Ed. 0423 - 70702630 REV00 VENERE - Pre-installation 7

• Read this guide carefully before install-

ing the appliance, and keep it with care

in an accessible place for any future

consultation by the various operators.

• Moreover, the manual must always ac-

company the product through its life,

even in case of transfer.

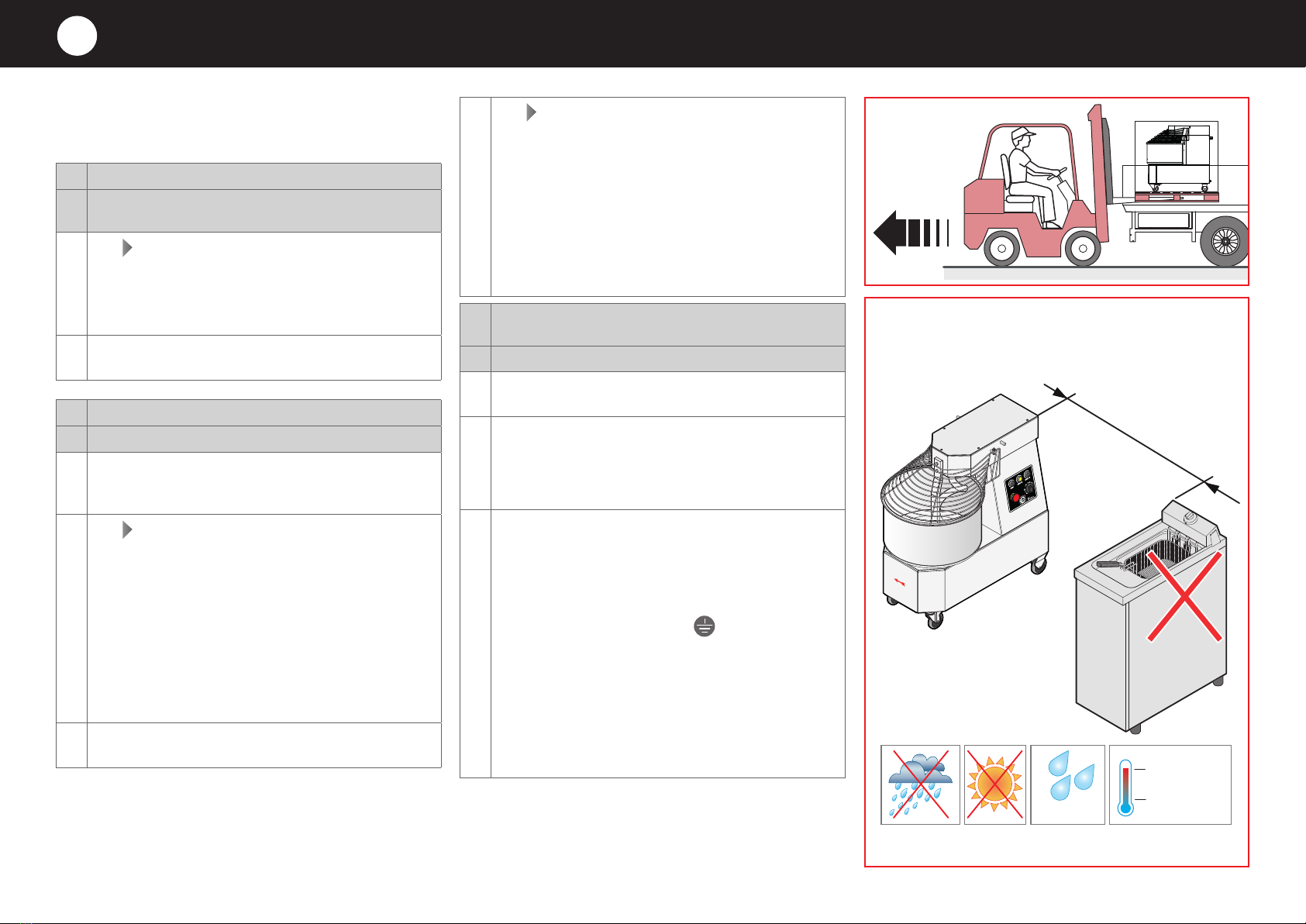

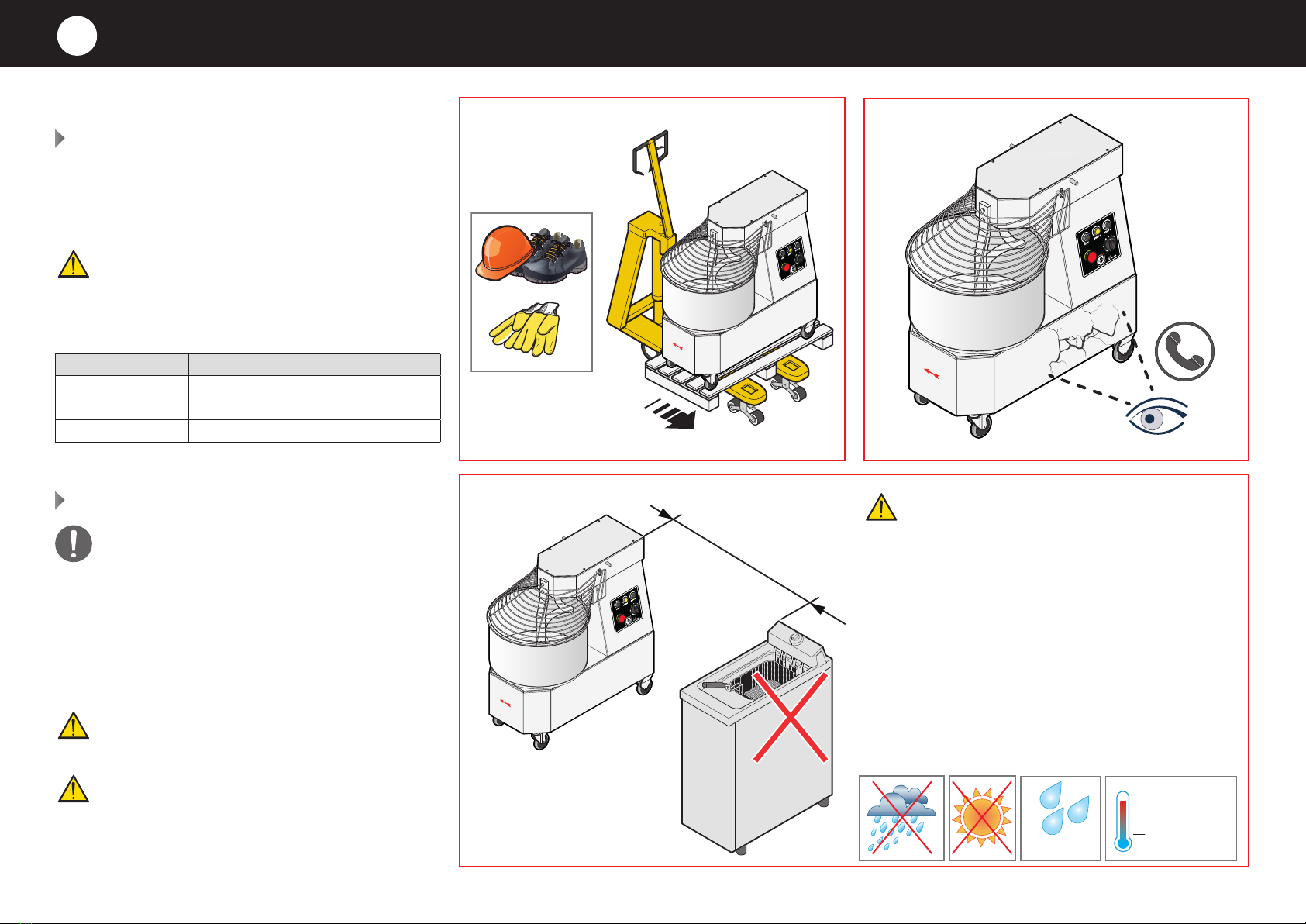

• Before any movement or installation,

check that the room is suitable and

systems comply with the installation

country standards and the specifica-

tions indicated on the appliance rating

plate.

• All installation, assembly and non-rou-

tine maintenance operations must

be performed exclusively by qualified

technicians that are authorised by the

Manufacturer, in compliance with the

regulations in force in the user country,

and with the regulations on systems

and work safety.

• Before performing any installation or

maintenance, disconnect the electric-

ity supply.

• Unauthorised actions, tampering or

modifications that do not follow the in-

formation provided in this manual can

cause damages, injuries or fatal acci-

dents and null and void the warranty.

• It is forbidden to install the product in

environments at risk of explosion.

• Installation or maintenance that fails

to comply with the instructions in this

manual may cause damage, injury or

fatal accidents.

• Do not obstruct the ventilation and ex-

haust holes of this or other equipment.

• Persons not involved with the appli-

ance installation may not pass through

or stand in the work area during appli-

ance assembly.

