SAFETY PRECAUTIONS

ALWAYS seek assistance when lifting heavy items.

ALWAYS keep children and animals away from tools and work area.

ALWAYS keep work area clean and free from oil spills etc.

ASSEMBLY

Before attempting to assemble the work bench, carefully unpack/unwrap and lay out all components,

check off against the list of contents on front page, notify your Clarke dealer ASAP of any shortages

and/or damage.

Tools required:

Cordless drill and drill bits (4mm and 5mm). Due to manufacturing tolerances, some holes may

not line up accurately and may require opening up in order to fit securing screws.

1 x 12mm open ended spanner.

1 x Medium flat bladed screwdriver.

1 x 8mm ring or combination spanner.

1 x 7mm ring or combination spanner.

1 x Spirit Level.

Optional:

Cordless screwdriver + screwdriver bits, 7mm and 8mm sockets, flexi drive and or nut spinners.

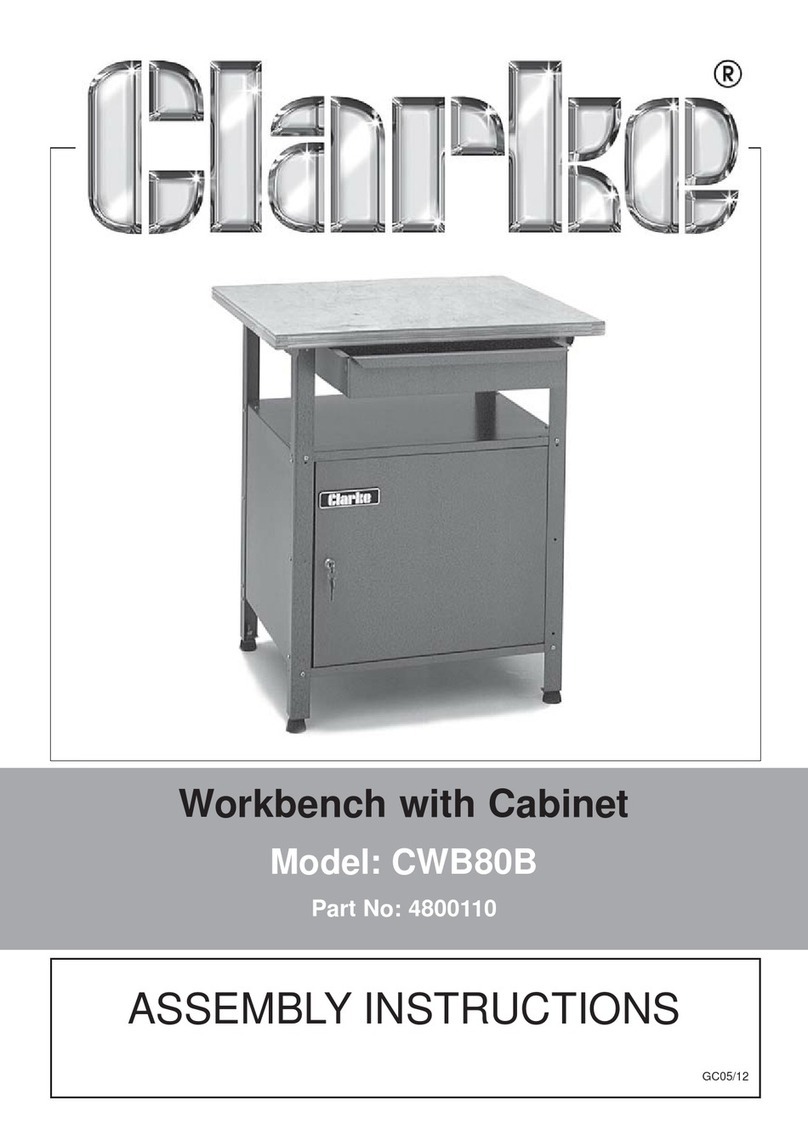

Base Unit Assembly

Hint - It may help with assembly to lay the legs and panels on their back edge until the bench is at a

stage where it can be stood on its feet. Ensure some form of protection is laid down to prevent

damage to the painted surfaces.

NOTE : Figures in brackets refer to item numbers in contents list on front page.

1. Assemble feet (10, 11& 12) and attach two to each leg (1 & 2). Screw in as far as possible. DO

NOT tighten.

2. Attach the top panel (3) to the left leg (1) using M5x8 round head screws, nuts and lockwashers,

DO NOT tighten at this stage.

NOTE: Top panel has cut out in the front lip for the cross panel to fit into.

3. Attach the bottom panel (4) with the left leg (1) and loosely secure with screws nuts and

lockwashers.

4. Attach the Right leg (2) to the upper and lower panels and loosely secure with screws etc.

5. Attach the cross panel (5) between the upper and lower panels. Before loosely securing

with screws and nuts etc, ensure the cross panel is fitted with the slot for a lock lever to the

front of the unit.

6. Carefully turn the assembly onto its front, attach the back panel (6) and loosely secure with

screws etc.

7. Carefully stand the assembly on its feet.

8. To ensure the assembly is as square as possible before continuing, position the bench where

it is to be sited. Place spirit level on the upper panel and adjust the feet until the unit is level in

both directions, i.e. front to back and side to side, secure with locking nuts. Once satisfied

the unit is as square as possible, proceed to tighten all screws and nuts, starting in the centre

and working outwards until all are tight, DO NOT overtighten.

9. Carefully lay the bench top upside down on the assembled bench.

Hint - Using if available, a cordless screwdriver/drill, drive woodscrews L5 x 20 fully into all the pre-

drilled holes, DO NOT overtighten. Remove afterwards.

10. Loosely fit drawer runners (18 & 19 type ‘A’) with L shaped brackets to bench top.

NOTE: Drawer runners are left and right handed and must be fitted in pairs so that the longest part of

rail protrudes the bracket at the front of bench top.