1

©2023 CYC MOTOR LTD

TABLE OF CONTENTS

SAFETY & PRECAUTION........................................................................3

General Safety ....................................................................................................................................3

Before the Ride...................................................................................................................................3

Installation & Use ...............................................................................................................................4

Disclaimer...........................................................................................................................................4

Warning............................................................................................................................................... 5

TECHNICAL SPECFICIATIONS .............................................................6

Description .........................................................................................................................................6

General ............................................................................................................................................... 6

Motor...................................................................................................................................................6

Controller............................................................................................................................................ 6

Gearbox ..............................................................................................................................................7

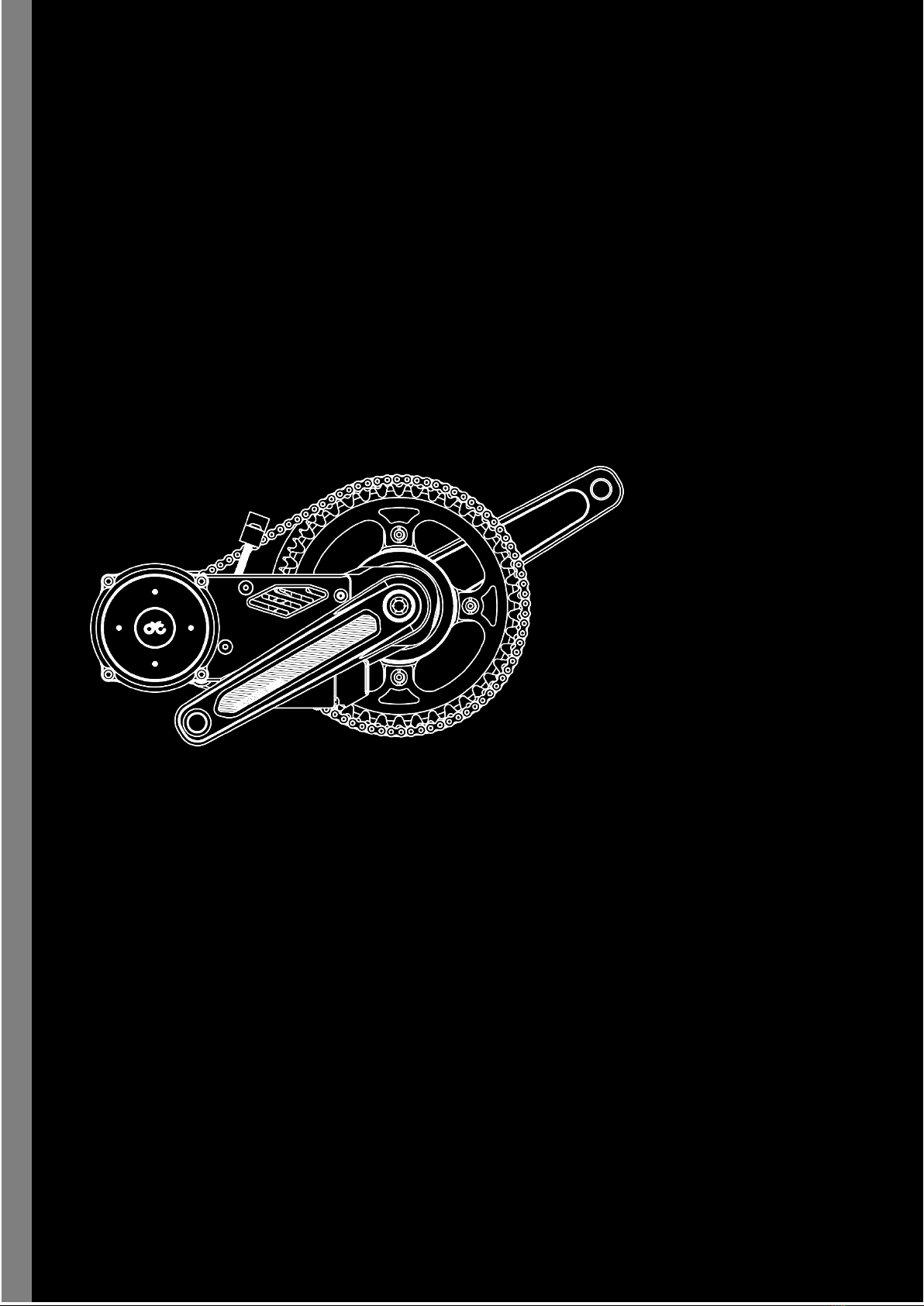

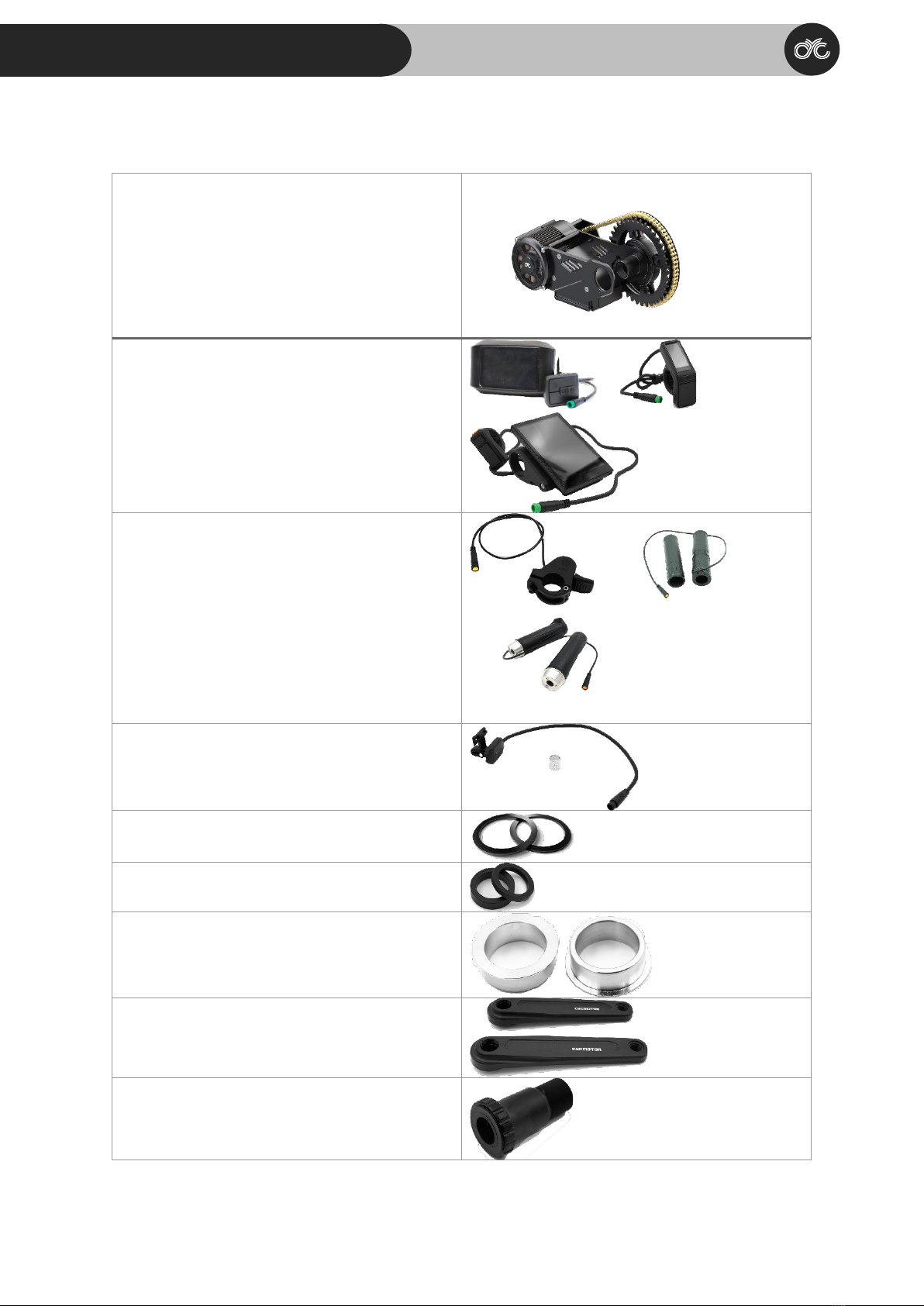

Parts List............................................................................................................................................. 8

Dimensions....................................................................................................................................... 10

BSA Threaded 68/73/83mm Version............................................................................................ 10

BSA Threaded 100mm Version .................................................................................................... 11

BSA Threaded 120mm Version .................................................................................................... 12

BB92 Version................................................................................................................................. 13

INSTALLATION....................................................................................... 14

Required Tools ................................................................................................................................. 14

Operating Notice.............................................................................................................................. 15

Mounting Options for Controller ..................................................................................................... 15

Adjusting the Width of the Bottom Bracket .................................................................................... 15

Installation of 68/73/83mm version ................................................................................................ 17

Installation of 100mm & 120mm version ........................................................................................ 21

Installation of BB92 version............................................................................................................. 25

Mounting the Hanger ....................................................................................................................... 29

Wiring & Connection......................................................................................................................... 31

MOBILE APP & DISPLAY.....................................................................32