3

ITALIANO

1 - presentaZIone......................................... 48

1.1 - Informazioni generali R-410A...................... 48

2 - proCedure dI sICureZZa.................. 49

2.1 - Informazioni generali..................................... 49

2.2 - Utilizzo delle unità......................................... 49

2.3 - Installazione delle unità................................. 49

2.4 - Collegamenti elettrici..................................... 50

2.5 - Assistenza e manutenzione ........................... 50

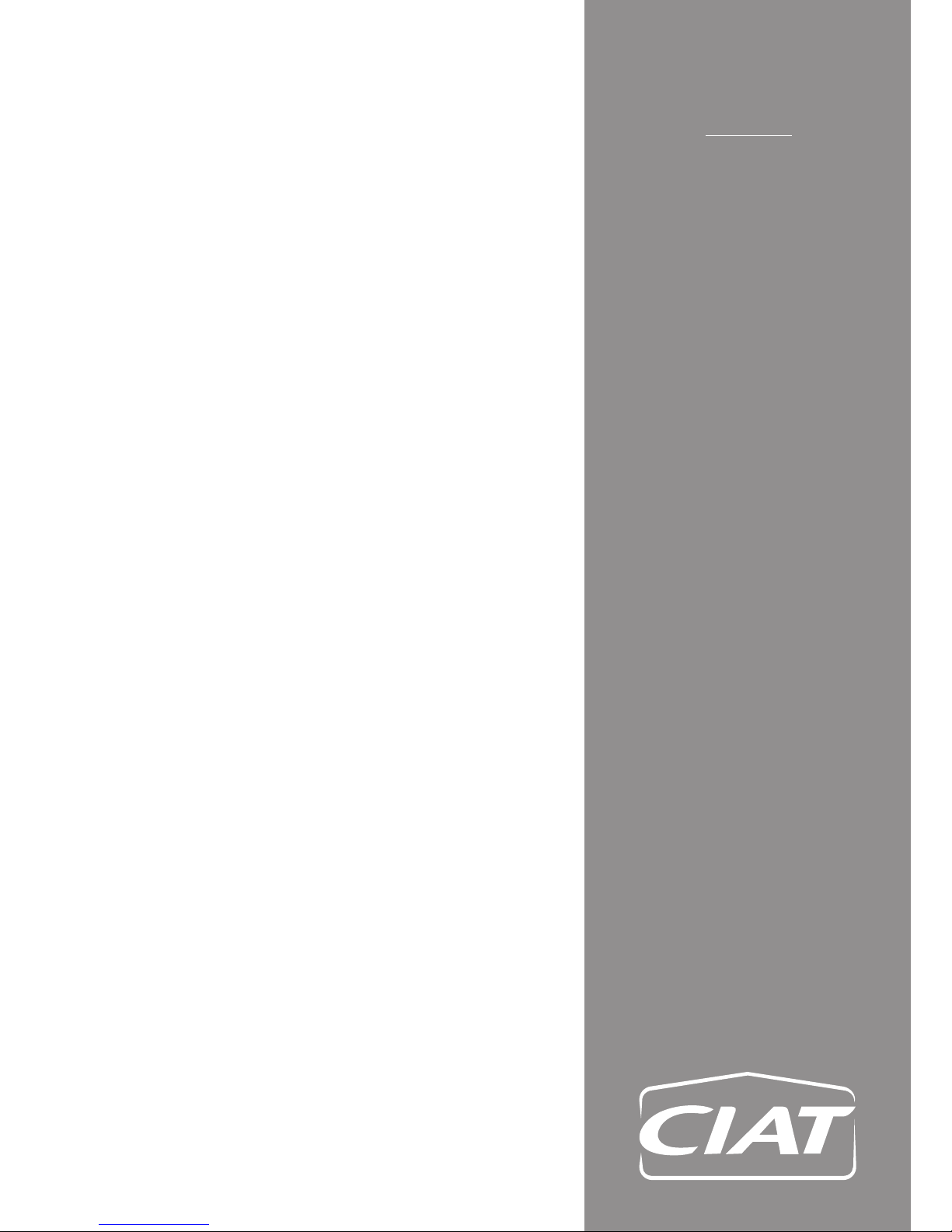

3 - dImensIonI e spaZI mInImI................. 51

4 - datI teCnICI ................................................ 51

5 - InstallaZIone .......................................... 51

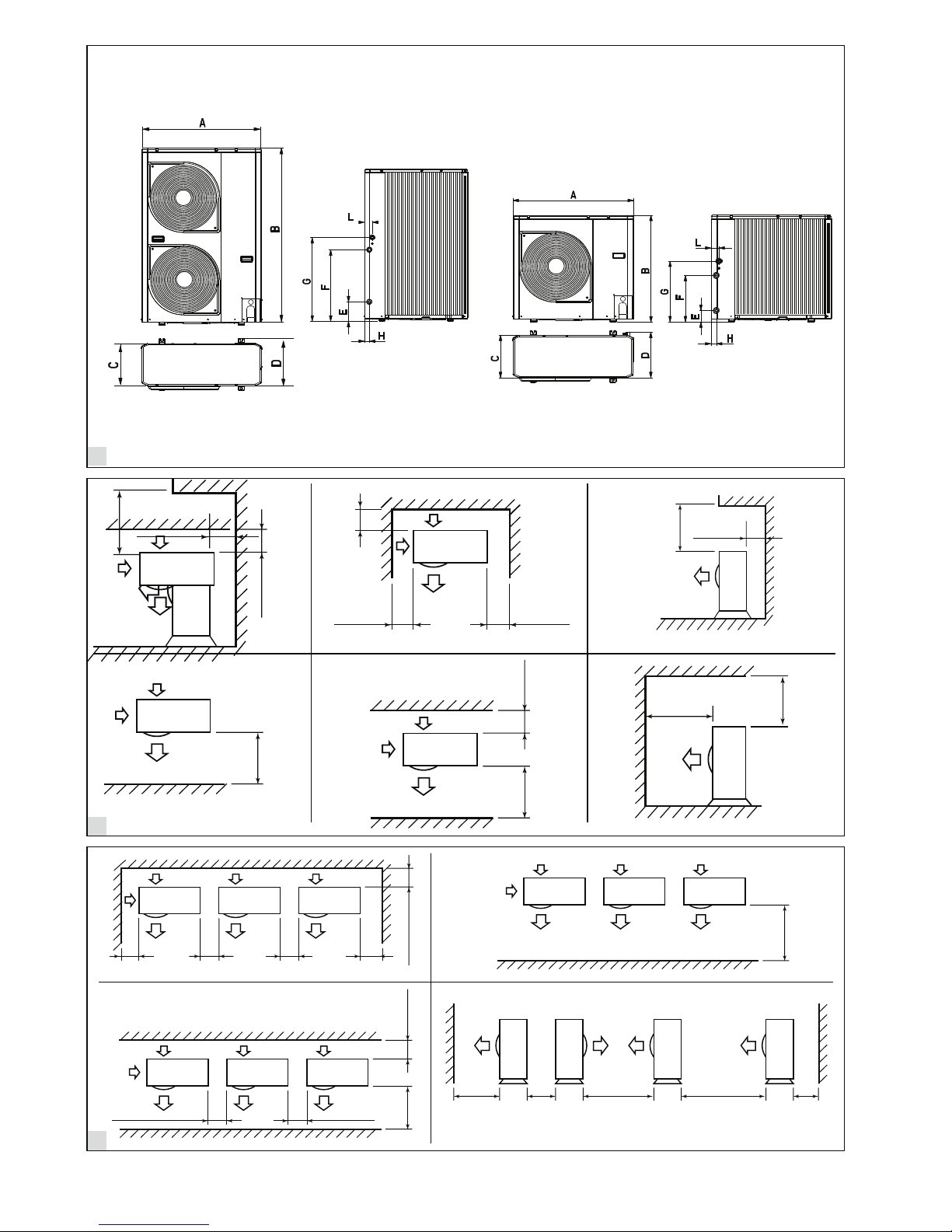

5.1 - Procedura di apertura passaggio

cavi (Fig. 4) .............................................................. 51

5.2 - Modalità di rimozione del pannello

anteriore (Fig. 5) ..................................................... 51

5.3 - Tubo di scarico condensa e fori pretranciati

della base (Fig. 6) .................................................... 51

5.4 - Limiti di funzionamento (Fig. 7/8)................ 51

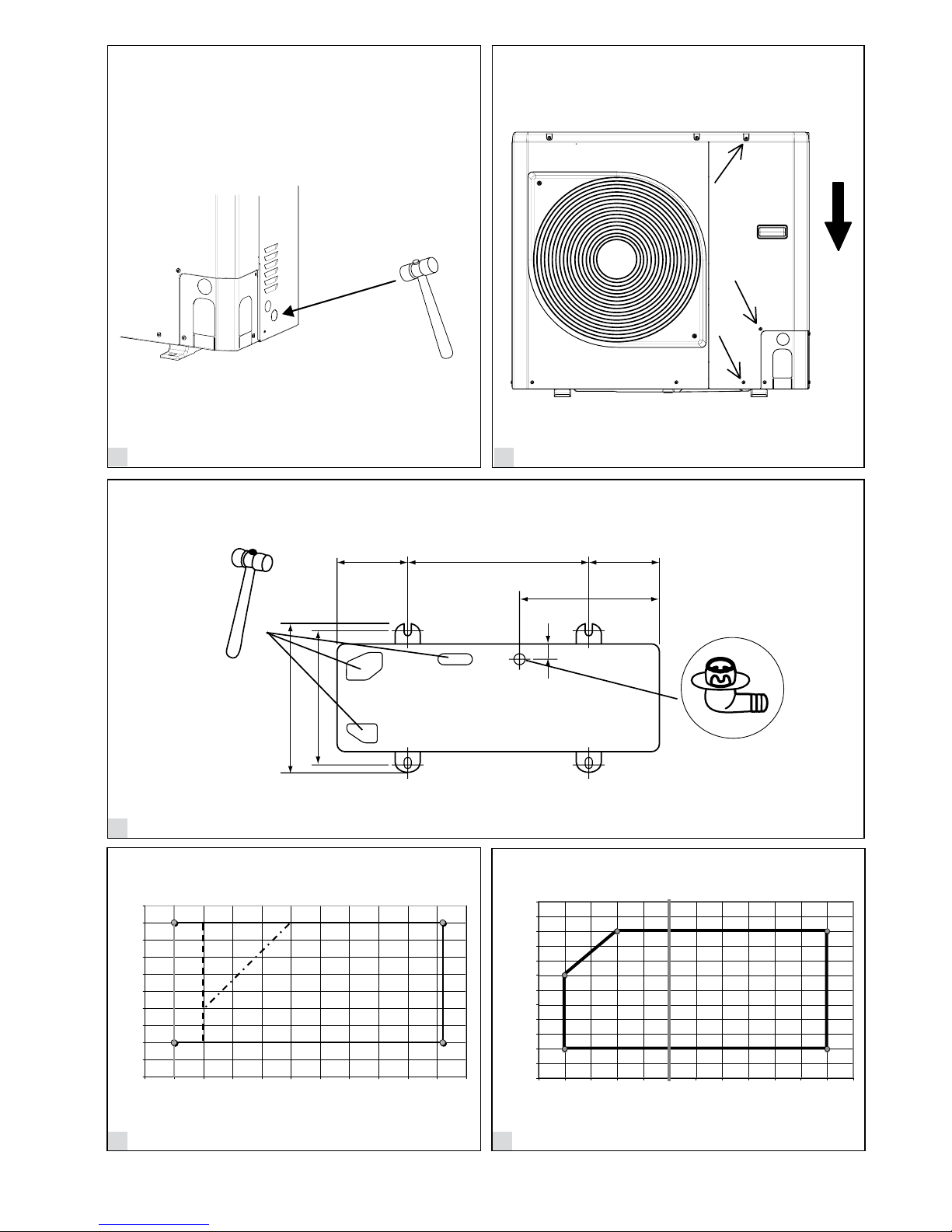

6 - CollegamentI IdraulICI .................. 52

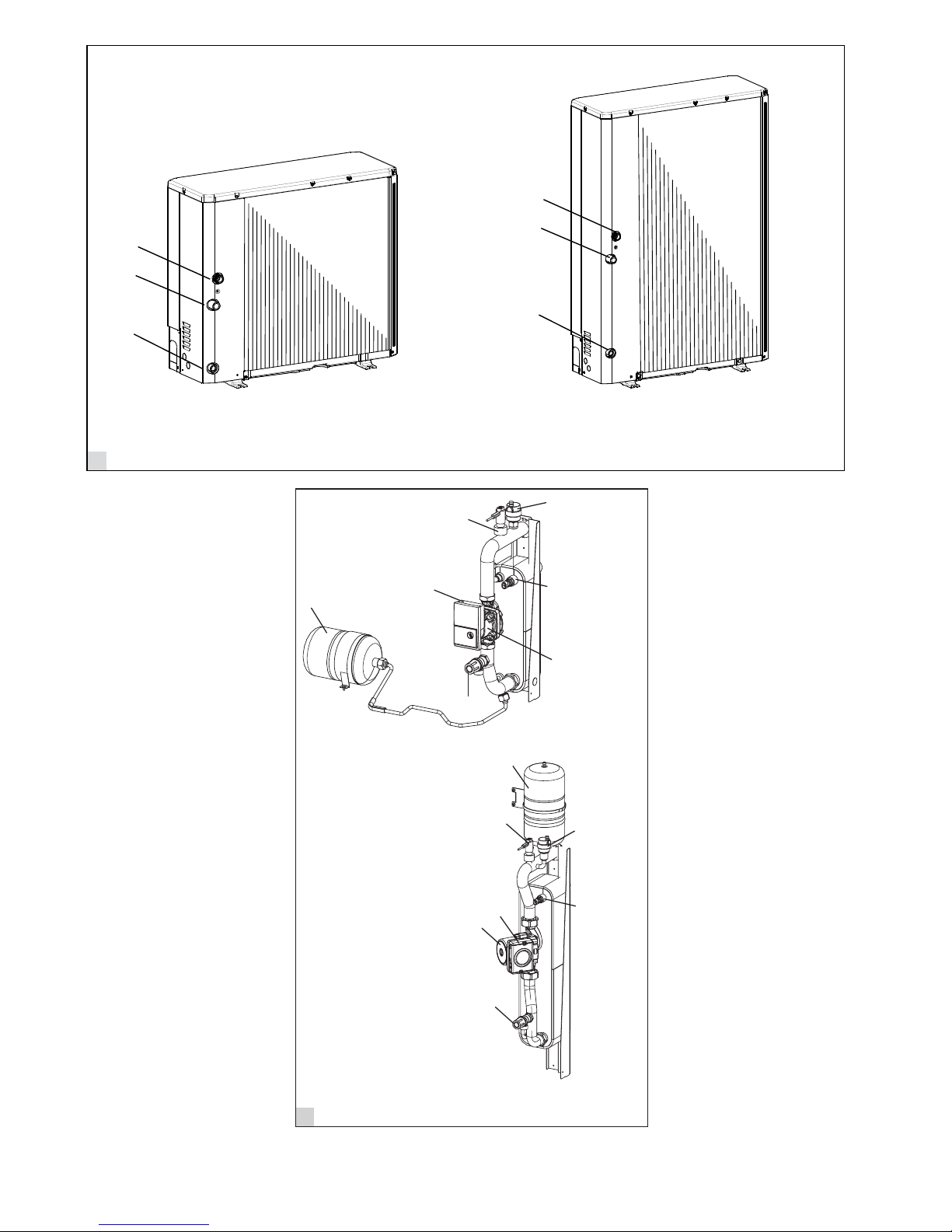

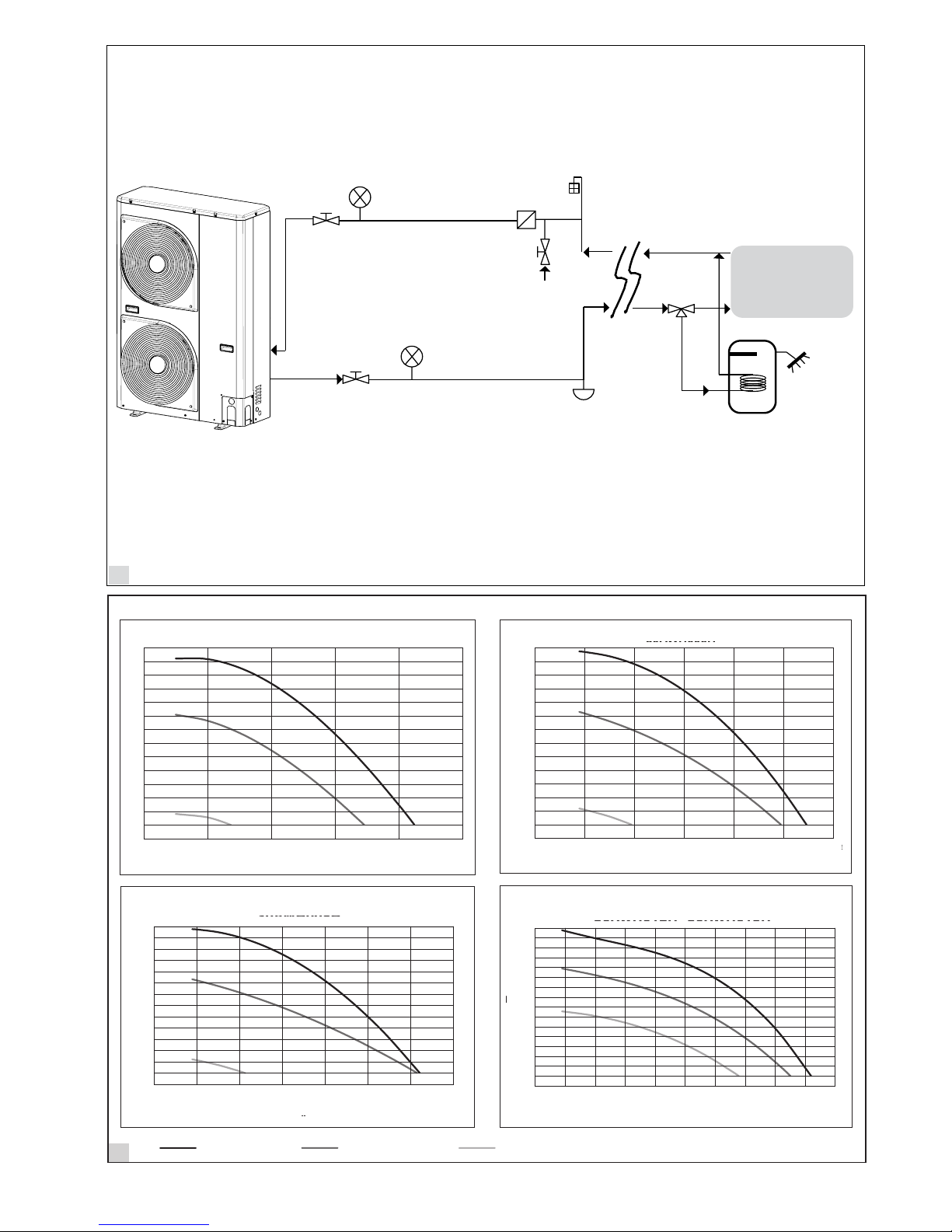

6.1 - Modulo idronico (Fig. 9/10)........................... 52

