DAELIM NS125III - SERVICE User manual

Other DAELIM Scooter manuals

DAELIM

DAELIM HISTORY User manual

DAELIM

DAELIM A-FOUR - User manual

DAELIM

DAELIM DELFINO User manual

DAELIM

DAELIM LIBERTY User manual

DAELIM

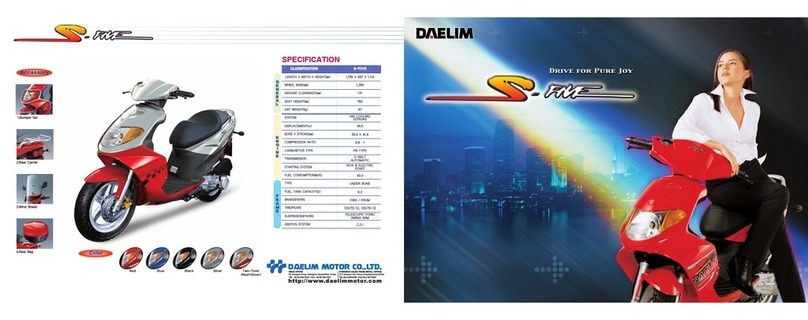

DAELIM S-FIVE - User manual

DAELIM

DAELIM S4 50cc User manual

DAELIM

DAELIM Q2 User manual

DAELIM

DAELIM S2 125 User manual

DAELIM

DAELIM S2 250 - User manual

DAELIM

DAELIM NS 125 DLX User manual

DAELIM

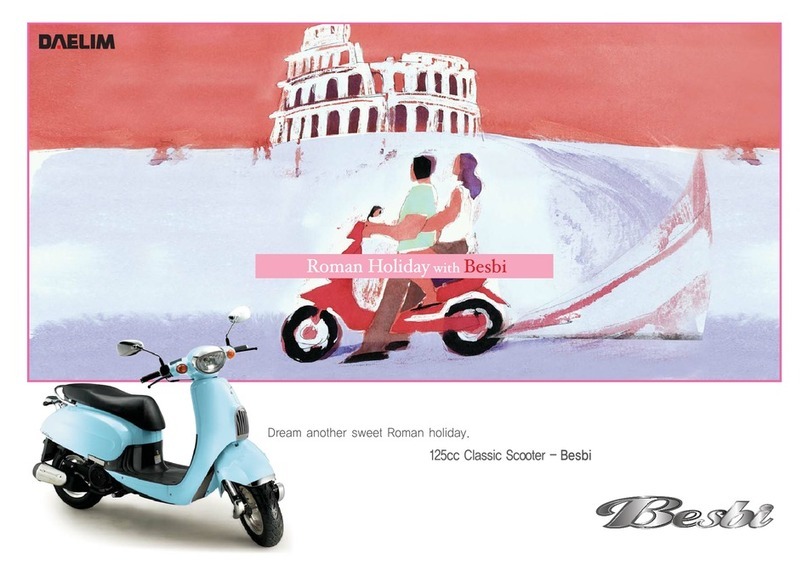

DAELIM BESBI SC125 - User manual

DAELIM

DAELIM S2-250 User manual

DAELIM

DAELIM B-BONE User manual

DAELIM

DAELIM A-FOUR - User manual

DAELIM

DAELIM S2 250 - User manual

DAELIM

DAELIM BESDI 125 - SERVICE User manual

DAELIM

DAELIM BESBI - User manual

DAELIM

DAELIM S1 125 - SERVICE User manual

DAELIM

DAELIM S-FIVE - User manual

DAELIM

DAELIM BONITA - CATALOG User manual