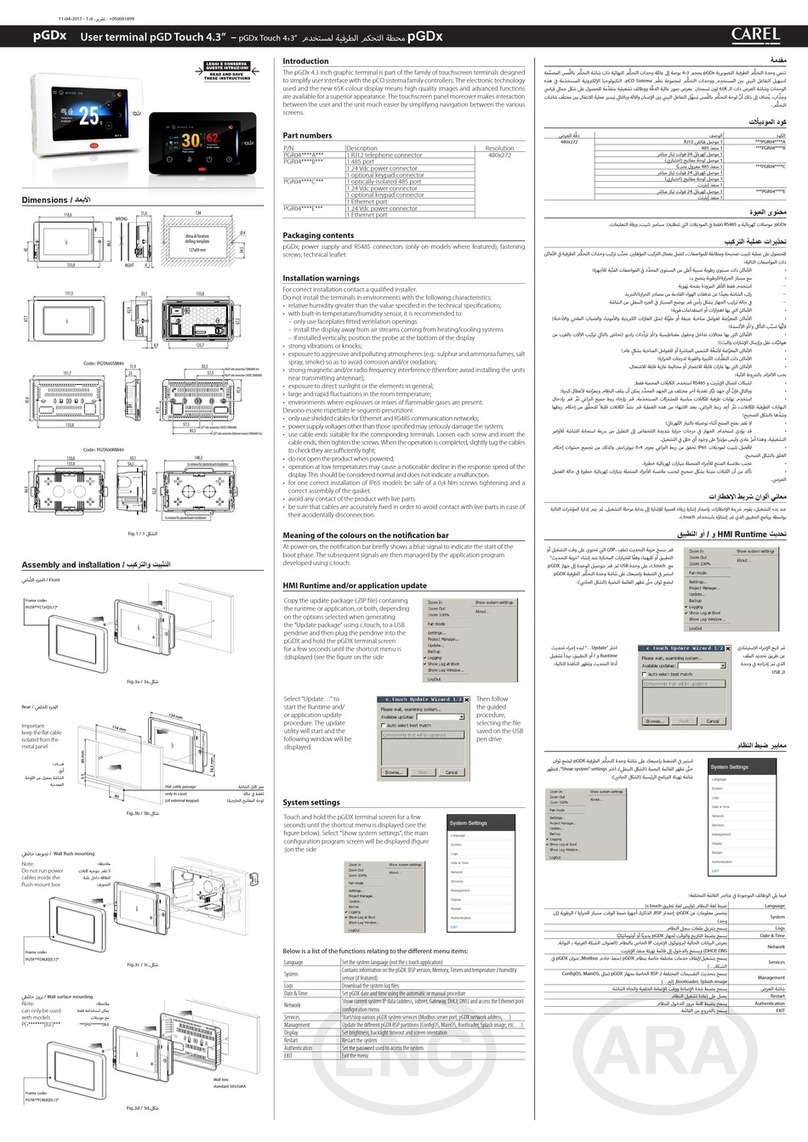

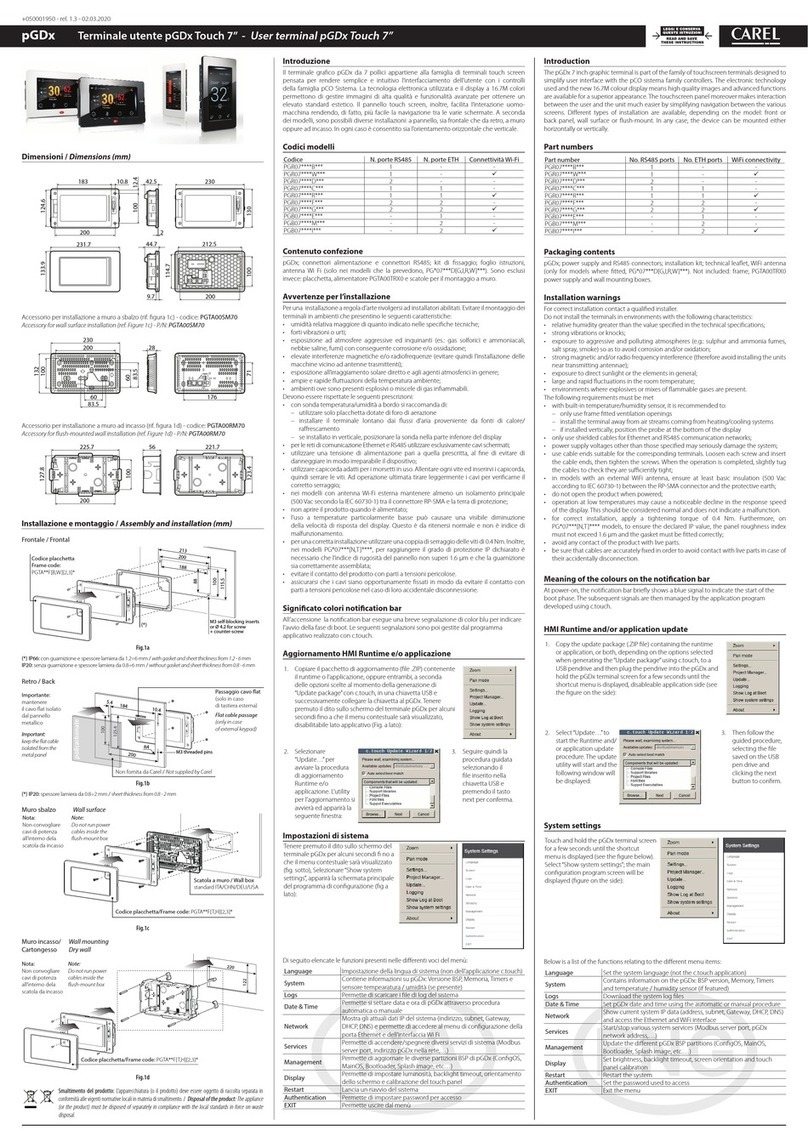

NFC/蓝牙通讯 NFC/BLE communication

近场通信(NFC)简单快速,可在与控

制器通信时使用。更多信息,请参阅

MPXone系统手册+0300086EN。

NFC (Near Field Communication) is

simple and fast and can be used when

commissioning the controller. For further

information, see the MPXone system

manual +0300086EN.

300086_028_R01

Fig. 5

(1)符合“微功率短距离无线电发射设备目录和技术要求”的具体条款和使用场

景,采用的天线类型和性能,控制、调整及开关等使用方法;

(2)不得擅自改变使用场景或使用条件、扩大发射频率范围、加大发射功率(包括

额外加装射频功率放大器),不得擅自更改发射天线;

(3)不得对其他合法的无线电台(站)产生有害干扰,也不得提出免受有害干扰保

护;

(4)应当承受辐射射频能量的工业、科学及医疗(ISM)应用设备的干扰或其他合

法的无线电台(站)干扰;

(5)如对其他合法的无线电台(站)产生有害干扰时,应立即停止使用,并采取措

施消除干扰后方可继续使用;

(6)在航空器内和依据法律法规、国家有关规定、标准划设的射电天文台、气象雷

达站、卫星地球站(含测控、测距、接收、导航站)等军

民用无线电台(站)、机场等的电磁环境保护区域内使用微功率设备,应当遵守电

磁环境保护及相关行业主管部门的规定;

(7)禁止在以机场跑道中心点为圆心、半径5000米的区域内使用各类模型遥控器;