6.2 - Collegamenti idraulici (Fig. 12) .................... 52

6.3 - Schema Idraulico Consigliato (Fig. 11)........ 53

7 - CollegamentI elettrICI (fIg. 14) . 54

8 - Collegamento aCCessorI

ausIlIarI (fIg. 14) ........................................... 55

8.1 - Valvola 3-vie.................................................... 55

8.2 - Limitazione Frequenza.................................. 55

8.3 - Segnali di Stop Unità o Sbrinamento........... 55

8.4 - Sonda di Temperature Esterna ..................... 55

8.5 - Deumidicatore o Umidicatore ................. 55

8.6 - Circolatore d’acqua aggiuntivo (ADD WP)55

8.7 - Segnale per richiesta di una Fonte di Calore

Esterna (EHS) ........................................................ 56

8.8 - Ingresso allarme esterno................................ 56

8.9 - Richiesta Sorgente Ausiliaria per produzione

acqua calda sanitaria .............................................. 56

8.10 - Pin Morsettiera............................................. 56

9 - verIfICa del sIstema........................... 57

9.1 - Codici allarmi scheda inverter (solo perr

EREBA) (Fig. 13)................................................... 57

9.2 - Codice allarmi scheda inverter (solo per le

taglie 15H 1Ph e 12HT-15HT 3Ph) (Fig. 13)........ 58

9.3 - Codici di Allarmi scheda GMC (Fig. 13) ..... 59

10 - dIsposItIvI dI proteZIone unItà 59

11 - manutenZIone ....................................... 59

