CAREL Industries HQs

Via dell’Industria, 11 - 35020 Brugine - Padova (Italy)

Tel. (+39) 0499716611 – Fax (+39) 0499716600 – www.carel.com – e-mail: carel@carel.com +05C001950 - rel. 1.2 - 19.09.2019

CAREL保留不预先告知而修改产品的权力。

CAREL INDUSTRIES reserves the right to modify the features of its products without prior notice.

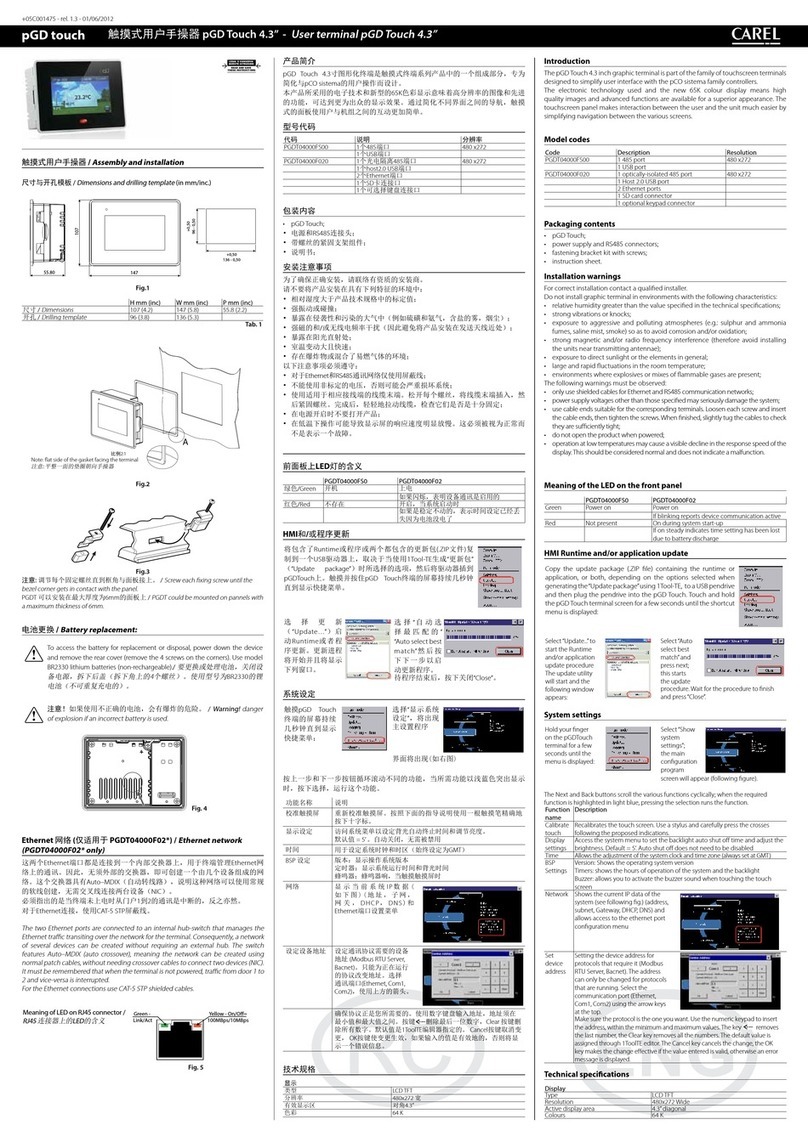

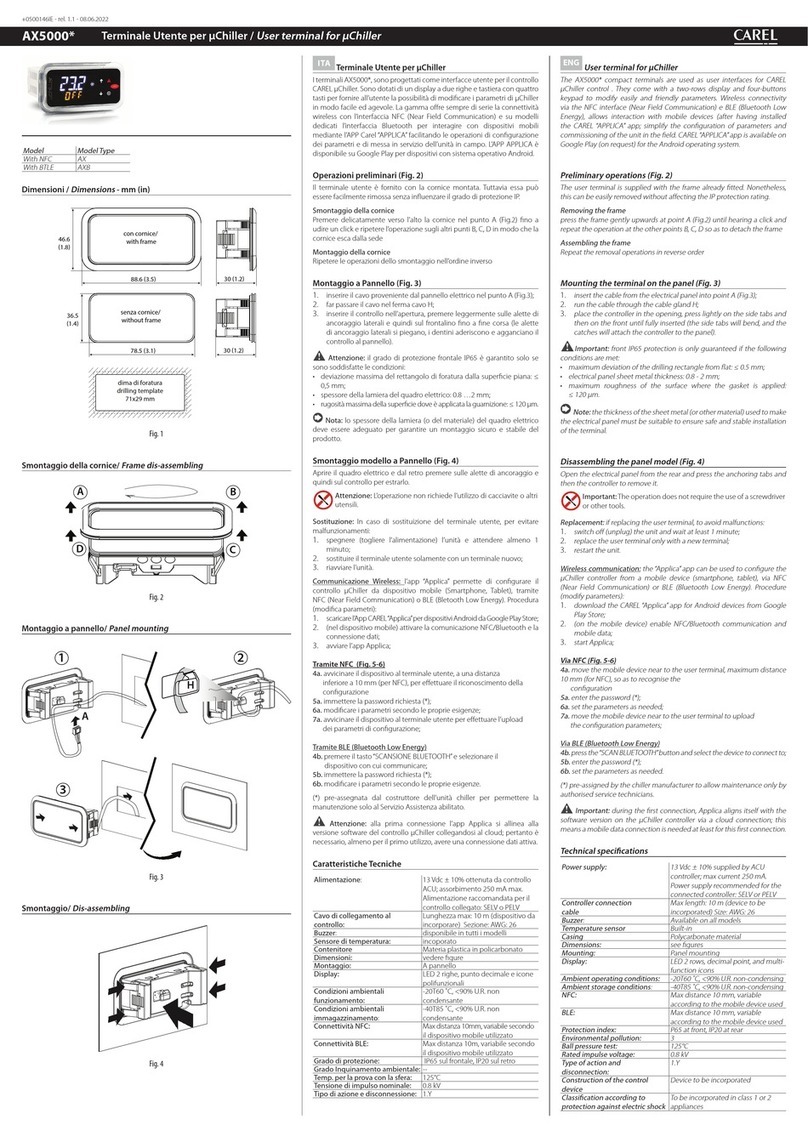

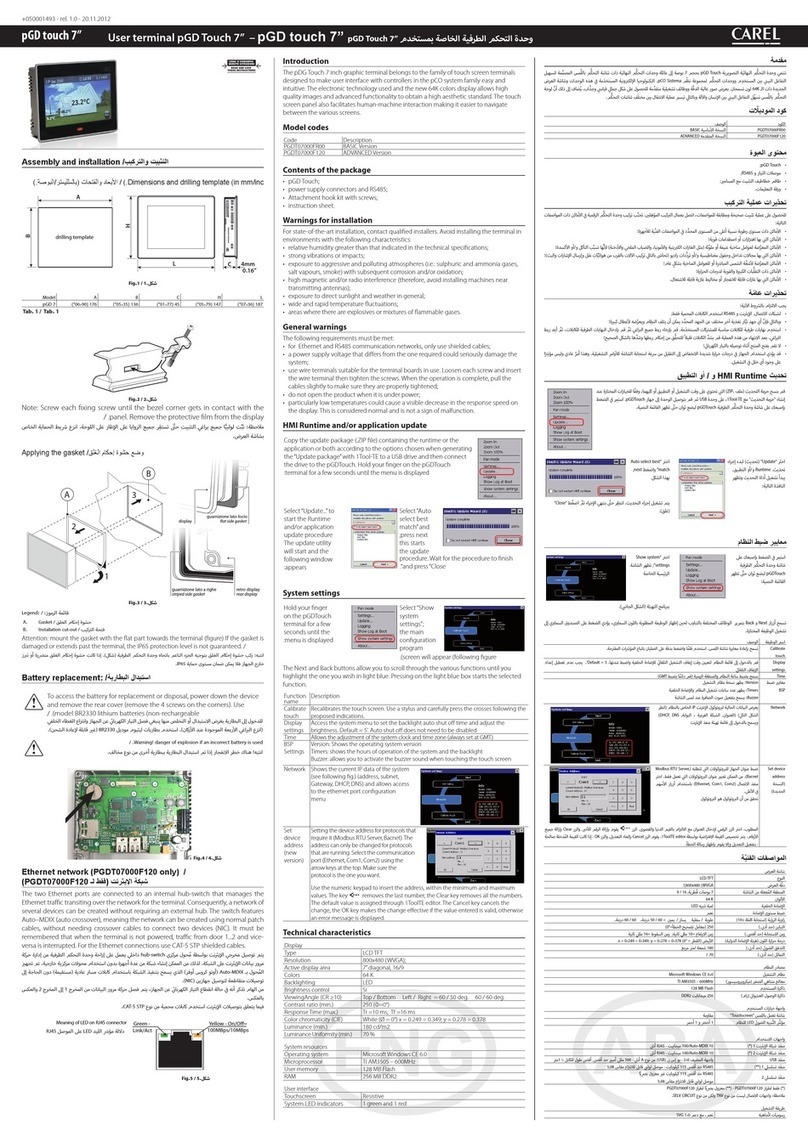

Technical specifications

Display

Type LCD TFT

Resolution 800x480 Wide

Active display area 7” diagonal

Colours 16,7M

Backlighting LED - Lifetime 20 khrs @ 25 °C

Brightness control Yes - auto-o by default after 15 min

Visual angle (CR ≥10) Up/Down (50/70 deg.) - Left/Right (70/70 deg.)

Contrast (typical) 400 (Φ=0°)

Brightness (typical) 500 cd/m2

User interface

Touchscreen Resistive

System signal LEDs 8-colour notication bar

Interfaces

ETH0, ETH1 Ethernet ports Auto-MDIX 10/100 Mbit - RJ45 female

STP CAT 5 cable Lmax = 100 m

Wi-Fi IEEE 802.11 b/g/n - STATION/ACCESS POINT mode

Built-in/external antenna based on model

Max Transmit Power = 17dBm

External antenna remote mounting Lmax = 2 m

External antenna connector RP-SMA female

(for models PG*07***D[G,I,R,W]***)

USB port () Host interface 2.0 - micro USB -B - 150 mA max

(do not use to charge devices) - Lmax = 1m

COM1 (), COM2 Serial ports RS485 max 115,2 Kb/s

Removable screw connector 3,81mm pitch

Shielded twisted pair cable AWG 20-22 for ±

Lmax = 500m - tightening torque 0.25Nm (2.2lbf x in)

Master/Slave set via dipswitch (Fig.3)

Temperature / humidity probe 0 to 50 °C / 20 to 80% rH

0 to 50 °C ±1 °C (static air)

20 to 80% ±5% (static air)

() only for service. The USB port can be damaged by ESD (Electro-Static Discharges).

It’s recommended to adopt appropriate precautions in order to avoid failures.

() opto-isolated for model PGR07****[C,D,F,G,R]***

Functions

Vector graphics Yes, includes SVG 1.0 support

