3

General -

1. Check for wear deter orat on.

Before each use, carefully inspect your

complete Ultra-Safe system for si ns of wear

or deterioration, or evidence of impact loadin .

Visually inspect for loose threads, pulled rivets,

burns, cuts, distortions, abrasions, or other

evidence of chemical or physical deterioration

that may have weakened the material or

assembly.

2. Inspect hardware for malfunct ons and cracks.

Check all snap hooks, buckles and D-Rin s.

3. Destroy and replace all worn

or damaged equ pment.

Immediately destroy and replace any component

which does not pass inspection.

Spec f c -

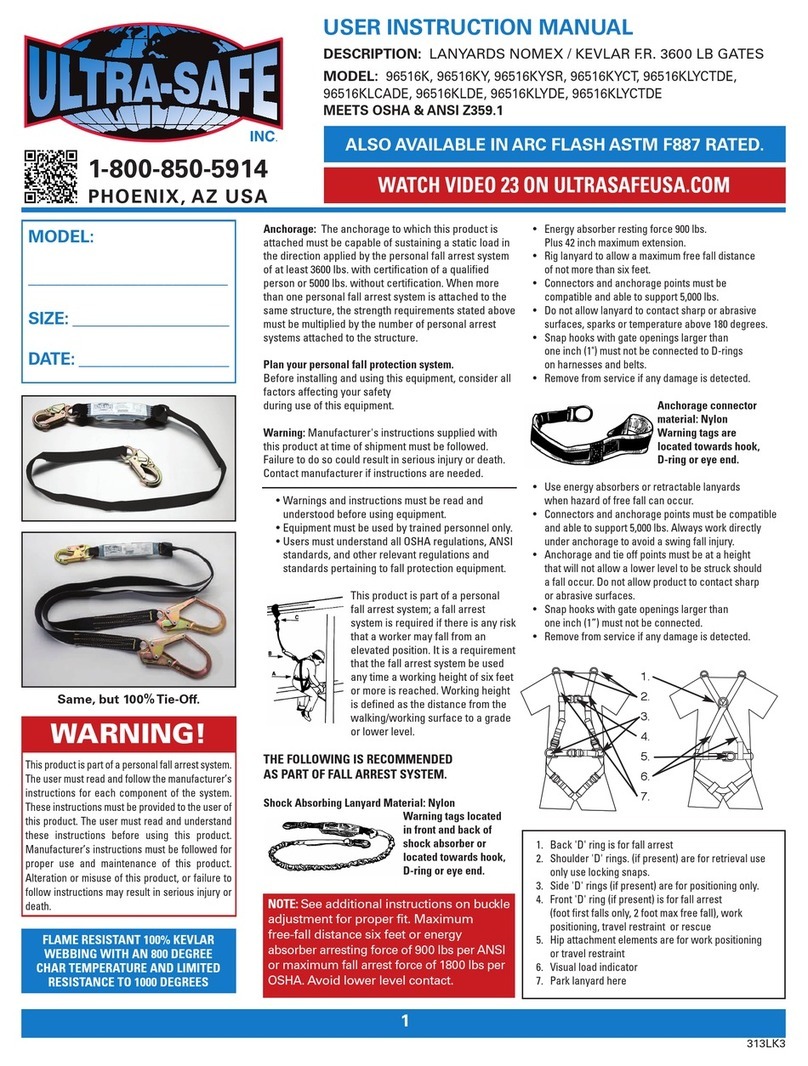

1. St tch ng and webb ng.

Check stitchin for broken, burned, cut or pulled

stitches. Broken strands of webbin appear as

tufts on the webbin surface. To visually check for

dama e caused by corrosives, heat, chemicals

and other conditions, hold the connectin device

with your hands six to ei ht inches apart. Bent the

webbin in an inverted "U" to cause surface

tension and expose problem areas. Inspect entire

len th. For deceleration units, check the stitchin

for broken, burned, cut or pulled stitches, and the

breakaway jacket for cuts, tears, broken stitches,

stretch marks or other evidence of impact load.

