EN - 2

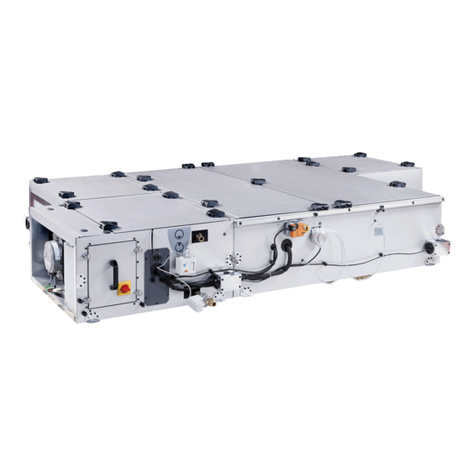

Thank you for choosing our air handling unit. The design and construction of your unit are the fruit of all the expertise offered

by our company's teams of technicians.

1.1 Intended use

The air handling units are designed for use indoors or outdoors (canopy and roof option mandatory)

The units are intended to provide ventilation and, depending on the composition:

- filtration of normal quality air,

- filtration of air in sterile environments (special version for clean rooms),

- air heating and/or cooling,

- air humidification and/or dehumidification,

- heat evacuation or recovery,

- filtration and handling of particularly moist and/or contaminated air (special versions, e.g. for extracting air from swimming

pools or kitchens),

- or a combination of the above characteristics.

Any use other than that described above is deemed improper.

If necessary, check whether your units are compatible with the applications for which you intend to use them.

The manufacturer is not responsible for damage resulting from improper use.

The user shall be held solely responsible.

Your machine's specific operating conditions are set out in the contract review.

The standard machine is designed to operate in urban and industrial environments with class C3 moderate pollution in

accordance with standard ISO 12944. Other options are available on request for more polluted environments or coastal areas.

WARNING: Take into account the quality of the ambient air and the conditioned air.