11.1 - Verica della carica refrigerante................. 59

IndICe

ESPAÑOL NEDERLANDS

tabla de materIas Inhoud

2 - veIlIgheIdsproCedures ................... 73

2.1 - Algemene opmerkingen ................................ 73

2.2 - Omgaan met de units..................................... 73

2.3 - Installatie van de units................................... 73

2.4 - Elektrische bedrading.................................... 74

2.5 - Reparaties en onderhoud.............................. 74

3 - afmetIngen en benodIgde vrIje

ruImte ................................................................. 75

4 - teChnIsChe gegevens......................... 75

5 - InstallatIe................................................. 75

5.1 - Procedure voor het openen van de

buisdoorgangen (Fig. 4).......................................... 75

5.2 - Zo verwijdert u het frontpaneel (Fig. 5) ...... 75

5.3 - Afvoerbuis en voorgevormde gaten

basishouder (Fig. 6) ................................................ 75

5.4 - Bedrijfslimieten (Fig. 7/8).............................. 75

6 - WateraansluItIngen.......................... 76

6.1 - Hydro module (Fig. 9/10) .............................. 76

6.2 - Wateraansluitingen (Fig. 12).......................... 76

6.3 - Aanbevolen Hydraulisch Schema (Fig. 11) . 77

7 - elektrIsChe aansluItIngen

(fIg. 14)................................................................... 78

8 - aansluItIng hulpaCCessoIres

