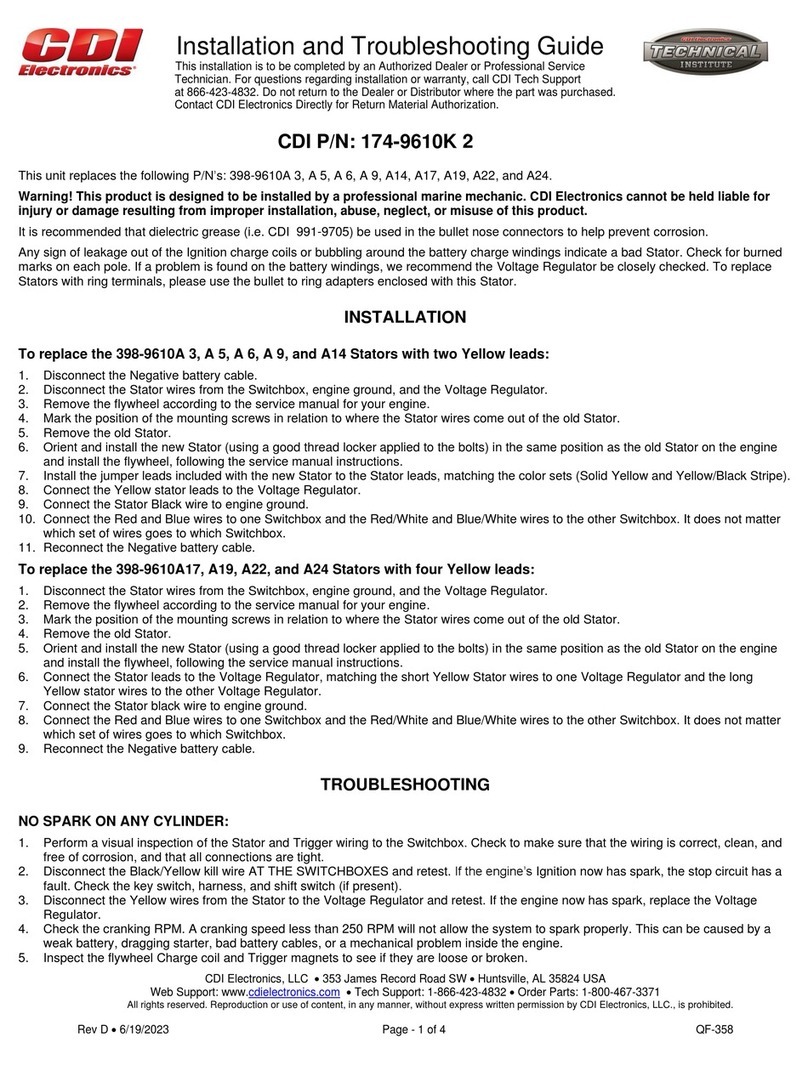

Installation and Troubleshooting Guide

This installation is to be completed by an Authorized Dealer or Professional Service

Technician. For questions regarding installation or warranty, call CDI Tech Support

at 866-423-4832. Do not return to the Dealer or Distributor where the part was purchased.

Contact CDI Electronics Directly for Return Material Authorization.

CDI Electronics, LLC •353 James Record Road SW •Huntsville, AL 35824 USA

Web Support: www.cdielectronics.com •Tech Support: 1-866-423-4832 •Order Parts: 1-800-467-3371

All rights reserved. Reproduction or use of content, in any manner, without express written permission by CDI Electronics, LLC., is prohibited.

Rev H •4/9/2021 Page - 1 of 3 QF-358

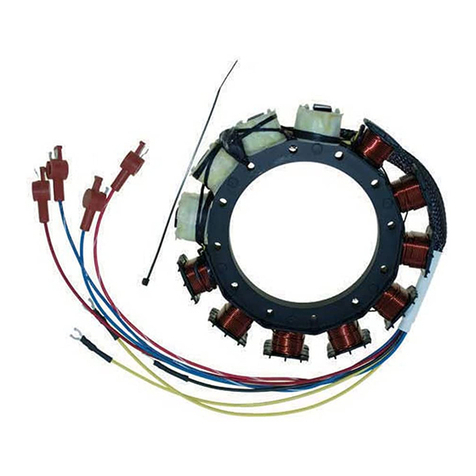

CDI P/N: 174-5454K 1

This Stator replaces the following 3 and 4 cylinder P/N’s: 398-5454A21, 22, 24, 25, 26, 41, 42, 56, 62, and 63. 398-5919A2, 3, 6, 7, 8, and

10. 398-18535A15. 398-5704A2, 4, 5 and 7.

