CAT900HD 4 7/30/14

Drain Daily

RegulatorOilerQuick CouplerLeader

Hose

Nipple

Do Not Install

Quick Coupling

Here

Nipple

Filter

Air Supply

Whip Hose

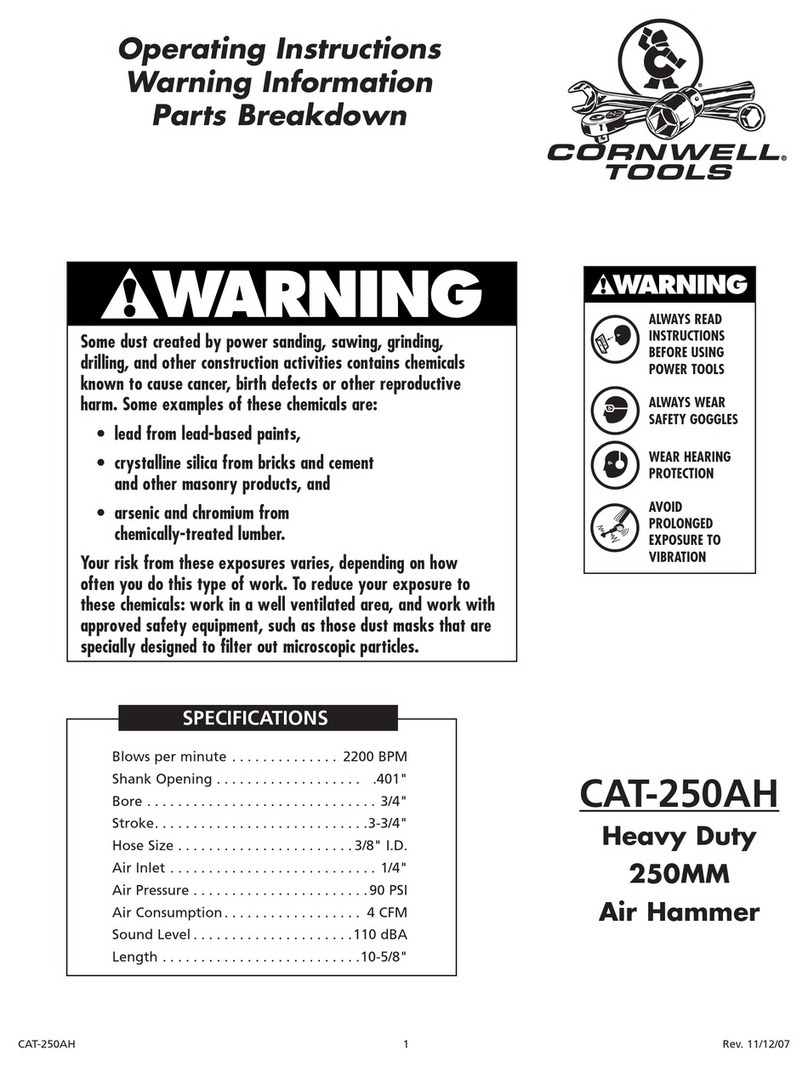

AIR SUPPLY

Tools of this class operate on a wide range of air pressures.

Itis recommended thatair pressuremeasures90 psigat the tool

withthetriggerfullydepressedandnoloadappliedtotool.Higher

pressure (over 90 psig; 6.2 bar) raises performance beyond the

rated capacity of the tool, which will shorten tool life and could

causeinjury.

Alwaysuseclean,dryair.Dust,corrosivefumesand/orwaterinthe

airlinewillcausedamagetothetool.Drainwaterfromairlinesand

compressor prior to running tool. Clean the air inlet filter screen

weekly.Therecommendedhookupprocedurecanbeviewedinthe

abovefigure.

Theairinletusedforconnectingairsupplyhasstandard1/4"NPT.

Linepressureshouldbeincreasedtocompensateforunusuallylong

airhoses(over25feet).Minimumhosediametershouldbe3/8"I.D.

andfittingsshouldhavethesameinsidedimensionsandbetightly

secured.

Ensureanaccessibleemergencyshutoffvalvehasbeeninstalledin

theairsupplylineandmakeothersawareofitslocation.

LUBRICATION

Lubricatethe airmotor dailywith highqualityairtool oil.If noair

line oiler isused,run1/2oz.ofoilthroughthetool.Theoilcanbe

squirtedintothetoolair inlet orinto the hoseatthe nearestcon-

nection to the air supply, then run the tool. A rust inhibitive oil is

acceptableforairtools.

WARNING:After an airtoolhas beenlubricated,oil willdischarge

throughtheexhaustportduringthefirstfewsecondsofoperation.

Theexhaustportmustbecoveredwithatowelbeforeapplyingair

pressuretopreventseriousinjury.

OPERATION

Always use the recommended wheel guard to

prevent injury from brocken grinding wheel parts.