For aircraft-cable lanyards, check the full len th

for breaks, burns or cuts in the vinyl coverin and

the aircraft cable.

2. Check for broken strands.

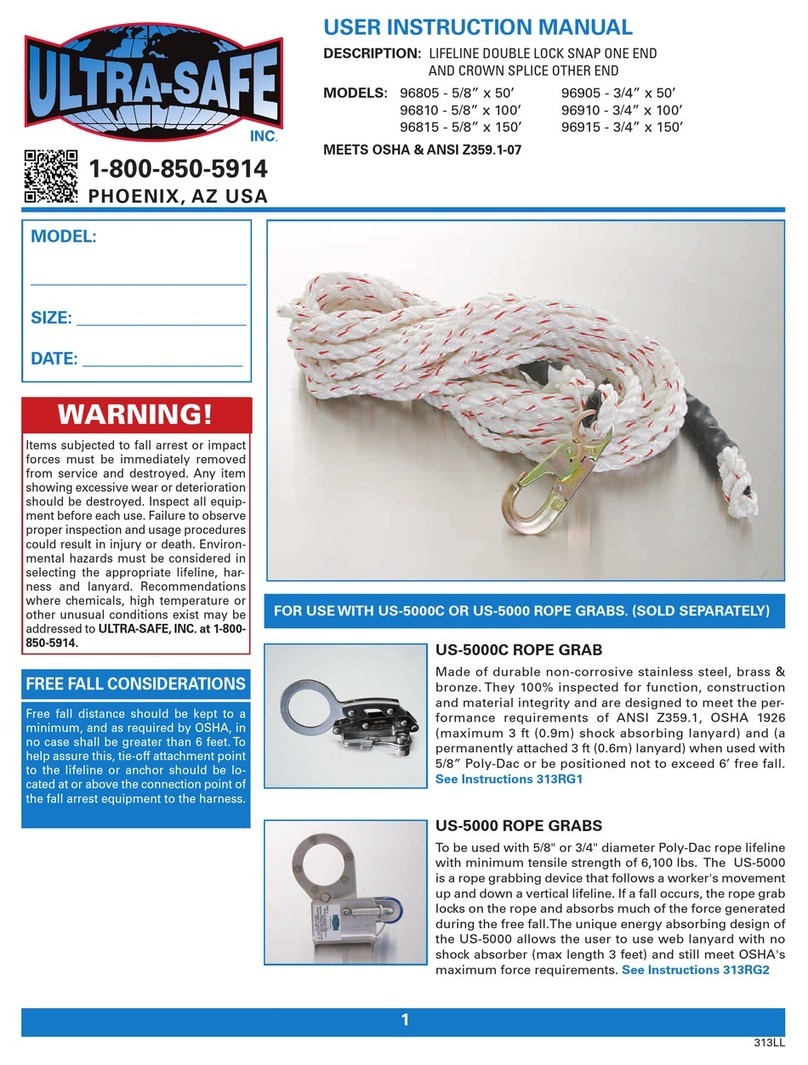

Inspect rope lanyards for broken strands by

twistin the rope sli htly to undo the braidin .

Inspect the entire lanyard in this manner.

Lanyards with broken strands must be discarded.

3. Inspect all snap hooks, D-R ngs and

other metal parts.

