Cleveland

™

Project ________________________________

Item __________________________________

Quantity _______________________________

FCSI Section ____________________________

Approval _______________________________

Date __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

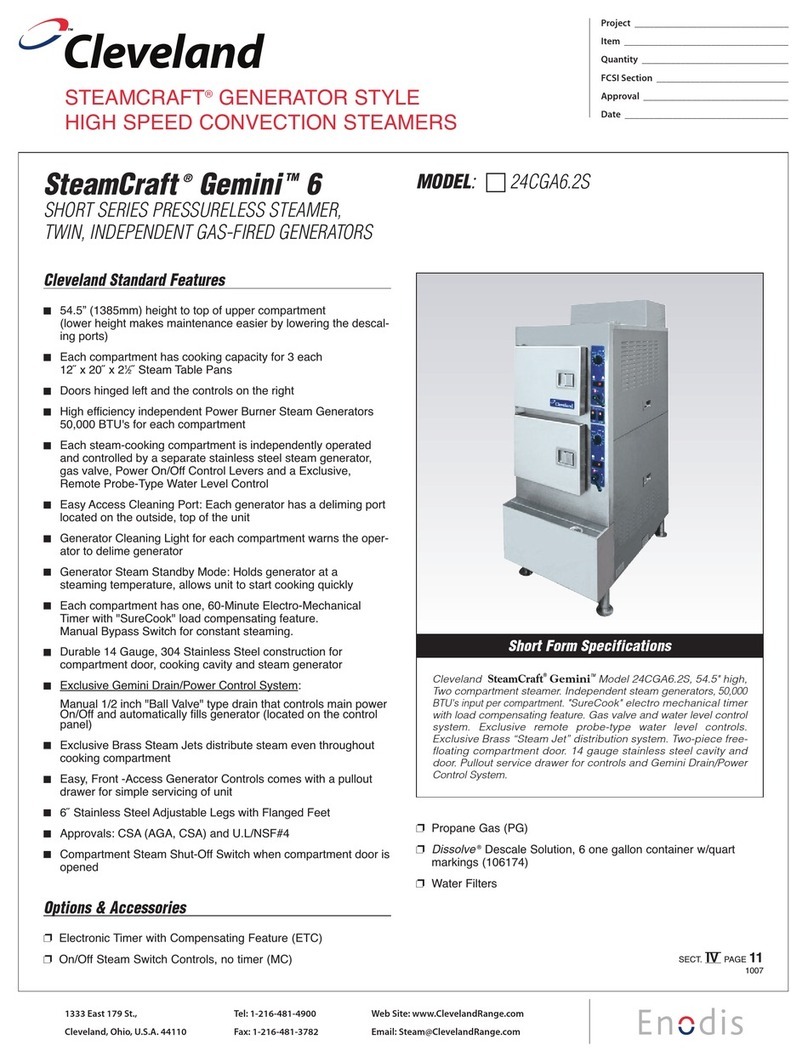

STEAMCRAFT®GENERATOR STYLE

HIGH SPEED CONVECTION STEAMERS

MODEL: c24-CDP-10

Cleveland Standard Features

nCooking Capacity for up to ten 12˝ x 20˝ x 21⁄2˝ deep

Cafeteria Pans.

nDurable 14 Gauge Stainless Steel Construction:

For compartment door, cavity and front.

nOne 60 Minute Electro-Mechanical Timer and Switch

for manual operation. Audible signal for cooking time

completion.

nSeparate Switch for Power “on/off.”

nExclusive Steam Cooking Distribution System: Exclusive

Brass Steam Jets produce a high velocity convection steam

without fans. Coved Corner design in cooking compartment

distributes heat evenly, and is easy to keep clean. Creased

top & bottom enhance drainage. Cold Water Condenser for

each compartment maintains a dry steam. Fully insulated

cooking compartment for thermal efficiency. Removable

Stainless Steel Slide Racks.

nExclusive “Cool to the Touch” Compartment Door

Design: Free floating inner door with reversible door gasket

provides an air tight seal. Stainless Steel Slam/Latch Door

Latch mechanism for reliability.

nCondensate Drip Trough: Provided under lower

compartment door to collect condensate.

nLeft Hand Door Hinging: Compartment Doors hinged left,

control on the right.

nMoisture Separator for incoming steam.

nPressure reducing Valve or 20-50 psi steam supply

pressure, based on a 3⁄4˝ line size.

nSingle Cold water Connection.

nNSF Certified 6˝ Stainless Steel Legs with adjustable

flanged feet for a one inch level adjustment.

nStandard voltage for controls: 115 volts, 60 Hz. single

phase.

oClean non-toxic, uncontaminated steam is required for all

“Direct Steam” steamers.

