(8)

10. Slide the spool body down the luff, into the cup and over the

main bearing, insuring thrust washer is in place. Lift the luff up off

the turnbuckle body, insert the luff support pin through the hole in

the spool throat. The luff rests on top of this pin.

CAUTION:

the luff

must not sit on the turnbuckle body as turning the furler might

unscrew the turnbuckle causing dismasting.

11. Pass the furling line through the opening in the side of the

cup, then up through the hole in the top of the spool flange. Tie an

overhand knot to prevent it from escaping. Before raising jib, rotate

the furler so there are about 20 turns of furling line on the spool.

This will be finished off later.

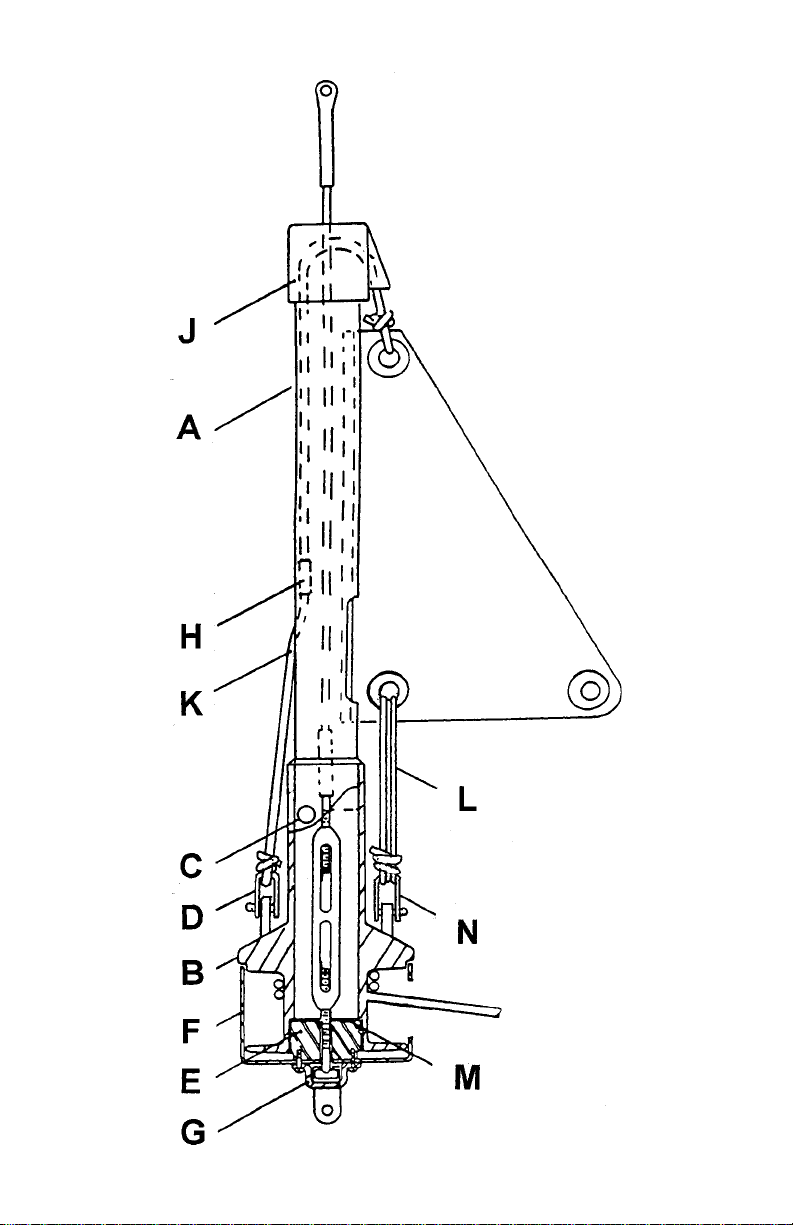

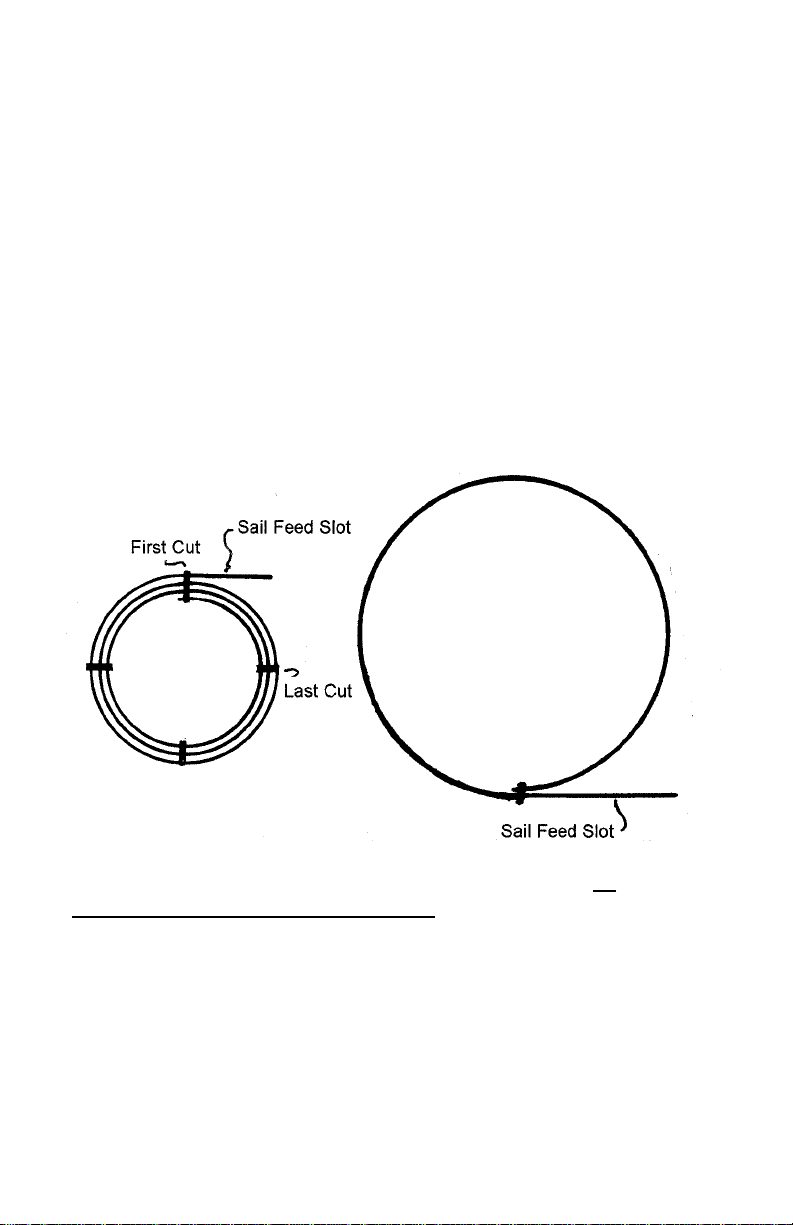

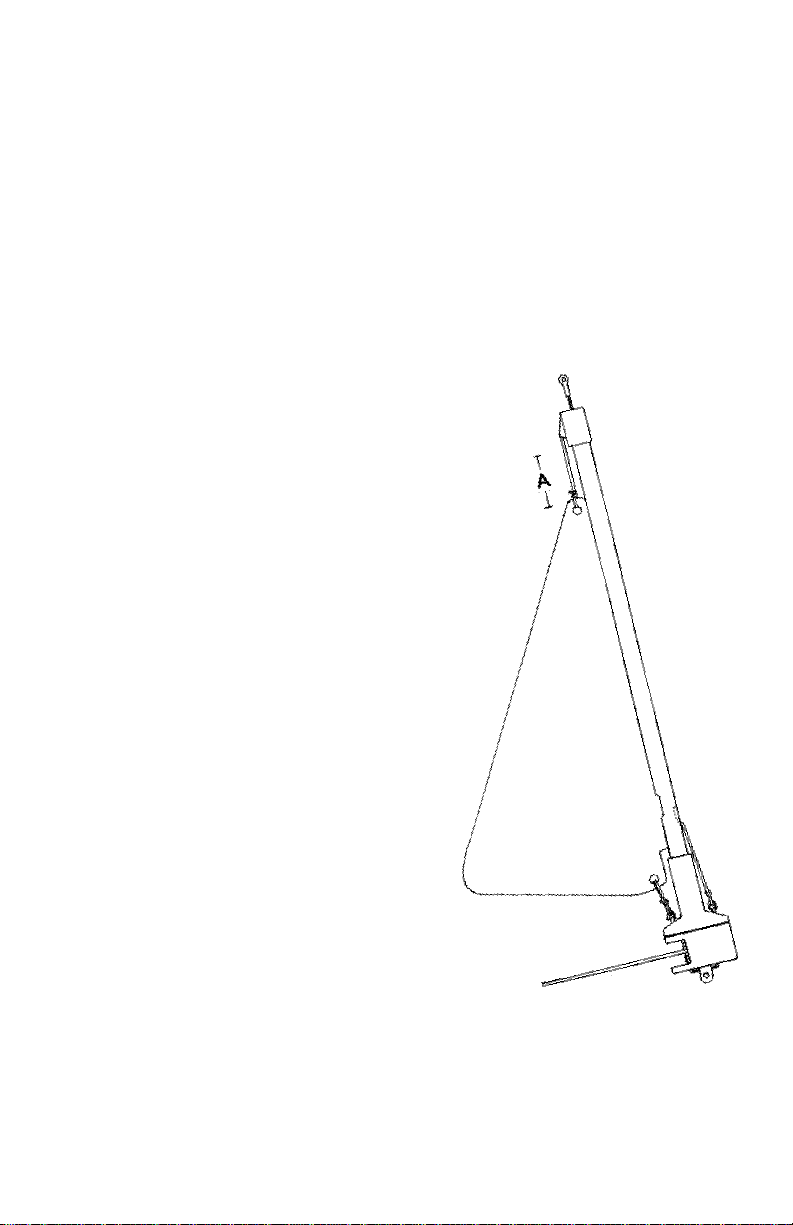

12. If your jib is full or almost full hoist

(dimension A in drawing at right is less than

12” when sail is in desired position), pull the

halyard ferrule hard up against the halyard

top fitting and cut the halyard so that when

it is tied to the sail, the head of the sail is

just below the sail feed slot. Melt end of

rope to prevent fraying.

If dimension A is more than 12” when jib

is hoisted to desired position, pull the

halyard ferrule up against the halyard

