DEMA MODEL 692T FOAM STATION I

INSTALLATION INSTRUCTION

I-719 Page 3 of 6

Rev. D-31918 12/22/05

knob back in to lock the setting in place. This operation must be repeated in the same order each time the 692T is shut down and

restarted (water first then gradually build up air pressure).

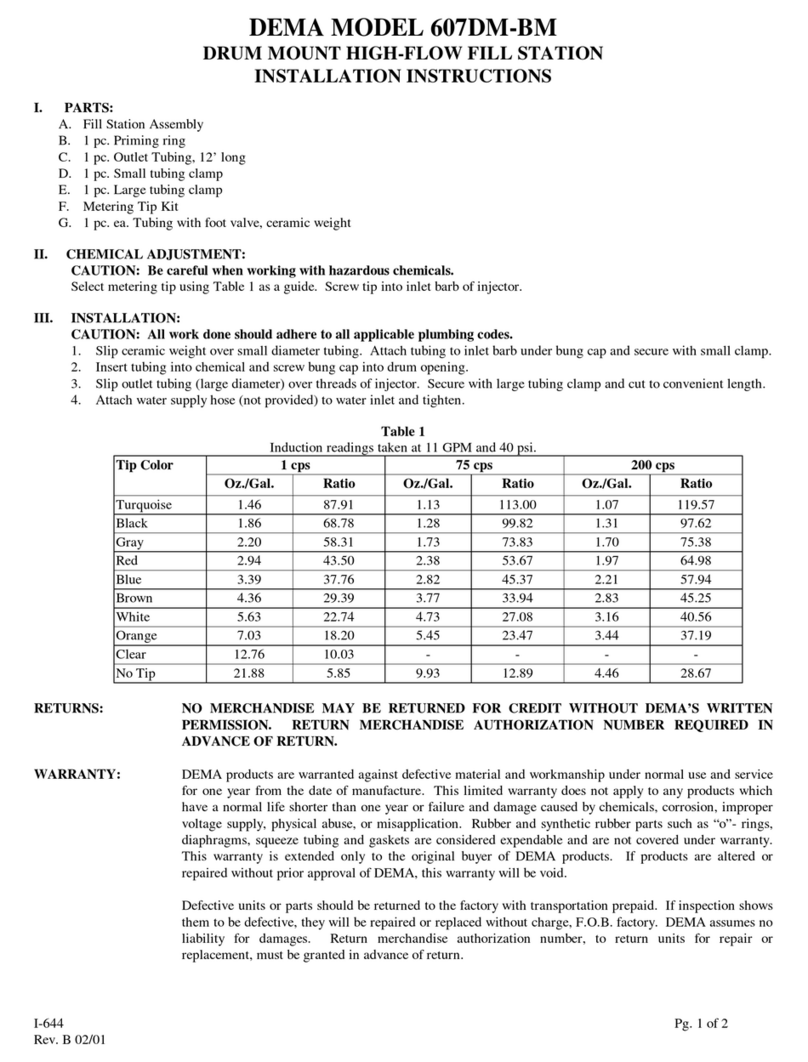

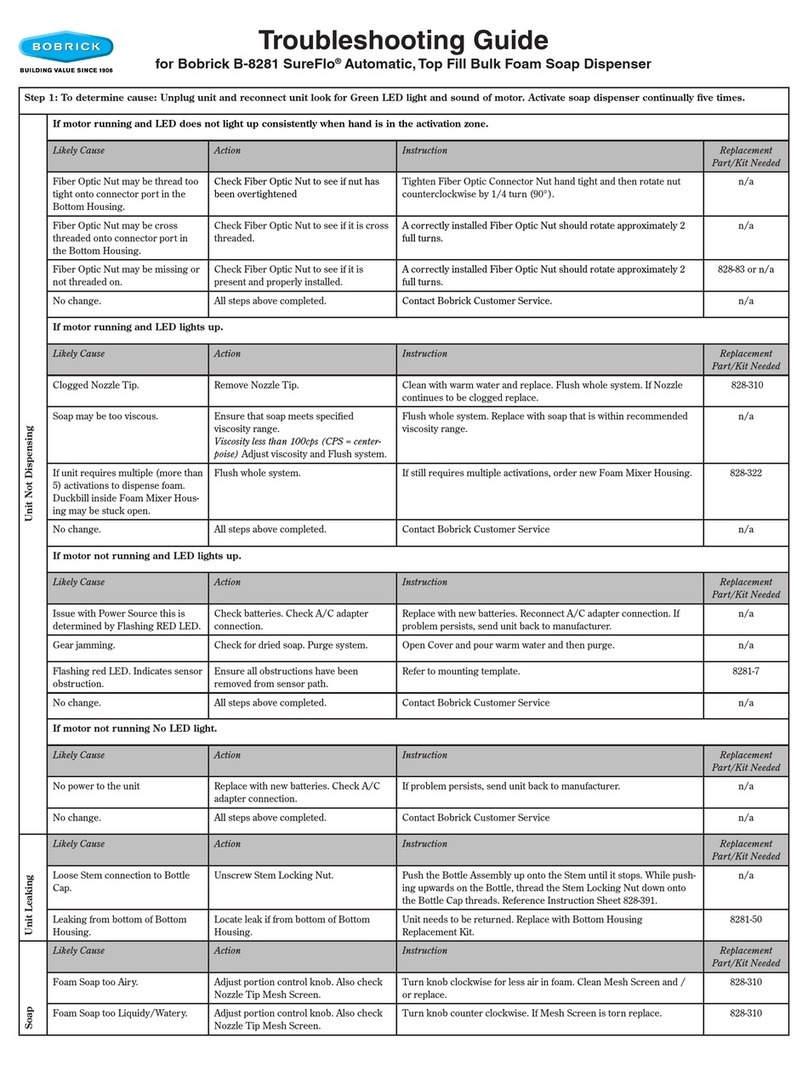

TABLE 3: Water Flow & Air Flow Setting

PRESSURE (PSI)

40 50 60 80

WATER FLOW (GPM) 1.4 1.6 1.7 2.1

AIR FLOW (SCFM) 3.5 4.2 4.8 6.1

5. SERVICING:

PROBLEM: SEE SITUATION:

Unit will not draw or stops drawing chemical 1, 2, 3, 5, 6, 10, 11, 12, 13, 15, 16, 17

Poor foam quality 1, 2, 3, 5, 6, 10, 11, 12, 13, 15, 16

Foam surges 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12, 13, 15, 16

Foam output is too wet 1, 3, 4, 5, 6, 7, 8, 9, 10, 11, 13, 16

Foam output is too dry 2

Water is flowing into chemical container 12

Foam does not clean adequately 4, 8, 11, 14

POSSIBLE SITUATIONS

Situation Cause Solution

1 Chemical tube not immersed in chemical

or chemical depleted. Immerse tube in chemical or replace.

2 Air pressure is too high for water. Adjust air regulator down.

3 Water pressure is too low. At least 30 psi is required. Increase if possible, or decrease air pressure.

4 Chemical to water ratio is too low. Change metering tip to one that is larger.

