Creality CR-3040 Pro User manual

Other Creality 3D Printer manuals

Creality

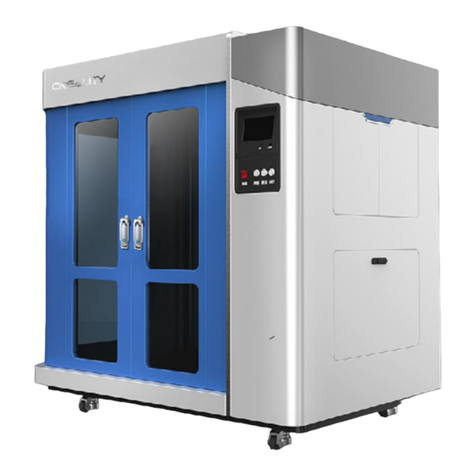

Creality CR-1000 Pro User manual

Creality

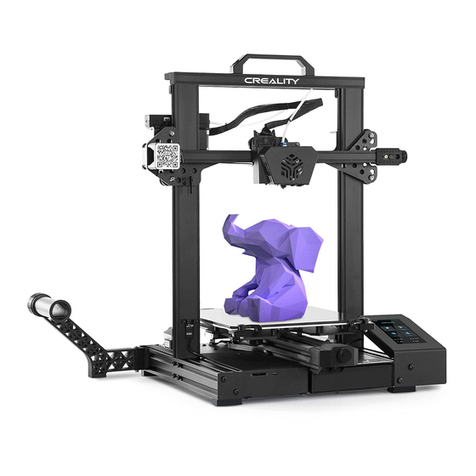

Creality CR-6 SE User manual

Creality

Creality HALOT-LITE User manual

Creality

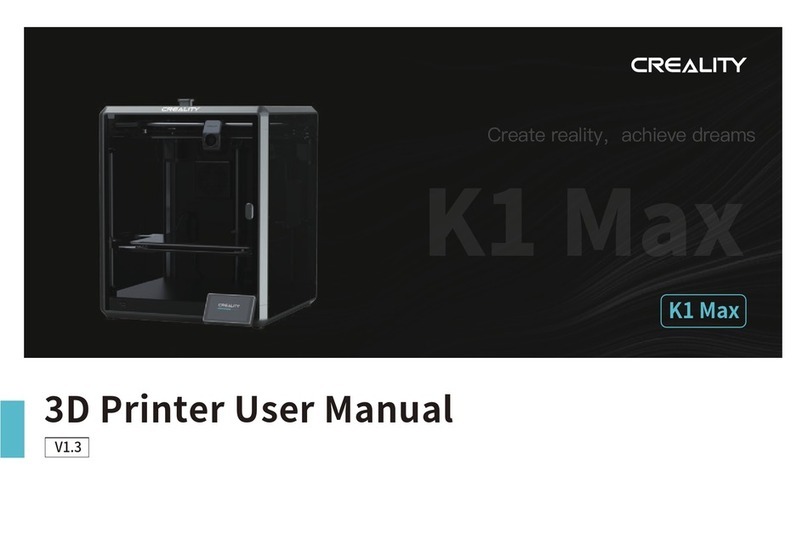

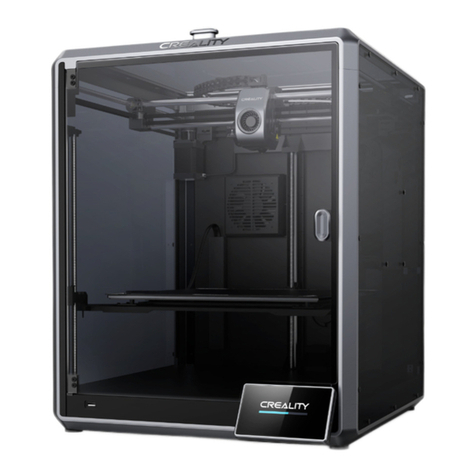

Creality K1 User manual

Creality

Creality Ender-5 Plus Manual

Creality