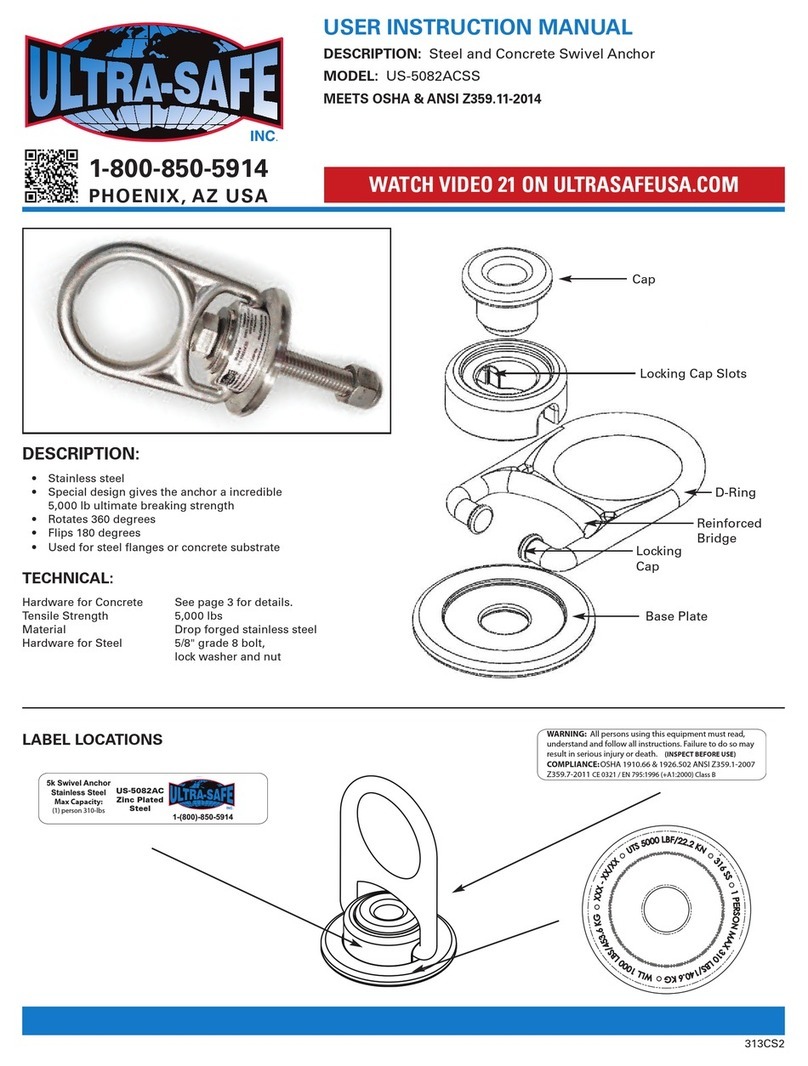

Hardware must be checked for sharp ed es and

cracks. Rollers should not be distorted in shape

and should roll freely. Check all parts, especially

corners and attachments points, for wear and

cracks.

4. Destroy and replace all worn or damaged

Ultra-Safe equ pment.

If evidence of excessive wear, deterioration or

mechanical malfunction is observed, replace the

equipment immediately. Never work w th worn or

damaged Ultra-Safe equ pment. Us ng damaged

or worn equ pment can cause njury or death.

5. The nspector s the most mportant part

of any nspect on procedure.

Check all equipment thorou hly and follow all

safety procedures and uidelines. Do not take

any shortcuts', they could result in injury or death.

NOTE: Twisted rope, such as the nylon filament

and polyplus rope used in Ultra-Safe lanyards,

is subject to a condition known as "hocklin ",

which is similar to the twistin we often see

in a telephone handset cord. This can be

caused by a repetitive twistin movement

such as normal hand rotation in hookin

and unhookin , a lanyard dan lin freely,

or by usin the lanyard to suspend equipment.

Prevent ve measures nclude:

1) Never usin a lanyard for towin or hoistin ,

2) Inspection and smoothin out after each use,

3) Storin neatly. Some hocklin is normal,

and in itself is not cause to discard

the lanyard.

Inspect on Procedures

Ser al Number:

Model Number:

Date Purchased:

Inspect on Date Inspect on Items Noted Correct ve Act on Ma ntenance Performed

Date of F rst Use:

INSPECTION AND MAINTENANCE LOG

IMPORTANT NOTE: OSHA specifies that all employers covered by the Occupational Safety and Health Act are responsible for inspection and

maintenance of all tools and equipment used by employees, whether owned by the employees or by the company. All Ultra-Safe equipment

should be inspected before each use, and immediately removed from service if equipment does not pass inspection.

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By: