Installation and Troubleshooting Guide

This installation is to be completed by an Authorized Dealer or Professional Service

Technician. For questions regarding installation or warranty, call CDI Tech Support

at 866-423-4832. Do not return to the Dealer or Distributor where the part was purchased.

Contact CDI Electronics Directly for Return Material Authorization.

CDI Electronics, LLC •353 James Record Road SW •Huntsville, AL 35824 USA

Web Support: www.cdielectronics.com •Tech Support: 1-866-423-4832 •Order Parts: 1-800-467-3371

All rights reserved. Reproduction or use of content, in any manner, without express written permission by CDI Electronics, LLC., is prohibited.

Rev F •2/21/2022 Page - 1 of 4 QF-358

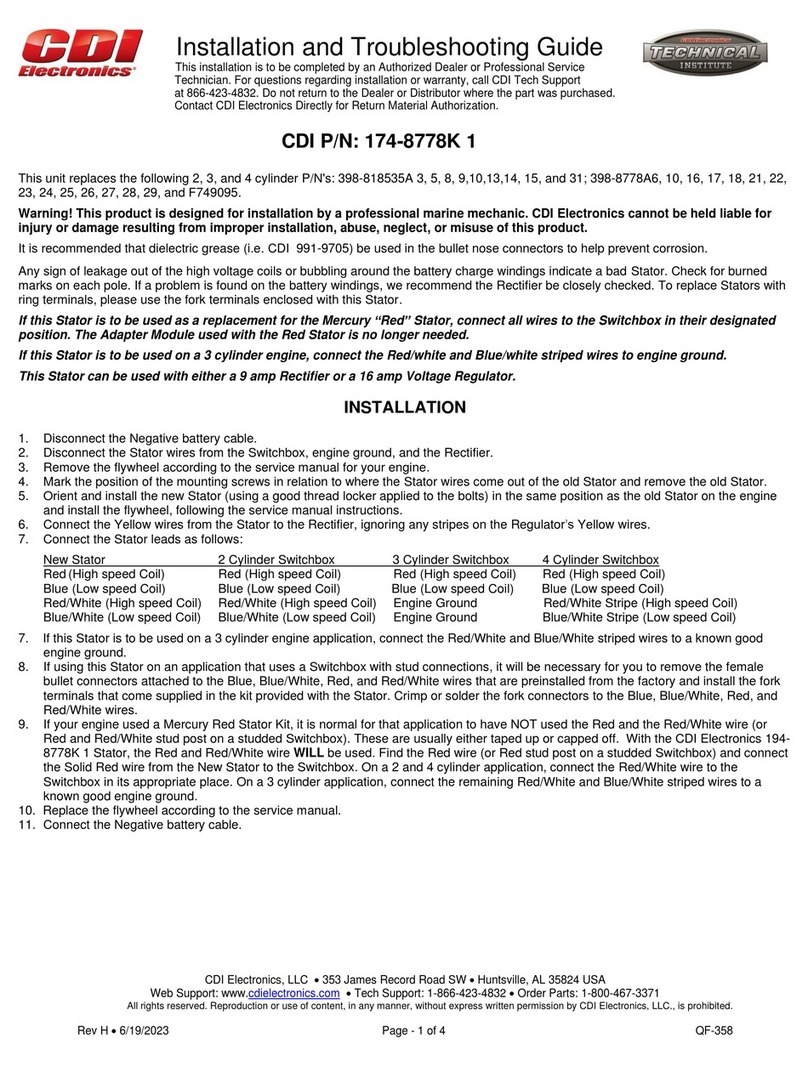

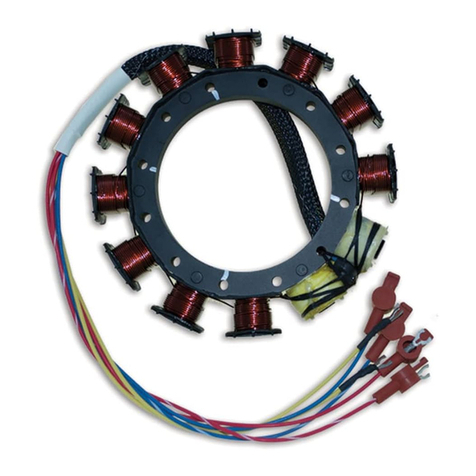

CDI P/N: 113-6367K 1

This unit replaces the following P/N's: 436367, 584122, 584265, 584919, 584920, and 584921.