(fIg. 14)................................................................... 79

8.1 - 3-wegsklep....................................................... 79

8.2 - Frequentiebeperking...................................... 79

8.3 - Signalen stop unit of ontdooien.................... 79

8.4 - Buitentemperatuurmeter .............................. 79

8.5 - Ontvochtiger of bevochtiger......................... 79

8.6 - Extra waterpomp (ADD WP) ...................... 79

8.7 - AanvraagSignaal voor een Externe

Warmtebron (EHS)................................................ 80

8.8 - Externe alarminvoer...................................... 80

8.9 - Backupverwarming is nodig voor sanitair

warm water.............................................................. 80

8.10 - Pin Klemmenbord........................................ 80

9 - systeemtest ............................................... 81

9.1 - Alarmcodes kaart inverter (alleen

EREBA) (Fig. 13)................................................... 81

9.2 - Alarmcodes kaart inverter (Alleen voor typen

15H 1Ph en 12HT-15HT 3Ph) (Fig. 13)................ 82

9.3 - Alarmcodes GMC Kaart (Fig. 13)................ 83

10 - besChermIngsmeChanIsmen

unIt........................................................................ 83

11 - onderhoud.............................................. 83

11.1 - Controle koudemiddelvulling..................... 83

1 - IntroduCCIÓn........................................... 60