Dynamic objects Yes Visibility, position, rotation

TrueType fonts Yes

Multi-protocol Yes

Logs and trends Yes. Limited to Flash memory capacity

Multilanguage Yes, run-time language setting and limited only by

available memory

Recipes Yes. Limited to Flash memory capacity

Alarms Yes

Event list Yes

Passwords Yes

Real Time Clock () Yes, with backup battery

Screen saver Yes

Buzzer () “Beep”when pressing the touchscreen (settable)

() only on models where featured

Electrical

Power supply 24Vdc Class 2/SELV supplied by PGTA00TRX0 accessory

Lmax = 50 m (-)- cable cross section AWG 12-20

tightening torque 0.8 Nm (7 lbf x in)

Max Power Absorption 9 W

Fuse Automatic

Weight Approx. 600 g

Battery Non-rechargeable lithium model BR1225

Software class and structure A

Purpose of control operation control

Controller construction incorporated control (PG*07***[D,F,N,T,W]****)

Type of automatic action type 1 action

Heat and re resistance Cat. D

Overvoltage category Cat. III

Insulation class Class III

() For PG*07***W**** models with ush mounting, accessory PGTA00TRX0 must be

installed in a dedicated box - () Power supply range: 24 Vdc ± 10%

Environmental conditions

Operating temperature PG*07***[D,N,T]****: -20 to 60 °C

PG*07***[F,W]****: 0 to 50 °C

Storage temperature PG*07********: -30 to 70 °C

Maximum operating and

storage relative humidity

85% @ 40 °C non-condensing

Ingress protection PG*07***T****: IP66, NEMA Type 1 (front)

PG*07***N****: IP66, NEMA Type 4X indoor (front)

if coupled with PGTA**F [B,W][2,3]* (frame)

PG*07***[D,F,W]****: IP20, NEMA Type 1 (front)

Pollution degree 3

废弃物处置规定 / Disposal regulations

•

请勿将此设备作为城市固废处理;请将其送至正确的处理中心。

•

此装置中含有电池,在进行处置前,请先断开电源,再将后盖拆下。

•

使用或处置不当可能对人体健康和环境都有不良影响。

•

必须按照当地法规规定的公共或个人废弃物回收系统对此装置废弃物进行处

置。

•

如果出现电子和电气废弃物违法处置,则将依据当地现行法律对废弃物处置的

规定进行处罚。

•

Do not dispose of the product as solid municipal waste; take it to the proper collection

centres.