top fitting and tie the halyard to the

sail so the head of the sail is below

the sail feed slot by an amount

approximately equal to dimension A.

When the sail is raised, there must

enough decored halyard to reach

and be made fast to the halyard

anchor shackle. This may take some

experimentation so cut the halyard

only after you confirm the length.

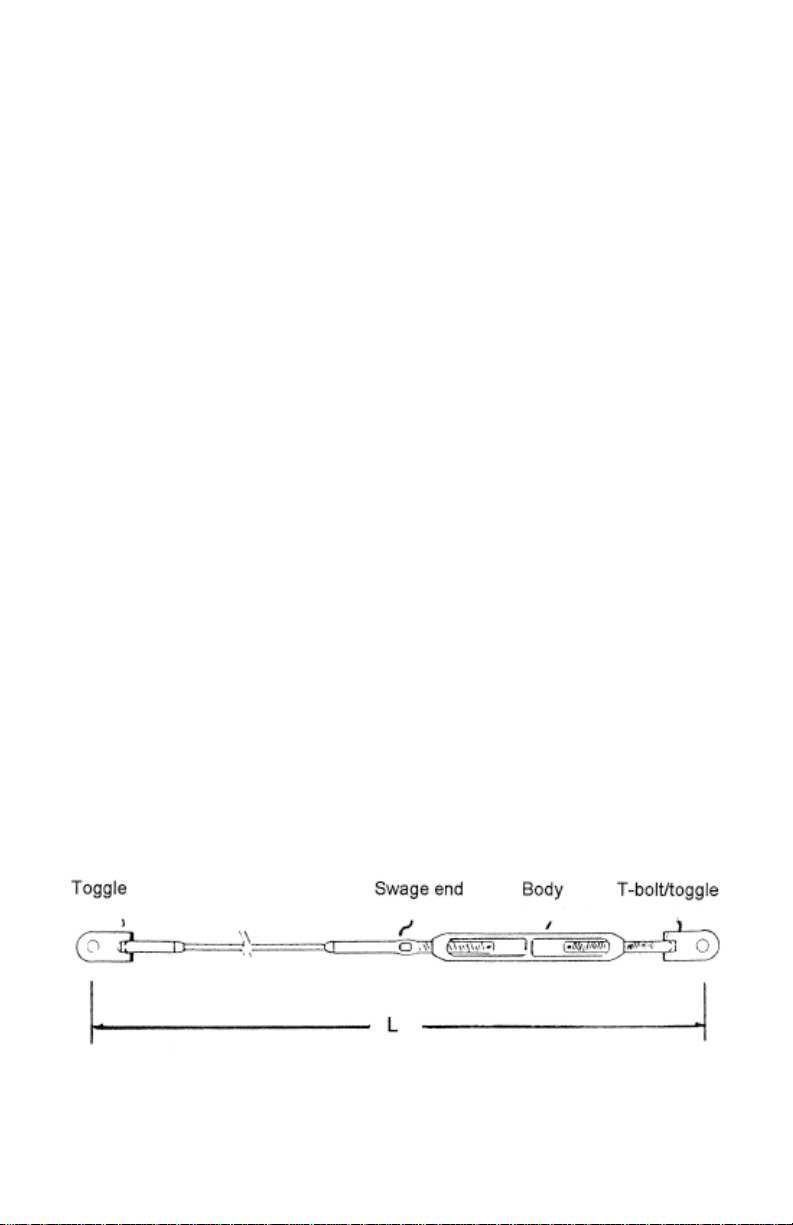

13. If the forestay length needs to be adjusted, remove the luff

support pin, slide up the spool to expose turnbuckle and make

your adjustment. In so doing, you may knock out the thrust washer.

After adjusting the turnbuckle, be sure thrust washer is in place.