Creality CR20Pro User manual

Creality

Creality BMG CR-10 PrintHead User manual

Creality

Creality HALOT-MAX User manual

Creality

Creality CR-10 SE User manual

Creality

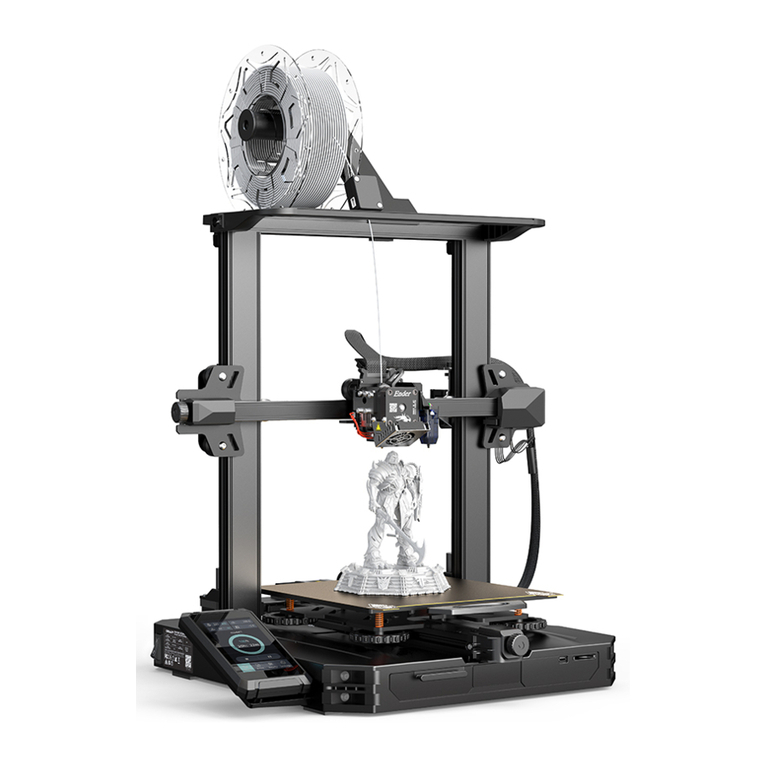

Creality Ender-3 S1 User manual

Creality

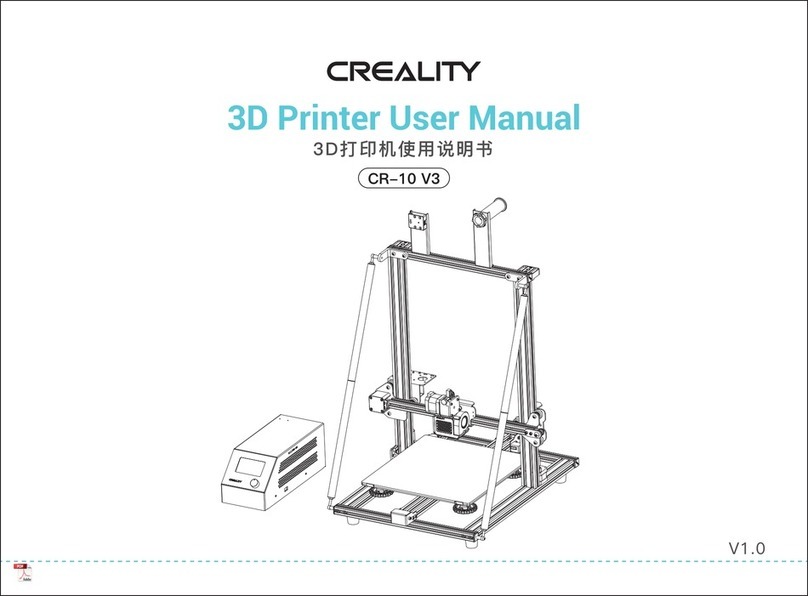

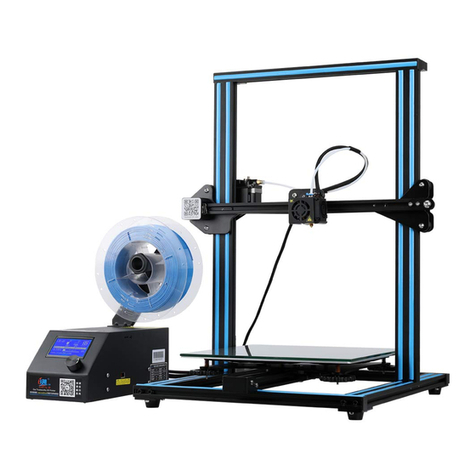

Creality CR-10 Series User manual

Creality

Creality CR-10 Smart User manual

Creality

Creality HALOT-LITE User manual

Creality