(8)微功率设备使用时温度和电压的环境条件。

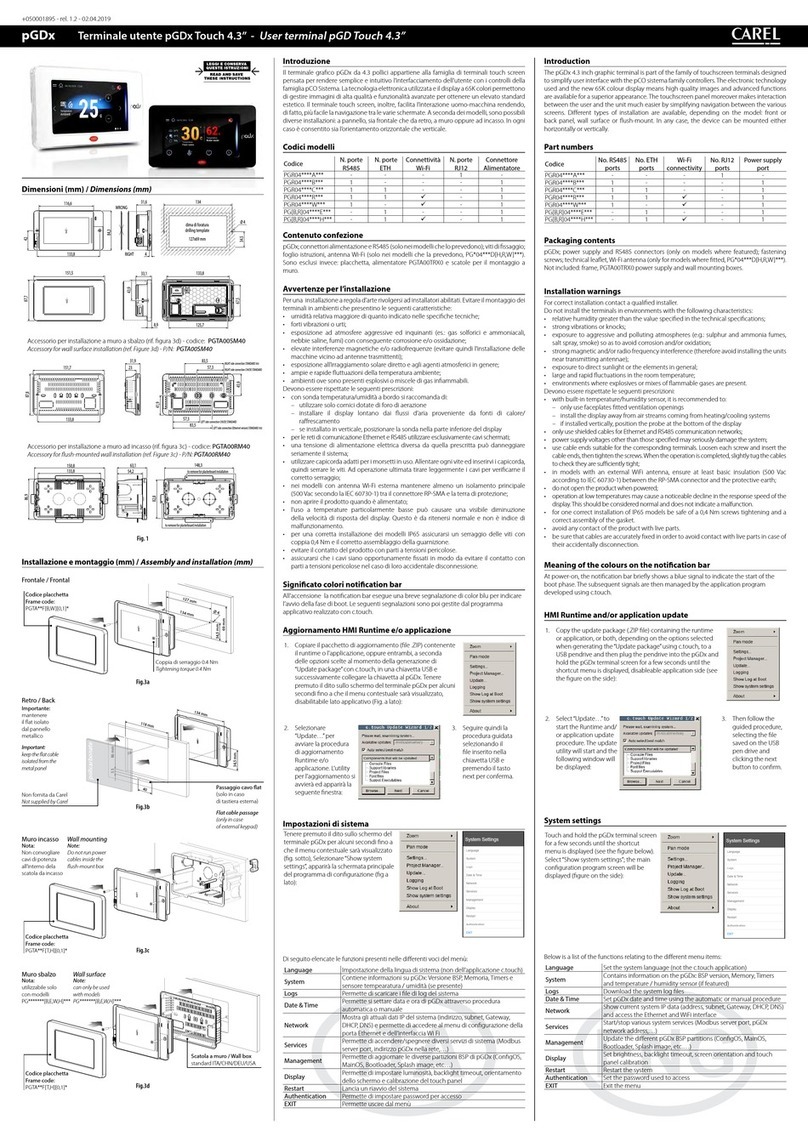

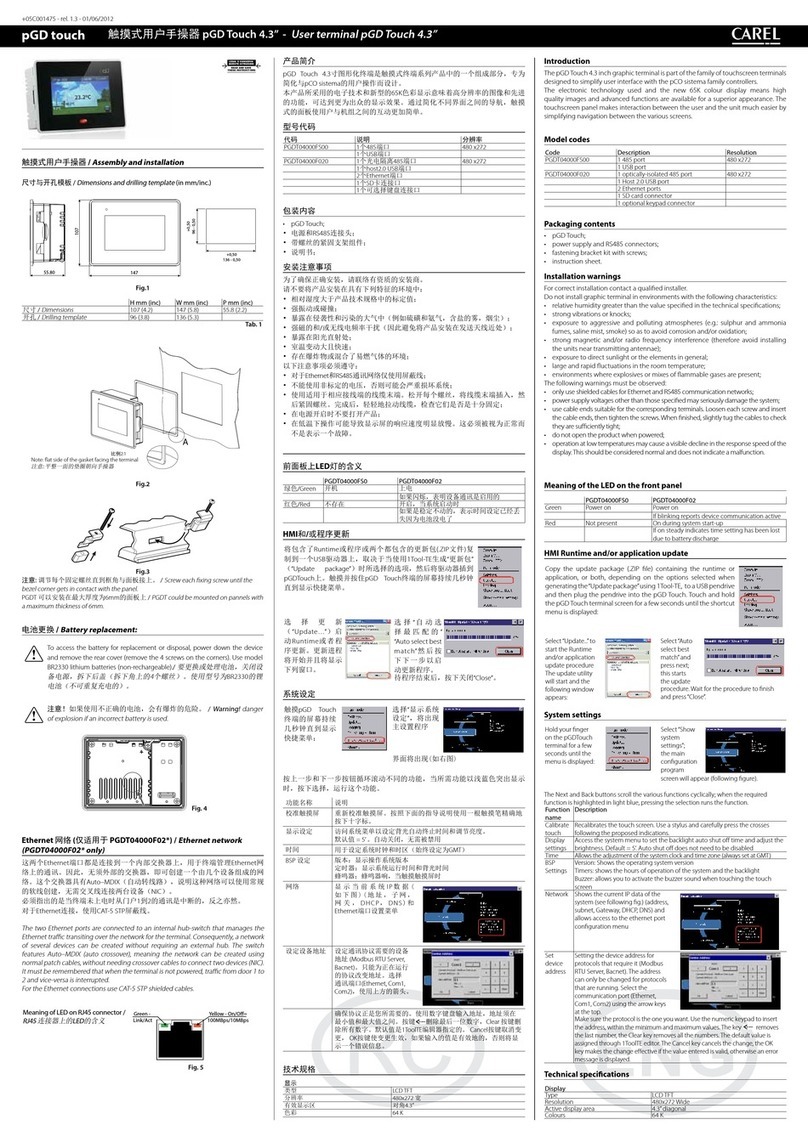

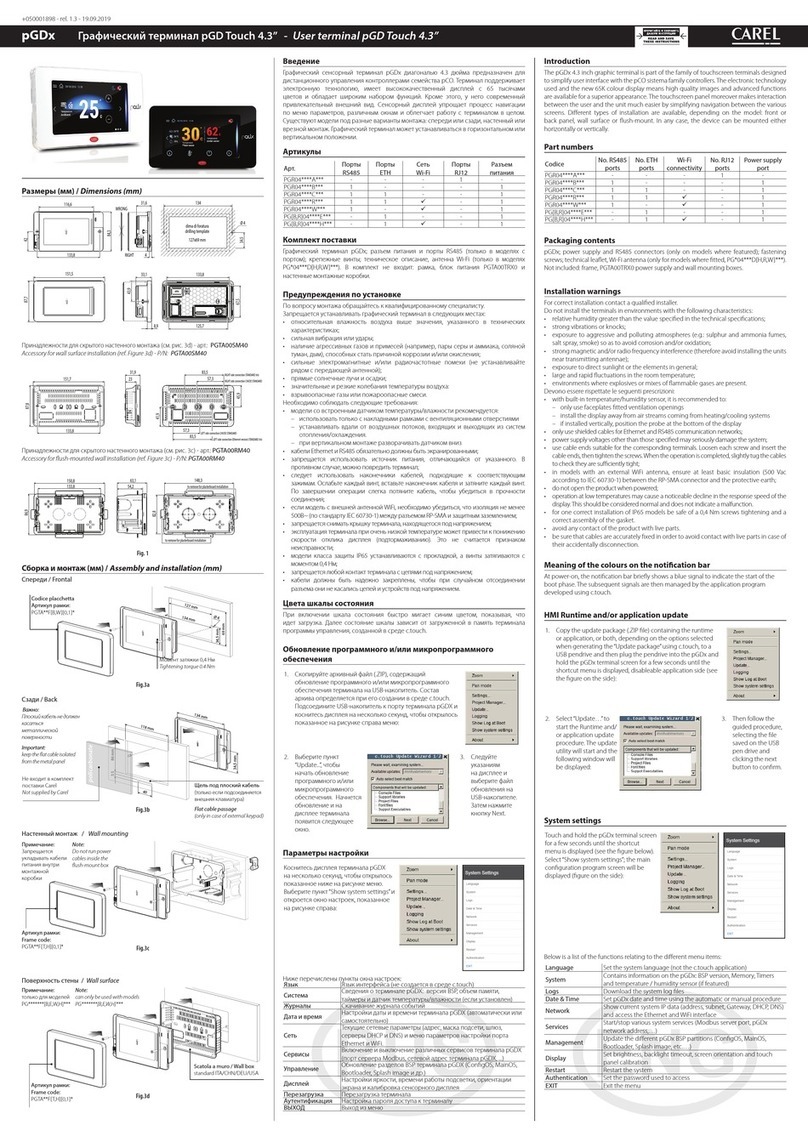

电气接线图 / Electrical connections

用户终端 User terminal

J8

J4 BMS

J3 J2

J5 FBus

S1 S3 5V

S2Y2

Y1ID1

ID2

ID3ID5

ID4S4

S6 +V

VL S5

to user terminal

ACS00CB0000** cable