1.1 - R-410A - Informacion general...................... 60

2 - proCedImIentos de segurIdad.... 61

2.1 - Informaciones generales................................ 61

2.2 - Utilización de la unidad................................. 61

2.3 - Instalación de las unidades............................ 61

2.4 - Conexiones eléctricas..................................... 62

2.5 - Asistencia y mantenimiento.......................... 62

3 - dImensIones y espaCIos lIbres ..... 63

4 - datos téCnICos......................................... 63

5 - InstalaCIÓn................................................ 63

5.1 - Procedimiento de apertura de los pasos de los

tubos (Fig. 4)............................................................ 63

5.2 - Cómo extraer el panel frontal (Fig. 5) ......... 63

5.3 - Tubo de evacuación de la condensación y los

oricios precortados de la base (Fig. 6)................ 63

5.4 - Limites de funcionamiento (Fig. 7/8) ........... 63

6 - ConexIones hIdráulICas ................. 64

6.1 - Módulo hidrónico (Fig. 9/10) ........................ 64

6.2 - Conexiones hidráulicas (Fig. 12)................... 64

6.3 - Esquema Hidráulico Recomendado

(Fig. 11) ................................................................... 65

7 - ConexIones eléCtrICas (fIg. 14).... 66

8 - ConexIÓn aCCesorIos auxIlIares

(fIg. 14)................................................................... 67

