Cleveland

™

Project ________________________________

Item __________________________________

Quantity_______________________________

FCSI Section ____________________________

Approval _______________________________

Date __________________________________

1333 East 179 St.,

Cleveland, Ohio,U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site:www.ClevelandRange.com

Email: Steam@ClevelandRange.com

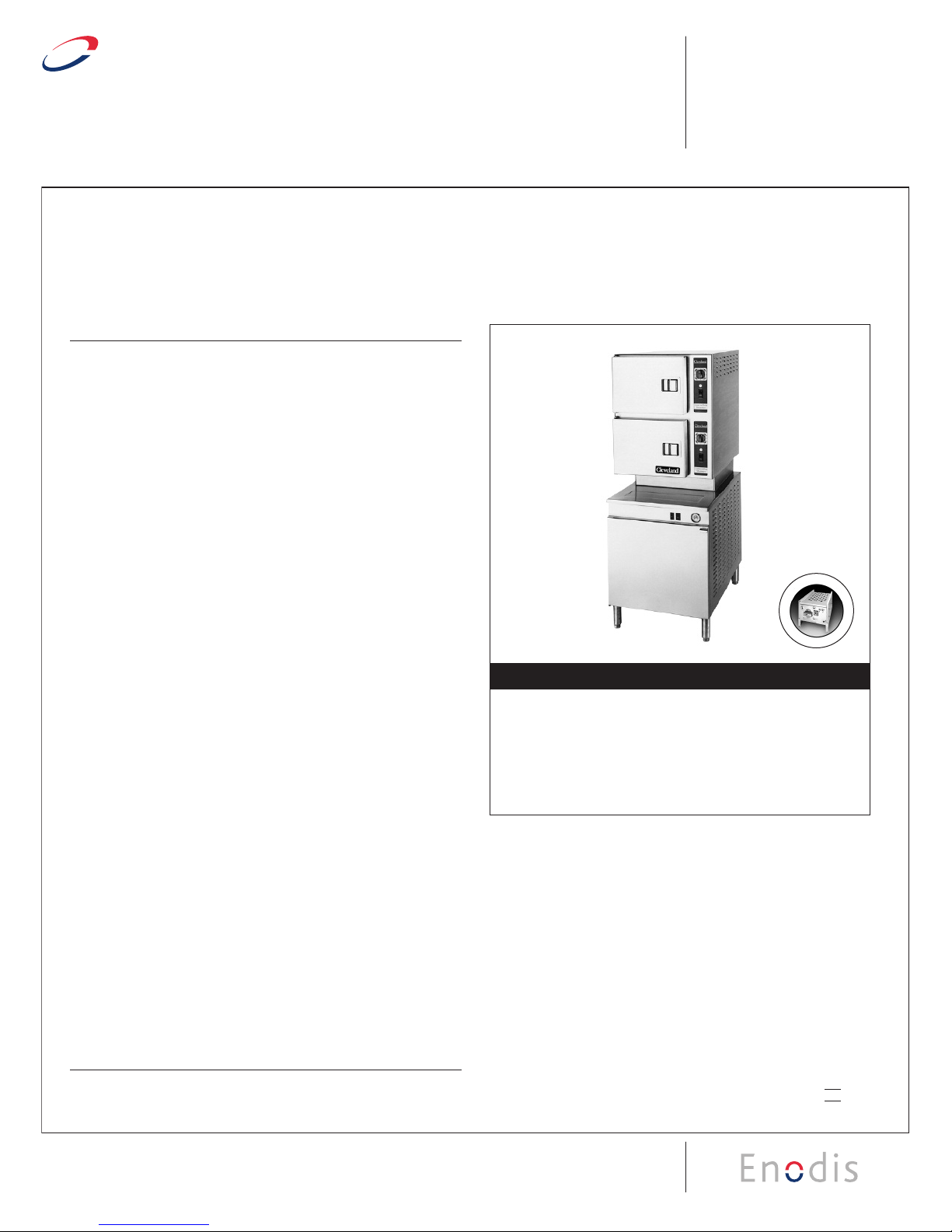

CLASSIC CONVECTION STEAMERS

15 PSI BOILER BASE STYLE

SECT. III PAGE 3

0707

MODEL:c24-CGM-200

Cleveland Standard Features

n

Cooking Capacity for up to six 12˝ x 20˝ x 2

1

⁄

2

˝deep Cafeteria Pans.