•

The product contains a battery, power down the device, remove the rear cover and

must be removed, before proceeding with disposal.

•

Improper use or disposal could have a negative eect on human health and the

environment.

•

Public or private waste collection systems dened by local legislation must be used for

its disposal.

•

in the event of illegal disposal of waste electrical and electronic equipment, penalties

have been established by the current local laws regarding disposal.

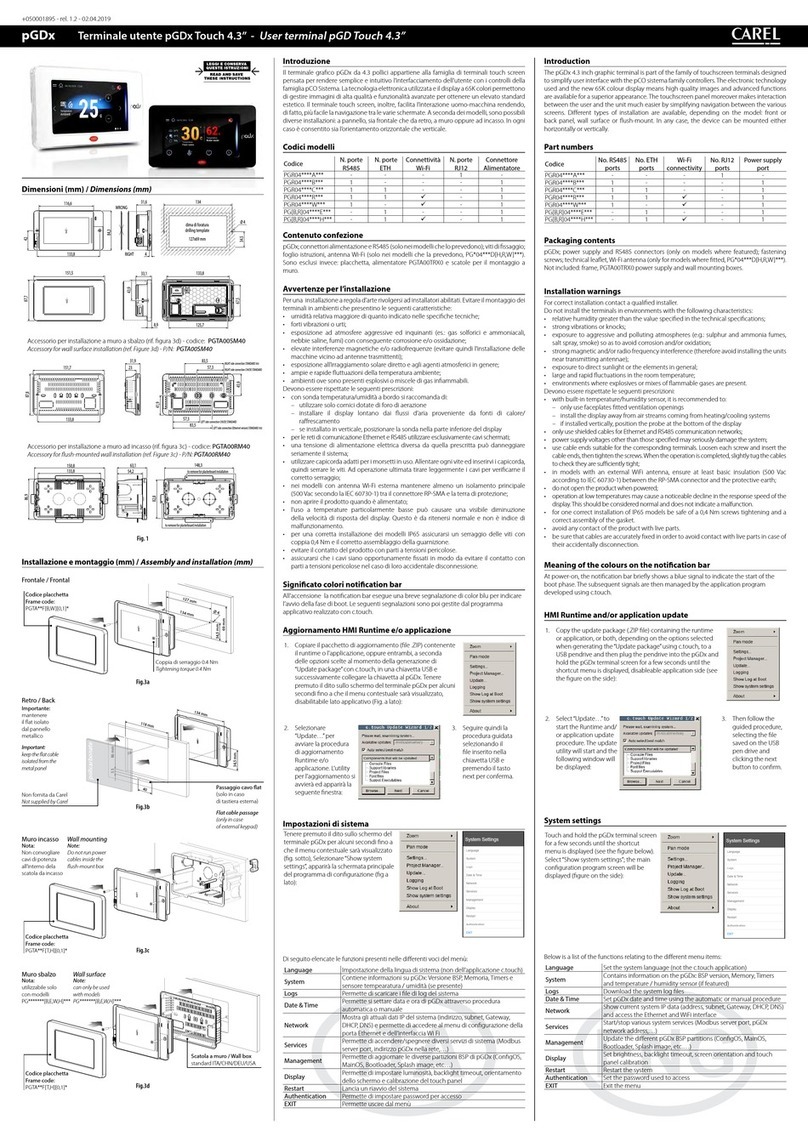

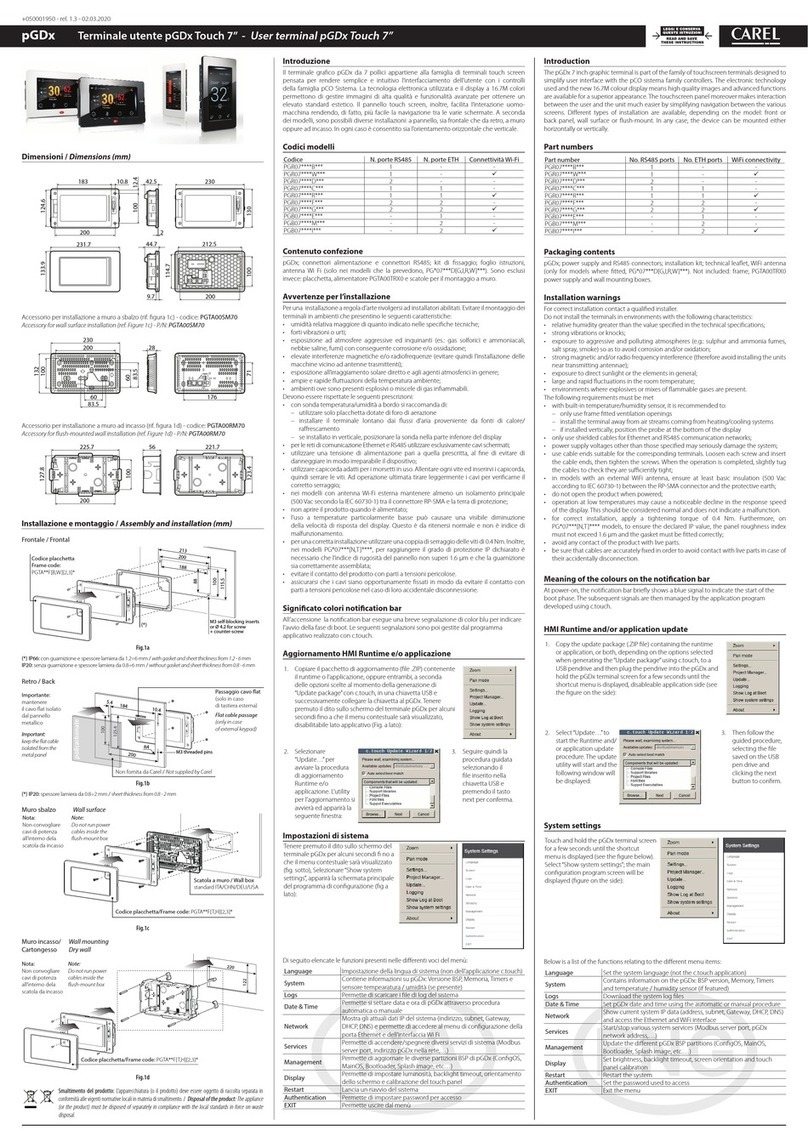

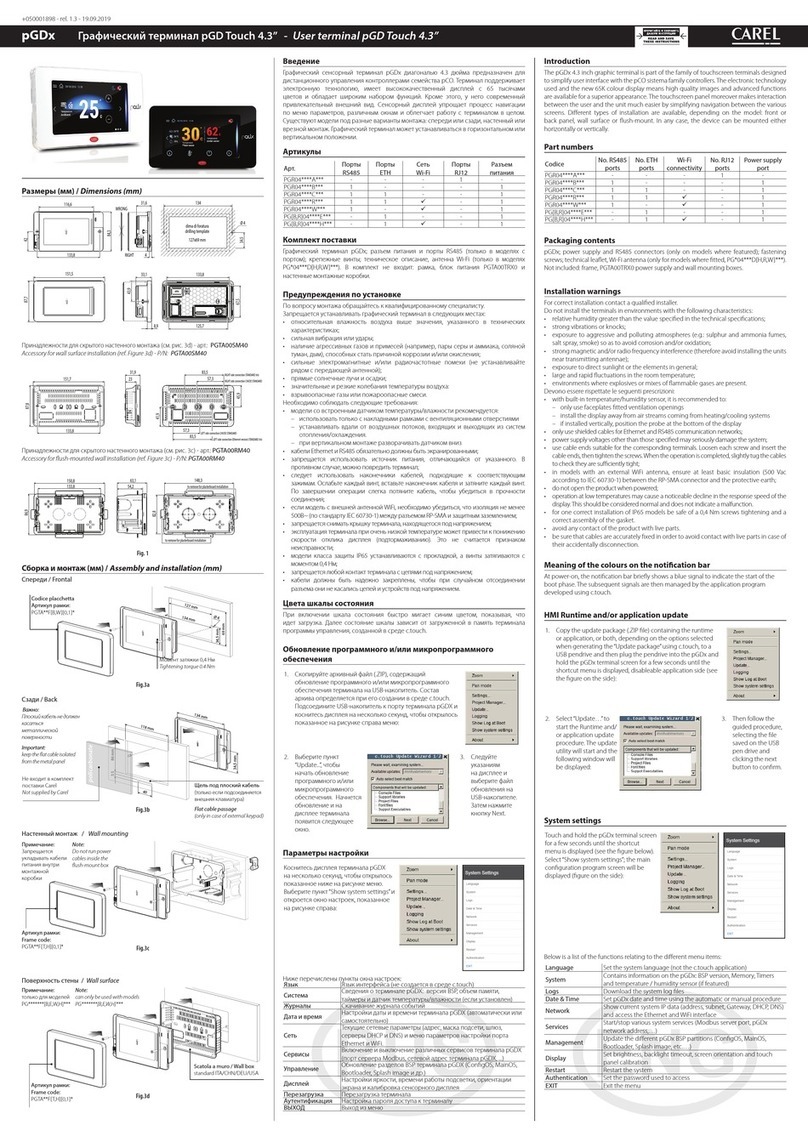

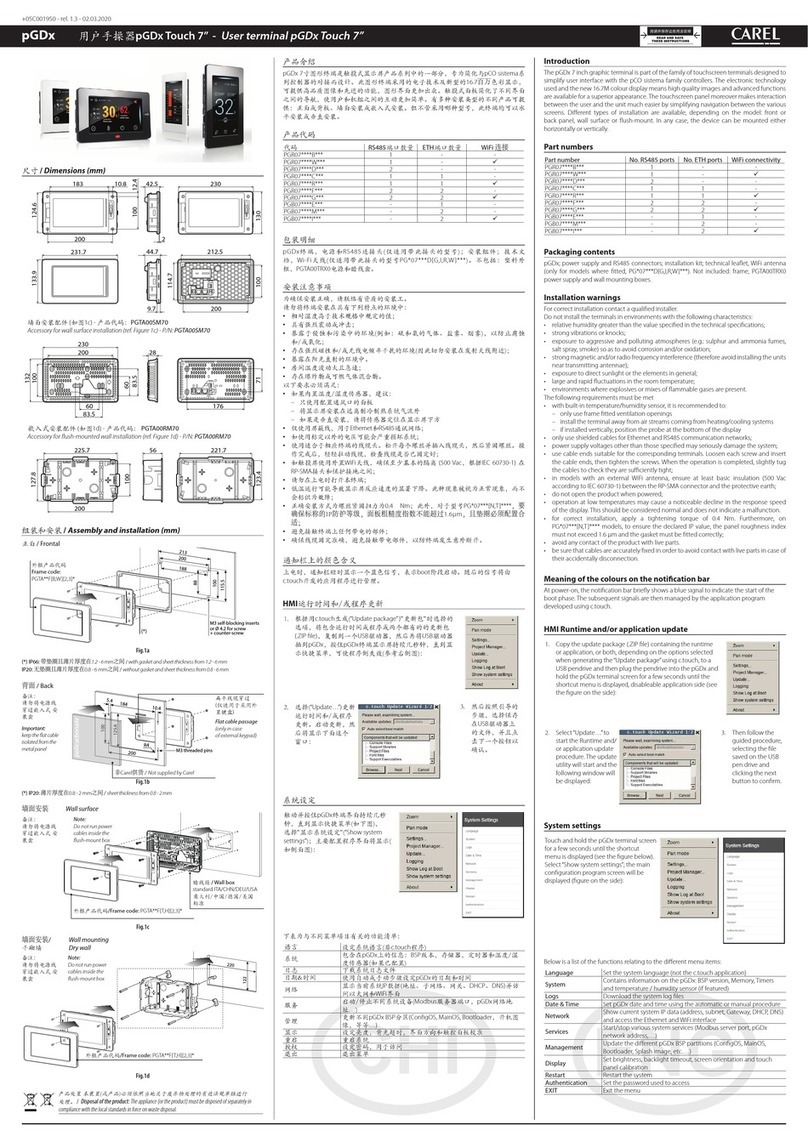

J1 J2 J3 J4 J5

J14

J10

J13

J12 J15

dracSMBdracsuBdleiF

4 3 2 1

J11 pLAN

Tx/Rx

GND

J26 FBus2

J24

+

XXXXXXXXXXXX

ETH0 ETH0

c.pCO/pCO

Access-Point/Station

J1 J2 J3 J4 J5

J14

J10

J13

J12 J15