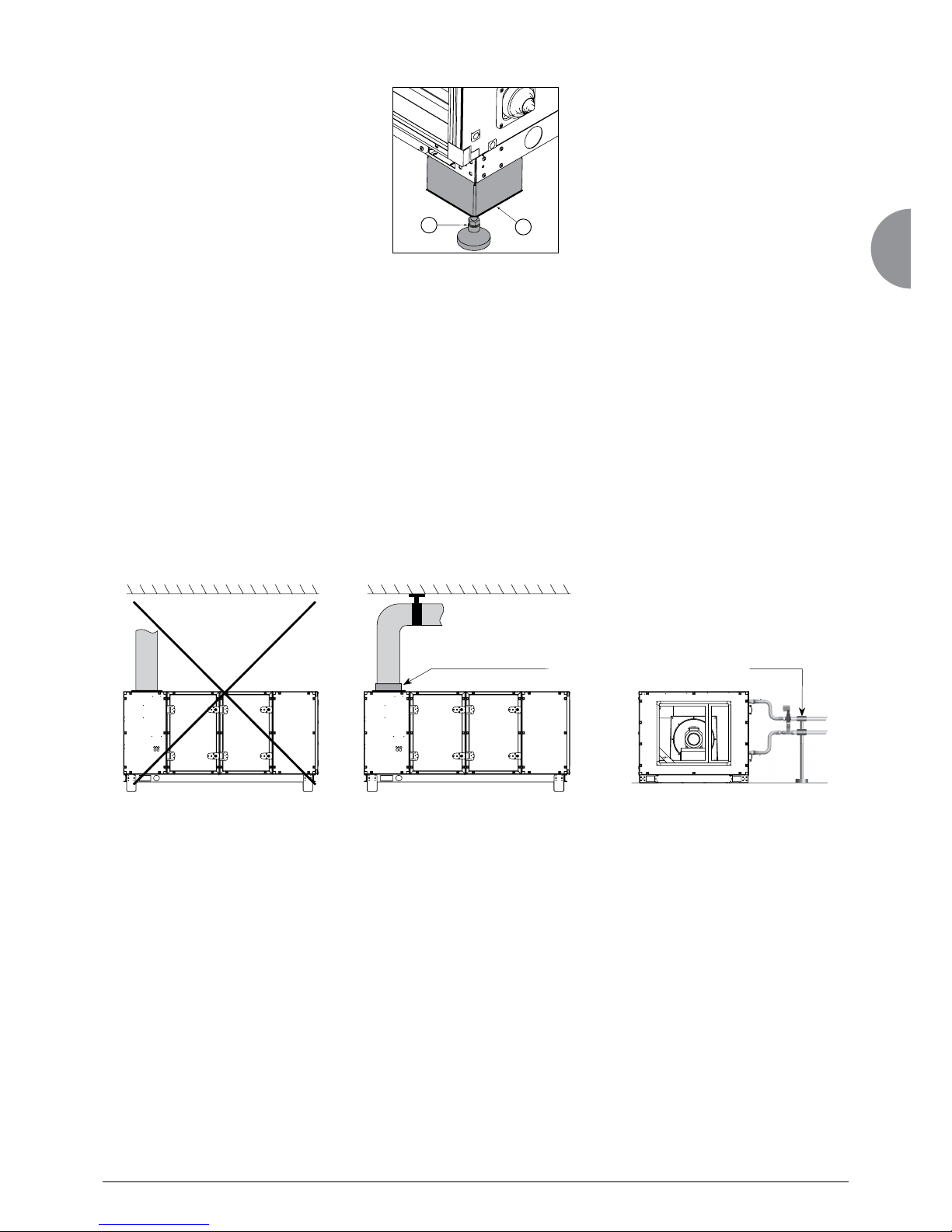

1.2 Documentation

This manual contains all of the installation and operating instructions for your unit. This document must be read in full before

carrying out any work on the unit. This manual must be kept in the immediate vicinity of the unit. It does not cover the entire

installation.

Please read all of the documents supplied with your order for information concerning the installation and system start-up

steps.

Depending on the options selected, specific handbooks may be included with this manual, and are also available from your

manufacturer. You should also read these handbooks before installing any options or carrying out any work (e.g. speed

variator, humidifier, control, etc.).

Devices installed and used in ATEX zones are marked with this symbol . A specific section of this manual is dedicated

to the limits of use and the precautions to be taken when installing, starting up and maintaining these devices. Refer to this

section before installing or carrying out any work.

1.3 Warranty

See general terms and conditions of sale.

Any modification made to the unit by persons other than the manufacturer's employees, or without prior consent, shall result

in cancellation of the warranty.