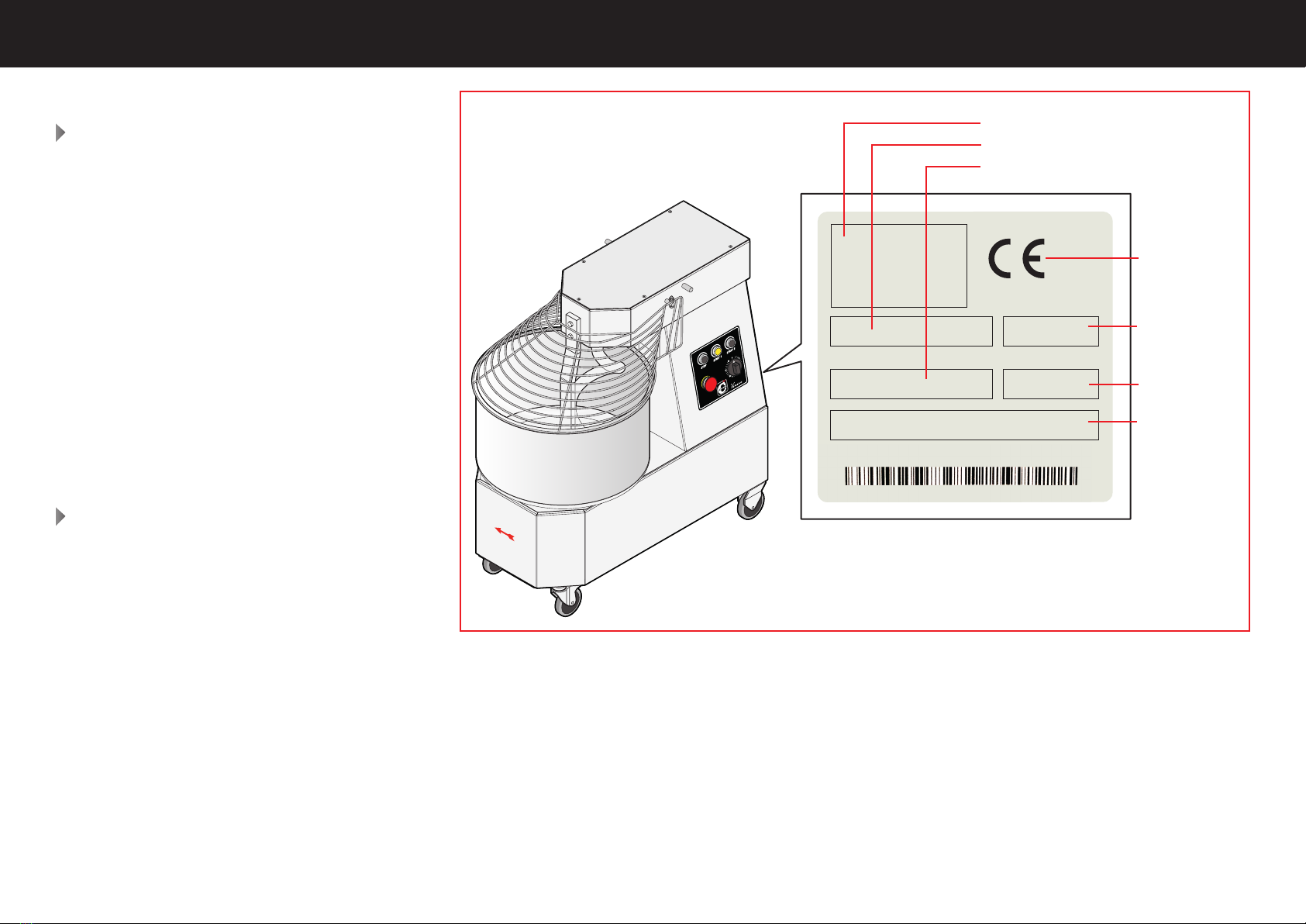

• The serial plate provides important

technical information. This is vital in

case of a request for maintenance or

repair of the equipment: please do not

remove, damage or modify it.

• These appliances are intended to be

used for commercial applications, for

example in restaurant kitchens, can-

teens, hospitals and commercial com-

panies such as bakeries, butcher shops,

etc., but not for the continuous and

mass production of food.

• To avoid risks, if the power cable is

damaged, it must be replaced by the

Retailer, its service agent or qualified

personnel.

• Failure to follow these regulations may

cause damage or even fatal injury, sub-

sequently invalidating the guarantee

and relieving the Manufacturer of all

liability.

• Noise levels lower than 70 dB.