dracSMBdracsuBdleiF

4 3 2 1

J11 pLAN

J25 BMS2 J26 FBus2

J24

+

XXXXXXXXXXXX

c.pCO

J1 J2 J3 J4 J5

J14

J10

J13

J12 J15

dracSMBdracsuBdleiF

4 3 2 1

Tx/RxGND

J25 BMS2 J26 FBus2

J24

+

XXXXXXXXXXXX

c.pCO/pCO

GND

–

+

L N

+ –

PGTA00TRX0

24 Vdc

+

–

GND

–

+

J25 BMS2

J11 pLAN

COM1

COM2

J1 J2 J3 J4 J5

J14

J10

J13

J12 J15

dracSMBdracsuBdleiF

4 3 2 1

J11 pLAN

Tx/Rx

GND

J26 FBus2

J24

+

XXXXXXXXXXXX

c.pCO/pCO

Access-Point/Station

c.pCO mini

J1 J2 J3 J4 J5

J14

J10

J13

J12 J15

dracSMBdracsuBdleiF

4 3 2 1

Tx/RxGND

J25 BMS2

Tx/Rx

GND Tx/Rx

GND

J26 FBus2

J24

+

XXXXXXXXXXXX

c.pCO/pCO

GND

–

+

L N

+ –

PGTA00TRX0

24 Vdc

+

–

GND

–

+

ETH1 ETH0

J25 BMS2

J11 pLAN

COM1

COM2

以太网开关配置 / Ethernet switch configuration 双MAC以太网配置 / Dual MAC Ethernet configuration

Fig. 4a Fig. 4b

网络连接 /

Network connection:

1 3 5

710 9 8 114 2

6

SW2

SW1

Fig.2

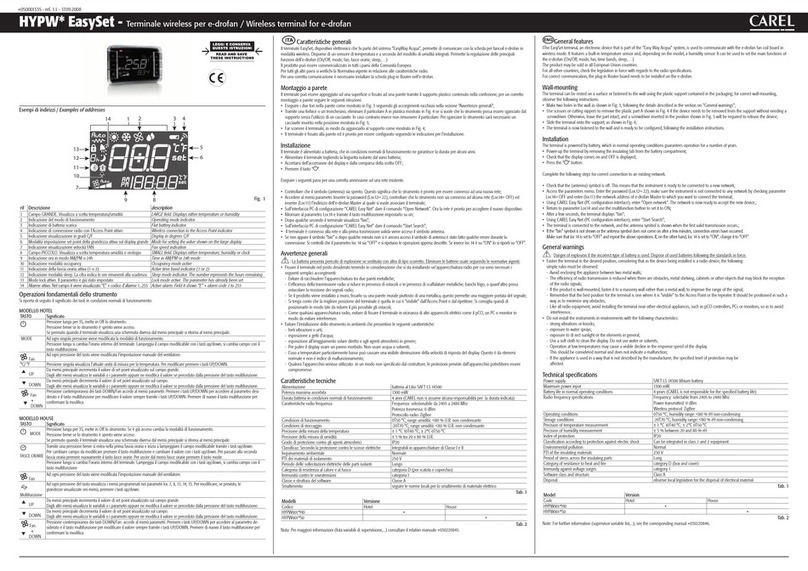

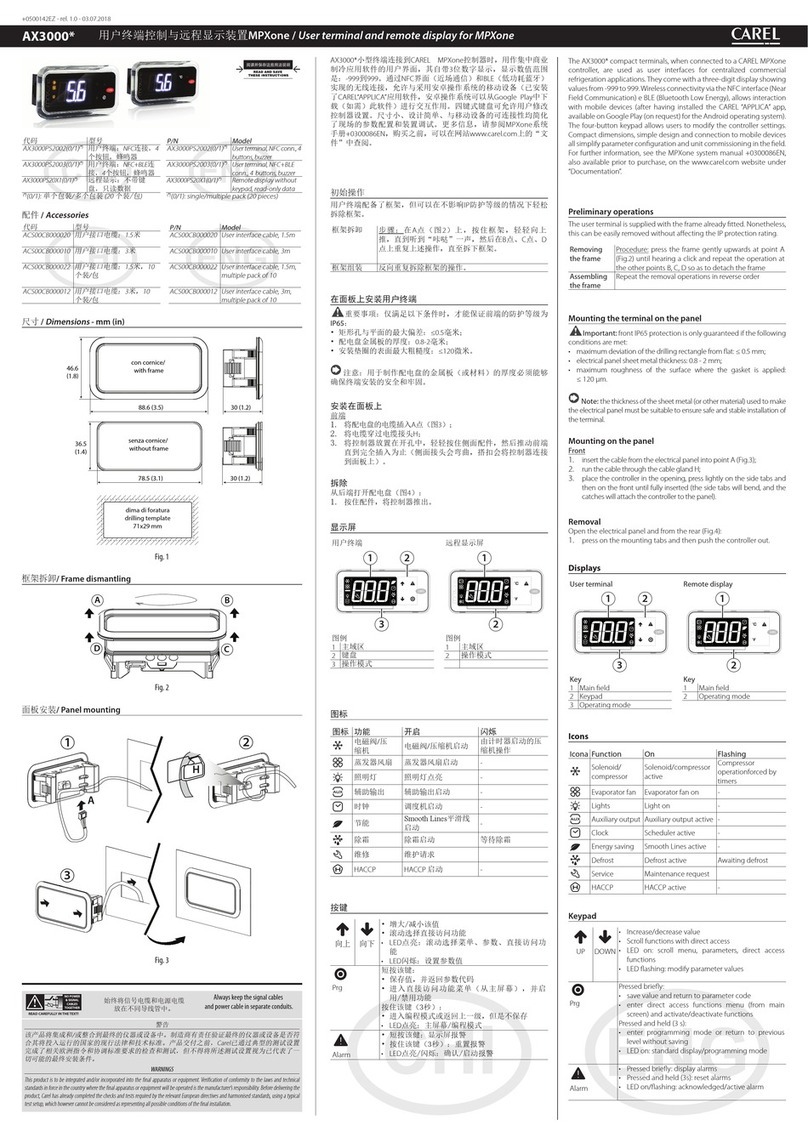

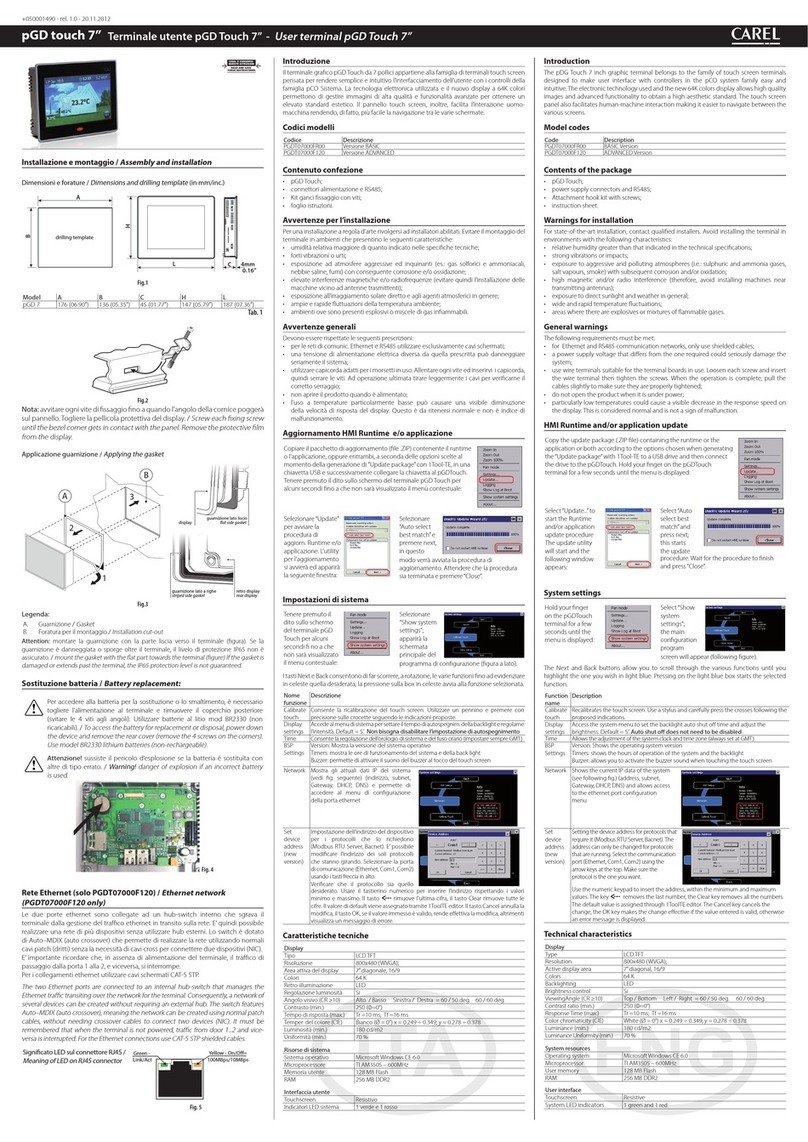

Mounting/安装 Connectivity/通讯

Description/描述

PG*07***[F,T]****

Front Panel/前面板

PG*07***N****

Front Panell /

前面板

PG*07***D****

Rear Panel /背板

PG*07***W****

Wall Mounting

墙面安装

PGR07****[B/W]***

PGR07****D***

PGR07****[C/R]***

PGR07****[F/G]***

PG*07****E***

PG*07****[I/M]***

1MicroUSB rear/背面

2MicroUSB front/正面

3external keypad connector/

外置小键盘连接头

4temperature and humidity probe ()/温

度和湿度传感器()

(option)

5Wi-Fi antenna SMA connector (RP-SMA)

Wi-Fi 天线SMA连接头(RP-SMA)

6RS485 port COM1/RS485端口COM1

7RS485 port COM2/RS485端口COM2

8Ethernet port ETH0/以太网口ETH0

9Ethernet port ETH1/以太网口ETH1

10 notication bar/通知栏

11 power supply/电源

Tab. 2

如果