nPressureless cooking with forced convection steam, permitting

doors to be opened while cooking continues.

n

Solid State Controls operate water level and safety functions.

n

Each compartment is equipped with a 60 minute mechanical

timer, separate bypass switch for constant steaming and a

cold water condenser for superior cooking results.

n

Instant Steam StandbyMode: Holds generator at steaming

temperature. Allows unit to start cooking instantly.

nDurable 14 Gauge Stainless Steel Construction:

For Compartment Door and Steam Cooking Cavity.

nSeparate Main Power Switch for “On/Off”

nExclusive Steam Cooking Distribution System:

The exclu-

sive Convection Jets produce a high velocity convection

steam

without fans. Coved Corner design in cooking compartmen

tdistrib-

utes heat evenly and is easy to keep clean. Creased top & bottom

enhance drainage. Cold Water Condenser for each compartment

maintains a dry steam. Fully insulated cooking compartment for

thermal efficiency. Removable Stainless Steel Slide Racks for easy

cleaning.

nExclusive “Cool to the Touch” Compartment Door Design:

Free floating inner door with reversible door gasket provides

an air tight seal. Stainless Steel Slam/Latch Door Latch

mechanism provides greater reliability.

nLeft Hand Door Hinging: Compartment Doors hinged left,

controls on the right.

nModular Cabinet Base with Hinged Door.

nHigh Efficiency Gas Steam Generator with NickelGuard,

Electronic Spark Ignition and Automatic Water Fill on start up.

nAutomatic Generator Drain at shutdown: Contains a “Water

Jet” Spray Rinse Cleaning Cycle to keep drain clear.

nAutomatic Generator Mineral Purging Cycle automatically

cleans generator, reducing scale build up

nAutomatic Water Level Control System with Low Water

Power Cut-off Circuit.

n

Steam generator equipped with High Limit Pressure Safety Switch,

15 psi Safety Valve, and Steam Generator Pressure Gauge.

nNSF Certified 6˝ Stainless Steel Legs with adjustable

flanged feet for a one inch level adjustment.

nGas Pressure Regulator and Control Valve.

nStandard Voltage for Control: 115 volts, 60 Hz, single phase.

nAll Controls are serviceable from the front.

Options & Accessories

pRight Hand Door Hinging, Controls on the Left (DHR)

pElectronic Timer with Compensating Load Feature (ETC)

pON/OFF Steam Switch only for compartment controls (MC)

pCafeteria pans in depths of 1˝, 21⁄2˝, 4˝ and 6˝

pPower T

ake OffKit (GPTO), Kettle Interconnecting Kit (IMK-)

pCorrectional Packages

pStainless Steel Base Frame (FSS)

pStainless Steel Insulated Flue Cover (SSF)

pQuick Disconnect for gas line (QDC)

pSecondary Low Water Cut-Off, factory installed (CALG)

(Required for AZ. AR. CA. CO. CT.DE. FL. GA. HI. IL. IA. KS. MD. MA. MI. MN. MT

.

NE. NV.NM. NC. OK. OR. PR. RI. TN. UT. VA. WA. WV., Buffalo, NY, Wash. DC)

pCompartment Door Steam Shut OffSwitch (SCS)

pBoiler Descaling Pump Kit (107142)

pWater Filters

pRear Gas Connection (RGT)

Shall be Two Compartments, CLEVELAND Convection Steamer,Model 24-

CGM-200, Gas-fired Steam Generator, NickelGuard, 200M BTU. Solid

State Controls operate timing, water level and safety functions. Steam

Generator with Automatic Water Fill on start-up, Automatic Blowdown with

additional Manual Drain Valve and Electronic Spark Ignition. For each

cooking compartment: 60 minute Mechanical Timer,Manual Operation

Mode and Cold Water Condenser. Type 304 Stainless Steel cooking com-

partment.

Short Form Specifications

Cleveland Classic Series

TWO COMPARTMENT, PRESSURELESS

200M BTU GAS FIRED STEAM GENERATOR

24” WIDE CABINET BASE DESIGN, with NICKELGUARD™

CONVECTION

STEAMERS

1

0

0

%

5

Y

e

a

r

B

o

i

l

e

r

W

a

r

r

a

n

t

y

N

i

c

k

e

l

G

u

a

r

d

™