If a guard has withstood a wheel breakage,

discontinue its use and replace it with a new

guard. It may be damaged. Position the guard

betweenthegrindingwheelandtheoperator.Usebarrierstoprotect

othersfromwheelfragmentsandgrindingsparks.

protection to guard against flying rust and

chips (users and bystanders). Even small

projectilescaninjureeyesandcause blindness.A

grindingwheelthatburstscancauseveryserious

injury.Dailymeasurethetoolspeedwithatachmetertomakesure

it'snotgreaterthantheRPMmarkedonthegrindingwheel.Never

use a grinding wheel marked with a speed lower than the tool

speed.

NOTE: Before grinding, test grinding wheel by briefly running the

toolatfullthrottle.Besuretouseabarrier(suchasunderaheavy

worktable)tostopanypossiblebrokenwheelparts.

NOTE:Always shut off air supply, drain hose of air pressure and

disconnecttoolfromairsupplywhennotinuse,before changing

accessoriesorwhenmakingrepairs.

TO ASSEMBLE CUTTING WHEEL:

1.Usedoubleendedspanner(#53)toholdspindle(#22).

2.Usehexkeywrench(#54)toremovescrew(#29).

3. Use double ended spanner (#53) to remove screw (#28)

andwasher(#27).

4.Placecuttingwheelontospindleendandreversesteps1-3.

TROUBLESHOOTING

Otherfactorsoutside thetool maycauseloss of powerorerratic

action.Reducedcompressoroutput,excessivedrainontheairline,

moistureorrestrictionsinairpipesortheuseofhoseconnections

ofimpropersizeorpoorconditionsmayreduceairsupply.Gritor

gum deposits in the tool may cut power and may be corrected

by cleaning the air strainer and flushing out the tool with gum

solventoiloranequalmixtureofSAE#10andkerosene.Ifoutside

conditionsareinorder,disconnecttoolfromhoseandtaketoolto

yournearestauthorizedservicecenter.

WARRANTY

CornwellQualityToolsCompany(“Cornwell”)warrantsthisproductagainstdefectsinmaterialandworkmanshipforaperiodofONE(1)YEARfromthedateoforiginalretailpurchase.

Subjecttotheconditionsandlimitationssetforthbelow,Cornwellwill,atitsoption,eitherrepairorreplaceanypartoftheproduct(s)thatprovesdefectivebyreasonofimproper

workmanshipormaterials.

This warranty does not cover any damage to this product that results from accident, abuse, misuse, natural or personal disaster, or any unauthorized disassembly, repair, or

modification.Repairs,disassemblyandmodificationareonlyauthorizedtobemadebyCornwelloraCornwellAuthorizedWarrantyCenter.

WARRANTY SERVICE

Inordertohaveyourtoolrepaired,returnthetooltoanyCornwellAuthorizedWarrantyCenter,freightprepaid.Pleaseincludeacopyofyourproofofpurchaseandabriefdescription

oftheproblem.Thetoolwillbeinspectedandifanypartorpartsarefoundtobedefectiveinmaterialorworkmanship,theywillberepairedfreeofcharge,andtherepairedtoolwill

bereturnedtoyoufreightprepaid.

EXCLUSIONS AND LIMITATIONS

THISWARRANTYANDTHE REMEDIESSET FORTHABOVEAREEXCLUSIVEANDIN LIEU OFALL OTHERWARRANTIES,REMEDIESAND CONDITIONS,WHETHERORAL ORWRITTEN,

EXPRESSORIMPLIED.CORNWELLSPECIFICALLYDISCLAIMSANYANDALLIMPLIEDWARRANTIES,INCLUDING,TOTHEEXTENTPERMITTEDBYAPPLICABLELAW,ANYWARRANTIES

OFMERCHANTABILITYANDFITNESSFORAPARTICULARPURPOSE.IFCORNWELLCANNOTLAWFULLYDISCLAIMIMPLIEDWARRANTIESUNDERTHISLIMITEDWARRANTY,ALLSUCH

IMPLIEDWARRANTIESARELIMITEDINDURATIONTOTHEDURATIONOFTHISWARRANTY.

INNOEVENTSHALLCORNWELLBELIABLETOTHEPURCHASERORTOTHEUSEROFACORNWELLPRODUCTFORANYSPECIAL,INCIDENTALORCONSEQUENTIALDAMAGESBASED

UPON BREACH OFWARRANTY, BREACH OF CONTRACT, NEGLIGENCE,TORT, ORANY OTHER LEGAL THEORY. SUCH DAMAGES INCLUDE, WITHOUT LIMITATION, EXPENSES, LOST

REVENUES,LOSTSAVINGS,LOSTPROFITS,ORANYOTHERINCIDENTALORCONSEQUENTIALDAMAGESARISINGFROMTHEPURCHASE,USEORINABILITYTOUSETHECORNWELL

PRODUCT.

Somestatesdonotallowtheexclusionorlimitationofincidentalorconsequentialdamagesorexclusionsorlimitationonthedurationofimpliedwarrantiesorconditions,sotheabove

limitationsorexclusionsmaynotapplytoyou.Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightsthatvarybystate.

RepairkitsandreplacementpartsareavailableformanyCornwellproducts,regardlessofwhetherornottheproductisstillcoveredbyawarrantyplan.