COM1

端口用作

pLAN(Modbus通过pLAN协议)或显示端口:请勿在网络中的第一

个和最后一个设备上连接120欧姆电阻。可连接到网络中的最大设备数量为32个,

最长距离为500m。

注意:仅

COM1

端口可用作

pLAN(Modbus通过pLAN协议)。

()定期检查传感器通风孔是清洁的。

If COM1 port is used as pLAN (Modbus over pLAN) or display port: DO NOT connect the

resistors 120 ohm termination on the rst and last device in the network. The maximum

number of devices that can be connected in the network is 32 and the maximum length

of the network is 500m.

Attention: only COM1 port can be used as a pLAN (Modbus over pLAN protocol).

() Periodically check that the probe ventilation holes are clean.

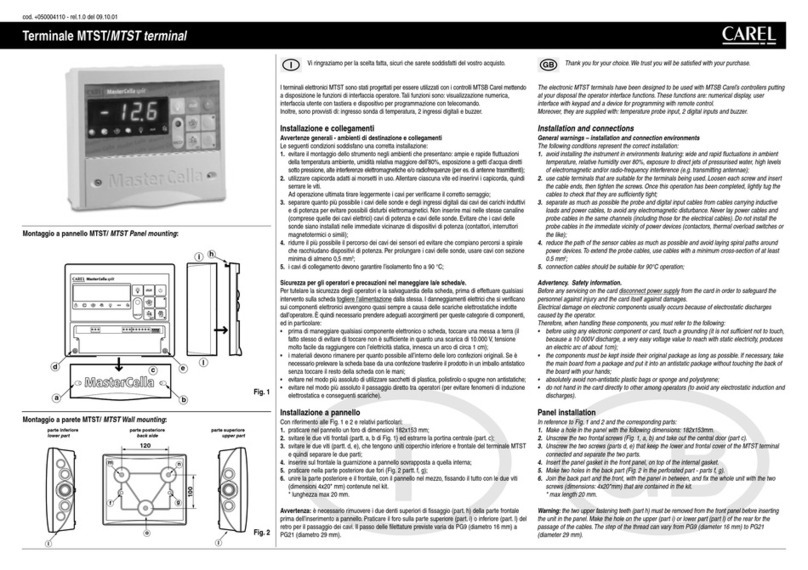

串行DIP开关配置 / Serial

Dipswitch Conguration

SLAVE/从控 MASTER/主控

Fig.3

端口电阻

terminator resistor

120 ohm - OFF 1 2 3

ON

ON

1 2 3

ON

ON

Pull-Up

Pull-Down - OFF

Pull-Up

Pull-Down - ON

(pLAN)