WARNING! This product is designed to be installed by a professional marine mechanic. CDI Electronics cannot be held liable for

injury or damage resulting from improper installation, abuse, neglect, or misuse of this product.

This unit requires the Factory Recommended Champion QL78YC (0.30 Gap) Spark Plugs and the Gray or Blue spark plug wires.

You must use the gray sleeved Stator (584981 or 173-4981) for warranty coverage.

DO NOT OPERATE ENGINE WITH PLASTIC ENCODER COVER OFF OF THE ENGINE.

How to test the Engine Stop Circuit (Kill) for DC Voltage:

1. DC voltage present on the kill circuit of the Power Pack due to a faulty key switch, boat harness, or engine harness will severely

damage the Power Pack’s internal kill circuit. Connect a Digital Multi Meter to the Ignition Stop wire AT THE POWER PACK while

disconnected from the Power Pack in reference to a known good engine ground. Turn the Ignition switch on and off several times. If, at

any time, you see over 2 VDC on the kill wire, there is a problem with one or both harnesses and/or the Ignition switch. The Ignition

Stop wire should not be connected back to the new Power Pack at any point until the problem is corrected OR DAMAGE TO THE

POWER PACK WILL OCCUR!

INSTALLATION

1. Disconnect the Negative battery cable.

2. Remove the Optical Sensor cover, the Power Pack cover, and Voltage Regulator cover (between the Optical Sensor cover and the

Power Pack).

3. Disconnect the Stator wire connector from the Power Pack.

4. Disconnect the harness wire connector from the Power Pack.

5. Disconnect the Optical sensor wire connector from the Optical sensor.

6. Carefully remove the sensor support return spring between the flywheel cover and the Optical sensor support assembly and set aside.

7. Remove the bolt securing the Encoder wheel and CAREFULLY remove the Encoder wheel, making sure not to crack or damage it in

anyway. Pay special attention to the timing pointer. Carefully move the timer pointer away from the Encoder wheel enough to pull the

Encoder wheel up and off without loosening the timer pointer. If the timer pointer is loosened, it will have to be recalibrated by

calibrating cylinder #1 with a dial indicator to TDC. If the Encoder wheel is damaged it will need to be replaced.

8. Remove the five Pozidriv screws holding the Optical sensor support retainers down that secure the Optical sensor support assembly in

place.

9. Remove the Optical sensor assembly from the flywheel cover.

10. Remove the two Pozidriv screws the secure the Optical sensor to the Optical sensor support assembly.

11. Install the new Optical sensor in the Optical sensor support assembly with the infrared LEDs facing up towards the Encoder wheel.

Secure with the two Pozidriv screws by tightening to 15-20 in. lbs.

12. Apply a light coat of marine grade grease to the sliding surfaces of the Optical sensor support. Position the Optical sensor support in

the flywheel cover. Position the two Optical sensor support retainers and tighten the five Pozidriv screws. Check to see that the Optical

sensor support arm rotates freely.

13. Attach the Optical sensor support return spring to the Optical sensor support assembly and to its post on the flywheel cover.

14. Reinstall the Encoder wheel by carefully moving the timing pointer out of the way just enough to slide the Encoder wheel on to the

crankshaft. The Encoder wheel is slotted for a keyway and will only go on one way.

15. Install the Encoder wheel retaining bolt to the crankshaft using a thread locking compound and tighten to 120-140 in. lbs.

16. Disconnect the spark plug wires from the spark plugs.

17. Unbolt and remove the Ignition coils and old Power Pack. Look for burned areas between the coil mounting holes on the stainless RF

shield. If a discoloration is found, replace that particular Ignition coil.

18. Disconnect the Orange Primary wires of the old Power Pack from the Ignition coils.

19. Make sure the RF noise shield is between the Ignition coils and the Power Pack.

20. Install the Ignition coils and connect the Orange Primary wires of the new Power Pack to the Ignition coils. The Orange/Blue Primary

wires are for cylinders #1 and #2, the Orange Primary wires are for cylinder #3 and #4, and the Orange/Green Primary wires are for

cylinders #5 and #6.

21. Install the new spark plug wires to the Ignition coils.

22. Install the Ignition coils and Power Pack to the engine. Take care not to over-torque the mounting bolts, OEM specification calls for 50-

95 in lbs. of torque.

23. Connect the Stator and harness connectors to the Power Pack. Use a small amount of dielectric silicone grease on the connector seal

but do not put any inside the sockets.

24. Connect the Optical sensor connector to the Optical Sensor.