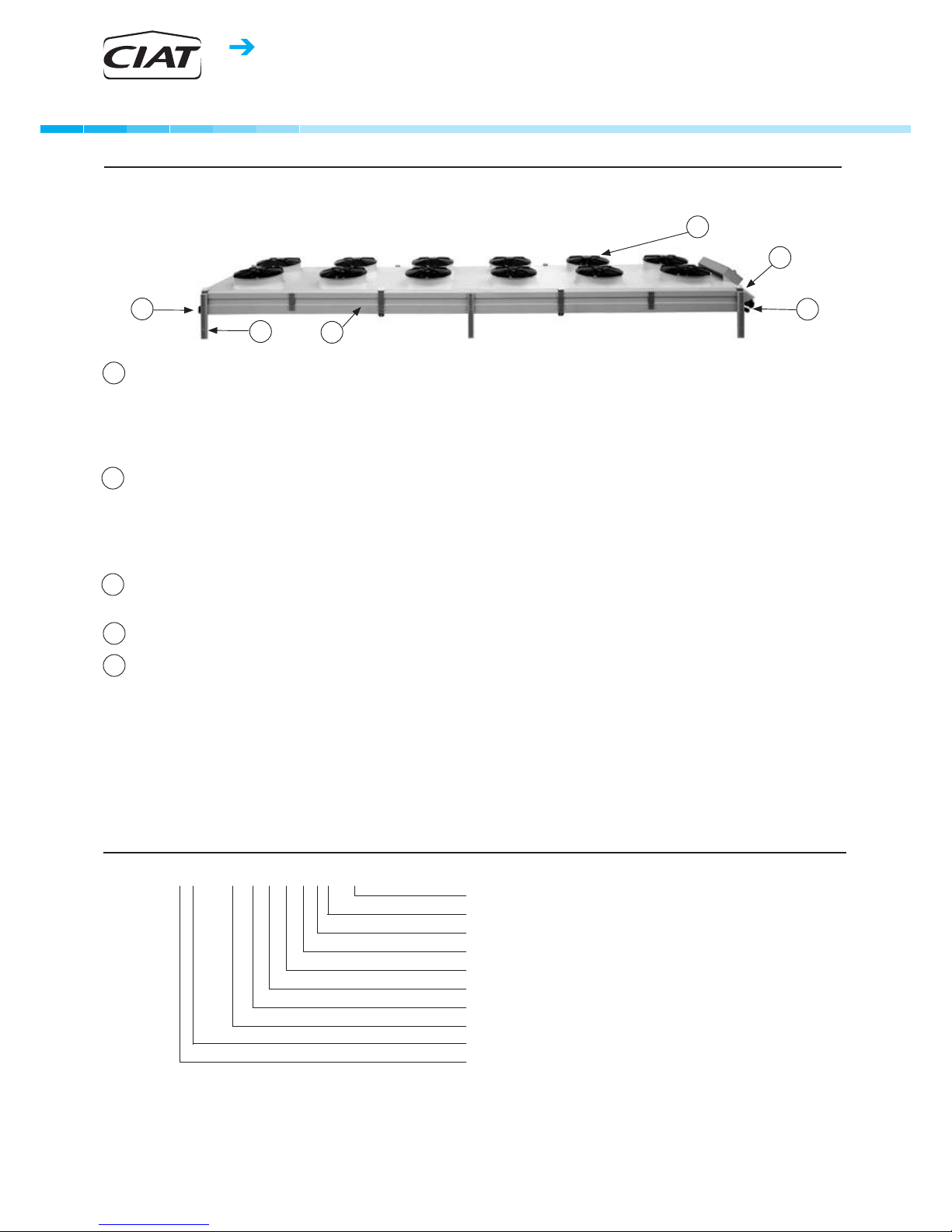

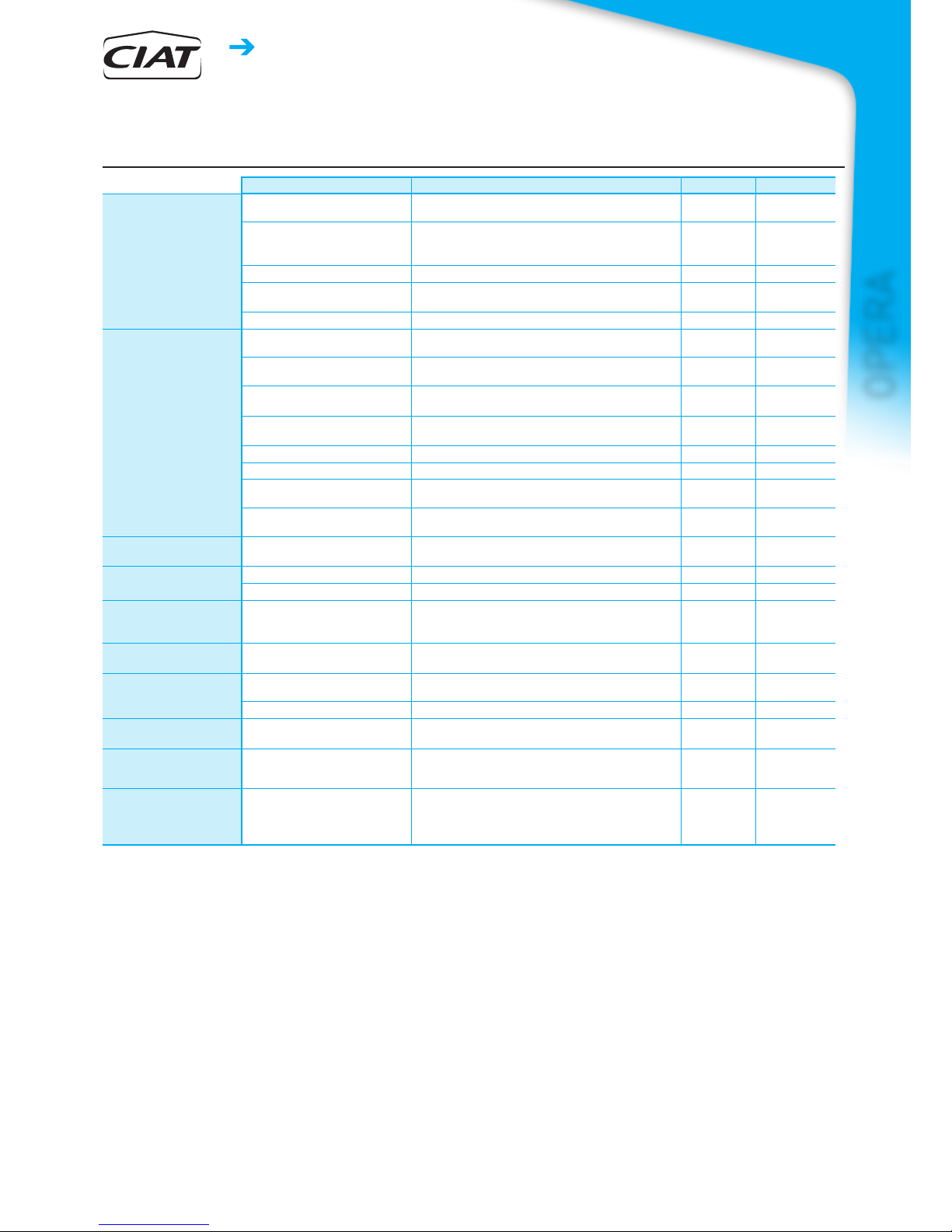

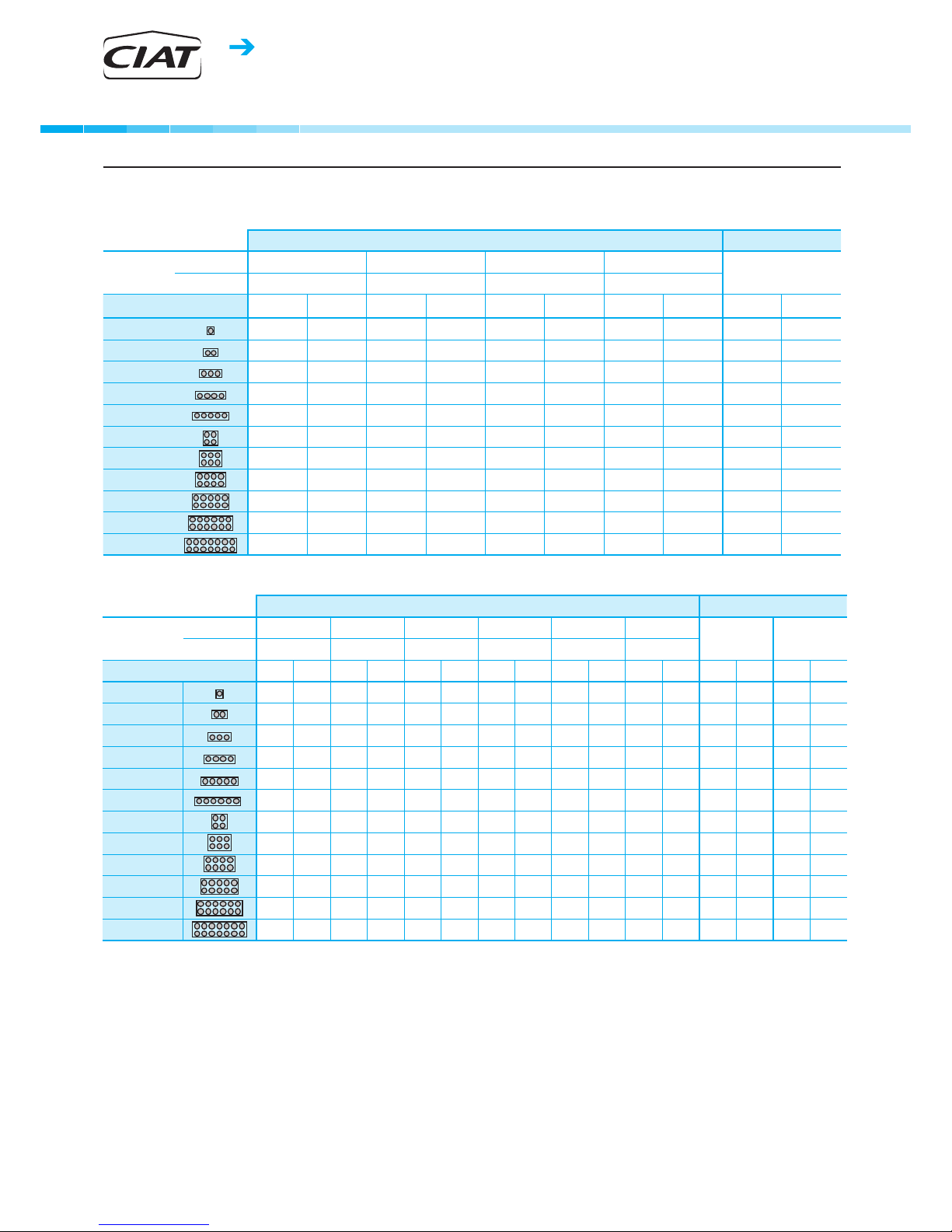

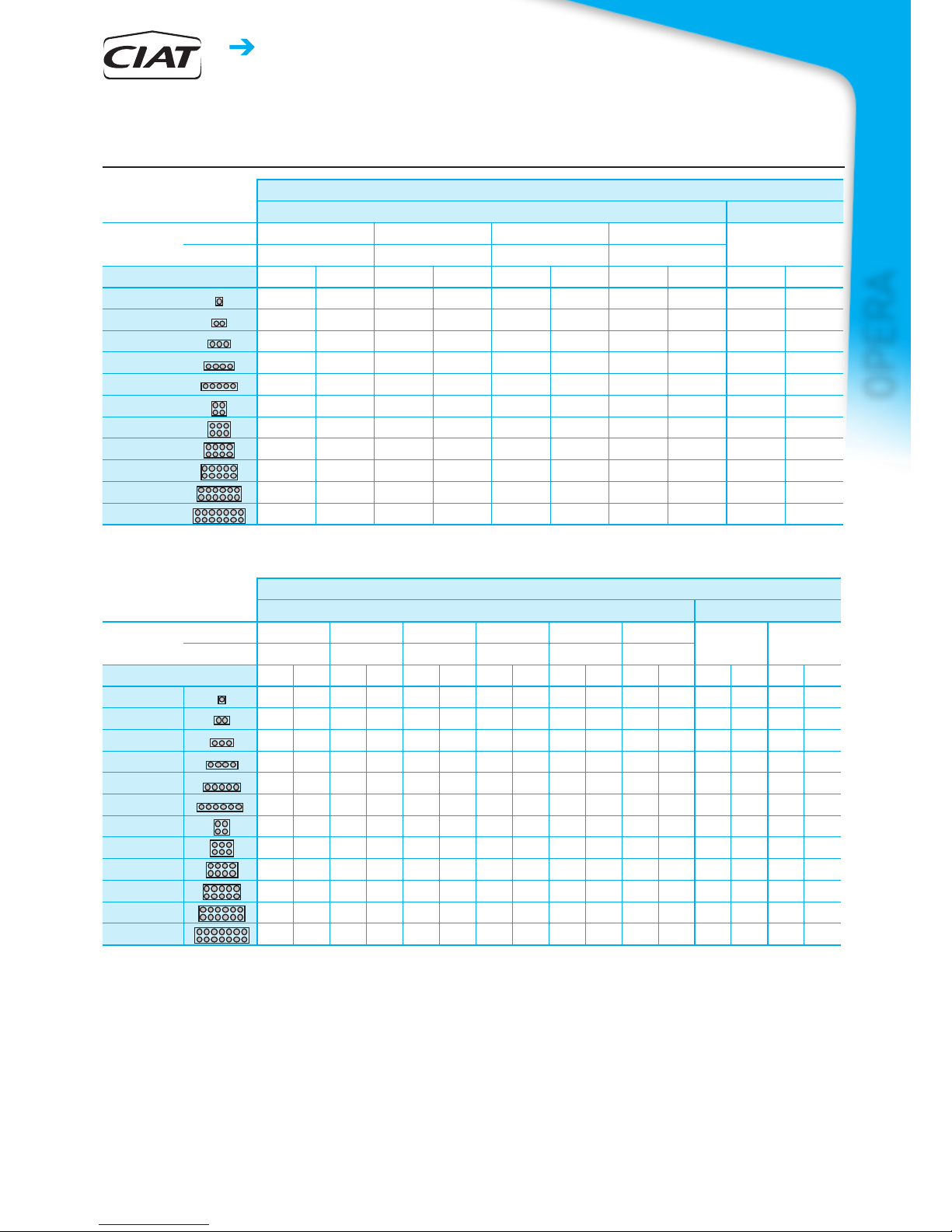

Options Description/Advantages DRYCOOLER CONDENSER

Protection adapted

for the environment

Pre-coated aluminium ns

Improves the resistance of the blades to corrosion.

For low corrosion environments. ● ●

High efciency coating on the

nned bundle:

ALUCOAT®507 or HERESITE

Improves the resistance of the blades to corrosion.

For corrosive environments. ● ●

Stainless steel tube bundle

For corrosive uids. ●

Corrosiveness resistance

category C5M

Casing and fan motor assemblies for corrosive environments. ● ●

ATEX II 2G/3G