端口电阻

terminator resistor

120 ohm - ON

连接到pCO/c.pCO控制器 /

Connection to

pCO/c.pCO

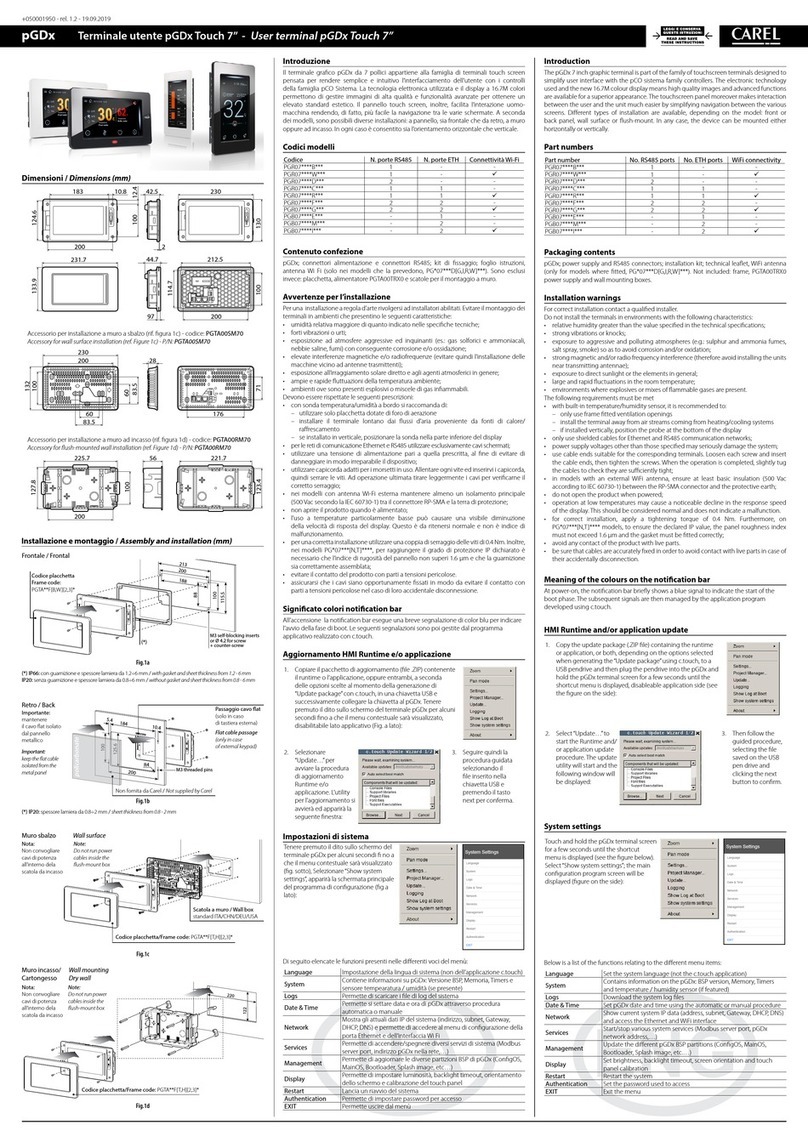

NEMA 4X前面板 / NEMA 4X Frontal

214

R2

116

Fig.1e

外框产品代码

PGTA**F[B,W][2,3]*

薄板厚度在 1.2~6 mm之间

Sheet thickness from 1.2 - 6 mm

技术规格

显示屏

类型 LCD TFT

分辨率 800x480

有效显示区域 7”

色彩 16,7M

背光 LED - 使用寿命 20 khrs @ 25 °C

亮度控制 是 - 自动关闭,默认为15分钟后

视角 (CR ≥10) 上/下 (50/70度) - 左/右(70/70度)

对比(典型) 400 (Φ=0°)

亮度(典型) 500 cd/m2

用户界面

触摸屏 阻性

系统信号LED灯8色通知栏

接口

ETH0, ETH1以太网口 自动极性识别10/100 Mbit - RJ45内插口

STP CAT 5 线缆最长 = 100 m

Wi-Fi IEEE 802.11 b/g/n - 站/接入点模式

根据型号可分为内置/外置天线

最大传输功率 = 17dBm

外置天线远程安装最长距离 = 2 m

外置天线连接头RP-SMA内插口

(适用于型号PG*07***D[G,I,R,W]***)

USB端口() 主机接口2.0 - 微型USB -B - 150 mA最大

(请勿使用充电设备) - 最长距离= 1m

COM1 (), COM2串行端口 RS485 最大115.2 Kb/s

可拆卸螺接头3.81mm 插脚

屏蔽双绞线AWG 20-22 ±

最长= 500m - 紧固扭力0.25Nm (2.2lbf x)

通过DIP开关设定主/从 (Fig.3)

温度/湿度传感器 0 ~ 50 °C / 20 ~ 80% rH

0 ~ 50 °C ±1 °C (静态空气)

20 ~ 80% ±5% (静态空气)

() 仅用于服务操作。USB端口可能会被ESD(静电释放)。建议采用恰当的预防

措施,以防止故障。

()光电隔离,适用于PGR07****[C,D,F,G,R]***

功能

向量图 是,包括支持SVG 1.0

动态对象 是,清晰度,位置,轮值

TrueType字体 是

多协议 是

日志和趋势 是,受限于闪存容量

多语言 是,运行时间语言设定,并且仅受限于可用的存

储器

配方 是,受限于闪存容量

报警 是

事件清单 是

密码 是

实时钟() 是,带备用电池

屏保 是

蜂鸣器 () “Beep” ,当按压触摸屏时(可设定)

() 仅适用于有此配置的型号

电气规格

电源 24Vdc 2类/SELV,通过PGTA00TRX0供电

电源线缆最长 = 50 m (-)- 线缆截面 AWG 12-20

紧固扭力0.8 Nm (7 lbf x in)

最大功耗 9 W

熔丝 自动的

重量 大约600 g

电池 非充电锂电池,型号BR1225

软件等级和结构 A

控制方式 运行控制

控制器结构 集成控制(PG*07***[D,F,N,T,W]****)