5 Foam hose is kinked. Straighten hose.

6 Foam hose is too long or wrong size. See Table 1.

7 Air supply is inadequate. Increase air pressure by regulating up.

8 Detergent is wrong. Use a more effective detergent, and be sure that product is recommended

for foaming.

9 Using an oiler on the airline may

deteriorate the quality of the foam. Use only clean, dry air.

10 Holes or cuts are in chemical inlet tube. Replace the tube.

11 Strainer and/or metering tip are blocked. Remove, clean or replace.

12 Solution check valve is not working. Remove, clean or replace.

13 Air regulator is not working. Remove, clean or replace.

14 Soil has hardened on surface. Reapplication may be necessary. Be sure to rinse foam off before it dries.

15 Rust or build-up is clogging the foamer

aspirator. Disconnect water from unit and remove injector from unit. Visually

inspect. Remove blockage.

16 Water scale or chemical build-up may

have formed in the water jets. Place the chemical tube in descaling acid and completely open the shut-

off valve. Let unit run until the chemical tube is filled with acid, then

close shut-off valve and water supply. Elevate the chemical tubing and

outlet hose until acid has had enough time to descale. Repeat if necessary.

For severe cases, disassemble unit and soak foamer body in descaling

acid.

17 More than one valve is open. Close the rinse valve.