8.1 - Válvula de 3 vías............................................. 67

8.2 - Limitación frecuencia .................................... 67

8.3 - Señales de Stop Unidad o Desempañado ... 67

8.4 - Sonda de Temperaturas Exteriores .............. 67

8.5 - Déshumidicateur ou Humidicateur......... 67

8.6 - Bomba de agua adicional (ADD WP)......... 67

8.7 - Señal para pedido de una Fuente de Calor

Externa (EHS)........................................................ 68

8.8 - Entrada alarma exterior ................................ 68

8.9 - Es necesario un calentador de respaldo para

agua caliente sanitaria............................................ 68

8.10 - Pin Caja de Bornes....................................... 68

9 - verIfICaCIÓn del sIstema ................ 69

9.1 - Códigos alarmas placa Convertidor (sólo para

EREBA) (Fig. 13)................................................... 69

9.2 - Inversor códigos panel de alarma

(unicamente para tamaños 15H 1Ph y 12HT-15HT

3Ph) (Fig. 13)........................................................... 70

9.3 - Códigos de Alarmas placa GMC (Fig. 13)... 71

10 - dIsposItIvos de proteCCIÓn de la

unIdad................................................................. 71

11 - mantenImIento...................................... 71

11.1 - Vericación de la carga de refrigerante ..... 71

1 - InleIdIng...................................................... 72

1.1 - R-410A - Algemene informatie .................... 72