自动动作类型 类型1动作

耐热和防火类别 D类

过压类别 III类

绝缘类别 III类

() 对于嵌入式安装的型号,PG*07***W**** PGTA00TRX0必须安装到专用的接线盒 -

() 电源范围:24 Vdc ± 10%

环境条件

运行温度 PG*07***[D,N,T]****: -20 ~ 60 °C

PG*07***[F,W]****: 0 ~ 50 °C

储存温度 PG*07********: -30 ~ 70 °C

最大运行和储存相对湿度 85% @ 40 °C 无凝露

防护等级 PG*07***T****: IP66, NEMA 类型1 (前面)

PG*07***N****: IP66, NEMA 类型4X室内(前面)

如果与PGTA**F [B,W][2,3]*结合 (外框)

PG*07***[D,F,W]****: IP20, NEMA类型1 (前面)

污染等级 3

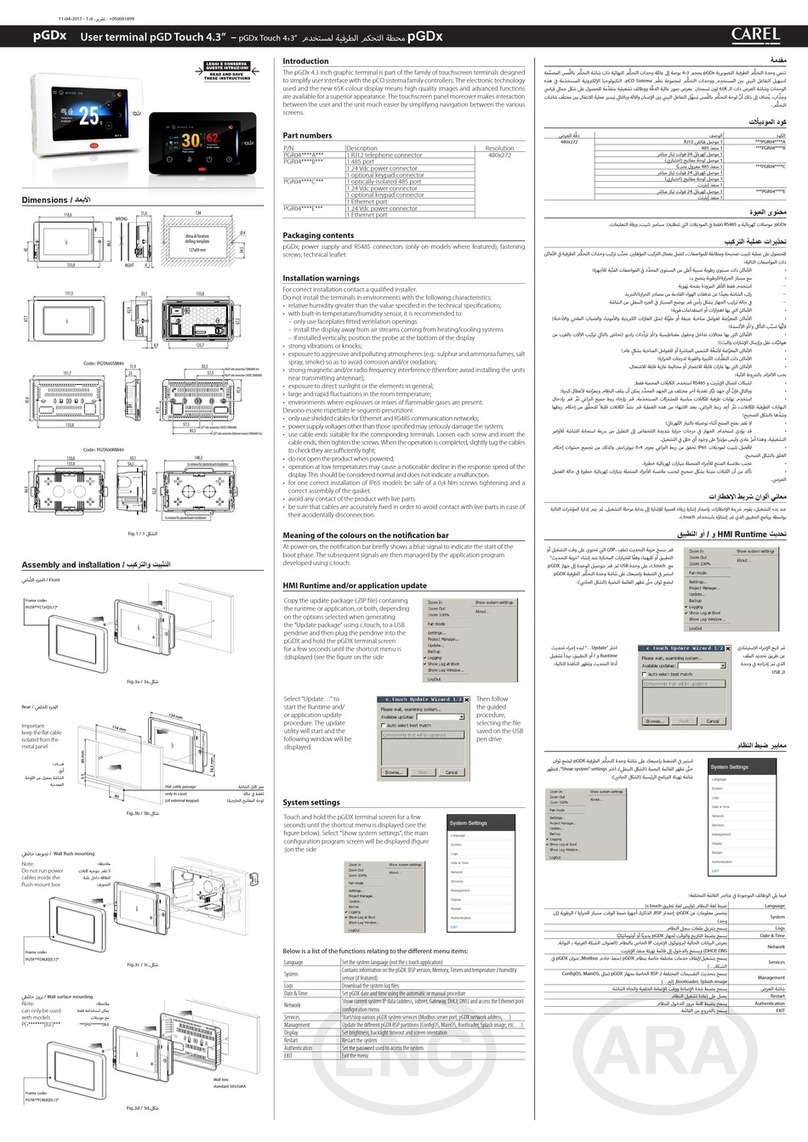

IMPORTANT WARNINGS: The CAREL product is a state-of-the-art product, whose operation is specied in the technical

documentation supplied with the product or can be downloaded, even prior to purchase, from the website www.carel.com.

- The client (builder, developer or installer of the nal equipment) assumes every responsibility and risk relating to the phase of

conguration the product in order to reach the expected results in relation to the specic nal installation and/or equipment.The

lack of such phase of study, which is requested/indicated in the user manual, can cause the nal product to malfunction of which

CAREL can not be held responsible. The nal client must use the product only in the manner described in the documentation

related to the product itself. The liability of CAREL in relation to its own product is regulated by CAREL’s general contract

conditions edited on the website www.carel.com and/or by specic agreements with clients.

Disposal of the product: The appliance (or the product) must be disposed of separately in compliance with the

local standards in force on waste disposal.

Standards

Safety UL UL60730-1

sch. CB IEC60730-1

EMC CE EN61000-6-1 / EN61000-6-2

EN61000-6-3 / EN61000-6-4

EN55014-1 / EN55014-2

Radio Red EN301489-1/EN301489-17

EN300328

FCC Part.15 Subpart.B

Other certication under approvals, please contact Carel

Representatives for other details

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

Always keep the

signal cables and

power cable in

separate conduits.

重要说明

CAREL产品是一种先进的装置,其操作在产品随附的技术文件中有详细说明,也可在购买之

前从www.carel.com网站下载。对于为达到与最终安装和/或设备相关的特定预期结果相关的产

品配置上的一切责任和风险,均由客户(最终设备的制造商、开发商或安装供应商)承担。

如果在所述阶段未完成用户手册中要求/指示的内容,就可能导致最终产品故障;在这种情况

下,CAREL不承担任何责任。客户必须通过与产品相关的文档所描述的方式使用产品。在CAREL

一般合约条件中,对CAREL在产品方面的责任进行了规定,详情可从www.carel.com网站和/或与

客户签订的特定协议进行了解。

产品处置

本装置(或产品)必须依照当地关于废弃物处理的有效法规单独进行处理。

合规性

安全 UL UL60730-1

sch. CB IEC60730-1

EMC CE EN61000-6-1 / EN61000-6-2

EN61000-6-3 / EN61000-6-4

EN55014-1 / EN55014-2

Radio Red EN301489-1/EN301489-17

EN300328

FCC Part.15 Subpart.B

其他获得批准的认证,请联系Carel代表以获取其他详细信息

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

请将电源线和信

号线

放在不同导线管

内。