远程显示 Remote display

GND

Rx+/Tx+

Power supply

Rx-/Tx-

J1J7

NO4CG0 G

J6

NO2 NO3

C

NO1

J2

J3

J4 BMSJ5 FBus

S1 S3 5V

S2Y2

Y1ID1

ID2

ID3ID5

ID4S4

S6 +V

VL S5

Fig. 6

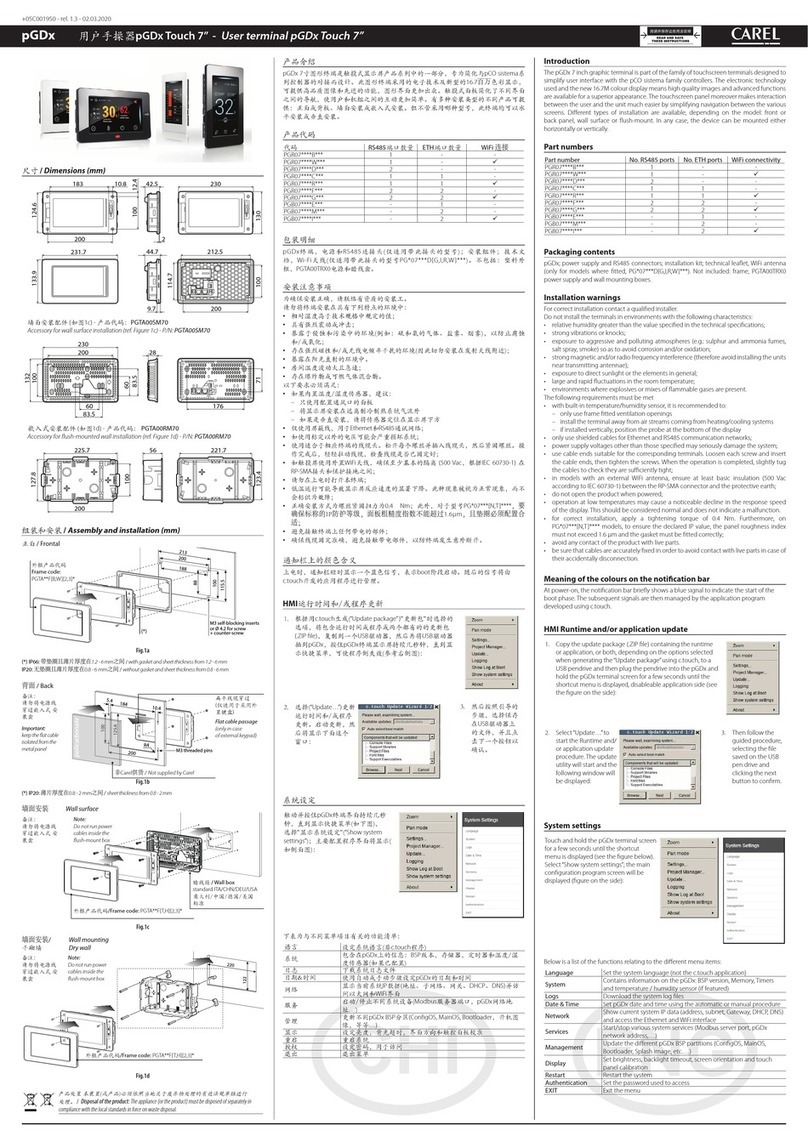

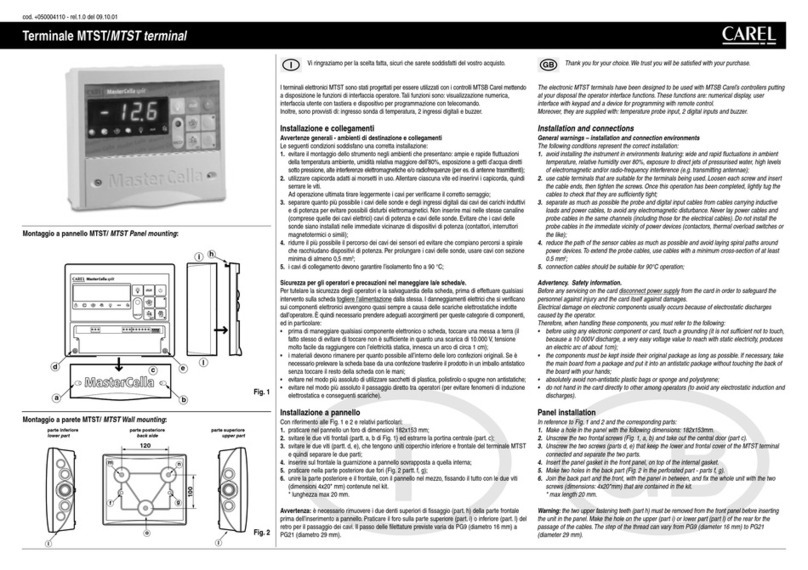

报警表

当报警发生时,ALARM图标变为红色,用户终端显示相应报警代

码。

代码 说明

rE 控制探头