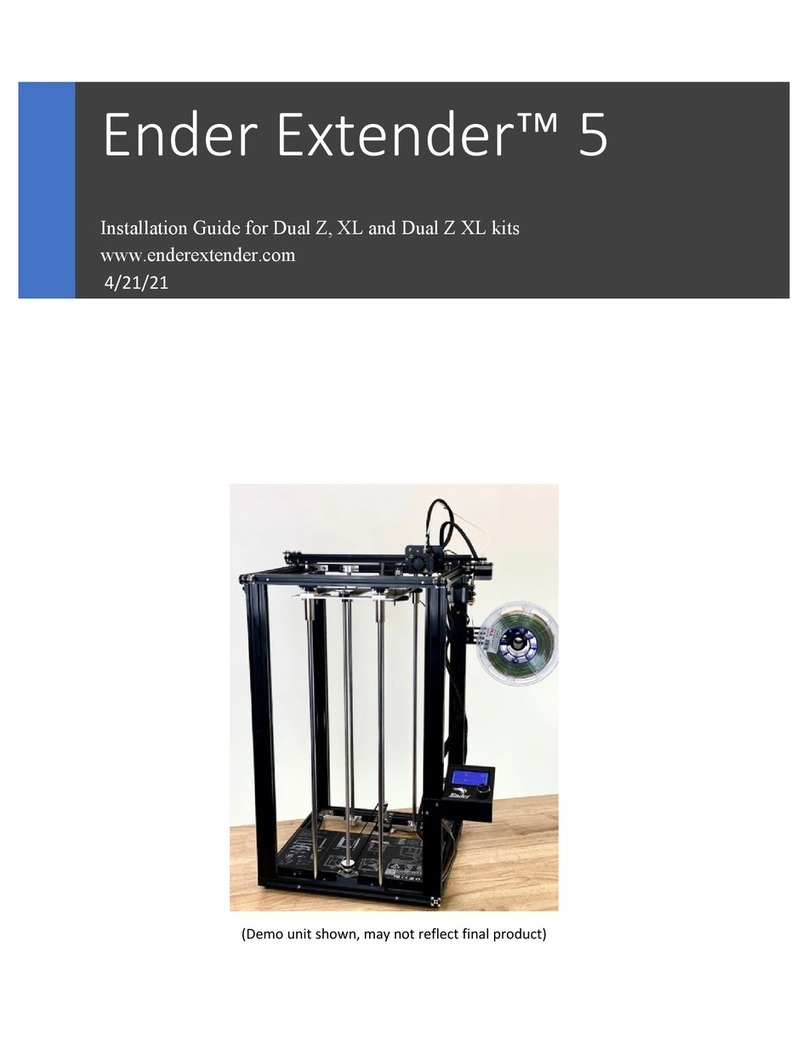

Creality Dual Z User manual

Creality

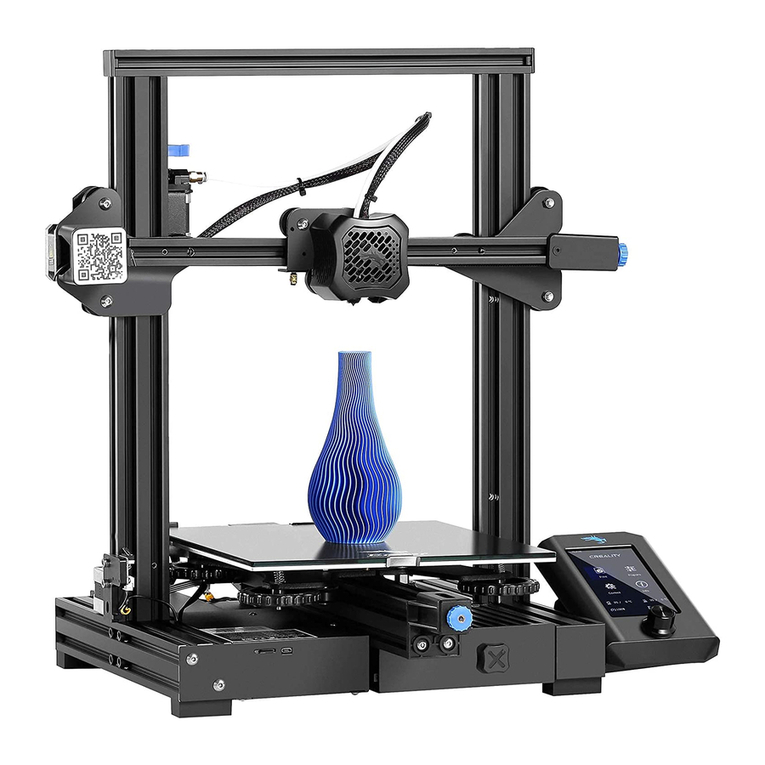

Creality Ender-3 User manual

Creality

Creality CR-10 Smart User manual

Creality

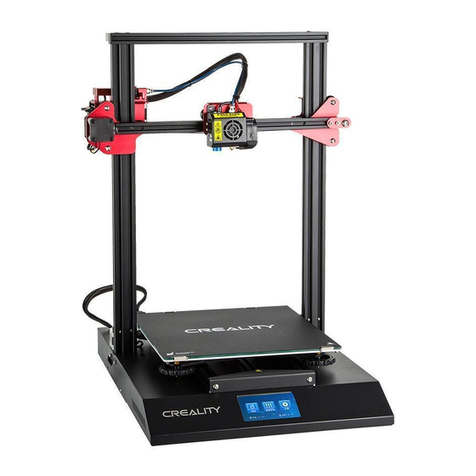

Creality CR-10S Pro User manual

Creality

Creality 3dpRINTmILL User manual

Creality

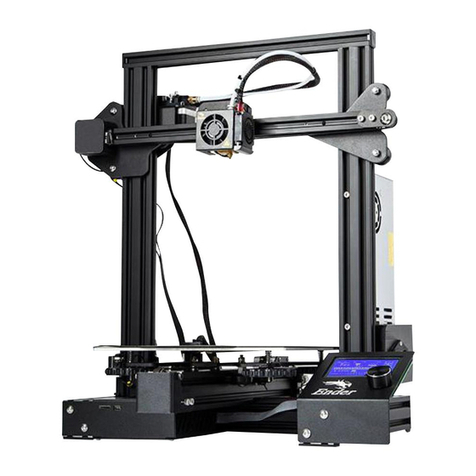

Creality Ender-3 Assembly instructions

Creality

Creality Sermoon V1 User manual