For explosive atmospheres. ● ●

Quick, simple installation

Terminal box

Connection to the terminals of each motor on the front panel

of unit. ● ●

Protection cabinet

Protected by a thermal-magnetic circuit breaker on each

motor. ●

Control cabinet with

AeroCONNECT

Protection for motors and stage regulation provided by an

electronic board according to temperature or pressure. ● ●

Control cabinet with stages on

terminals

Motor protection and stages controlled by the customer

control. ●

Maintenance switch

For stopping individual motors. ● ●

Companion anges

In stainless steel, with gaskets and bolts. ●

Raised feet

To ensure a good ow of air depending on how the units are

installed: against a wall, side by side, etc. ● ●

Blade protective screen

Protection against hail, impacts, etc.

For forced draught, vertical units. ● ●

Installation surface

constraints Vertical position

For narrow terraces. ● ●

Optimised, secure

transport

Stacking of 2 identical devices

● ●

Skid for transport by container

Secure transport and easy loading/unloading. ● ●

Optimisation

of electrical consumption

and sound levels

EC motor

(with electronic switching)

Variable speed control from 0 to 100% using a 0/10V signal.

With the control cabinet via electronic board option, the

device is self-regulating

● ●

High-temperature

uid application Forced draught

Motors in the ow of fresh air. ●

Generator application Double circuit drycooler

Cooling of 2 water circuits (LT – HT) in series using air from

just 1 unit. ●

Expansion vessel

Max permissible pressure: 0.5 bar eff. ●

Application for water

without glycol Drainable coil

Device located on a slope to prevent frost - drainage by gravity ●

Free cooling application Free cooling valve kit

Valves with motor and sensor, controlled by the electronic

board. Controlled according to the operation of the drycooler

or chiller.

●

Application with

adiabatic cooling AEROFRESH (water misting

into the air ow)

Size of the unit reduced by cooling of the ambient air.

Operates completely safely due to the antibacterial

treatment applied to the water.

● ●