Warning! This product is designed for installation by a professional marine mechanic. CDI Electronics cannot be held liable for

injury or damage resulting from improper installation, abuse, neglect, or misuse of this product.

DO NOT USE WITH THE FLYWHEEL CONTAINING GLUED-IN MAGNETS (1988 and newer) AS DAMAGE TO THE SWITCHBOX

WILL OCCUR!

It is recommended that dielectric grease (i.e. CDI 991-9705) be used in the bullet nose connectors to help prevent corrosion.

Any sign of leakage out of the Ignition charge coils or bubbling around the battery charge windings indicate a bad Stator. Check for burned

marks on each pole. If a problem is found on the battery windings, we recommend the Regulator/Rectifier be closely checked. To replace

Stators with fork terminals, please use the bullet to fork adapters enclosed with this Stator.

If this Stator is to be used as a replacement for the Mercury “Red”Stator, connect all wires to the Switchbox in their designated

position. The Adapter Module used with the Red Stator is no longer needed.

If this Stator is to be used on a three cylinder engine, connect the Red/White and Blue/White striped wires to engine ground.

INSTALLATION

1. Disconnect the Stator wires from the Switchbox, engine ground, and the Regulator/Rectifier.

2. Remove the flywheel.

3. Mark the position of the mounting screws in relation to where the Stator wires come out of the old Stator and remove the old Stator.

4. Orient and install the new Stator (using a good thread-locker applied to the bolts) in the same position as the old Stator on the engine

and install the flywheel, following the service manual instructions.

5. Connect the Yellow wires from the Stator to the Regulator/Rectifier, ignoring any stripes on the Regulator/Rectifier’s Yellow wires.

6. Connect the Stator leads as follows:

New Stator 3 Cylinder Switchbox 4 Cylinder Switchbox

Red(High speed Coil) Red (High speed Coil) Red (High speed Coil)

Blue (Low speed Coil) Blue (Low speed Coil) Blue (Low speed Coil)

Red/White (High speed Coil) Engine Ground Red/White Stripe (High speed Coil)

Blue/White (Low speed Coil) Engine Ground Blue/White Stripe (Low speed Coil)

7. If this Stator is to be used on a 3 cylinder engine application, connect the Red/White and Blue/White striped wires to a known good

engine ground.

8. If your engine used a Mercury Red Stator Kit, it is normal for that application to have NOT used the Red and the Red/White wire (or

Red and Red/White stud post on a studded Switchbox). These are usually either taped up or capped off. With the CDI Electronics 194-

5454K 1 Stator, the Red and Red/White wire WILL be used. Find the Red wire (or Red stud post on a studded Switchbox) and connect

the Solid Red wire from the New Stator to the Switchbox. On a 4 cylinder application, connect the Red/White wire to the Switchbox in

its appropriate place. On a 3 cylinder application, connect the remaining Red/White and Blue/White striped wires to a known good

engine ground.

9. Replace the flywheel according to the service manual.

TROUBLESHOOTING

How to test the Engine Stop Circuit (Kill) for DC Voltage:

1. DC voltage present on the kill circuit of the Switchbox due to a faulty key switch, boat harness, or engine harness will severely damage

the Switchbox’s internal kill circuit. Connect a Digital Multi Meter to the Ignition Stop wire(s) AT THE SWITCHBOX while disconnected

from the Switchbox in reference to a known good engine ground. Turn the Ignition switch on and off several times. If, at any time, you

see over 2 VDC on the kill wire(s), there is a problem with one or both harnesses and/or the Ignition switch. The Ignition Stop wire

should not be connected back to the new Switchbox at any point until the problem is corrected OR DAMAGE TO THE SWITCHBOX

WILL OCCUR!

NO FIRE ON ANY CYLINDER:

1. Perform a visual inspection of the Stator and Trigger wiring to the Switchbox. Check to make sure that the wiring is correct, clean, and

free of corrosion, and that all connections are tight.

2. Disconnect the Black/Yellow kill wire AT THE SWITCHBOX and retest. If the engine’s Ignition now has spark, the stop circuit has a

fault. Check the key switch, harness, and shift switch (if present).