Options & Accessories

pSecond Pressure Reducing Valve for 50-120 psi steam

pressure. (PRV)

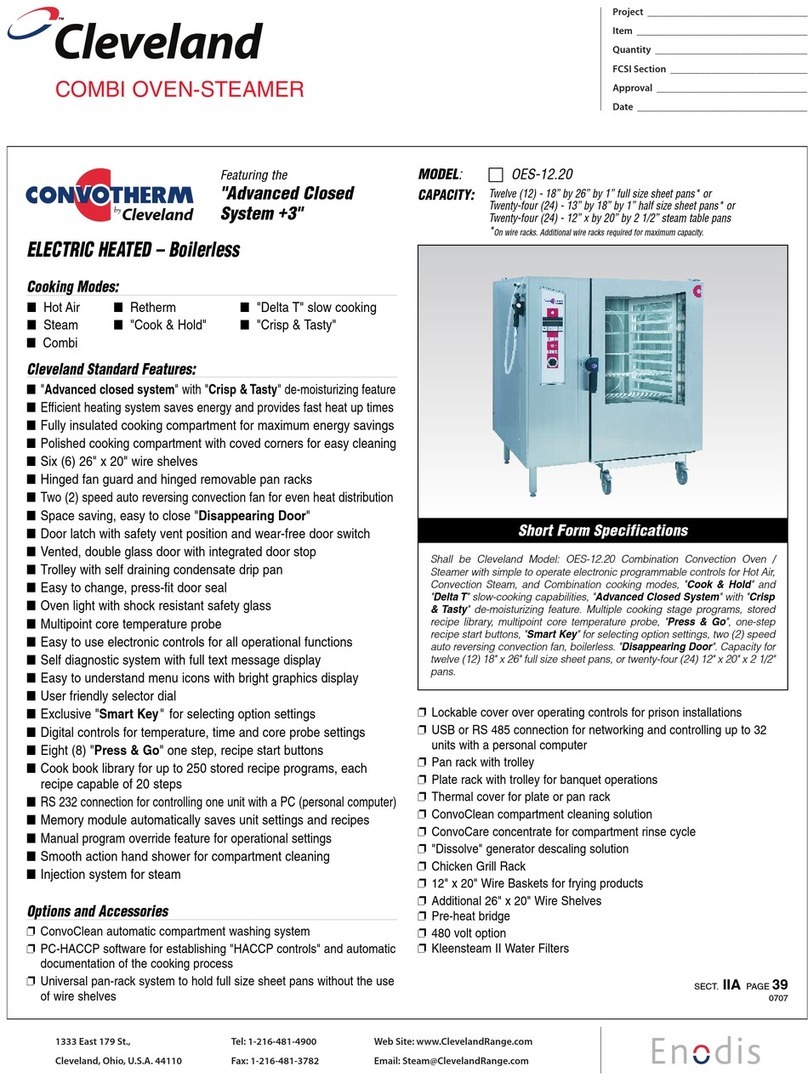

Shall be CLEVELAND,

SteamCraft

Ultra 10

, two compartments,

Direct Steam Floor Model Steamer, Model 24-CDP-10, single, large

capacity Pressureless Convection Steamer. Choice of Compartment

Controls, Manual By Pass Operation Mode, Compensating

Thermostat, Exclusive Cold Water Condenser design, Type 430

Stainless Steel exterior and cooking compartments.

pRight Hand Door Hinging, Controls on the Right (DHR)

pElectronic Timer with Compensating Load Feature (ETC)

pON/OFF Steam Switch only for compartment controls (MC)

p10˝ Stainless Steel Legs (LF10)

pCompartment Door Steam Shut Off Switch (SCS)

pCafeteria Pans in depths of 1˝, 21⁄2˝, 4˝

and 6˝

pWater Filters

pCorrectional Packages

Short Form Specifications

4

SteamCraft ®Ultra 10 D

TWO COMPARTMENT FLOOR MODEL DESIGN

PRESSURELESS CONVECTION STEAMER

DIRECT STEAM, 24˝ WIDE DESIGN

SECT. IV PAGE 21

0707