Installation and Troubleshooting Guide

This installation is to be completed by an Authorized Dealer or Professional Service

Technician. For questions regarding installation or warranty, call CDI Tech Support

at 866-423-4832. Do not return to the Dealer or Distributor where the part was purchased.

Contact CDI Electronics Directly for Return Material Authorization.

CDI Electronics, LLC •353 James Record Road SW •Huntsville, AL 35824 USA

Web Support: www.cdielectronics.com •Tech Support: 1-866-423-4832 •Order Parts: 1-800-467-3371

All rights reserved. Reproduction or use of content, in any manner, without express written permission by CDI Electronics, LLC., is prohibited.

Rev F •6/19/2023 Page - 5 of 6 QF-358

HIGH SPEED MISFIRE OR WEAK HOLE SHOT:

1. Connect a DVA meter to the Green/White and White/Green Stator wires and perform a running test. The voltage should show a smooth

climb throughout the RPM range. A sudden drop or decline in voltage indicates a problem usually found in the Stator, although a

Voltage Regulator can cause the same symptom.

2. Connect a DVA meter to the Adapter Module Blue and Blue/White wires on 2 and 4 cylinder engines (or the Blue wire in reference to

engine ground on a 3 cylinder engine) and perform a running test. The voltage should show a smooth climb throughout the RPM range.

A sudden drop or decline in voltage indicates a problem with the Adapter Module.

3. Disconnect the Voltage Regulator and retest. If the problem disappears, replace the Voltage Regulator and retest.

4. Rotate the Stator one bolt hole in either direction and re-test. If the miss is gone, leave the Stator as is. If the miss is worse, rotate the

Stator back where it was.

ENGINE WILL NOT STOP (KILL):

1. Disconnect the Black/Yellow wire(s) at the Switchbox. Connect a jumper wire to the stop wire from the Switchbox and short it to engine

ground. If this stops the Switchbox from sparking, the stop circuit has a fault. Check the key switch, harness, and shift switch (if

present). If this does not stop the Switchbox from sparking, replace the Switchbox.

BATTERY CHARGING ISSUES:

1. Regardless of whether the charging issue is overcharging or not charging at all, the #1 cause of all charging issues is the battery often

due to improper style and/or charging neglect. #2 is the battery’s connections. #3 is the Voltage Regulator. #4 is the Stator.

2. The recommended type of battery for outboards is a single (NOT more than one) 850+ CCA dual purpose or cranking/starting non-

maintenance-free battery.

3. Non-maintenance-free batteries (lead-acid flooded cell; has vent caps on its top) have heavy, thick plates. They’re ideal for outboards,

where batteries are commonly drained by accessories while fishing, etc. when there is no charge applied to a battery while the battery

is in use. Its heavy plates can withstand constant discharging and charging. These batteries have much more reserve time and are

much more suited for this behavior.

NOTE: Some Maintenance free batteries will have vented caps on top. When in doubt, change the battery to a non-

maintenance free type.

4. Maintenance-free batteries should NEVER be used in an Outboard application. A new, fully charged maintenance-free battery may

work fine at first but their life span is dramatically shortened due to the constant charging and discharging. This activity will cause the

cells to become weak, and/or the cells will become dead. When this happens, the battery is unable to accept a full charge, thus putting

the Voltage Regulator at extreme risk of failure. Therefore, maintenance-free style batteries commonly cause charging issues shortly

after installation.

5. Check all battery connections, particularly at engine ground. Make sure that all connections are tight and free of corrosion. Do NOT use

wing nuts as they tend to loosen over a period of time from vibration. A loose connection WILL cause a premature battery and/or

Regulator failure(s).

6. If there is no change, try a single (NOT more than one) known good fully charged battery that is 850+ CAA Dual Purpose, or a

cranking/starting battery that is non-maintenance free. Make sure the battery is a lead acid flooded cell battery (has vent caps on its

top).

7. Measure the DVA across the Stator’s Yellow battery charge wires, while connected to the Voltage Regulator. At idle the DVA will

normally between 8-25 DVA. If not, disconnect the Yellow wires from the Voltage Regulator and retest. DVA will normally be 17-50 DVA

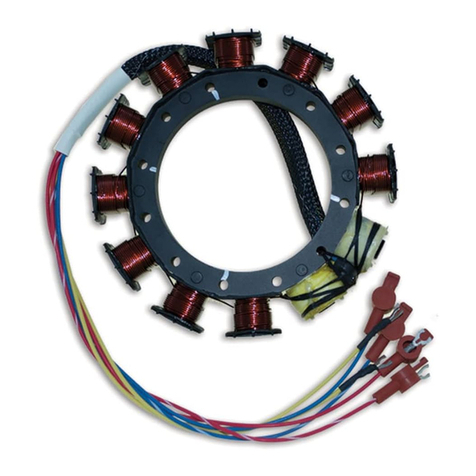

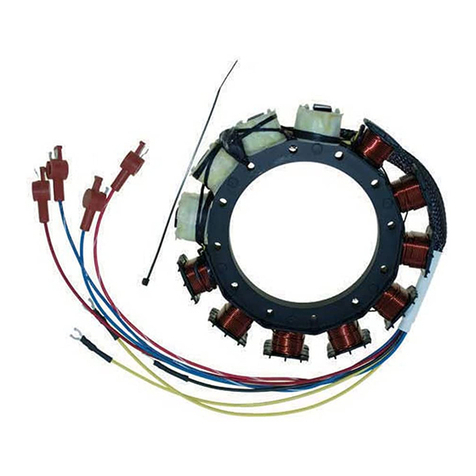

at idle. If the voltage is low, the Stator is possibly faulty. Perform a visual of the Stator for browning and varnish dripping. These are

signs that the Stator has overheated. If the visual inspection shows any of these signs, replace the Stator.

TACHOMETER TESTS

1. Measure the DVA across the Stator’s Yellow battery charge wires, while connected to the Voltage Regulator. At idle the DVA will

normally be between 8-25 DVA. If not, disconnect the Yellow wires from the Voltage Regulator and retest. DVA will normally be 17-50

DVA at idle. If the voltage is now within specification, the Voltage Regulator is likely defective.

2. Disconnect the Voltage Regulator’s Gray wire. At 800-1,000 RPM, check the DVA on the Gray wire FROM THE VOLTAGE

REGULATOR in reference to engine ground. The reading should be 8 DVA or more. If not, replace the Voltage Regulator.

3. If at least 8 DVA, run a jumper wire from the Gray wire out of the harness to one of the Stator’s Yellow wires.

4. If still no tachometer signal, try a known good tachometer.

5. If still no tachometer signal, replace the Stator.