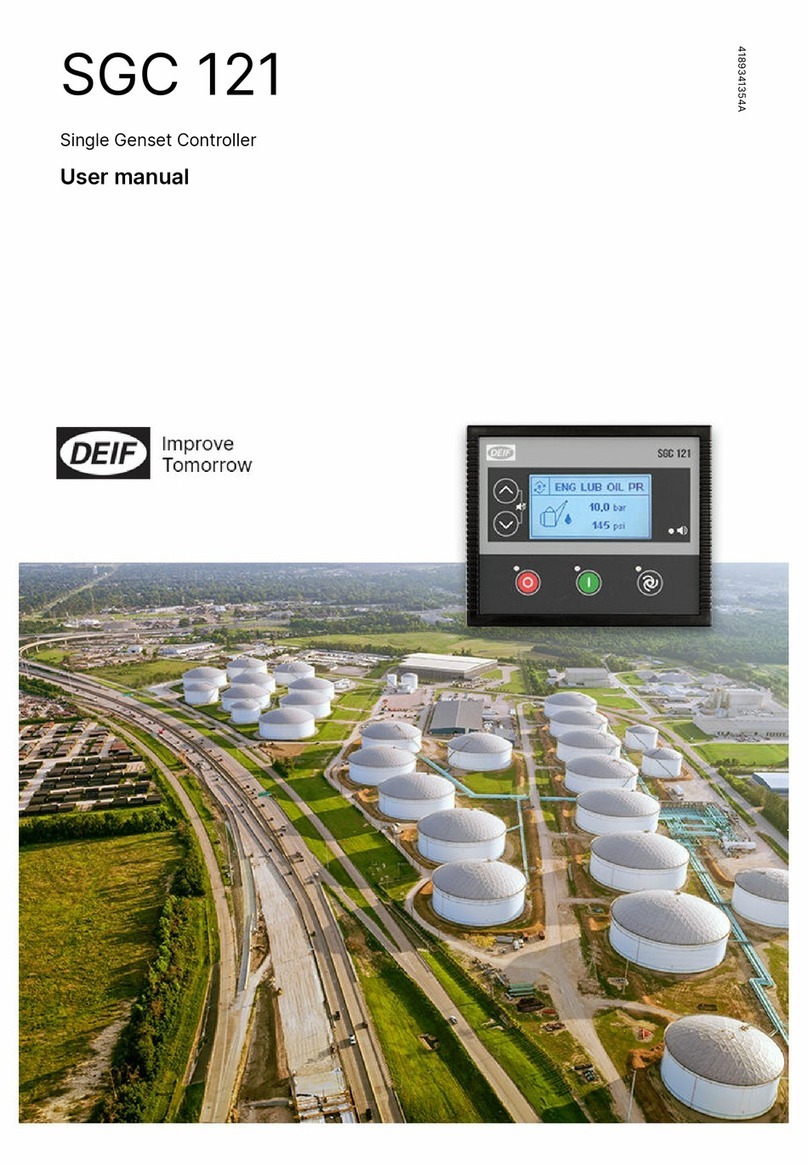

1. Introduction

1.1 About SGC 120/121................................................................................................................................................................................................................... 4

1.2 Key functions............................................................................................................................................................................................................................... 4

1.3 Product overview....................................................................................................................................................................................................................... 4

1.4 Passwords..................................................................................................................................................................................................................................... 5

1.5 Overview of controller buttons...........................................................................................................................................................................................6

1.6 Legal information.......................................................................................................................................................................................................................7

2. Safety instructions

2.1 General safety instructions.................................................................................................................................................................................................. 8

2.2 Electrical safety...........................................................................................................................................................................................................................8

2.3 In operation safety.....................................................................................................................................................................................................................8

3. Technical specifications

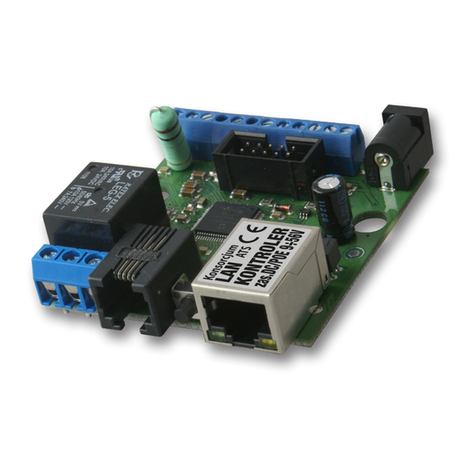

3.1 Terminals........................................................................................................................................................................................................................................ 9

3.2 Power supply................................................................................................................................................................................................................................9

3.3 Genset voltage and frequency measurements....................................................................................................................................................... 10

3.4 Genset current measurements........................................................................................................................................................................................ 10

3.5 Mains voltage and frequency measurement............................................................................................................................................................ 10

3.6 Digital inputs.............................................................................................................................................................................................................................. 11

3.7 Analogue resistive sensor inputs...................................................................................................................................................................................11

3.8 Analogue inputs used as digital inputs...................................................................................................................................................................... 12

3.9 Analogue voltage/current input.......................................................................................................................................................................................12

3.10 Magnetic pick-up (MPU) input........................................................................................................................................................................................13

3.11 Digital outputs........................................................................................................................................................................................................................ 13

3.12 Rotary actuator outputs (SGC 121 only)..................................................................................................................................................................13

3.13 D+ Charger alternator.........................................................................................................................................................................................................14

3.14 Sensor common point........................................................................................................................................................................................................14

3.15 Communication ports.........................................................................................................................................................................................................14

4. Installation

4.1 Dimensions.................................................................................................................................................................................................................................15

4.2 Mounting in panel....................................................................................................................................................................................................................15

4.3 Terminal details........................................................................................................................................................................................................................ 16

4.4 Typical wiring diagrams.......................................................................................................................................................................................................18

5. Monitoring mode

5.1 Monitoring mode......................................................................................................................................................................................................................20

6. Configuration mode

6.1 Configuration mode............................................................................................................................................................................................................... 22

6.2 Configurable parameters.................................................................................................................................................................................................... 22

6.2.1 Configurable parameters..............................................................................................................................................................................................22

6.2.2 Module..................................................................................................................................................................................................................................23

6.2.3 Digital inputs...................................................................................................................................................................................................................... 24

6.2.4 Analogue inputs................................................................................................................................................................................................................25

6.2.5 Outputs.................................................................................................................................................................................................................................28

6.2.6 Timers...................................................................................................................................................................................................................................28

6.2.7 Generator............................................................................................................................................................................................................................29

6.2.8 Mains.................................................................................................................................................................................................................................... 31

6.2.9 Engine.................................................................................................................................................................................................................................. 32

6.2.10 Maintenance....................................................................................................................................................................................................................36

USER MANUAL 4189341226A UK Page 2 of 72