E1 S1探头故障

E2 S2探头故障

E3 S3探头故障

E4 S4探头故障

E5 S5探头故障

E6 S6探头故障

E11 S11串行探头未更新

E12 S12串行探头未更新

E13 S13串行探头未更新

E14 S14串行探头未更新

LO 低温

HI 高温

LO2 低温2

HI2 高温2

IA 外部触点瞬时报警

dA 外部触点延迟报警

dor 门开启过长

Etc 实时时钟未更新

LSH 低过热

LSA 低吸气温度

MOP 高蒸发温度

LOP 低蒸发温度

bLo 阀门阻塞

Edc 与步进驱动器的通讯误差

EFS 步进电机损坏/未接通

HA HA型HACCP报警

HF HF型HACCP报警

MA 与主机通信误差(仅在从机上)

u1...u9 与从机通信误差(仅在主机上)

n1...n9 网络中装置1... 9的报警

GPE 自定义气体参数误差

技术规范

电源 13 Vdc ± 10% ACU控制器电源;

最大电流 250 mA. 控制器连接推

荐电源:SELV或PELV

接头 (内置式) JST 4-针ZH P/N S4B-ZR-SM4A-TF

控制器连接电缆 最大长度:10米。B如果其长度

超过2米,且没有内置设备,那

么使用屏蔽电缆。

尺寸: AWG: 26

连接器:

• 终端侧:JSTZH 4条引线;

外壳:ZHR-4;终端 SZH-

002T-P0.5

• 控制侧:

–用户终端:JSTXH 4路,

外壳:XHP-4,终端 SXH-

002T-P0.6

–远程显示:线对线

蜂鸣器 所有机型均配备

温度传感器 内置

壳体 聚碳酸酯材料

尺寸:见图纸

组装 面板安装

显示 3位数字、小数点及多功能图标

操作温度 -20T60°C

操作湿度 <90%rH 无冷凝

储存温度 -35T70°C

储存湿度 <90%rH 无冷凝

NFC 最大距离:10毫米,可根据使用

的移动设备进行调整。

低功耗蓝牙 最大长度:10米,根据使用的移

动设备确定

防护等级 IP65 前端, IP20 后端

环境污染等级 3

球压试验 125°C

额定冲击电压 0.8 kV

启动和断开类型 1.Y

控制设备的结构 设备将进行整合

防电击等级 整合为1类或2类器械

串行接口 RS485以上的Modbus通讯协议

软件类和结构 A类

前端清洁 只能使用柔软、非研磨抹布和中

性洗涤剂或水

认证 CE, UL

电气安全:

EN60335-1, UL60335-1,

EN60730-1, UL60730-1

电磁兼容性:

EN61000-6, EN61000-3, EN55014-1,

EN61000-4, EAC

Alarm table

When an alarm occurs, the LED on the controller turns red and the user

terminal displays the code corresponding to the alarm

Code Description

rE Control probe

E1 Probe S1

E2 Probe S2

E3 Probe S3

E4 Probe S4

E5 Probe S5

E6 Probe S6

E11 Serial probe S11 not updated

E12 Serial probe S12 not updated

E13 Serial probe S13 not updated

E14 Serial probe S14 not updated

LO Low temperature

HI High temperature

LO2 Low temperature

HI2 High temperature

IA Immediate alarm from external contact

dA Delayed alarm from external contact

dor Door open for too long

Etc Real time clock not updated

LSH Low superheat

LSA Low suction temperature

MOP Max evaporation pressure

LOP Low evaporation pressure

bLo Valve blocked

Edc Communication error with stepper driver

EFS Stepper motor broken/not connected

HA HACCP type HA

HF HACCP type HF

MA Communication error with the Master (only on Slave)

u1...u9 Communication error with the Slave (only on Master)

n1...n9 Alarm on unit 1 ... 9 in the network

GPE Error in the custom gas parameters

Technical specications

Power supply 13 Vdc ± 10% supplied by ACU

controller; max current 250 mA.

Power supply recommended for the

connected controller: SELV or PELV

Connector (built-in) JST 4 pin ZH P/N S4B-ZR-SM4A-TF

Controller connection

cable

Max length: 10m. If of lengths longer

than 2m and device not uilt-in, use

shielded cable.

Size: AWG: 26

Connectors:

• terminal side: JST ZH 4 pin; housing

ZHR-4; terminal SZH-002T-P0.5

• control side:

– user terminal: JST XH 4 way,

housing XHP-4, terminal SXH-

002T-P0.6

– remote display: wires to wire

Buzzer Available on all models

Temperature sensor Built-in

Casing Polycarbonate material

Dimensions: see gures

Assembly Panel mounting

Display 3 digits, decimal point and

multifunction icons

Operating temperature -20T60°C

Operating humidity <90% RH non-condensing

Storage temperature -35T70°C

Storage humidity <90% RH non-condensing

NFC Max distance 10 mm, variable

according to the mobile device used

Bluetooth Low Energy Max length 10m, depend on the

used mobile device

Index protection IP65 at front,

IP20 at rear

Environmental pollution 3

Ball pressure test 125°C

Rated impulse voltage 0.8 kV

Type of action and disconnection 1.Y

Construction of the control

device

Device to be incorporated

Classication according to

protection against electric shock

To be incorporated in class 1 or 2

appliances

Serial interface Modbus over RS485

Software class and structure Class A

Cleaning the front side Only use a soft, non-abrasive cloth

and neutral detergents or water

Certications CE, UL

Electrical safety:

EN60335-1, UL60335-1,

EN60730-1, UL60730-1

Electromagnetic compatibility:

EN61000-6, EN61000-3, EN55014-1,

EN61000-4, EAC

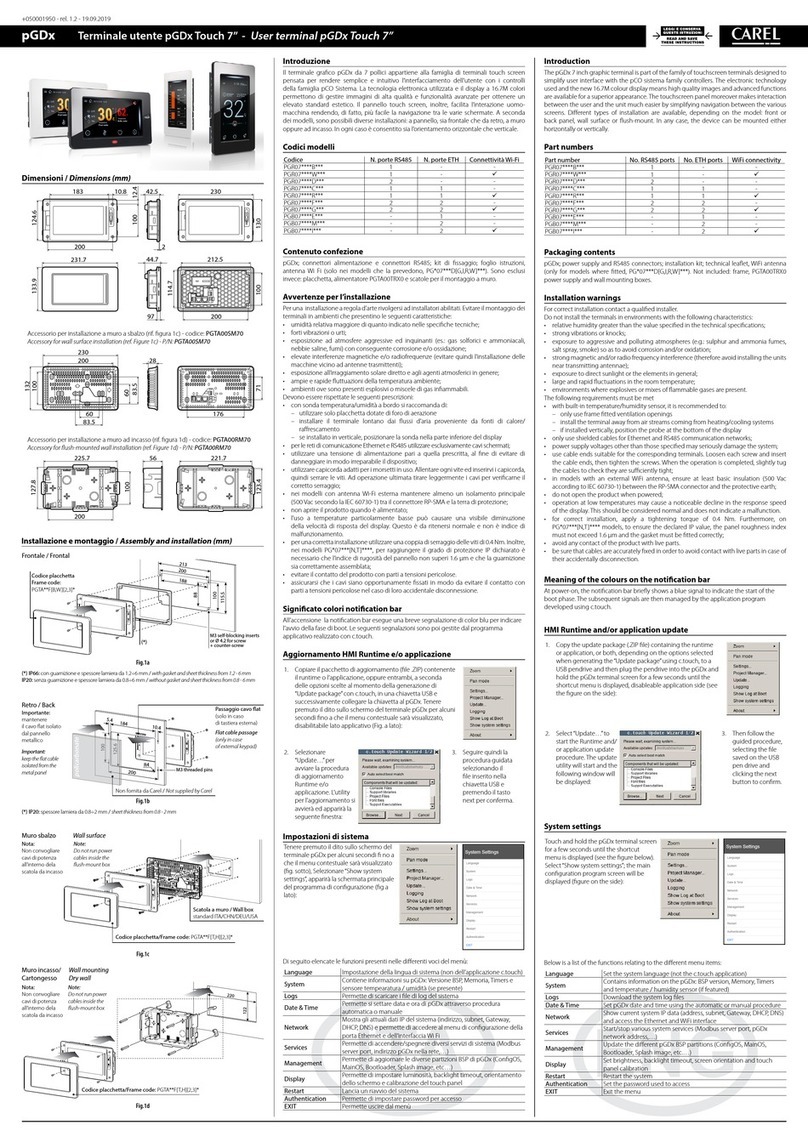

Thecompleteusermanual (+0300086EN)forthe

product can be downloaded at www.carel.com

under the “Services / Documentation” section

or via QR Code.

Disposal of the product

The appliance (or the product) must be disposed of separately in

compliance with the local standards in force on waste disposal.

重要警告

CAREL始终致力于为您提供最先进的产品和服务,相关操作方法已在产品随附的技

术文档中加以说明,也可以在购买前从www.carel.com网站下载。客户(制造商、开

发商或最终设备的安装人员)承担与产品配置有关的所有责任和风险,旨在实现与

特定最终装置和/或设备有关的预期结果。如果未能完成用户手册中要求/指明的此

类操作,可能会导致最终产品出现故障;在这种情况下,CAREL不承担任何责任。

客户须按照与产品有关的文档中所述的方式使用本产品。CAREL的通用合同条款规

定了CAREL公司对其产品的责任,该条款可从www.CAREL.com网站和/或与客户达成

的特定协议中获得。

有关本产品的用户手册完整版(代码

+0300086EN)可从www.carel.com网站中

的“Services / Documentation”(“服务/文档”)

板块下载,或通过扫一扫左侧二维码获取。

产品的处置

根据当地现行的废物处置法规必须单独处置本设备(或本产品)

。