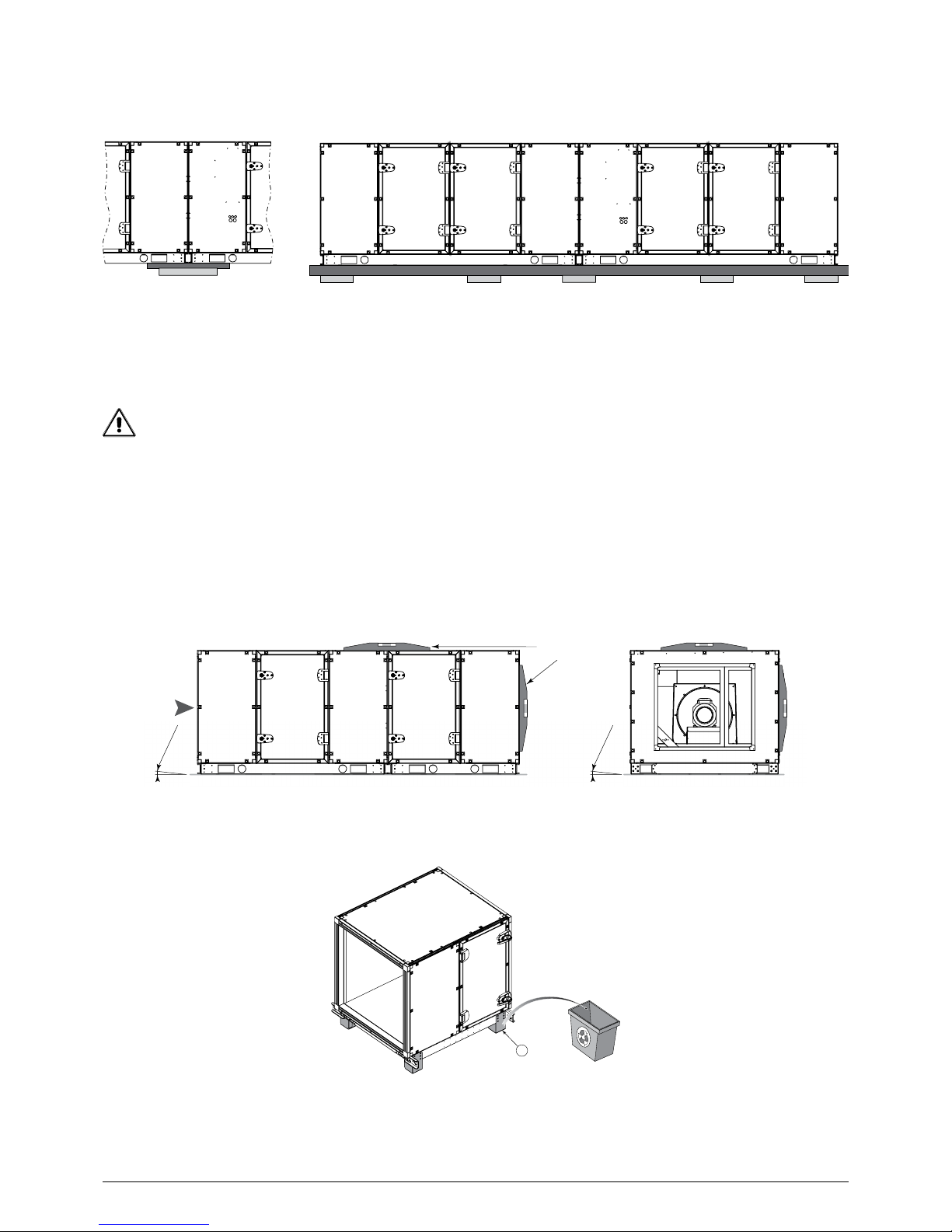

3.1 General information

Always follow and comply with the instructions in this manual and the regulations and legislation in force in the country of use.

Any modifications or welding to pressurised parts is dangerous and may be prohibited by regulations.

The use of this equipment under seismic loads has not been verified.

1 - GENERAL INFORMATION

2 - SAFETY CONSIDERATIONS

3 - REGULATIONS

The air handling units are designed in compliance with recognised safety rules.

These units must be used in perfect condition and within their field of application.

Only qualified technicians may work on the machine. They must have all the necessary Personal Protective Equipment

(PPE): glasses, gloves, safety shoes, hearing protection, dust mask, etc.

Check the following points before carrying out any work on the air handling unit.

- Cut the main fan power supply. Warning follow the shutdown procedure: A 15-minute fan delay must be applied after the

electric heaters and gas heating systems are shut down to allow complete cooling.

- Equipment lock-out in accordance with standard EN 60204/DIN VDE 0113.

-Warning: depending on the options selected, there may be several different power supplies on the various units (main unit,

supply unit for electric heaters, humidifier). Make sure all power supplies are cut and locked out.

- All moving or rotating parts must be shut down.

- Wait at least 15 minutes if using a frequency inverter (resultant voltage).

- All of the casings must be at atmospheric pressure before work can be carried out.

- Wait until the heat exchangers have cooled (heaters, steam, hot water coils).

- Make sure there are no foreign objects in the air handling units before starting them up.

For units that can be entered, an "internal handle" option is available to prevent accidental entrapment.