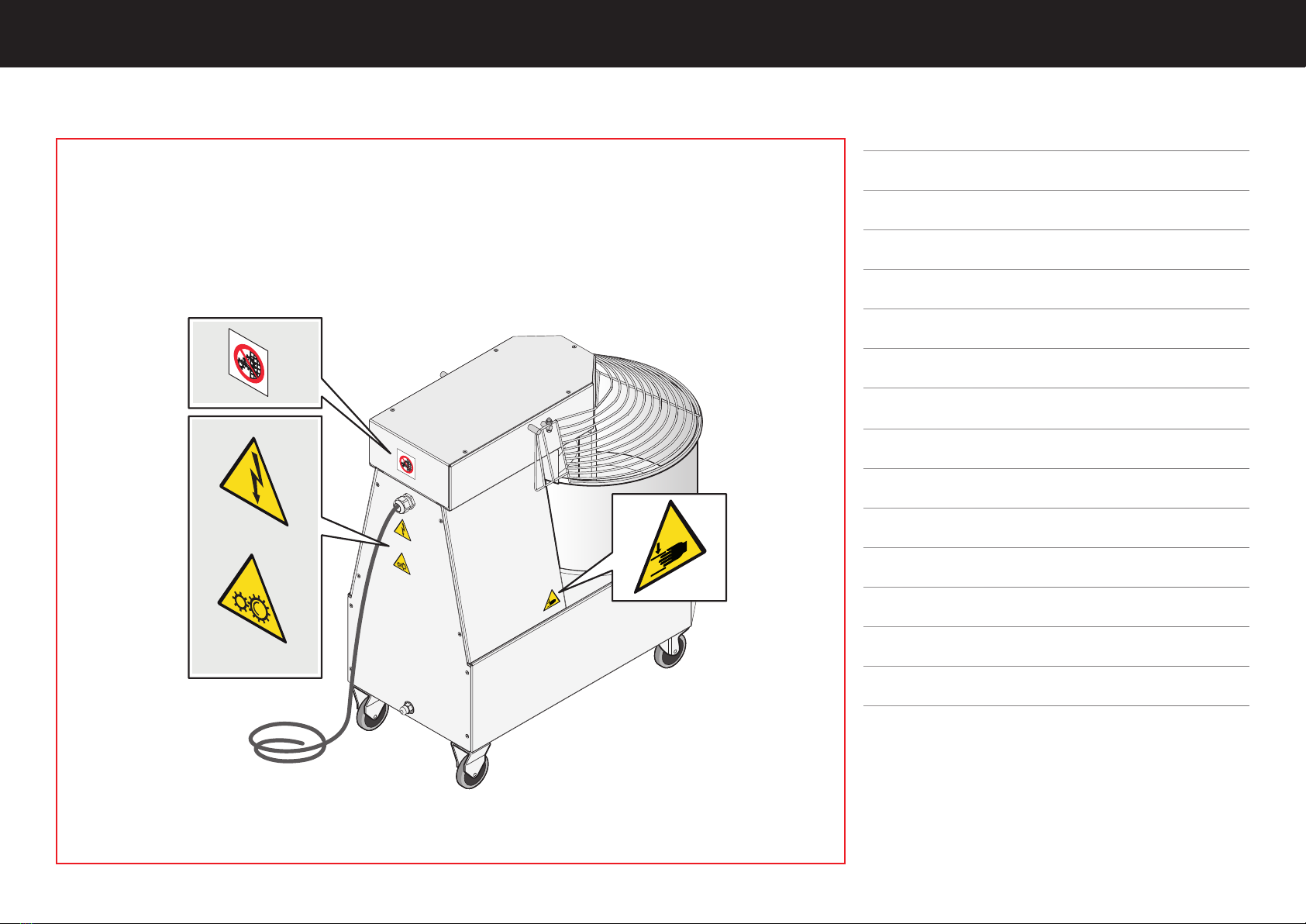

SYMBOLS USED IN THE MANUAL

AND ON THE LABELS APPLIED TO

THE MACHINE

Indicates that caution is required when perfor-

ming an operation described in a paragraph

that bears this symbol. The symbol also indi-

cates that maximum operator awareness is

required in order to avoid unwanted or dange-

rous consequences

Dangerous voltage

Risk of explosion

Gears danger

Hand crushing hazard

Do not remove the guard

Reference to another chapter where the

subject is dealt with in more detail.

Manufacturer’s tip

Manufacturer’s warning

Indicates that it is necessary to read carefully

the paragraph marked with this symbol befo-

re installing, using and maintaining the equi-

pment

SAFETY INSTRUCTIONS

3